|

| Trinten's SBC/F23 build - The work has begun! (Page 50/76) |

|

Trinten

|

MAY 26, 09:49 PM

|

|

As shelter in place restrictions have eased up, I was able to head over to Mike's on the 16th.

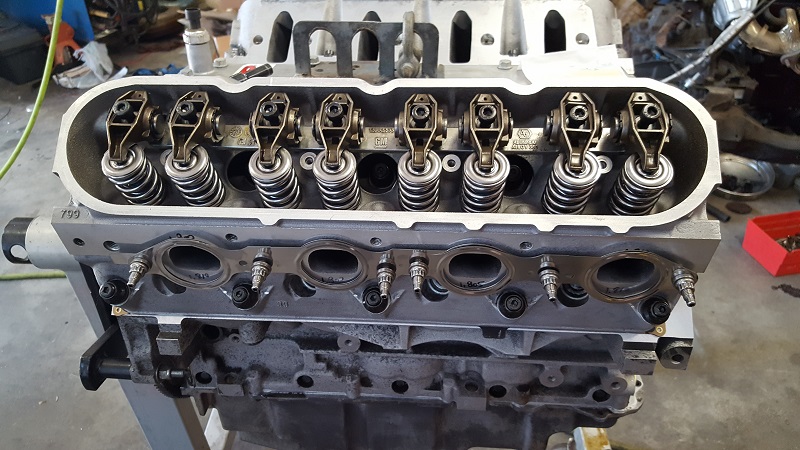

He was installing the trunnion upgrade in my rockers when I got there. The upgrade is "shoulderless" trunnions (apparently stock trunnions have these little shoulders that can break from extreme forces). It also has captive rollers, which is one of the pieces that can pop out of whack and cause all sorts of headaches!

The bottom end is all torqued down. The upper end is all loosely bolted together for fitment checks and what not.

Pistons and rings are:

D.S.S. FX-Series Forged Piston and Ring Kits

Part number DMS-K1-2800-3780

Also, the cam bolts are not ARP! GASP! I could have sworn I bought ARP cam bolts... maybe this is one of those things that Mike talked me out of. Or I didn't think about it. Or because this is a loose bolt-together, Mike hasn't installed them yet. Hmmm...

Anyhow! In addition to the pictures below, Mike also did some work on things for under the frunk, including mocking up the water/ice box for the intercooler.

The rockers with the new trunnions installed, rockers loosely bolted into place.

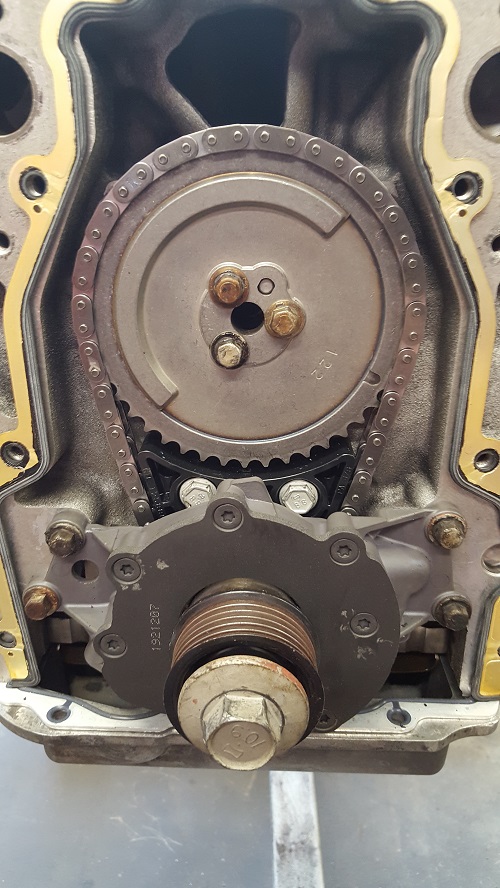

My spiffy Ka-Tech chain installed, with the new chain damper to prevent 'wrap around'.

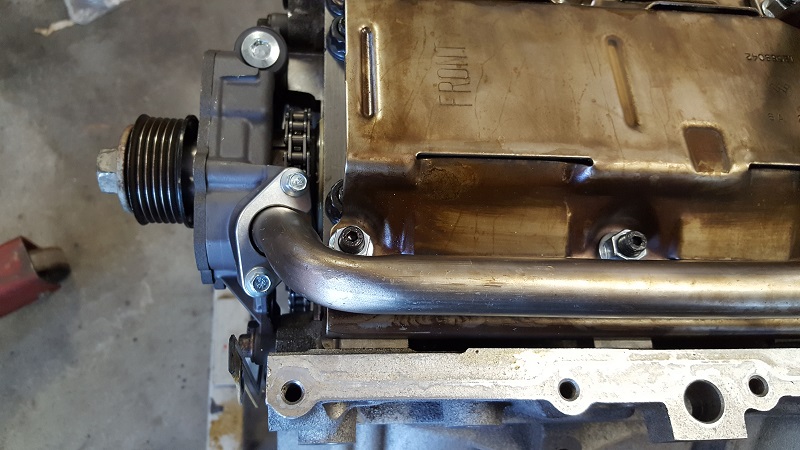

The Oil Pickup Tube, with the addition bracing hold down.

