|

| 88 Coupe 4.9 Swap Thread (Page 7/69) |

|

Rickady88GT

|

SEP 15, 11:10 AM

|

|

| quote | Originally posted by josef644:

On your build how did you run your VSS sensor wire? Did you lay your wires along the intake, down the passenger side of the engine, then to the VSS plug, or distrubitor end underneath the exhaust manifold to the VSS plug. I don't want to fry these two wires.

Joe Crawford

|

|

You can get some good wire loom that is very good for reflecting heat. I got some from Jegs. It looks like chrome loom but is a rolled up aluminized heat shield fabric. I ran it under the exhaust manifold on top of the tranny. BTW I changed the manifolds. I did not keep those.

|

|

|

Rickady88GT

|

SEP 15, 11:25 AM

|

|

| quote | Originally posted by Fieroseverywhere:

If I sent you a fuel rail would you modify it like this for me? I really hate having the fuel lines running accross the rocker covers. I'll pay you well for you time.

|

|

Sorry, one off custom. I cut it into a bunch of pieces and mocked them up where I wanted them. Then had a machine shop weld (braze) them together.

|

|

|

josef644

|

SEP 15, 11:50 AM

|

|

I went ahead and ran the VSS wires under the manifold, on the outside of the transmission dipstick, outside if the shift switch then merged into the rest of the wiring around the center of the left transmnission side. I wanted to stay away from the area where the rear manifold/crossover pipe, and the transmission all 3 were very close.

I am not worried about the dash lights yet. I only had the battery charger hooked to one of the fuseable links. It wasn't mounted on the threaded hold down block. Just a down the road item for de bugging if they don't worl later.[This message has been edited by josef644 (edited 09-15-2009).]

|

|

|

Fieroseverywhere

|

SEP 15, 02:15 PM

|

|

| quote | Originally posted by Rickady88GT:

Sorry, one off custom. I cut it into a bunch of pieces and mocked them up where I wanted them. Then had a machine shop weld (braze) them together.

|

|

Oh well. I do have 20' of stainless tubing thats the right diameter. Guess I'll have to do the same. It just looks so much better.

|

|

|

josef644

|

SEP 15, 04:17 PM

|

|

Today I managed to merge the C203 into the Cadillac harness today. I also mounted the AC and Fuel Pump relays. I ran most of those wires that operate them both. I switched out the temperature sensor for the new one, and located those three wires for soldering. Plugged in the C500 and untangeled all of those wires so I can merge them one at a time into the harness. The temperature one isready to be soldered in.

No rain here today, looks like tomorrow will be a mowing day

|

|

|

josef644

|

SEP 15, 06:59 PM

|

|

I searched to find out how to mod my tach for my V8. There was a thread where I saw that Capt Fiero had used "10x turn high precession pot" to mod his tach. I used google to find one of these. There are thousands of different ones 3W 10K, and on and on etc. Anybody know what the W and K value needs to be for modding my tach?

Joe[This message has been edited by josef644 (edited 09-17-2009).]

|

|

|

fieroguru

|

SEP 15, 07:42 PM

|

|

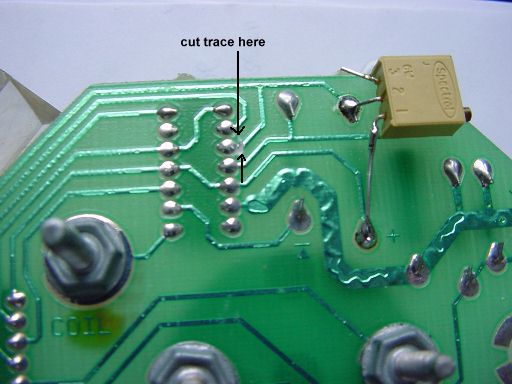

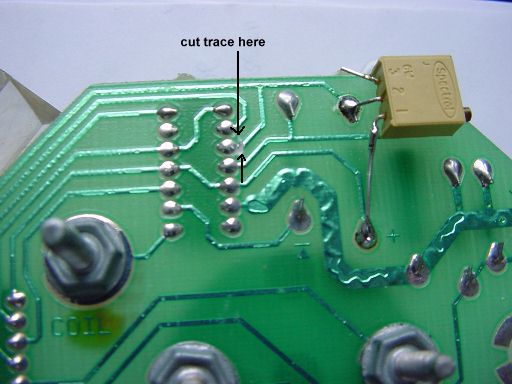

Here is the thread I always use:

