|

| Trinten's SBC/F23 build - The work has begun! (Page 61/76) |

|

Trinten

|

APR 05, 03:57 PM

|

|

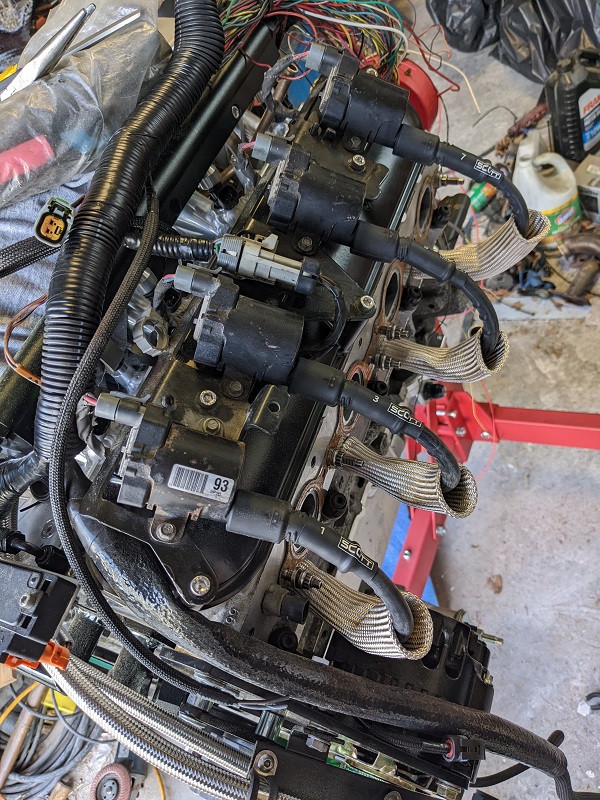

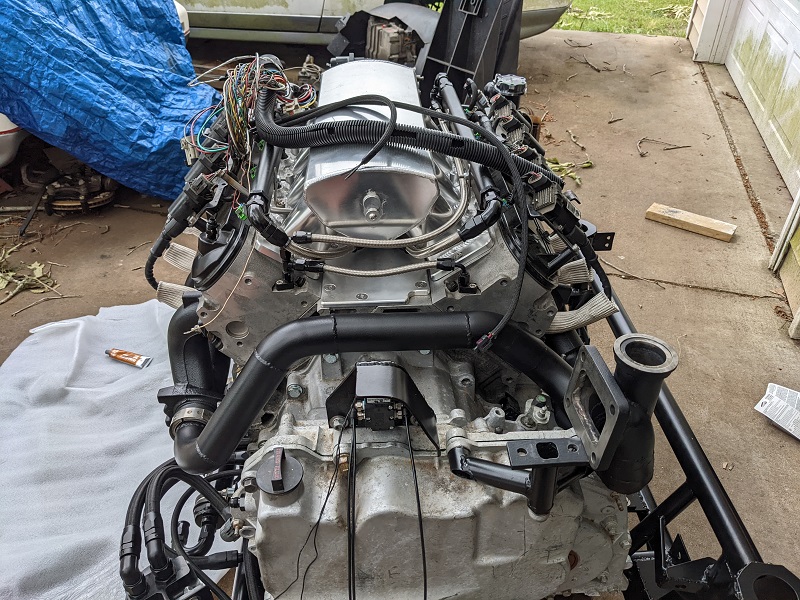

Small update. Mike and I spent this past Sunday marrying the engine wiring harness to the Deutsch connection that will be at the bulkhead/firewall of the engine compartment. We did a point-to-point test with the voltmeter.

I think there is still a few wires left that we need to do. Besides what he had already done, we finished all the coil pack wires, injector wires, IAC, TPS, MAP. We left off with a sensor that he had to look up info on the sensor itself, because the FAST system had two different wiring configurations, depending on how the sensor functioned (I think he said that sensor could either be a 5v reference or a PWM?)

I also think I have everything ironed out for my axles. I'm going to hold off on details until I have them in my hands and they work, then I'll gladly share details on the company, process, etc.

To that end, the company wants us to weld up a mock-up of the axle center shaft (in addition to filling out their paperwork with measurements), and send in the mock up axles, along with one tripod and one CV joint. I suppose they want to make doubly sure a number wasn't misread, or a typo, or whatever, so the mock up axles are a 'verifiable' standard.