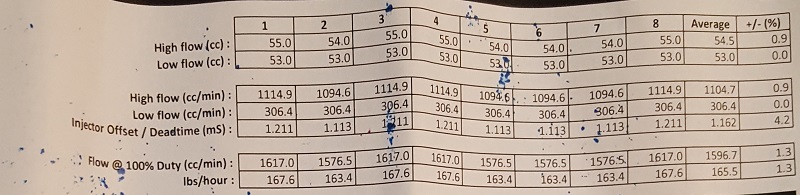

Oh yeah, and I got my 1500cc injectors! They showed up with the flowchart. It seems that the company had a little issue replacing the 'cyan' laser printer toner! lol

Things left to buy for the engine:

Intake

Throttle body

-8 AN fuel rails

Heat exchanger for the A2W intercooler

Water pump for the same

Pushrods (waiting on confirmation of length from Mike, Brian Tooley Racing makes some nice one piece chromoly ones that I'll get)

And this really awesome setup from FueLabs. Great pre-sales support. I told them what I was running, what my max demands were going to be, etc. They were really cool, wrote back and recommended a pre-pump filter, a pump, a post-pump filter, and a damn spiffy electronic fuel pressure regulator that can slow the pump down when it doesn't need the demand, helping reduce wear on the pump.

I ran their recommendations past the fuel injector company, to make sure it would meet their standards (Especially around filtering, I was concerned it would be a choke point with E85), and got their thumbs up, too. They said the surface area of the outlets on the filters would definitely allow enough through.

So that being said, here's the fuel setup:

FUELAB 828 Series Inline Fuel Filters 82823-1

FUELAB Prodigy Fuel Pumps 42401-1

FUELAB 818 Series Inline Fuel Filters 81833-1

FUELAB 529 Series Electronic Fuel Pressure Regulators 52902-1

Yes, it's a little pricey, but I would rather have that then worry about wrecking an engine from an abrupt lean condition!

[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Will

|

JUN 03, 11:01 AM

|

|

| quote | Originally posted by Trinten:

A couple candy shot ofa piston and rod

The coated bearing

|

|

What pistons are these again?

|

|

|

Trinten

|

JUN 03, 02:40 PM

|

|

Hey Will,

The Company is called D.S.S. Mike tells me that they do not make their own piston (very few company's do anymore, I suppose).

Here is the model I bought.

D.S.S. FX-Series Forged Piston and Ring Kits

Part number DMS-K1-2800-3780

|

|

|

Trinten

|

JUN 10, 10:40 PM

|

|

Some updates!

Pictures will be following this weekend sometime. Sunday was busy and work has kept me busy, so I haven't had the chance to download them from my phone, resize them, rename them, upload them to my site, etc etc. I try not to use the photo hosting here just so I'm not adding overhead to Cliff.