http://www.fieros.de/en/articles/tach.html

Doing it this way, you only need to cut the trace and install the proper resistor value - Radio Shack sells packs of 100K and 10K resistors - just put them in series to get the 210K value.

I prefer the V6 tach with the 6K redline and for the 2.8 tach to the V8 you need to install a 210K ohm resistor (or a variable resistor with that range).

For the 88 4 cyl tach with DIS, I "think" the current resistor value in your tach needs to be reduced by 75%.[This message has been edited by fieroguru (edited 09-15-2009).]

|

|

|

josef644

|

SEP 15, 08:30 PM

|

|

| quote | Originally posted by fieroguru:

Here is the thread I always use:

http://www.fieros.de/en/articles/tach.html

Doing it this way, you only need to cut the trace and install the proper resistor value - Radio Shack sells packs of 100K and 10K resistors - just put them in series to get the 210K value.

I prefer the V6 tach with the 6K redline and for the 2.8 tach to the V8 you need to install a 210K ohm resistor (or a variable resistor with that range).

For the 88 4 cyl tach with DIS, I "think" the current resistor value in your tach needs to be reduced by 75%.

|

|

I removed a 85 4 cy tach spare I had, and cut the trace. Using the 200K range I got a measurement of 12.9

Measuring where he soldered the Pot in this picture I lifted from him

If I flip it over and measure again from the other side of the resister I get 5.6, again using the 200K range. I don't understand why.

I will remove the DIS tach form my car and add this one if I can get it ready to go.

So what resisters do I need to solder in to get this working correctly. What about a tach filter? WIll I need to add one to the system?

|

|

|

Fieroseverywhere

|

SEP 16, 10:11 AM

|

|

| quote | Originally posted by josef644:

I removed a 85 4 cy tach spare I had, and cut the trace. Using the 200K range I got a measurement of 12.9

Measuring where he soldered the Pot in this picture I lifted from him

If I flip it over and measure again from the other side of the resister I get 5.6, again using the 200K range. I don't understand why.

I will remove the DIS tach form my car and add this one if I can get it ready to go.

So what resisters do I need to solder in to get this working correctly. What about a tach filter? WIll I need to add one to the system? |

|

All that makes it more complicated then it actually is. Get a 200k trimming potentiometer (trim pot). Multi-turn (10 turn) is better for fine tuning the adjustment but a single turn one will work also. The 200k is the important part here.

Cut trace and solder in 2 of the 3 pins. Doesn't matter which 2. Put on a scanner and adjust the trim pot til the tach matches what the scanner reads for RPM. Done.

I didn't bother to measure anything. I just dialed it in. I believe the exact resistance value is close to 187k. This is why you use the 200k pot. If you don't have a scanner you can measure the resistance between two pins amd set ot tp 187k to get it very close til you get to a scanner and dial it in perfectly. You don't need any other parts. Any fiero tach will work. Cutting the trace removes the ceramic resistor from the equation. The trim pot acts as a variable resistor. Hope this helps.

EDIT: Forgot to mention. Solder it in with a couple of lead wires and let it hang under the dash. That way it can be dialed while installed into the car, engine running.[This message has been edited by Fieroseverywhere (edited 09-16-2009).]

|

|

|

Fieroseverywhere

|

SEP 16, 11:13 AM

|

|

Hey Joe,

Do you need a speedo circuit? I'll send you one if you do, free of course. I have a few lying around that I'll never use.

|

|

|