|

| JohnWPB 1986 GT Fastback worklog (Page 5/71) |

|

yardee

|

MAR 16, 03:38 PM

|

|

|

|

JohnWPB

|

APR 17, 01:25 AM

|

|

Ok, not much of an update, other than what is to be done, not what has been done

Well, after working on this custom center console, I got to thinking, the dash is still going to look very stock in comparison. DIY_Stu was telling me about Archie moving to a new shop, and he was unloading some stuff, including a fiberglass dash cover. So I had a look, and ordered one.

It is a slide over cover, that covers the instrument cluster "pod", and has a nice spot to install a full size glove box. It was manufactured to just slide over the existing dash. I am going to remove the upholstery from my stock dash (It's pretty cracked anyways, so no loss there) and permanently affix this cover to the stock dash, making a drop in replacement dash. With some cutting and fabricating, I intend to mount some nice 6" round speakers where the 4 x 6 ones were. I also am going to change the knee knockers....errr.... A/C vents to round ones, and relocate them a bit.

I figure if I am covering the original instrument cluster, and doing some fabrication, I may as well swap out the instrument cluster entirely  So I started looking around, and I just purchased a digital dash from mattwa out of a Cavalier Z-24. It is a pretty easy swap, as it uses all the same sensors as the Fiero, and is a wire-to-wire swap for the most part. So I started looking around, and I just purchased a digital dash from mattwa out of a Cavalier Z-24. It is a pretty easy swap, as it uses all the same sensors as the Fiero, and is a wire-to-wire swap for the most part.

My plan is to remove the bezels and such from the digital dash, and put a smoked Plexiglas cover over the whole thing. I will have some additional "Dummy lights" along the top of the dash showing when the CarPC has power, when cruise control is on ect ect. I also have a back up sensor system that I will put behind the glass as well. It shows the distance to objects behind the car when backing up.

This is the dash cover from Archie:

From the top:

Front of the dash:

This is a quick PhotoShop job, on how I am planning to install the cluster in it:

I am also putting a blue gel (The plastic sheets they put on stage lights to change colors of lighting colors on a stage) over the gauges, to make the dash more blue instead of the existing teal.

I still have a lot of fabrication work to do, but It is all starting to come together as to how it will all be done now.[This message has been edited by JohnWPB (edited 04-17-2011).]

|

|

|

JohnWPB

|

MAY 02, 09:24 PM

|

|

|

|

JohnWPB

|

AUG 06, 11:17 PM

|

|

LONG time no update! Time to fix that....

It is has been HOT here, as well as most everywhere else this summer really..... I do not have the luxury of an air-conditioned garage, so I am waiting till the weather cools down a bit to get back into the Fiero for the most part.

In the mean time, I just got back from Frazee, attending the 2nd Annual Tyler Shipman Memorial Car Show. DIYStu brought up, and hand delivered a set of Timo's buckets to me. It is the last piece of the puzzle, as far as the headlights are concerned. I purchased a set of Gen2 headlight motors, complete Gen2 wiring harness, the headlights, plugs, painted up the motors and mounting ect ect... Now that I have the buckets, I should be able to put it all together.

I sanded down the bare metal buckets with some really coarse sand paper, to scratch them up a bit. I then cleaned them real good with some TSP to remove any oil ans such. I then hit them with self etching primer yesterday. This morning, I painted the first coat of black on them, and this evening the second coat. I will let them cure a couple of days, and then wet sand them down, and hit them with one more coat, before topping it off with a generous coat of clear.

Here are the buckets with the 2nd coat of paint: (Fairly smooth for not sanding the paint at all yet)

The lights and hardware all ready to install when I finish up painting the buckets:

|

|

|

ThatFieroKid

|

AUG 07, 12:49 AM

|

|

|

This is a wonderful build thread! Subscribed.

|

|

|

JohnWPB

|

AUG 07, 02:25 AM

|

|

Well not much of a build thread so far, more of a "getting everything ready for the build thread". Now that I have all the parts, and direction where I am wanting to go, I hope to start seeing some visible progress soon!

|

|

|

JohnWPB

|

AUG 23, 04:05 PM

|

|

[2 weeks ago]

Above, I detailed how I painted the headlight buckets..... big mistake

After they dried for a few days, in a hot shed I took a buffer wheel, on a medium speed, with car polish to give them a nice glassy shine. I had barely started when EVERY layer, the primer, paint and clear started to peel off like the surface had been sprayed with Pam cooking spray before I painted them!