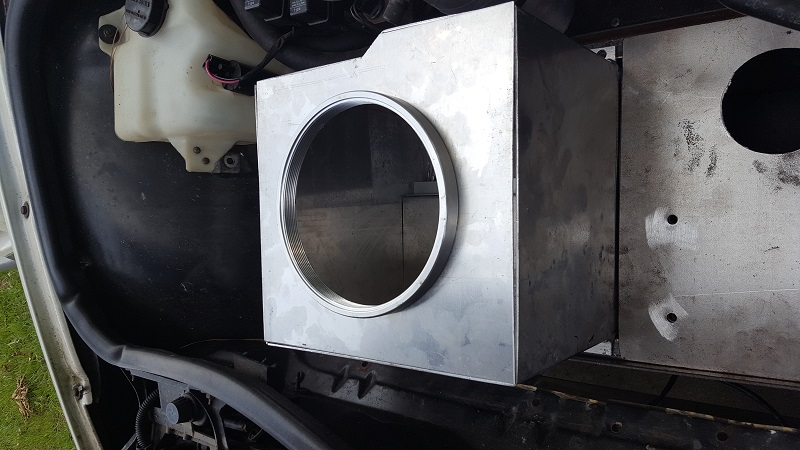

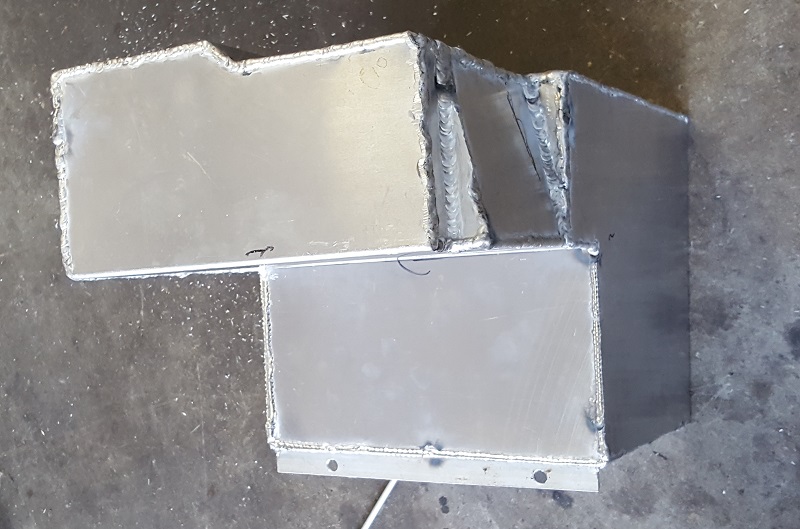

What the pictures will show is the custom water tank pieces and tack-weld-for-fit pictures of it. One of the pictures also captured the new "floor" in the "frunk" during the test fit pictures. Eyeballing the tank, I think it'll hold 3 to 3.5 gallons. Mike wanted it closer to five, but only so much room to work with, which he maximized!

The tank has a "tail" that goes below the funk floor, to utilize as much space as possible and still give everything appropriate clearance. It also has a 7.5-ish inch cap/opening, to make it easy to put ice into it for track days.

He also had me order a fairly large A2W heat exchanger. The thing is nearly the size of a radiator. It's 24"x12"x1" and comes with a radiator style fill cap and a a drain petcock. Makes it easy to drain out excess water from the aforementioned ice! The heat exchanger was bought from frozenboost.com, which has a few other "affiliates", which are just DBAs of the same company to the best of my minimal investigation.

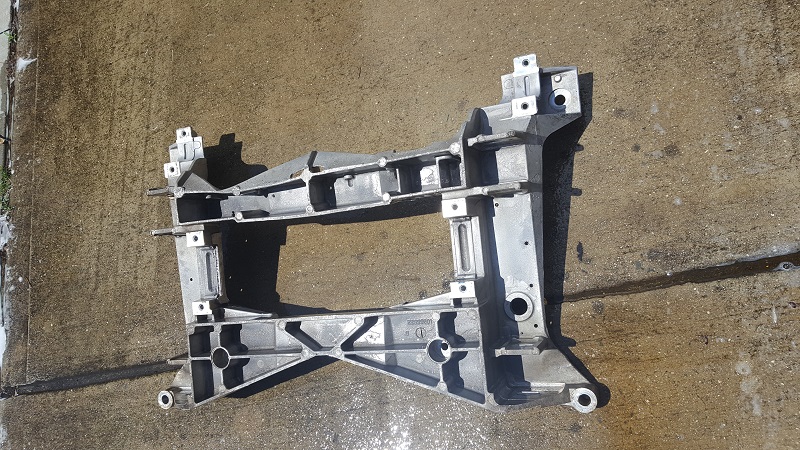

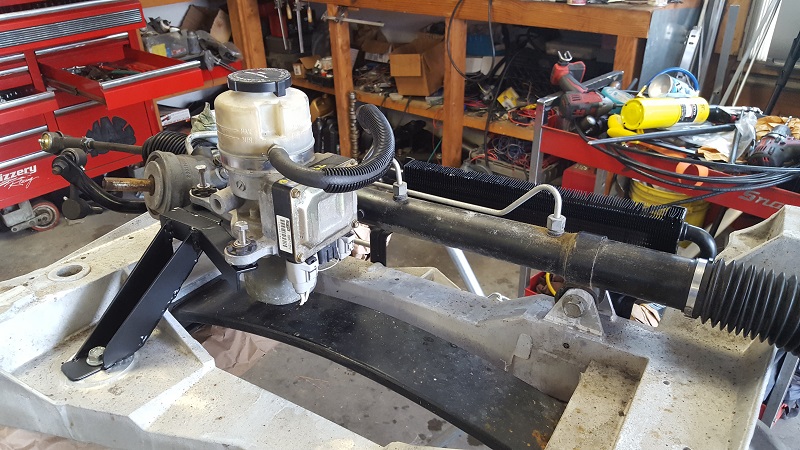

We (I say we, because I sorta helped) also dropped the front cradle again, this time so Mike can do some finish-welding work on the mounting plate for the rack, and replace a few components (outter tie rods, upper ball joints, and we're putting on adjustable/lowering spring pads). I suspect he's also going to clean up, finish-weld and seal/paint the bracket that will hold the EHPS, which is bolted to the steering rack.