Mike was a little annoyed by that news, and said "What if the customer doesn't have someone like me that can weld? Even if it's just a crap weld to hold them together, not everyone has a welder." To which I replied "If someone is calling up and needs custom length axles, the owner probably modified the car enough that they DO have someone like you working on the car."

|

|

|

La fiera

|

APR 07, 11:08 PM

|

|

|

The fact the axle company is asking you to mock things up after you have given them or haven't given them measurements is an indication they have incompetent staff and lack of understanding to ask you for that info to make your axles. If they don't fit they can't blame nobody but mike! That's the way I see it Vince!

|

|

|

Trinten

|

APR 08, 12:03 AM

|

|

| quote | Originally posted by La fiera:

The fact the axle company is asking you to mock things up after you have given them or haven't given them measurements is an indication they have incompetent staff and lack of understanding to ask you for that info to make your axles. If they don't fit they can't blame nobody but mike! That's the way I see it Vince! |

|

It might be more to avoid legal headaches, too. I've continued discussions with another very well known axle shop, and in my last email put down some details and included pictures for reference. When he replied back, he asked "So does your transmission have male stubs? Can you send me pictures of your transmission?"

So, I responded back and politely pointed out I had attached those in the last email, and attached the the relevant pics again. He followed up with additional measurement instructions. Given that there are known math factors here that I supplied them with -- the corvette flanges, which I had also provided measurements of, and the measurement between flanges when they were mounted, and from the transmission case to the wheel hub on both sides -- it adds that it's just as much trepidation and offloading liabilities.

I get it, there are a lot of really incompetent people out there, including buyers! So these guys are just doing a CYA. I don't hold anything against them, and all these extra measurements and precautions between these two (possibly three) companies is going to help make absolutely sure that when I say "I need x", I will get the right thing.

In the end, as long as what I get fits and I get it in the time they quote me, I'm happy to jump through these little hoops. And then once I have a set that is spot on, I can do the "compressed length" measurement and the measurement of the intermediate rod itself, and get extras much easier!

|

|

|

Trinten

|

APR 11, 08:53 PM

|

|

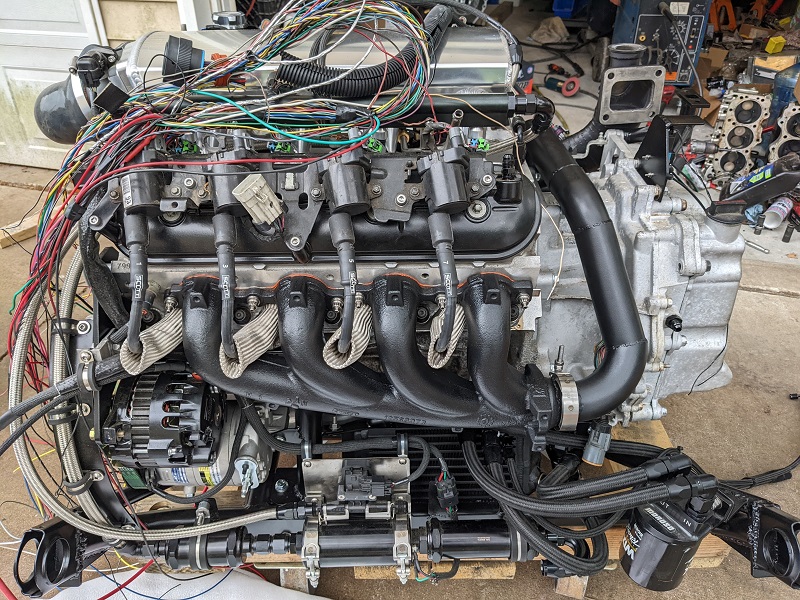

April 2022, Page 16 of build thread

This past Saturday we made some progress.

Mike has finished up all of the engine harness wiring. The Deutsch connector I got for the bulkhead doesn't have enough spots for the transmission, so I'll be getting another one for that.

