|

| NS F355 Project (Page 56/73) |

|

zkhennings

|

OCT 23, 04:20 PM

|

|

|

Could you use U joints from the transmission to an intermediate stationary point where you could attach CV joints for the axles? Much cheaper and possibly less problematic than the drive belts, which I could see being a little noisy (even if they are relatively quiet) and getting dirty unless they are protected by pretty large housings. I haven't looked at how much space you will have to achieve the displacement you need so maybe the angles would be too high for U joints, but maybe not. Also a factor is axle length, I do not know what minimum axle length you would require to keep the CV joints happy through the full range of motion.

|

|

|

Yarmouth Fiero

|

OCT 23, 09:41 PM

|

|

Here is a quick drawing showing a drive shaft with CV joints. It produces a joint angle of about 21 degrees. This could be improved on by tucking the engine in a little tighter to the firewall. Is this sort of what you had in mind zkhennings?

|

|

|

zkhennings

|

OCT 27, 07:29 AM

|

|

Well what I was trying to accomplish was exactly what your belt drive is doing, except getting that shift with short axles with U joints.

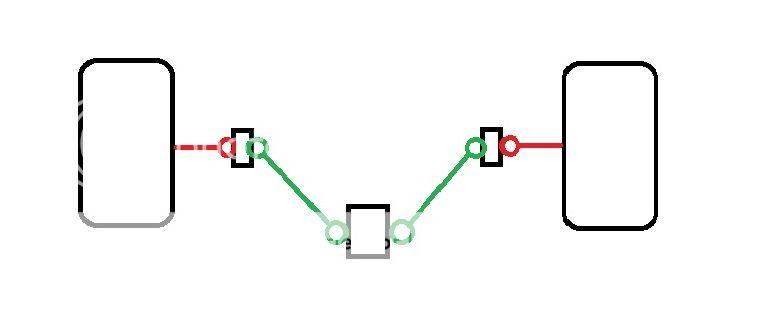

Here is a quick MS paint picture of what I mean

Green is U joints and intermediate axle

Red is CV joints and axle to the wheels.

The black boxes with sharp edges are solid mounted positions.

I believe the U joints can achieve higher angles than CV joints as well as operate better as well. The tradeoff is that they can't accommodate for length changes like the CV joints can. The intention of the intermediate axles is to accomplish exactly what your belt drive system is doing. This way the CV joints don't have to be angled during operation at all times and would most likely function better and last longer.

At the same time however 21* isn't very bad compared to what the 4x4 guys run but they break CV joints a lot.

|

|

|

Bloozberry

|

OCT 27, 12:53 PM

|

|

The reason car manufacturers have gotten away from U joints and moved to CV joints is because when run at an angle, the U joint parts speed up and slow down as they cycle around one full revolution (hence the development of constant velocity joints). Just try turning a couple socket wrench extensions with a U joint between them using your fingers and you'll see what I mean. That whipping gets worse the larger the angle is at the joint and transmits into the chassis as a vibration.

Personally, I'd stick with the belt idea. On a side note, when I was researching my own axle angle limitations I found that most CV joints can operate to a maximum of about 26 degrees, though some were limited to only 16 degrees. Also of interest is that an angle of at least one degree is required to ensure proper lubrication. Just call me Cliff Clavin.

|

|

|

355Fiero

|

OCT 27, 01:01 PM

|

|

A buddy of mine used CV joints on an axle with a large angle several years ago. He found that after running it for about a week, it ran itself out of lubricant. He phoned a pile of places and finally got an expert ( I think its was an engineer at one of the axle places) and found out that CV joints are not designed to run at CONSTANT large angles. They are designed to accept large angles but only for a short periods of time such as cars turning or bumps etc. What happened to my buddy's axle was that it heated up to the point that it melted the axle grease out of the CV joint and then failed.

This was many years ago though so I am sure the CV joint technology might have improved since then and this info is from my buddy so I don't have confirmed engineering confirmation of the info. Belts would be a better option in my opinion for this much of an offset.

Cheers

Don

|

|

|

FieroWannaBe

|

OCT 28, 08:58 PM

|

|

| quote | Originally posted by zkhennings:

I believe the U joints can achieve higher angles than CV joints as well as operate better as well. The tradeoff is that they can't accommodate for length changes like the CV joints can. The intention of the intermediate axles is to accomplish exactly what your belt drive system is doing. This way the CV joints don't have to be angled during operation at all times and would most likely function better and last longer.

At the same time however 21* isn't very bad compared to what the 4x4 guys run but they break CV joints a lot.

|

|

Universal joints can take higher loads than most Constant Velocity joints per mass.

Universal joints do not run at a constant velocity and induces an oscillating angular acceleration in the shafts. This requires more shaft material to resist the cyclic loading and fatigue stress. The condition worsens at larger angles, this is why most RWD cars use rubber drive discs and a CV joint in their drive shafts to reduce driveline vibration, and NVH.

There are shaft designs that utilize universal joints that can accomidate the required change in length needed with splined male and female ends, or like the Jaguar and corvette, some designs utilize the drive shaft as a suspension member, so length can stay fixed.

|

|

|

Jefrysuko

|

OCT 29, 05:59 PM

|

|

|

|

Yarmouth Fiero

|

OCT 31, 06:11 AM

|

|

|

Thanks for the great video jefrysuko. We use cardan shafts ( a shaft with U joint at each end and splined section in the middle) a lot in the marine field and that is the best video I've seen on the use and misuse of shafts and U joints. A couple years ago we invested in a laser alignment tool just for aligning cardan and its almost completely eliminated shaft issues. But I have to wonder how automobiles don't have more issues considering that the wheel end of the shaft is not fixed relative to the engine end, especially at high rpm's. Anyone with thoughts on this?

|

|

|

Neils88

|

OCT 31, 06:00 PM

|

|

|

Instead of belts, have you considered a simple 1:1 ratio gear train?

|

|

|

Yarmouth Fiero

|

OCT 31, 06:20 PM

|

|

|

I had considered gears but keeping it all lubricated would require building fully enclosed gearboxes. The belts do not require any lubrication.

|

|

|