|

| LS4 / F40 swap - fieroguru (Page 61/216) |

|

fieroguru

|

JAN 16, 02:19 PM

|

|

| quote | Originally posted by RumbleB:

That method of lifting won't rip at the metal, in the trunk? .

|

|

The metal is folded over into the cutouts which makes it stronger and harder to bend. If you lift the whole car with the complete drivetrain it will put a small dent in the edge of the hole, but it is still one of the best methods of lifting a fiero. Using some 3/8" bolts to a chain on the strut towers works as well, but it is easy to scratch the paint on the strut towers with that method.

|

|

|

fieroguru

|

JAN 16, 02:20 PM

|

|

| quote | Originally posted by F355spider:

A lot of nice work. I like the detail and thanks for the nice pics of the fuel filter set up. |

|

Thanks and you are welcome![This message has been edited by fieroguru (edited 01-16-2013).]

|

|

|

qwikgta

|

JAN 18, 06:13 PM

|

|

| quote | Originally posted by fieroguru:

If the 3800's use a vacuum referenced FPR, then they probably can not use the Vette filter/regulator. If they are not vacuum referenced, then I see no reason that it wouldn't work.

Yes, these filter/regulator assemblies are set for 58psi. |

|

I have this same setup on my LS3 and asked Ryan if I could use it on my 3800 swap. He explained it all to me, bottom line "no".

