|

| LS4 / F40 swap - fieroguru (Page 5/216) |

|

fieroguru

|

DEC 19, 07:33 PM

|

|

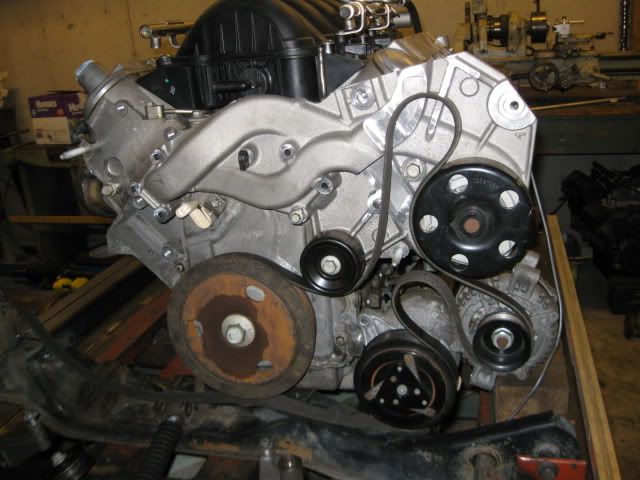

Mocked up the LS4 compressor and Fiero alternator and made a template for the bracket. It is made of several pieces of 16ga sheet metal. The sheet metal is quick to shear and shape and allows me to fit the contours of the accessories one section at a time. Then tack weld them together as you build the final bracket shape. Once the template is done, then tape can be used to smooth out some of the sections as well.

I wasn't completely satisfied with this bracket... concerned with the amount of material (or lack there of) between the AC compressor / engine and between the alternator / water pump. For grins I mocked it up with the 88 4cyl a/c compressor:

If I use the 88 4 cyl AC compressor, the bolt boss right next to the alternator would need to be cut off... The other downside of the fiero AC compressor is the smaller pulley. It was designed for an engine with a much smaller crank pulley (about 6") and the LS4's crank pulley is HUGE. Using the fiero AC compressor would speed it up considerably vs. the LS4 compressor... Going to spend a few more days doing some more checking other alternator alternatives (like the one from my 97 truck).

Spent the rest of the day gathering some weight measurements to keep track of the +/- of the various component weights. Ideally, I would like to end up with a lighter combination than the stock LS4 setup and a relatively light overall drive train. Here is a rough run down so far..

code:

Engine Components Stock LS4 LS2/LS7 Fiero/Custom

Alternator: 12.5 -- 11.0

A/C compressor: 14.5 -- 13.0

F/R exhaust manifolds (no crossover): 31.0 25.0 --

MAF, TB, Fuel Rail and Coil Brackets: 7.0 7.5 --

P/S pump & Reservoir: 7.5 -- --

Alternator/AC Bracket: 4.0 -- ?? 7.0 estimate

Totals: 76.5 32.5 31 (62.5 combined)

.

.

Transmission Components: Stock LS4 LS2/LS7 Fiero/Custom

Flex Plate/Flywheel: 4.0 -- 14.0

Starter Bracket: -- -- 0.5

Transmission 214 -- 124

Clutch/Pressure plate: -- -- ?? 15lbs estimate

Totals: 218 -- 153.5 (153.5 combined)

There are still alot of things left unaccounted for like the material removed from the valve covers and water pump, axle differences, stock vs. my custom mounts... largely because I either didn't weigh the stock parts before modifying them or I never had them to start with (like axles/mounts).

When I pull the 2.8/Getrag from the Formula, I plan to take the whole drivetrain as it is dropped from the fiero into work to wieght it on one of our pallet scales. This will include the cradle, engine/tranny/mounts/brackets/accessories, harness, ecm, axles, suspension/brakes and exhaust. Then I plan to do the same to the LS4/F40 in the same configuration to see how much total weight I will add to the backend vs. stock. This will also account for the weight increase for the 12" brakes and possible weight reductions in coil overs.[This message has been edited by fieroguru (edited 12-19-2010).]

|

|

|

mwhite

|

DEC 20, 04:19 PM

|

|

Fieroguru,

You have a great build going there. And it is really timely, as I have an LS4 and F40 in my garage waiting to be installed. With your accessories setup, were you planning to put an idler pulley between the alternator, and the AC compressor, to get enough rap around the compressor pulley? Where in your belt system, were you going to put a tensioner, or was the alternator going to be pivot mounted.

Cheers,

Mike

|

|

|

fieroguru

|

DEC 20, 04:39 PM

|

|

| quote | Originally posted by mwhite:

Fieroguru,

You have a great build going there. And it is really timely, as I have an LS4 and F40 in my garage waiting to be installed. With your accessories setup, were you planning to put an idler pulley between the alternator, and the AC compressor, to get enough rap around the compressor pulley? Where in your belt system, were you going to put a tensioner, or was the alternator going to be pivot mounted.

Cheers,

Mike |

|

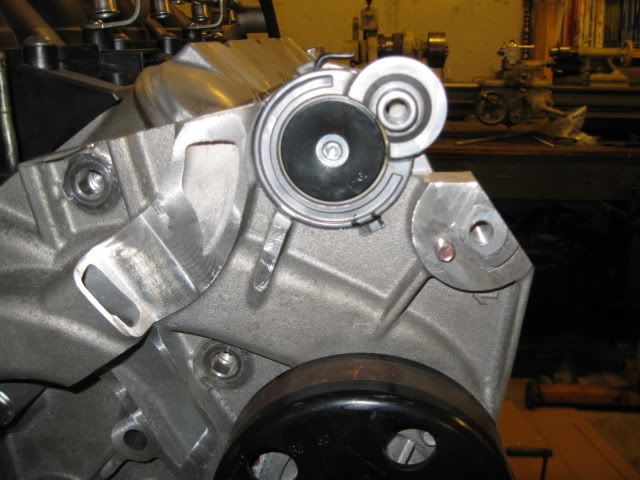

This picture shows the approximate locations for idlers (loops in the belt):

I am still researching tensioner options and will most likely put the tensioner up top over the water pump. I could cut the upper aluminum webbing and install this compact tensioner for $35.99 (part # 305232).