I can see now way, that they I could possibly have painted them any better, or with better prep. So, lesson learned, I will never try to paint stainless steel again in the future. At least when it has been galvanize coated. They are now at the Tolliver Powder Coating here in West Palm Beach, and should be ready for pick-up in a couple of days. I gave them instructions on masking off the area where the headlight bolt holes are counter sunk for clearance.

[ 1 week ago ]

I got the headlight buckets back, paid for the work, and went to the car and unwrapped them. The first thing I noticed is the fact they did not mask off the counter sunk mounting holes! I told them they forgot, and he says he does not remember any mention of masking anything off, and he had to go check with someone on how to handle it. As he left, I noticed my work order behind the counter from a few minutes ago when I paid for them. I reached over and grabbed it  Right there on the work order was a nice hand drawn sketch, and arrows pointing to the 8 holes to mask off. When he returned he started to say something about they were not responsible, when I handed him the work order. He changed what he was saying really fast haha! He said they would have to sandblast them, and re-do them. Right there on the work order was a nice hand drawn sketch, and arrows pointing to the 8 holes to mask off. When he returned he started to say something about they were not responsible, when I handed him the work order. He changed what he was saying really fast haha! He said they would have to sandblast them, and re-do them.

I called a few days later and they said they would be ready on Friday afternoon. I stopped by Friday just before closing, and they were sitting right where I left them in the "received parts bin". I was not happy to say the least, he said that someone changed the schedule, and they would be painted next week sometime now. I let him know how unhappy I was, as it was going on 2 weeks now!

[ Today ]

I got a call at 8am saying that they were done. I went on lunch and picked them up. As I unwrapped them, I think the first words to him were "are you serious?!?!" I wanted to throw them against the wall of something LOL! I was quite truthful, and told him that is the worst powder coating work I had ever seen.

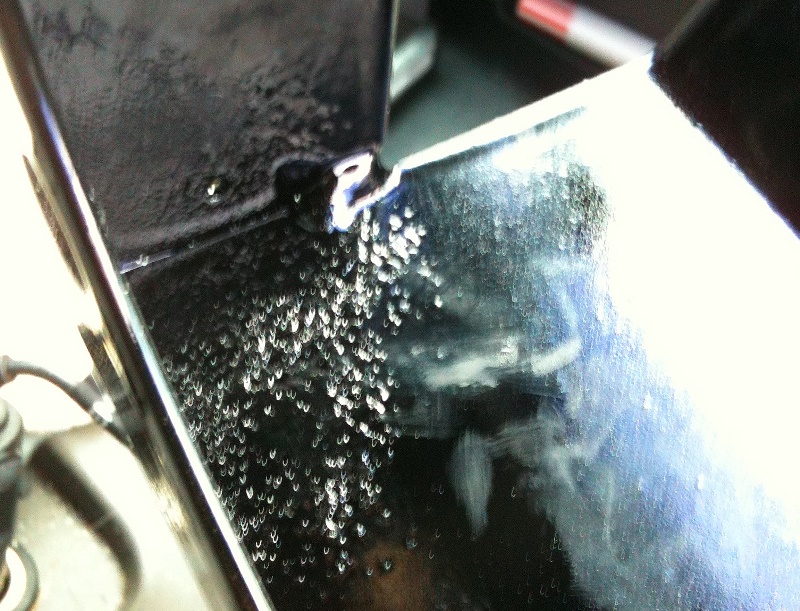

Here, you be the judge: (Forgive the crappy cell phone pictures)

Not pictured are 3 runs and drips on bucket#1, enough of a drip that it is almost a 1/2 long!