His goal is to get the front mechanically done in the next few weeks. That will just leave the skid plate for the front, and duct-work to push air into the heat exchanger, radiator, and AC condenser.

After that he wants to get the Deutsch HDP20 Bulkhead connectors in place. We're going to put one at the front firewall, and one at the rear firewall.

Then the cradle will come out, the SBC will be moved to a stand temporarily, and the cradle modified for the LS and 4T80.

I plan on offering the original cradle, modified to hold the SBC, along with the SBC and a F23 transmission, along with a copy of my tune for a 0411 PCM for sale if anyone wants to pick it up. It will be a very-close-to-drop in way to get a forged, high performance SBC swap done. I don't know how many people will have an appetite for the price. I'm asking 5,000 USD, which is about 40% what the setup cost me.

The rundown of what's in the SBC engine is further up in the thread (maybe a page back?).

I know that's steep for most Fiero owners, but I know I can turn around and sell the engine by itself for 4k, give or take 500. I think getting it, the transmission, all mounted and ready on a cradle is worth the ~1000 more. If someone would like to buy just the engine, please let me know. Again, pick up only unless you want to arrange for it be shipped.

|

|

|

Trinten

|

JUN 22, 10:44 PM

|

|

A'right a'right a'right...

/Mcconaughey impression

At Mikes last Saturday. He had finished disassembling the whole front setup so we could clean everything, and put some parts aside to be powdercoated (brackets, calipers, caliper brackets... water tank will eventually go, there will be other trips).

So here are some pics, some of these are from the week before last.

First up, some pics of the water box! Mike had to do a lot of test fitting and mock up for this, he wanted to use as much room as possible, so it has a 'tail' that will go below the 'floor' in the frunk. Obviously not finished yet. lol

Next is where I'm kicking myself a bit. I just jumped into starting to clean stuff when I realized.... I didn't have a "before" pic. Not that everything came out looking brand new, but it did come out looking significantly better!

Then here is the new lowering spring pad bolts we got for the front:

and last pic is part of the first batch going out for powdercoating! I took this before we had everything together. And some things can't go yet (stages!)

I haven't listed the old engine and (non-LSD) F23 and cradle setup in the Mall yet. I want to wait till we have the new cradle out and the engine is off of it. I don't think I'll get any bites here. I'm sure what I'm asking is just too much for the average Fiero owner, and that's okay. I've had conversations with some shops to make sure my figure for the engine alone wasn't unreasonable. So I will put "the combo" up in the mall, but will be putting the engine by itself on Craigslist as well.

I also took some time to re-read through this thread, and I was glad I did!! I found some notes from FieroGuru, namely on the spiffy hinges he made for me, to make sure Mike mounts them right in the new car (we don't think we fished out the spreaders that go under the lip of the hinge). I'm also trying to convince him to move the C500 the same way as FieroGuru did as well. He hasn't quite warmed up to that yet.

We did have a funny conversation. He looked at me and said "I want you to give me the same courtesy that I gave you." I immediately stop in shock, thinking I did something super offensive, and just stare at him while my brain is spinning. And he waits a moment and says "If you ever decide to sell the Fiero, I want you to offer it to me, first. I'm building this like I would build it if it were mine, and the more we do, the more I like it." At the explanation I relaxed and laughed and agreed. He's referring to his Grand National, and I told him if he ever wants to sell it, I'd like to be the first to know, and he agreed.[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Trinten

|

JUN 28, 07:42 PM

|

|

Yesterday I got to help a little with some simple stuff, Mike was mostly working on finishing welding up the water tank. It's fairly thin aluminum, so it takes a lot of care to do it, and it still makes the metal wiggle around, but he has a ton of crazy shaped clamps just for that purpose.

He put in a little "distributor" plate, so when the water sprays up into the tank, it'll hit that and scatter out, mixing in more with the existing water. Then we filled it with water and checked it for any leaks. There were a few pinholes he hand to take care of. He was hoping it'd hold 6 gallons, I guessed 4.5. With about an 1.5" of gap at the top, it held 5 gallons. He set it up overnight to make sure there were no more drips, and there weren't!