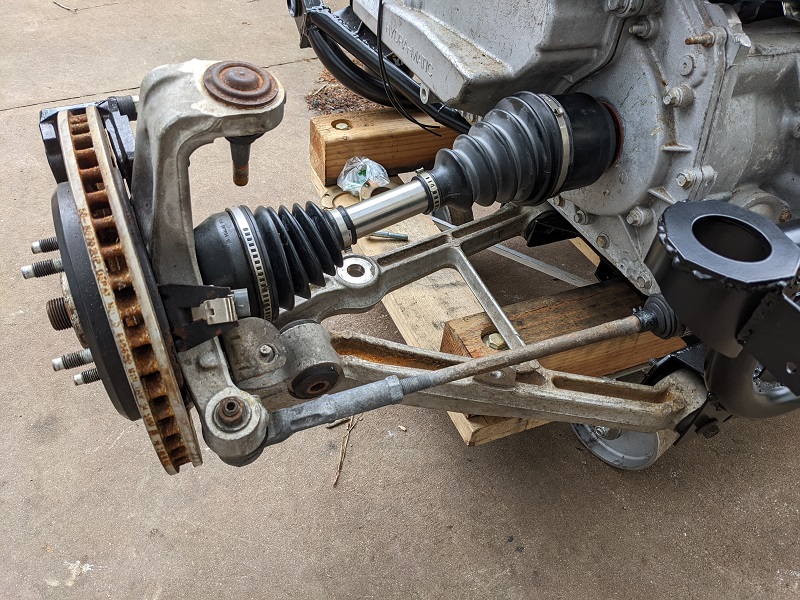

This weekend the priority was getting the axle mockups done. So we used the measurements I had taken for one of the other companies I was working with (who wanted flange-to-flange at neutral, droop and compression). We measured out that flange to flange measurement again and marked the axle shaft then made the cuts. Mike then took off the flanges.

This is where things got fun. The inner flanges were no issue. On one side, it is a tripod setup, so just wiggled out. And the tripod itself was held on the shaft with a basic spring clip (the kind with the eyelets). The other inner side though, was a CV Joint held in with a spring clip.

Now the axle with the tripod was an aftermarket Corvette replacement that I had bought -- at least I think it was that side. lol

When taking off the outer flanges, one side popped off the c-clip without issues. The other side fought us. We tried a number of things, and ultimately had to use destructive force. When we got it off, we found that the c-clip had caught the very edge of the teeth just the wrong way, and our force was making the teeth slightly deform, making an indent for the c-clip. Of course we had no way to know this, and even rotating the axle and wiggling the flange before hammering it again didn't make a difference.

The CV Joint in the outer flange does NOT want to come out. It's not held in with any kind of clip. Talking with the axle folks, they said we could use a hammer and screwdriver to push the cage far enough away to pop out a ball, then rinse and repeat until the cage came loose, and the star would come out too.

Of course, GM does (did?) sell the outer flange ( part #88952504 ), and even that is a "kit", with the cv joint installed. When it can be found, it's three times the cost of entire replacement axles. Similar to the inner flange (88952505 ) and the center shaft (28 spline, 10311201 ). Even finding those part numbers were a pain in the ass.

I've yet to find the part numbers for the actual CV joints (or the tripods) that the axles use.

I have another corvette axle on the shelf, so if we can take that one apart without any headaches, we'll use that outer flange. Mike would also like to make the inner flanges match as far as mechanisms, and he'd prefer the CV joint versus the tripod, so here's hoping the inner is the cv joint on this one.

After Mike welded up the mock up axles, we then took the drive train off the cradle and split the engine from the transmission. This week Mike is planning on putting in time to get the final welding done on the cradle, and drop it off at the powder coater by Friday.

Before we had taken the flanges off the mocked up axles, I wanted to pop them in the drive train and check things out, but Mike was confident in our measurements. I explained I was more worried that I could have fat-fingered one of the measurements when I was putting them into my phone. Fingers crossed that I didn't make any mistakes there.

Today I shipped off the mock up axles. They should get them by Friday. I'll get into details on how it goes once I get them back. If they fulfill their estimated timeline, I should be getting my axles about the same time I get my exhaust back from Jet Hot (sometime in the last week of the month or First week of May).

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Will

|

APR 12, 09:54 AM

|

|

You checked for axle and CV joint binding through the full range of suspension travel, right?

Would be a shame to hit a pothole and break transmission mounts (or worse) because the axle turned into a drift/punch.

|

|

|

Trinten

|

APR 12, 10:26 AM

|

|

In theory, yes.

When we took the original set of measurements (flange to flange), had the wheel bolted on, and had done full compression, droop and ride height. So we knew the extremes of travel plus the center point. Mike used those measurements to work out what should the appropriate length with a safety margin for the reason you stated, hitting a nasty pothole and making sure the cv joints have appropriate travel space inside the flanges.

As mentioned, my major concern with stuff like this is if I did a good job at correctly punching the numbers in on my phone. I can ten-key on a keyboard at rapid fire pace and high accuracy. The phone (and it's propensity to autocorrect) is a little more challenging.

When the axles get back, if there is an issue with the extreme positions, we can still use them to trailer the car to the dyno and possibly to the track while I get another set made.

|

|

|

Trinten

|

APR 17, 10:49 PM

|

|

This weekend was small but important stuff.