Rob

|

|

|

fieroguru

|

JAN 20, 01:34 PM

|

|

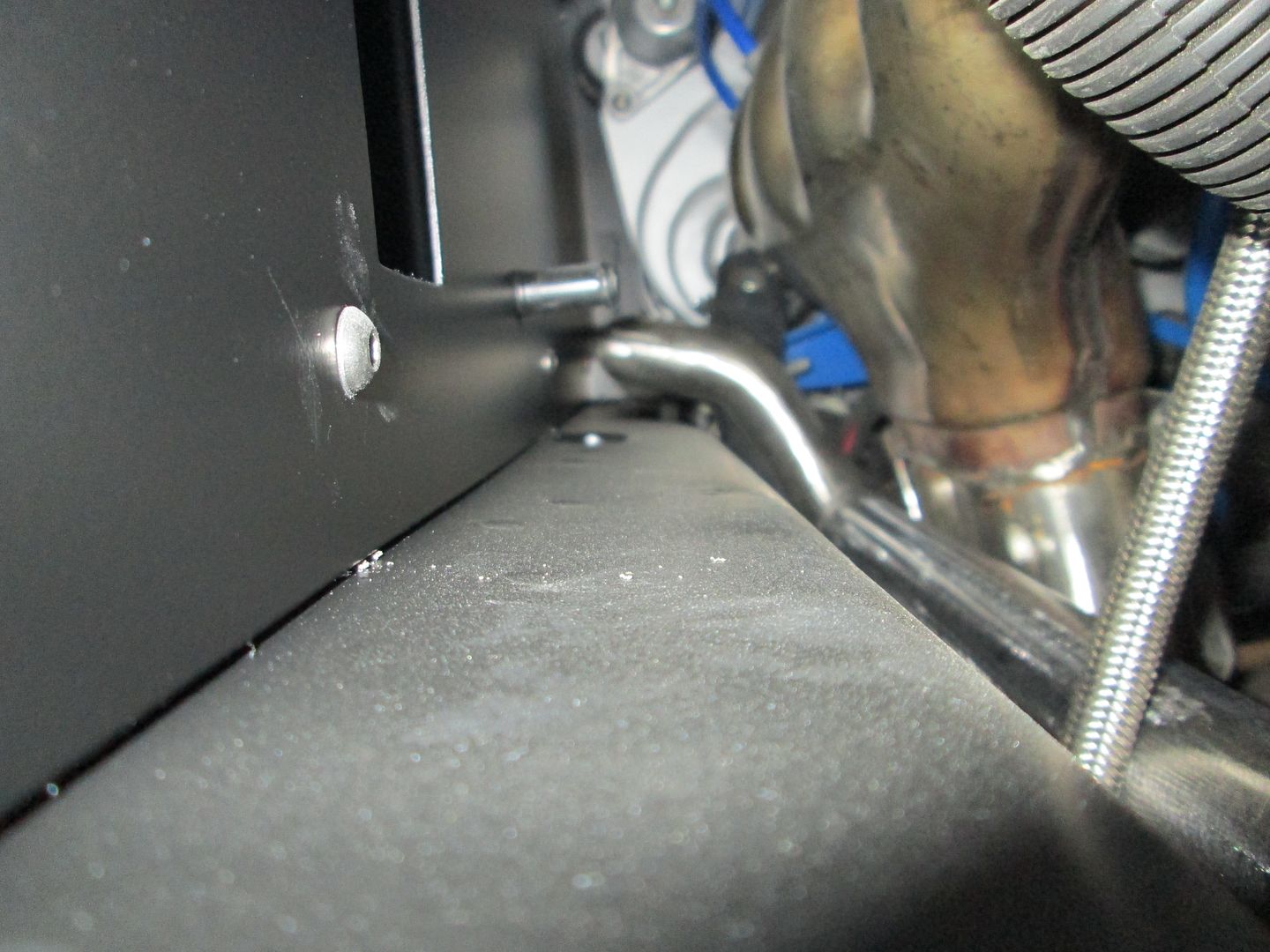

Finally got around to reworking the coolant pipes. The driver side one was an easy fix, just shorten the offset section by 1" and cut off the flange and reweld it in a new position.

Original setup:

Modified one:

Here are a couple installed pictures. There is now about 3/16" between the tube and the PS front cradle mount tab:

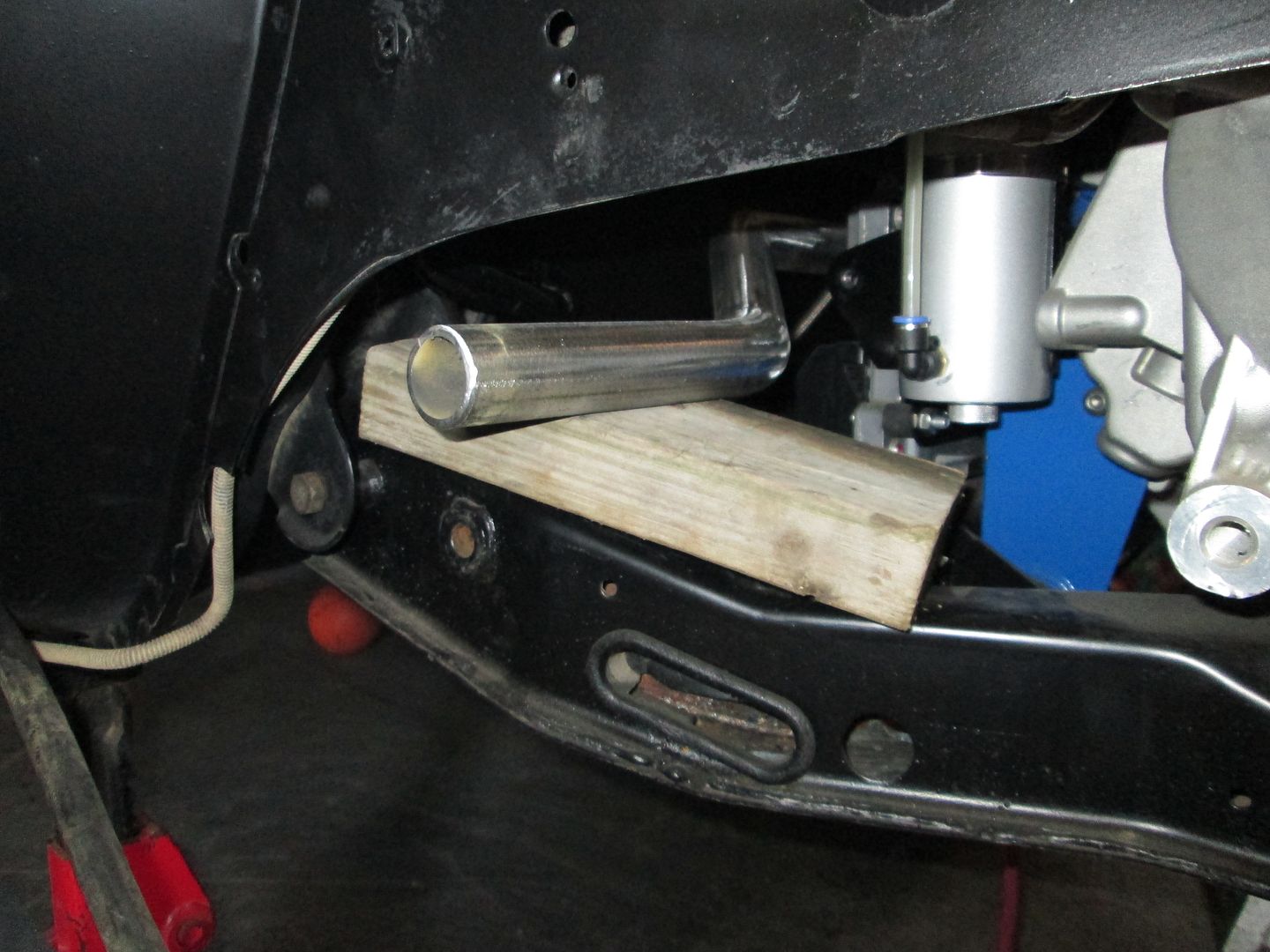

The DS tube was a pain... I ended up using the cradle tip method to remove/install this tube about 10 times during the fabrication process... but now it fits quite well and is nearly complete (just need to make the last mounting tab.

|

|

|

DPoppelll

|

JAN 20, 07:39 PM

|

|

|

I think that if you ever made a swap kit like this I would save every last penny to buy it. This really is a fantastic build, technically and visually.

|

|

|

ericjon262

|

JAN 29, 09:09 PM

|

|

|

|

fieroguru

|

JAN 29, 09:53 PM

|

|

The coolant tubes are done and installed, the harness is installed and fully connected, the fuel system is completely installed and connected (replaced the fill 90 degree hose), the battery relocation cables are connected at the engine and routed along the tank and up to the battery - these still need to be terminated at the battery.

Once the battery is connected, I can power up the ecm and HP tuners and start doing the basic sensor checkout. I will also pull the plugs and crank the engine over to build oil pressure and purge the air from the fuel rail (returnless, so air must pass through the injectors to purge). Then I need to work on the base tune for the security, larger injectors and maf change... then cross my fingers and see if she will make some noise...

My laptop/netbook (HP 2133 running 32G SSHD and windows XP) died yesterday - black screen of death, so with the help of google I tore it down to the motherboard and placed it in the oven at 395 degrees for 8 minutes. Let it cool, reassemble and the laptop is functional again! I know absolutely zero about PC's, but with the help of the internet, the wife is impressed once again at the things I can fix!

|

|

|

ericjon262

|

FEB 02, 06:58 PM

|

|

| quote | Originally posted by fieroguru:

The coolant tubes are done and installed, the harness is installed and fully connected, the fuel system is completely installed and connected (replaced the fill 90 degree hose), the battery relocation cables are connected at the engine and routed along the tank and up to the battery - these still need to be terminated at the battery.

Once the battery is connected, I can power up the ecm and HP tuners and start doing the basic sensor checkout. I will also pull the plugs and crank the engine over to build oil pressure and purge the air from the fuel rail (returnless, so air must pass through the injectors to purge). Then I need to work on the base tune for the security, larger injectors and maf change... then cross my fingers and see if she will make some noise...