Of the few things I could do yesterday, I took the heatshields off the exhaust manifolds (they'll be jet-hotted when the exhaust manifolds go there), and tried to get the exhaust studs off... that didn't work. Mike is going to cut them off and cut off the end of the manifold anyway, so he can weld on the v-band bung. He loved how close the bung was in size to the exhaust manifold, he said I was a good luck charm when it came to fabricate. The next car he builds, he'll have me just hang out for good luck. lol

Then the last thing is I did was used the airgun and a brush attachment to get as much rust as I could off the surface of the steering shaft. Mike then painted it with an etching epoxy primer, and epoxy paint.

The guy that is doing the powdercoating for Mike has one of those GIANT ovens (They do railings and stuff), so he was annoyed that I didn't want to powdercoat them all the same color (some stuff will matte black, so it looks stock-ish. Some stuff will be glossy black, and for contract, some stuff will be silver). He said we'd have to wait for other things to come that were the same color, unless I wanted to pay an additional fee for the oven. I told Mike I was fine with that if it holds him up from assembly.

[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Trinten

|

JUL 25, 09:18 PM

|

|

Okay! Some awesome news for the last few weeks that I'm excited to share, and vindicates why I always buy extra stuff!

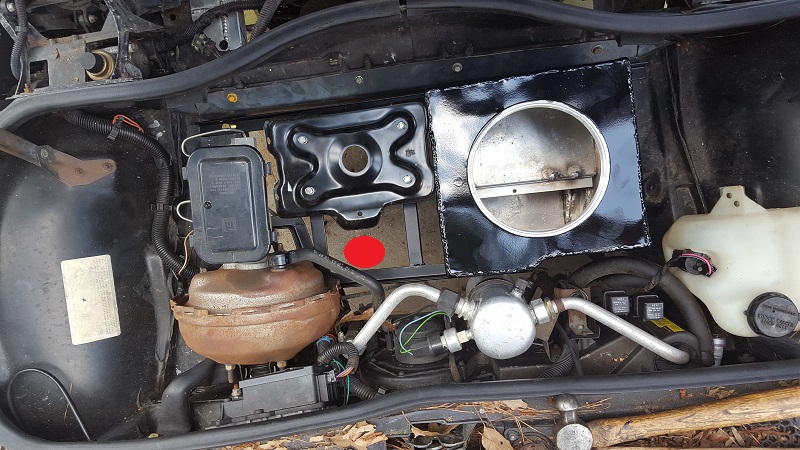

As seen in other pictures over the last year, Mike has fabricated a variety of things for my build, some structural, some to close things up (you'll see a bit more of that in the planning stages in this post), and to fit things together. Among these was the bracket for the new "Frunk floor", and the covering panels, and the bracket to hold the power steering pump.

I think I mentioned before that when we got this stuff powdercoated, Mike and I negotiated a little. He wanted the pieces that could be confused with OEM by the casual non-Fiero person to be coated in a matte black, to help keep that OEM look. And I wanted anything that obviously didn't belong to have some pop! Namely following the color scheme I started when FieroGuru had the car - glossy black and silver/chrome. Now the guy that Mike was originally going to use threw a fit about the "custom colors". He apparently works almost exclusively in matte black. So Mike is using him for that, and found a "home business" guy that did the the glossy and silver bits.

So if you notice the differences in the powdercoating, you know why! Onto some pictures!

Here's a shot of the bakes, still disassembled and then assembled. I wanted them to have some contrast and pop. So the calipers are silver, and there looks like it has a light mettalic mica in it. The brake brackets are glossy black.

Then we have the other assorted bracketry in a group shot! Along with my water tank. Mike was not happy with the watertank's coating. In person it has a few 'fish eyes' in it. But still looks great for being a custom sized tank. More on that another time (the tank, not the 'eh' powdercoating on it). Mike won't be using the "home business" guy anymore because of the tanks poor showing.

So now that we had (most) of the powdercoating done, I got to start to reasseble the front cradle! Yay I helped. lol. Put the A-arms back in and the sway bar. Then Mike attached the bracket he made to hold the power steering pump, which utilized a few things on the cradle, including of the unused Vette motor mounts.

But wait! There's more! Here's a pic with the <i>first</i> steering pump mounted on there (I bought three). More to that story in a moment!

In this next pic you'll see the pump is fully hooked up, Mike connected some longer leading wires to the correct pics we needed to jump to make the pump run, and after making sure it was running, gradually filled it with fluid and let it burp itself out.

How we got there was the fun part. That "lower" hose you see in the picture is a custom hose. The hose which connects there on the Toyota made the MR2 Spyder 2nd Gen was ... bizarre. Probably to help keep it cool, it looked a lot like a giant bobby pin. It would have been a hassle to connect, and looked out of place.

To fix this I took the Toyota hose into a nice little company that supplies a variety of hoses, all the way up to industrial hydraulic stuff. I stopped by with the toyota hose, and said "I need a hose with these ends, and (however long it was, I don't remember right now. Maybe 15 inches)." This was early in the year, maybe even late last year. (the steering rack side just required a M2M adapter).