The alternator will be solid mounted, but if I wanted a manual belt adjustement, I would use the mercedes offset idlers (cam operated to tighten/loosen the belt).[This message has been edited by fieroguru (edited 12-20-2010).]

|

|

|

fieroguru

|

DEC 23, 03:39 PM

|

|

|

|

fieroguru

|

DEC 24, 04:26 PM

|

|

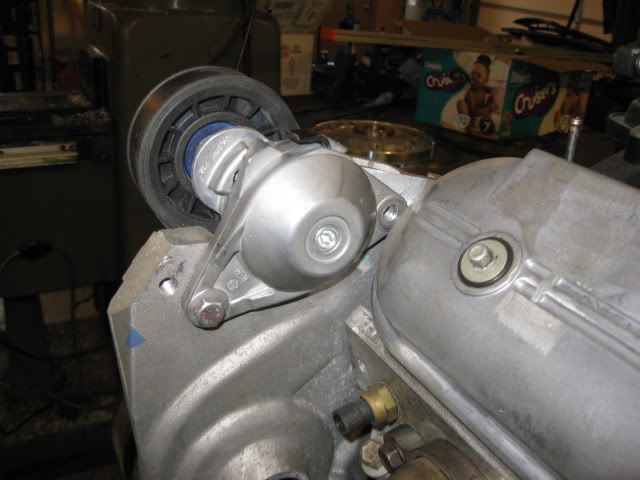

More LS4 water pump butchery today... but now I have a belt tensioner and upper idler pulley:

This location places the tensioner on the slack side of the belt and places both bolts in an area of the water pump casting that is quite thick. This will provides ample material for threads as well as milling about 1/8” off the back side to level out the area where the tensioner mounts (and give the front bolt clearance to the valve cover). I still need to make a spacer for the idler to position it in line with the balancer and might relocated the bottom idler by the balancer up about 1/2" to give more room between the two belts.

|

|

|

deezil

|

DEC 24, 04:50 PM

|

|

Sweet! Check your pm's

|

|

|

fieroguru

|

DEC 25, 03:43 PM

|

|

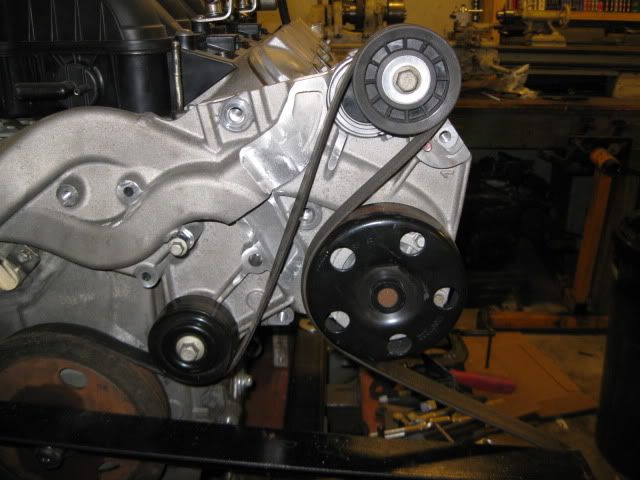

During "quiet time" I was able to fire up the mill and clearance the water pump housing for the tensioner:

There should be enough room for the stainless steel button head now.

The belts do not really get much closer as the tensioner moves:

I still need to do some more clearancing to the boss on the water pump so the tensioner has full range of motion. Right now it takes up about 1" of belt slack and I would like to to be closer to 2".

Maybe on Sunday I will switch the welder over to aluminum and do some welding on the water pump.

|

|

|

Seanpaul

|

DEC 29, 05:44 AM

|

|

| quote | Originally posted by fieroguru:

The LS4 bolts directly to the F40, no adapter plate needed. |

|

I'm paying close attention to this as i have an Ls1 and want to mate it with an F40.

Will the F40 bold up to the Ls1 or just the Ls7?

|

|

|

fieroguru

|

DEC 29, 06:35 AM

|

|

| quote | Originally posted by Seanpaul:

I'm paying close attention to this as i have an Ls1 and want to mate it with an F40.

Will the F40 bold up to the Ls1 or just the Ls7? |

|

The LS4 is the only LS based engine with the FWD Metric pattern and is the only LS based engine that will bolt directly to the typical fiero transmissions including the F40. The LS1, LS2, LS3, LS6, LS7 and LS9 will all require an adapter plate.

|

|

|

dobey

|

DEC 29, 10:12 AM

|

|

| quote | Originally posted by fieroguru:

The LS4 is the only LS based engine with the FWD Metric pattern and is the only LS based engine that will bolt directly to the typical fiero transmissions including the F40. The LS1, LS2, LS3, LS6, LS7 and LS9 will all require an adapter plate. |

|

Don't forget the LSX and LSA.

But to be more specific, the LS4 block is the only small block V8 from GM to ever be in a FWD vehicle, and the only one that will mount to the FWD Metric pattern directly. And it's not very likely that GM will produce a new small block V8 like that anytime soon. If you want a V8 that bolts straight up to the GM FWD Metric transaxles, your only choices are LS4 or Northstar. And both will require some small modifications to any manual trans.

Just thought I'd post in case anyone wanted to come ask about any other V8 possibilities for a direct bolt up.

|

|

|

|