My laptop/netbook (HP 2133 running 32G SSHD and windows XP) died yesterday - black screen of death, so with the help of google I tore it down to the motherboard and placed it in the oven at 395 degrees for 8 minutes. Let it cool, reassemble and the laptop is functional again! I know absolutely zero about PC's, but with the help of the internet, the wife is impressed once again at the things I can fix! |

|

I got a laptop with a fubar'd keyboard, put a piece of paper under the ribbon cable, now it works! google FTW indeed!

|

|

|

fieroguru

|

FEB 02, 07:23 PM

|

|

Finished hooking up the battery and put power to the car and started checking things out.

Never store a gas tank empty... I put a new fuel pump in the tank a couple years ago when I picked up this car and wanted to see if the old 2.8 would run for part out purposes. After that I drained the tank and stored it indoors ever since. Well the fuel pump was locked up and the fuel sender had zero continuity at any setting. So I spent the majority of today dropping the tank, replacing the fuel pump and then cleaning all the electrical terminals in the tank and the sender.

Sunday I will confirm +12V at the ECM/TCM pins as well as the ground connections and then power up the ECM/TCM and hook up HP Tuners.

|

|

|

fieroguru

|

FEB 03, 08:23 PM

|

|

Fuel tank is back in and pumping gas. All the battery, ignition and ground feeds to the ECM/TCM checked out, so I hooked up HPtuners and did the initial download of the ecm/tcm calibration and worked up a base tune with the following changes...

VATS 1 and VATS 2: both set to Disable. This "should" turn off VATS

MAF Air Flow Frequency (Low): Compared to 07 Vette Table (same MAF I am using) and copied it, then confirmed the difference was 0. For MAF change

MAF Air Flow Frequency (High): Compared to 07 Vette Table and copied it, then confirmed the difference was 0. For MAF change

Injector Flow Rate vs. Pressure: Compared to 07 Vette Table and copied it, then confirmed the difference was 0. For Injector change

Tach Output- Tach Type. Originally was set for serial, the TBSS was Frequency so I changed it to Frequency. I "hope" this will enable the direct tach output like the TBSS has

ETC Scalar - Change to 4725 for 90mm TB

Effective Area Max - Changed to 8191 for 90mm TB

Effective Area Min - Changed to 0

Effective Area Min Fail - Changed to 5

RPM Limits - Extreme Cutoff - Changed to 6800

RPM Limits - Extreme Resume - Changed to 6720

Cutoff RPM vs. Gear - Changed all values to 6800

Cat Over Temp Protection: Disabled. I don't have a cat and this adds 25% fuel to protect the cat under certain conditions

Displacement On Demand: Disabled - it need to be off for all tuning. I will turn it back on at a later date

DoD RPM Thresholds - Min RPM: Changed to 1600 rpm. I only want it to work in 5th/6th gears between 45 and 80 mph

DoD RPM Thresholds - Max RPM: Changed to 2300 rpm. I only want it to work in 5th/6th gears between 45 and 80 mph

DoD Enable VSS: changed to 45 mph

DoD Disable vs PRNDL: D4 was 0, so I changed everything to 0 so DoD shouldn't care what the range switch says, even though the TCM is hard wired to show D4

DoD Disable vs Gear: 3rd gear and 4th gear were set to 0, so I changed 3rd gear to 1 and 5th and 6th gears to 0. No idea if this will work, but I changed it anyway

Engine Torque Management Spark: Disabled. I don't want any torque management

Engine Torque Management ETC: Disabled. Same reason

Transmission Diff Score: Disabled

Transmission Abuse Mode Torque Reductions vs. RPM: Set every value to 0 - no torque reductions

Transmission Abuse Mode Torque Reductions Duration vs. transmission temp: Set every value to 0 - no torque reductions

Starter Diag: Disabled. Using Fiero starter control

Clutch Interlock: Disabled. Using Fiero clutch pedal wiring

Number of Fans: Set to 1

Ignition off run time: set to 60 seconds. Reduced from 360 seconds due to my smaller battery