15 minutes and 45 dollars later, I had said hose! I left. Thankfully I asked for the Toyota hose back! Fast forward to last Saturday. We got to attach the hose... and the side that fits to the pump will not tighten down enough for the flared end to sit securely. It would have just leaked. Sadly, we discovered this too late to go to the hose place!

This morning, I throw another one of the pumps in the trunk with the Toyota hose and the hose they made. I go in there, explain the situation. The guy asks if it was okay if he chopped up the Toyota hose and used the fitting. I agreed. He asked if I wanted him to cut off the end on the hose they made, and put the new end on, losing a little bit of the hose length. Uncertain of the tolerances, I opted for a full new hose.

One hour and 61 dollars later, I had the new hose. He did bring the fitting out before construction and we made sure it was sealing on the pump. Huzzah!

So back at Mikes, we get everything setup, and before we put in fluid, Mike wanted to make sure the pump works. We jump it... it makes a single little stutter and stops. Mike taps it with a hammer, we try again. No joy. Tap, try, tap, try. We double check out wiring diagram.

I remind him I have the spare in the trunk from my trip to the hose place! We get that, move the connectors over... it hums to life! So a little swap-around later, another dry test, then careful filling and running of the pump. Mike then turned the steering input shaft this-way-and-that a little as the pump ran, just to work out some of the air. He was amazed at how quiet it was, but we could see the fluid circulating through. No leaks! And this is why I buy extras.

The pump looks like it might be rebuildable, and at the very least the 'control box' unscrews, so I have spare parts.

Alright, so onto other things!

One of the yet-uncoated parts is a new 'shroud' that Mike made for the 'frunk'. This will close a gap from the front sheet metal down to the new 'frunk floor'.

We also did some other test fitting with the powdercoated support frame of the new frunk, where the water tank for the intercooler would mount, battery track and the ECM bracket. The 'red dot' you see is to represent a hole that exists in the frunk floor (also still needs to be coated), the power steering resevoir will 'float' up in that hole. Some soft rubber liner will go around the sheet metal to protect things and seal it off from water splashing up through it.

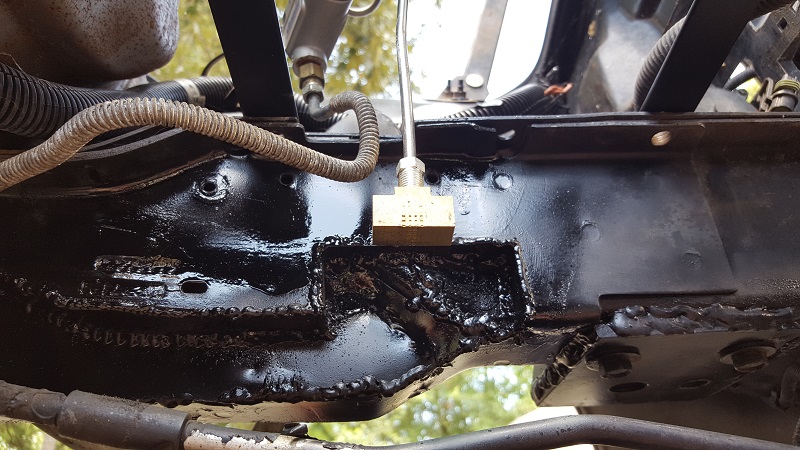

Lastly, a picture of some of the other mounts that Mike is test fiting for the cradle, and the bits he is starting to fabricate to box-off/close up the holes in the frame that were made when cuting out the OEM mounting points!

Lastly, he did also finish the welding for the Radiator brackets (the radiator was 'final fitted' last weekend). Sadly, this weekend I noticed one of the oxide coated bolts already somehow had some rust on it (I checked my picture from last week, no rust. This week, rust). So I'll have to buy some good quality stainless to go there I guess.

[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Trinten

|

AUG 07, 12:41 AM

|

|

Okay, so last update I talked about the steering setup, and took a pic of some of the custom-piece welding that Mike is doing to close up the frame where he cut off the old mounts. You'll see a lot of unfinished welds, or spot welds. Mike wanted to make sure the frame would be at least as strong as stock, if not stronger. So welding in metal and the positioning of the new mounts for for the upper control arms and the steering rack, plus the tightly fitted metal fill and frame-closing metal, it'll be pretty tough!

And here is a picture of the steering rack in a final test fit, making sure everything lined up where it was supposed to!

And also found the sunroof has another small leak, this one is from the seal just being too hard and shrinking some. I noticed a slight dampness in the car, and then noticed that pine needles had worked themselves under the glass. That's pretty impressive!