Inside of bucket #1

Outside of bucket #2

It is VERY hard to tell from the photo's above, but the buckets were glass smooth, Zink galvanized steel. From the pictures they look as if they were almost rust buckets when they started!

I talked to a manager, and he assured me that they would correct this, and would put a rush on it to have them done ASAP. As he was looking at the job they did, I had this feeling that when I left someone was gonna get really really chewed out. You could just see it in his eyes and expression while he was looking them over.

So, now I sit and wait, and wonder how they are gonna look this time.......[This message has been edited by JohnWPB (edited 09-07-2011).]

|

|

|

ThatFieroKid

|

AUG 23, 04:17 PM

|

|

|

Wow, what a fiasco with the powdercoat! I hope they'll do it right this time.

|

|

|

JimmyS

|

AUG 23, 05:38 PM

|

|

|

After all this trouble I hope they give you some sort of refund!

|

|

|

JohnWPB

|

SEP 07, 02:28 PM

|

|

Well I called them last Wednsday, and they said they could not mask off the counter sunk holes! Are you kidding! This is what your company does for a business LOL! They said they were going to sandblast them (3rd time now) and to come pick them up, and they would refund my money.

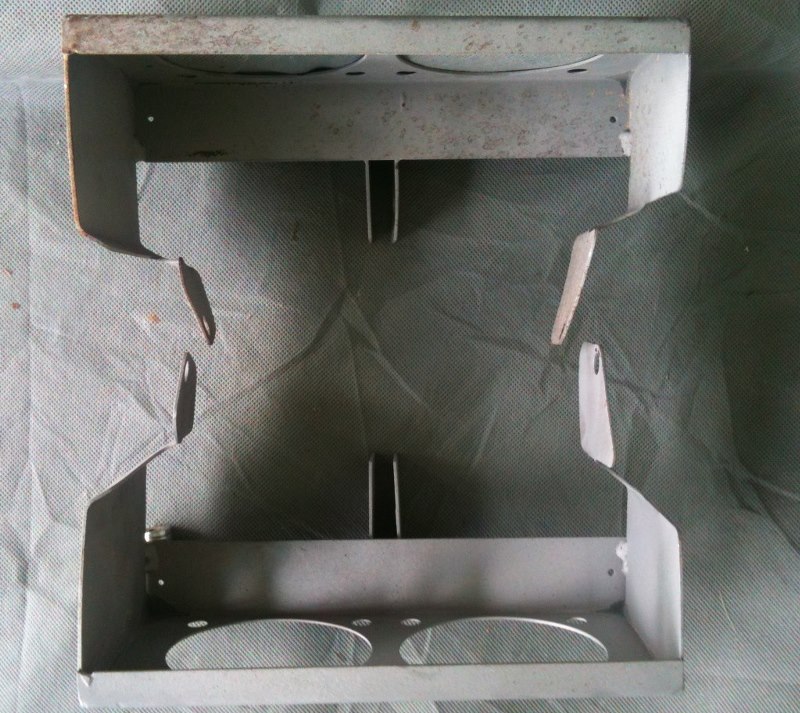

So, I just picked them up and I am LIVID! They blasted away all of the galvanized Zink coating! On top of that, I think they left them outside for a week, and now they are rusting! I called Fiero1Fan in Germany, and he said they absolutely will need re-galvanized. If any speck of rust is on them, and they are powder coated again, it will continue to rust underneath.

To top it off, like this isn't enough... they bent the H E Double L out of them! I am just fuming right now!!!! I called them back, and am trying to resolve this in some manner, and he asked me to send him photo's in email. So I just sent the pictures to the manager.

This photo shows how bent up they are now:

(Pictures will be posted shortly, PFF Image poster is acting up... AGAIN!)

( EDIT: I had to use Image Shack for now, as PFF Image Poster just refuses to work today )

This Photo shows how bent up they are now:

This photo shows just how nicely rusted they are:

A far cry from what they looked like well over a month ago when I dropped them off:

[This message has been edited by JohnWPB (edited 03-06-2014).]

|

|

|

|