We built the spark plug wires. They're all 10" long. The amount of wire that came with the kit will let us get at least an entire second set if necessary, I would just need to get the crimps.

Mike was happy with the quality of the fiberglass sheathing, the EFI wind wire, insulation, etc. The fiberglass boot protectors seem to be really good quality, too. Mike mounted up a spare 6.0 header (same as the one that we modified) to make sure the spark plug wire would clear everything, and not kink the boot protector.

We did test each wire after it was made. Mike pointed out that his voltmeter for his day job was different than what an electrical engineer would have, it only has one Ohm setting. He used a Fluke 79 Series II voltmeter.

My wires do have a higher resistance than Will's Magnecore set by quite a bit. So even though they don't have a 10mm wire, it might be something to keep in mind for the future.

1: 22.9

2: 23.1

3: 24.2

4: 23.0

5: 23.4

6: 23.2

7: 23

8: 23.1

We also tested an uncrimped wire to get an idea of resistance per foot, it worked out to be 29.05 / foot.

We also adjusted the stainless steel tube that runs to the underside of the intake for vacuum. That required us removing the intake, which was an exercise in disassembly/assembly of everything in that area.

While the intake was off, we did a detailed check of all the cylinders using his bore scope while I rotated the crank. No issues, though there was a dead bee in one. It must have flown in there one of the times we had the intake off, and then couldn't escape.

Mike also connected the main feed wire and solenoid wire to the starter, and got that sleeved. I have more of the ultra-high time secondary layer of wire protection stuff on it's way (J&T Fire Flex).

Last week he finished getting the cradle welded up, and it's at the powder coaters. It's expected to be back sometime after the 25.

The axle shop received my mock up axles and paperwork on Friday. If I don't hear from them tomorrow, I'll call them on Tuesday. The guy I was emailing with said he would call me once they got said materials.

The last week of this month, and the first few months of May are going to be hectic, we'll have the cradle back, should have the exhaust back from Jet Hot, and by mid-May should have my axle shafts.

Though time is tight, Mike still thinks we can get enough done to be able to drive the car up to Carlisle this year. He wanted to drive up his 3800 swapped Fiero -- but the swap isn't done. lol. His swap is all mounted on the cradle, nothing else (wiring for example) still needs to be done. Some things are just taking longer than anticipated for my build, unfortunately.[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Will

|

APR 18, 12:30 PM

|

|

Magnecor's custom order form and other items on their website now list 10mm wire.

It's nice to come down to the end of the mechanical work, though.

|

|

|

Trinten

|

MAY 03, 07:04 PM

|

|

This past weekend Mike did a double check on the transmission. we learned from Brandon Furches that the 2-3 shift in the 4T80 is a long/slow shift, and not good for longevity when you're beating it up on the track. Thankfully there is an easy way to fix it!

I think I mentioned earlier that Dave at TripleEdge wasn't sure if he had done any magic with the 2-3 shift. The upside is he had. It's supposed to have one spring under that piston, it had a dual spring in there. Mike was also happy that it was very easy to get to that component, we didn't have to tear down the whole transmission.

