|

| Northstar rebuild: Will style (Page 57/119) |

|

Will

|

DEC 14, 06:16 AM

|

|

|

|

mrgrimes

|

DEC 22, 01:02 AM

|

|

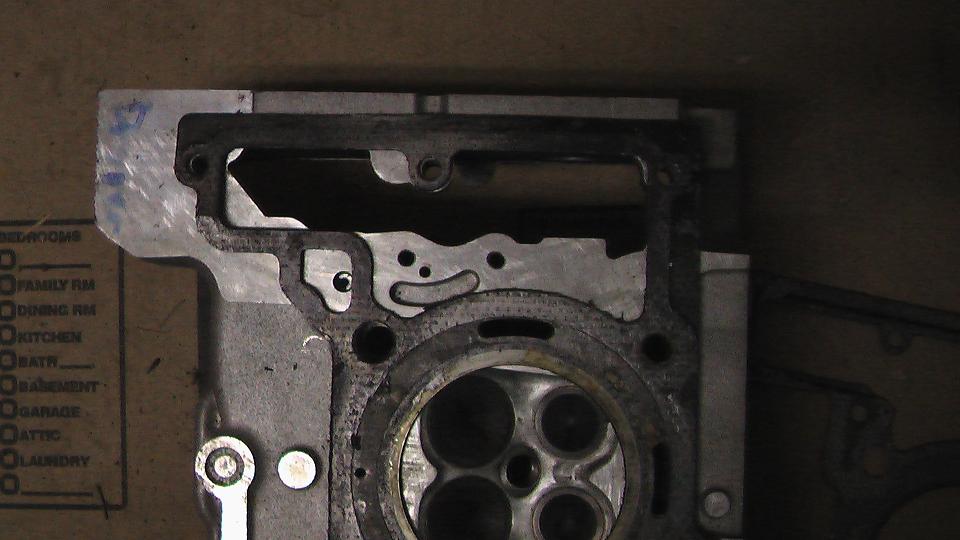

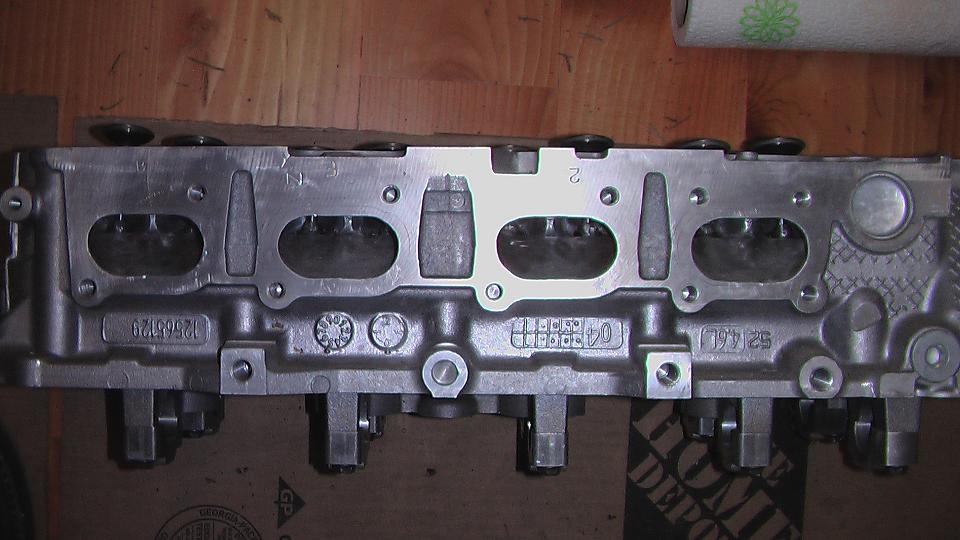

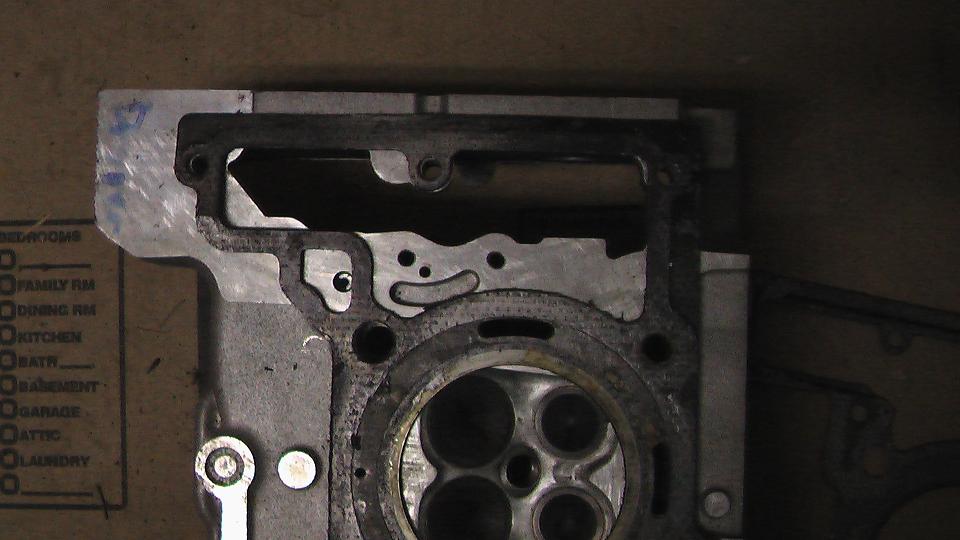

OK I finally got around to it.