So when I replace the rails with the awesome stainless steel ones I have, I need to get another seal.

Last I noticed something similar in the door jam seal. It's dry cracking in places. So I want to replace those, too. Which I'm sure will help keep down wind noise and other potential leak points. You may recall that the speaker in the driver side b pillar was rusting, I wonder if the slow leak on the sunroof, and potentially the door, could be the cause.

Mike was working on the finish welding last Saturday, but weather kept him from finishing. If he didn't have the opportunity to do anything over the week, I suspect the first hour or two this Saturday will focus on that. Then we'll be bolting up the steering rack, and work on moving the car into the garage... to drop the cradle!

Once cradle is dropped, engine/trans off and split, the beefed up SBC will go on an engine stand, I'll clean it up, and it'll go on craigslist. Mike will start working on the new engine mounts for the LS4![This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Trinten

|

AUG 09, 04:33 PM

|

|

PROGRESS!

Okay, so all of the front-frame-related welding is done. Steering rack mounts are done, frame fill and caps are done, and steering column tunnel is done! Mike finished all of it up yesterday.

After the etching primer and epoxy paint dried, we moved the steering rack under the car again and bolted it up.

We then had an adventure with putting the new upper ball joints into the knuckles. The design of the corvette knuckle made Mike get out ALL the ball joint tools and then some. Once he pressed them out, we then scratched our heads while we hunted for the replacements. I looked in the Fieros, we both looked on the shelves and around the garage, and he looked inside his house were my awesome interior is being stored. No luck!

Mike swears he saw them recently, because he remembered how odd it was to find balljoints before realizing they were for my car. I'm of course looking for either a RockAuto box or a Moog box(es). After ~30 minutes of hunting, came my 'Eff-it' moment, and asked Mike to call the local shops to see if anyone had any. The answer was sadly predictable "we can have them for you tomorrow..."

So we had started to resign that I would need to double check to make sure I did get them, and Mike would look while he cleaned up the garage. As we started to put some things away, Mike moved a piece of cardboard that was by my brake calipers... and there they were! Serendipity!

So he pressed in the new ball joints, and we went about getting the suspension mounted.

Quick funny story. This was late in the day, so we'd been out working on things since about 10am, and this was about 4:30. We didn't stop for our usual lunch break, since we both late late breakfasts. I do not do well in heat. So I feel drained. Mentally and physically. Plus, my hearing is not the best. I go to put the tie rod end in... it won't fit.

"Mike. I think we did something wrong. Do we have these on the wrong sides? Upside down?"

"No, that's not possible."

"My tie rod is not going in, the wrong side is tappered."

There's a pause.

"The tie rod end will turn. It's upside down."

So I sigh, because it was obvious and I didn't think about trying that, and say "I'm an idiot."

Mike "Did you just call me an idiot?" my hearing didn't process it right, because I'm split with focusing on getting this done, and I thought he asked if I called myself an idiot... so what do I say? "Yes."

Now he sounds offended (rightfully so thanks to our Fawlty Towers situation) "I'm an idiot. Really?"

"Wait, what? No. I'm the idiot because I didn't think of that. I wasn't call you an idiot."

Moral of the story... if I'm going to admonish myself, do it silently! lol

Anyhow. Brakes are back on there!

In that picture you can see the plate that the upper control arms bolt to. It is not welded on yet. Mike wants to wait for us to get the alignment as close to done/neutral as possible first, and do so by scooting that plate around as needed. Once that's dialed in, he'll weld it in place.

Once that was done, we bolted the wheels on and lowered the front to the ground.