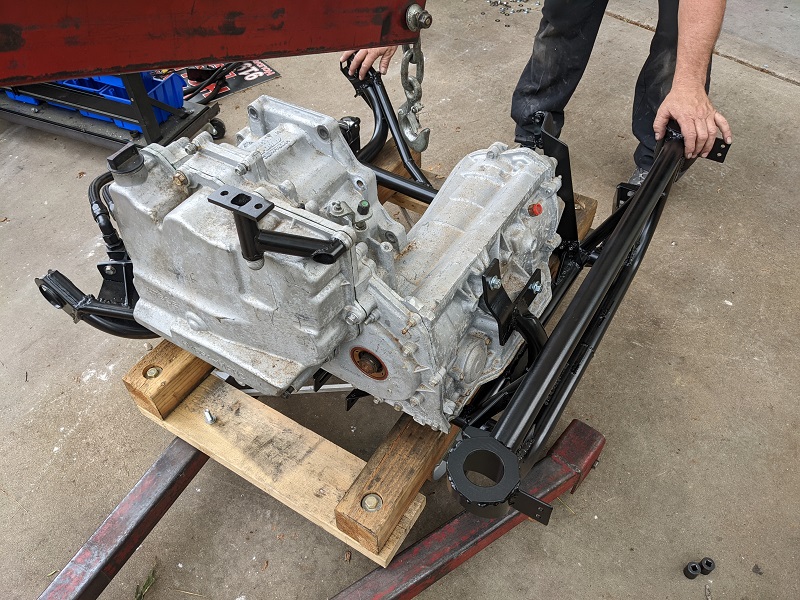

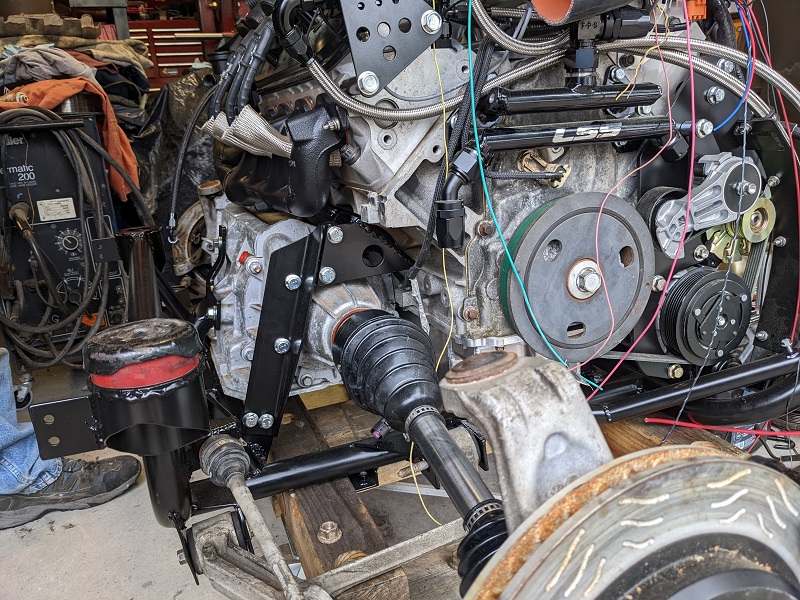

The cradle and cradle components came back from powder coating, so we started mounting things back onto it. Transmission and fuel system.

And today the turbo housing and exhaust components came back from Jet hot, with the spiffy 2500 degree coating applied!

Tomorrow the half shafts for the axles should be showing up. If Mike doesn't have the time/interest in putting the axles together during the week (I wouldn't blame him), then we'll do that this weekend, along with mounting the engine back on the cradle, start prepping the engine bay, and possible replacing the last few suspension components in the back.

Besides the engine bay mods and prep, we still have a fair amount of wiring to do. Then there's wheel alignment, tuning, shakedown...

There is a big Grand National thing in Kentucky this month. So the weekend of the 14th there won't be anything done. And the last weekend of the month is our mutual friends birthday party. So I know I'll be at the party on Saturday. Not sure if Mike will or not.

Mike is going to start putting Saturdays and Sundays into my car. He really wants to try to push to get it to a point where we can put miles on it and drive it up to Carlisle (end of June). I suspect we'll be trailering it up there again this year, but will hopefully be moving under it's own powering onto and off of the trailer.  [This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

Trinten

|

MAY 08, 08:28 PM

|

|

[chapter]Custom axles arrived![/chatper]

Productive day!

Dutchman axles is the company I worked with. Travis was the person there that handled my order. He was really responsive by email, and we had good communication.

The material they used for my axles is called Hy-Tuff alloy, which is stronger than 4340, but not as much as 300M.

And they had it in stock, versus another place that used the same material but said it was 8-10 weeks, at best.

Dutchman originally quoted 3-5 weeks after they spec-sheeted the axles. They beat that by leaps and bounds. They had them packed up and shipped out to me in LESS THAN A WEEK!

Here is one of the half shafts next to the mockup.

The only drawback is that Dutchman doesn't make complete cv joints, so Mike and I had to disassemble the Corvette axles, and assemble the joints/flanges on the new half shafts. It went smoothly.

And once the axles were ready, we went about putting the knuckles on and replacing suspension components. The outter tie rod ends on the 'stabilizer bars' were shot on both sides. I had one complete unit that was in good shape, and I have managed to find 4 of the actual outer ends (which are not the same as the ones in the front), so used one of those on the other side.

We also replaced a balljoint. It was made by ProForge, and it's greasable, which is nice. What wasn't nice is that it uses it's own nut, in a different thread pitch. So in the future if I have to take that apart, I have to make sure to keep all that stuff straight.

Mike learned that some of the Corvette guys were running into issues with tearing out the inner tie rod end in the back when running big power and slicks. So he had made sure that mounting point was reinforced.

We put on the exhaust parts that came back from Jet Hot. (except the downpipe, that's not mounted yet).

And here is just a generic shot of some of the bracing that supports the transmission and keeps it from wrenching itself around under power.

[This message has been edited by Trinten (edited 03-26-2023).]

|

|

|

|