Speedometer - Tire Size: Set to 24.6

Speedometer - Gear Ratio: set to 3.55. F40 final drive ratio

Speedometer - VSS PP Rev: set to 78. # of teeth for F40 VSS

Speedometer - VSS PP Rev - Trans: set to 78. # of teeth for F40 VSS

Speedometer - VSS PP Mile: set to 63949

Speedometer - Revs per Dist (1 mile): Set to 819.86

Speedometer - Revs per Dist (1 mile) - trans: Set to 819.86

Speed Limiter (fuel cut off): Changed to 200mph

Speed Limiter 2 (fuel cut off): Changed to 200mph

The below Diagnostic Trouble Codes were turned off for missing components from the installation (Evap, Fuel Pressue, Post Cat O2 sensor, Cat, etc)

P0036 - HO2S Heater Control Circuit Bank 1 Sensor 2 - Turned off

P0054 - HO2S Heater Resistance Bank 1 Sensor 2 - Turned off

P0137 - HO2S Circuit Low Voltage Bank 1 Sensor 2 - Turned off

P0138 - HO2S Circuit High Voltage Bank 1 Sensor 2 - Turned off

P0140 - HO2S Circuit Insufficient Activity Bank 1 Sensor 2 - Turned off

P0141 - HO2S Heater Performance Bank 1 Sensor 2 - Turned off

P0420 - Catalyst System Low Efficiency - Turned off

P0422 - Evaporative Emission System Small Leak Detected - Turned off

P0443 - Evap Purge Solenoid Valve 1 Control CKT - Turned off

P0446 - Evap Vent Solenoid Valve Control System - Turned off

P0449 - Evaporative Emission Vent Solenoid Control Circuit - Turned off

P0451 - Evaporative Emission Control System Pressure Sensor Range - Turned off

P0452 - Fuel Tank Pessure Sensor Circuit Low Voltage - Turned off

P0453 - Fuel Tank Pessure Sensor Circuit High Voltage - Turned off

P0454 - Evaporative Emission Control System Pressure Sensor Intermittent - Turned off

P0455 - Evaporative Emission System Leak Detected - Turned off

P0461 - Fuel Level Sensor Performance - Turned off

P0462 - Fuel Level Sensor Circuit Low Voltage - Turned off

P0463 - Fuel Level Sensor Circuit Low Voltage - Turned off

P0464 - Fuel Level Sensor Circuit Intermittent - Turned off

P0481 - Cooling Fan Relay 2 Control - Turned off

P0496 - Evaporative Emission System High Purge Flow - Turned off

P2544 - Torque Management Request Input Signal A - Turned off

P2A01 - O2 Sensor Circuit Range/Performance Bank 1 Sensor 2 - Turned off

Once all these changed were saved, I did a Write Entire to the ECM/TCM.

After I pulled the plugs and cranked the engine to build up oil pressure, I had several DTC's.

0315 - needs a case learn - need to have the engine running to perform it, but some say you can do it with a manual transmission. This will wait till it is running

0340 - Camshaft Sensor - need to run through the sensor/harness diagnostics on this one. Wiring, sensor or ECM issue

0557 - Brake Booster Sensor. I didn't have the connected plugged in

1516 - TAC Control - need to run through the sensor/harness diagnostics on this one. Wiring, Throttle Body or ECM issue

2101 - TAC Control - need to run through the sensor/harness diagnostics on this one. Same as above.

When I tried to start the engine after revision 2 of the tune, the fuel pump primed for about 1/2 second (should be 2 seconrs) then shuts off. The engine cranks without starting... I need to listen better to see if the fuel pump is working while it is cranking and check for spark at the coils. I suspect it is due to the cam sensor issue and the engine not knowing which cylinder is ready for fuel/ignition.

I am please that the mini battery has been able to spin this engine quite a bit to both prime the oil (about 1 minute of cranking) and to crank the engine (for another minute or two).[This message has been edited by fieroguru (edited 02-05-2013).]

|

|

|

|