|

|

|

mrgrimes

|

DEC 22, 01:06 AM

|

|

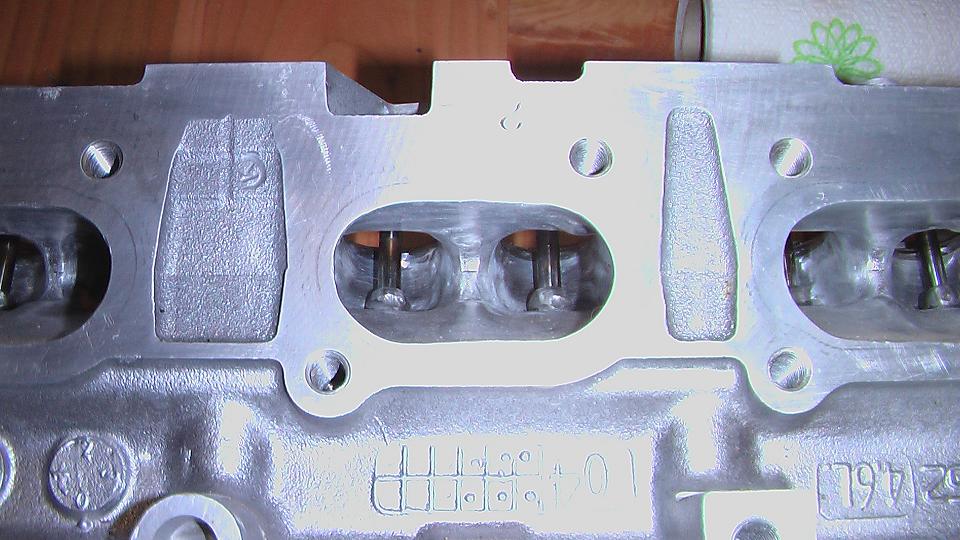

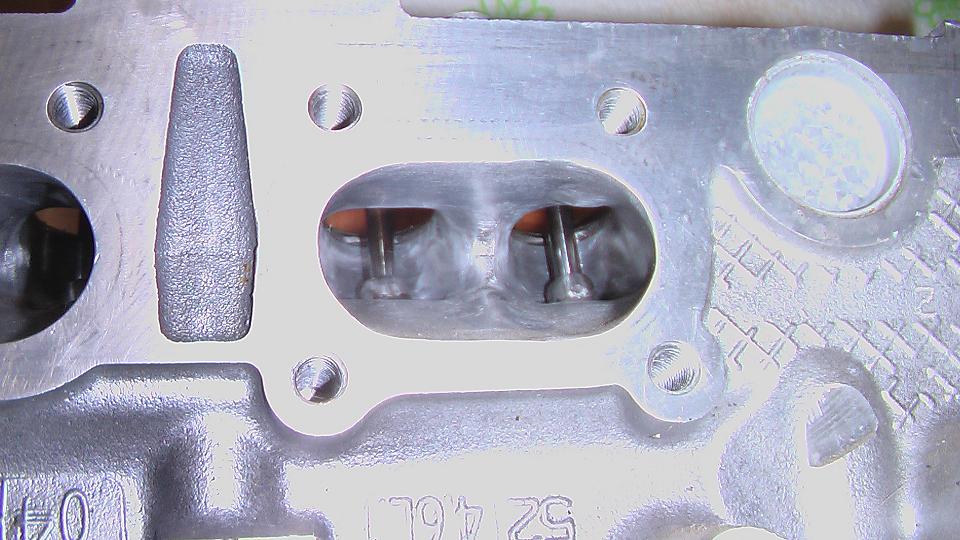

Also these are the differences between < 02 and > 02 valves

2004/2005/2002

Intake

Valve: 1.42”

Lift: .395”

Stem: 6mm

Exhaust

Valve: 1.16”

Lift: .365”

Stem: 6mm

Wrist Pin

Dia: .866”

Length: 2.4”

1996

Intake

Valve: 1.3”

Lift: .370”

Stem: 6mm

Duration: 266°

Exhaust

Valve: 1.14

Lift: .339”

Stem: 6mm

Duration: 244°

|

|

|

afgun

|

JAN 01, 01:34 PM

|

|

| quote | Originally posted by Will:

So I understand from what you said that the '00+ reluctor wheel is the same as the LS1 reluctor wheel. Does the Northstar continue to use two crank sensors to synch faster?