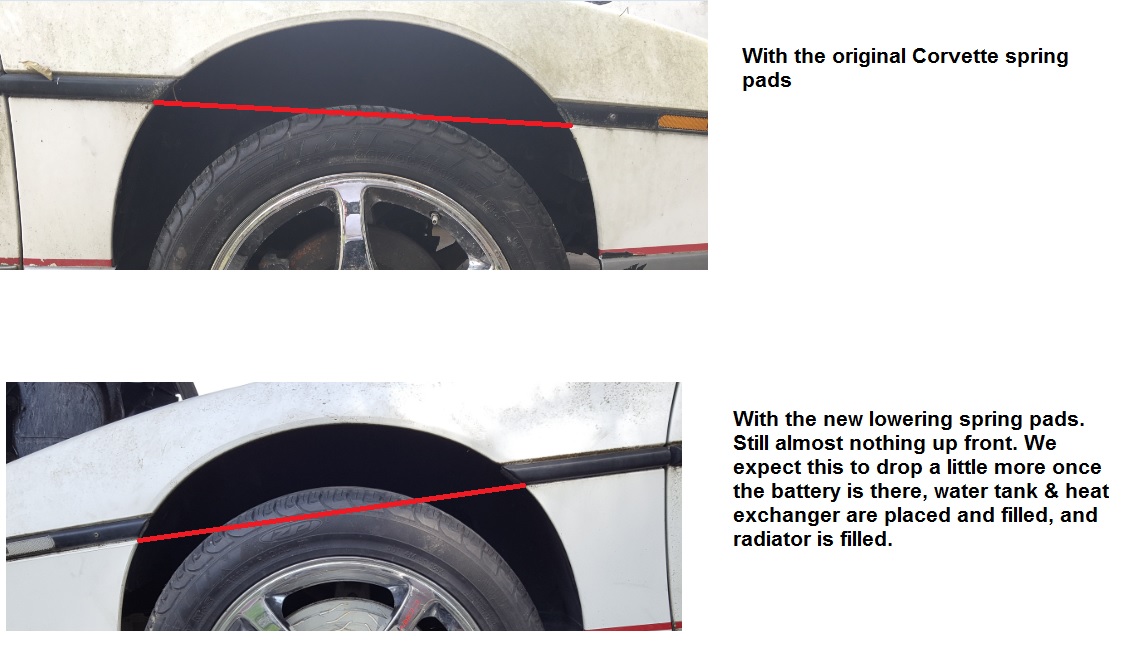

The top picture is back when Mike had mocked things up, and the mounting plates were just tacked into place. The front suspension still had all used stuff, including the stock adjustable spring pads. So I bought a new set of 'lowering' spring pads, which are advertised to bring the Corvette down about an inch. You can see the difference that's there already.

Once everything is loaded and filled up, we figure it'll sit a little lower. It'll likely still have a crazy wheel gap at the top, but since I'll be getting some custom body work done, I don't really mind that for now.

Lastly, here's a shot from the back line!

Hopefully next weekend we will have the car rolled into the garage, so the rear cradle can come out, and start working on getting the LS4 mounted!

[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

Trinten

|

AUG 16, 11:02 PM

|

|

Despite the weather, amazing progress was made this past week. Mike took a few days off during the wheel to clean up his garage and then work on the rear suspension. When I showed up on Saturday, I saw the rear wheels were bolted on, and it appeared the car was sitting on it's own for the first time since the project started. No jackstands!

I was a little dumbstruck. I could see it, but I was having a tough time processing it. It sunk in when Mike gave the car a little push and it rolled. It was a really awesome moment for me. We decided to give the car a much needed bath, so that was done. Then Mike had me start taking apart the rear suspension on the passenger side, so he could start doing some final welding, we could mount the brake calipers, and I could replace the rear hubs.

Onto the pictures!

Check out that pretty weld. When he's got the space to move, Mike welds like a machine! As we progress in the back, more and more will get it's finish welds, starting with the suspension mounting points. You can see more of it a little further down.

Check that out! Yes, huge wheel gap, we know. This is what the custome flared fender wheels are going to help fix.

A shot focusing a little more on the rear tire, since we have some good ones of the front tires already in past posts.

In that first "flank shot" the front wheel is straight(er). In the subsequent pictures, it had turned a little as we were moving the car around. In the last shot there, you can see just how much further that rear tire sticks out. The Z06 (I think) has the same offset, or is super close, so it'll stick out ~1" more in the front and back. To hammer the point home...

This is why I need to get some custom fender flares. With the few inches the wheels stick out up front, and the bigger jump in the back, my car will have an 'hourglass' similar to some Porsches. You can also see a little more of the welding/mounting coming together for the lower control arms.

Plenty of tire grip!

Mike was also happy with how well the rear brake lines fell into place. The Fiero stainless lines have the same style banjo fitting that GM used on a bunch of stuff (including Vettes) for ages, so, at least in the back, it just had to create some new tabs as he finalizes the hose routing, and I don't have to buy new stainless steel brake lines! And I have a coil of stainless steel brake "hard line" still, so if we need to remake anything, we can.

The rain did cause a small delay, but nothing to drastic. I'm trying to convince Chug to come out next Saturday to help Mike with pulling the cradle/engine, and getting the SBC/4T80E off, while I do tool fetching.

When the SBC is free, I'll be posting up the "package deal" in the mall, though I suspect many do not want that much power or might not be able to afford it, regardless how close to 'turnkey' it'd be, so I'll be listing the engine separately on Craigslist, too.

Only regret (hindsight is 20/20, right?), before we decided on the LS4, we had to trim the starter pad to get the transmission to mate up to it. No issues for any Fiero folks that want to run the F23 that'll come with it, but might be a dealbreaker for anyone looking to put the engine into something more traditional.[This message has been edited by Trinten (edited 06-04-2024).]

|

|

|

|