The positions of the crank sensors were tweaked slightly for '00. Do you know why that was done? For example, was it to make the "reference angle" variable the same between the two engines?

|

|

The reluctor wheel is not the same, nor the sensors that read it... however, the patterns look to be similar, if not the same. The LS1 24x reluctor is a pressed-together pair of opposite wheels. The 2000+ N* reluctor wheel is machined with simple highs and lows. I measured both patterns with a caliper and generated a spreadsheet... they matched, the 24x reluctor wheel that I have, in the opposites with the high/low patterns on the late N* crank. What I don't know is if they align on the same TDC or not; I would suspect that they do, but haven't gotten a chance to verify yet. I also haven't gotten a battery to spin the N* on my engine stand to scope the reluctor signals out yet.

| quote | Originally posted by Will:

If I put the '00-'04 crank into my engine, would I be able to run it with the 0411 and LS1 program (and just tweak whatever amounts to a crank reference angle)?

That would upgrade me from DIS to coil/cylinder, but I'm just curious as I'm not about to change crankshafts for that relatively small benefit.

|

|

That would only work if a few things worked out... 1, the primary crank sensor was in the same place on both motors, 2 the updated sensor fit in the same hole and mounted up and 3 if you swapped the cam gear and sensor to the later models... the early N* cam gear is a single point blip, whereas the later cam gear is a 50% on/off (pictures if you like).

I am going to try to use my 0411 to run both styles of engine, depending on which tune gets flashed into it. Finances have things on hold for me these days, though I'll probably make a trip out to the junkyard soon to pick up a cheap battery to at least scope out reluctor patterns with. Unless someone has a late N* crank that they want to machine the reluctor from and mail it to me.

|

|

|

Will

|

JAN 01, 02:11 PM

|

|

| quote | Originally posted by mrgrimes:

OK I finally got around to it.

|

|

These are '05 front wheel drive heads? Interesting. I'll have to get an '05 engine and tear it down to see what makes it tick.

|

|

|

Will

|

JAN 01, 02:16 PM

|

|

| quote | Originally posted by afgun:

That would only work if a few things worked out... 1, the primary crank sensor was in the same place on both motors, 2 the updated sensor fit in the same hole and mounted up and 3 if you swapped the cam gear and sensor to the later models... the early N* cam gear is a single point blip, whereas the later cam gear is a 50% on/off (pictures if you like).

I am going to try to use my 0411 to run both styles of engine, depending on which tune gets flashed into it. Finances have things on hold for me these days, though I'll probably make a trip out to the junkyard soon to pick up a cheap battery to at least scope out reluctor patterns with. Unless someone has a late N* crank that they want to machine the reluctor from and mail it to me.  |

|

Thanks for the info on the trigger wheel.

I'm familiar with the Y2K engines... I just haven't taken apart anything as new as '05. The late crank in the early block should work with either a tweak to the reference angle in the PCM (if there is such a variable in the LS1 program) or by doing a block adjustment of the entire timing table to compensate for the difference in crank sensor location (only 2 degrees or so).[This message has been edited by Will (edited 01-01-2010).]

|

|

|

philbur120

|

APR 07, 11:46 PM

|

|

|

Lots of good info here guys! I will possibly starting a rebuild soon, just need to find a new block.

|

|

|

Will

|

APR 08, 12:29 PM

|

|

Just get a whole engine: www.car-parts.com

Hope your learning curve is shallower than mine was...

|

|

|

Nashco

|

APR 09, 11:29 AM

|

|

| quote | Originally posted by Will:

Just get a whole engine: www.car-parts.com

Hope your learning curve is shallower than mine was... |

|

No doubt! Everything I learned about reasons not to rebuild a Northstar, I learned from you, Will.  From what I've learned of the Northstar, inserts and head gaskets are about as far as I'd go into one. If anything in the bottom end rotating assembly is screwed up, it looks like the best method of repair is replacement. As cheap as these engines are used, it's hard to justify anything otherwise (on a cost basis). From what I've learned of the Northstar, inserts and head gaskets are about as far as I'd go into one. If anything in the bottom end rotating assembly is screwed up, it looks like the best method of repair is replacement. As cheap as these engines are used, it's hard to justify anything otherwise (on a cost basis).

I'm still curious to see how the over-complicated rebuild turns out in the long run...but probably not nearly as curious as Will.

Bryce

|

|

|

Will

|

APR 09, 04:48 PM

|

|

Haha... It only has a few dozen little gotchas...

The biggest of course is getting the hone job right on the ridiculously hard iron in the bore liners.

The next is installing threaded inserts. I went for head bolts AND main bolts, of course.

Rod bearings are $20 each.

Odd bore size means it's hard to get top shelf piston rings.

Case halves don't seal with the factory seals, just oodles of anaerobic goo.

Must stretch rod bolts BEFORE installing lower crank case.

Some subsets of engine components were changed together, but not all subsets changed in the same year.

Valve cover gaskets for '99 and older engines are hard to get. Once they swell up they are non-reusable.

Stainless fuel rails.

Harmonic balancer bolt size changed. Bolt must match crankshaft of course.

Nobody makes 8mm flywheel bolts.

etc. etc.

I'm just curious about really driving the thing...

|

|

|

|