|

| Ferrari 288GTO build (Page 43/64) |

|

dobie1

|

DEC 19, 10:27 PM

|

|

|

|

FRANKENSTEIN

|

JAN 20, 04:35 PM

|

|

|

Watching this work or art in progress

|

|

|

dobie1

|

JAN 29, 10:50 PM

|

|

Sorry everyone for the long delay on a update, I've been very busy over the last few weeks helping a couple buddies Don O. and another friend with their projects.

I was helping Don mold a Lambourgini Countach OEM interior for a future project for him, It all went very well molding the15 pieces.

Once it was finished I started up laying mat into my molds to build my body, the molds have fully cured and are ready....

I started on the front spoiler as it was already handy and a good starting point.

I used 4 layers of 1 1/2oz mat with a extra layer on the top and the ends for attachment points.

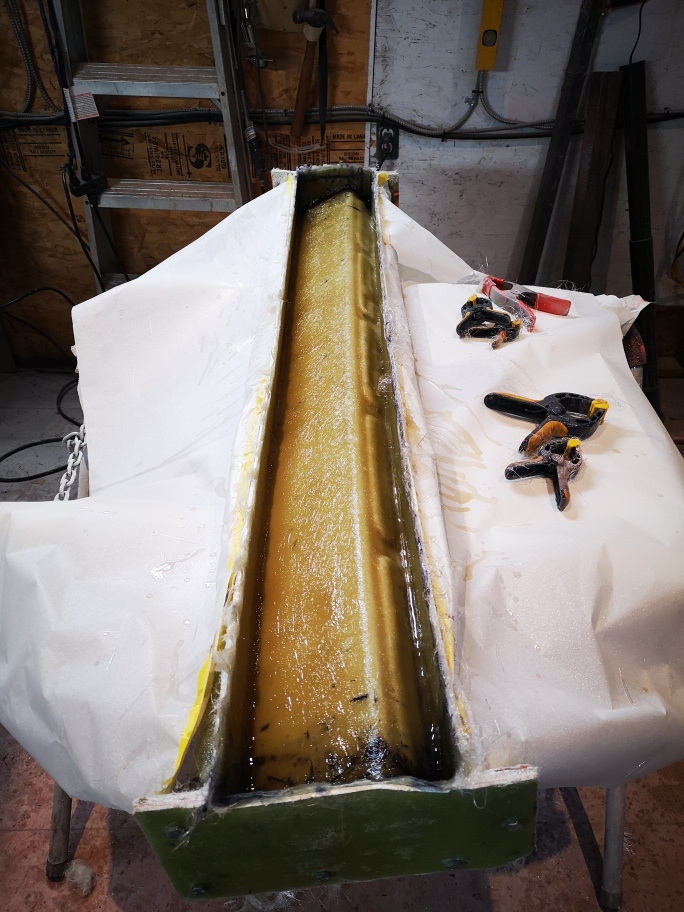

then I moved onto the first lower air duct ,it needs to be built in two pieces then i'll reattached the parts in the mold to ensure correct alignment crossing my fingers on this as I haven't done this before. I am fairly confident though in the concept ,we'll see.

Although the rear engine hood works and is functional it isn't correct looking ,and with the steel frame I feel is too heavy. So I've decided to design and build a new one that will use the frame of the hood itself as at the structure and the vents will attach to the side walls of the openings. just as the OEM car uses. There are compound curves in two directions front to back as well as left to right at the back by the spoiler. I've cut it all out but can't continue until I have the rear body out of the mold. ( coming soon)

this is the one I'm replacing

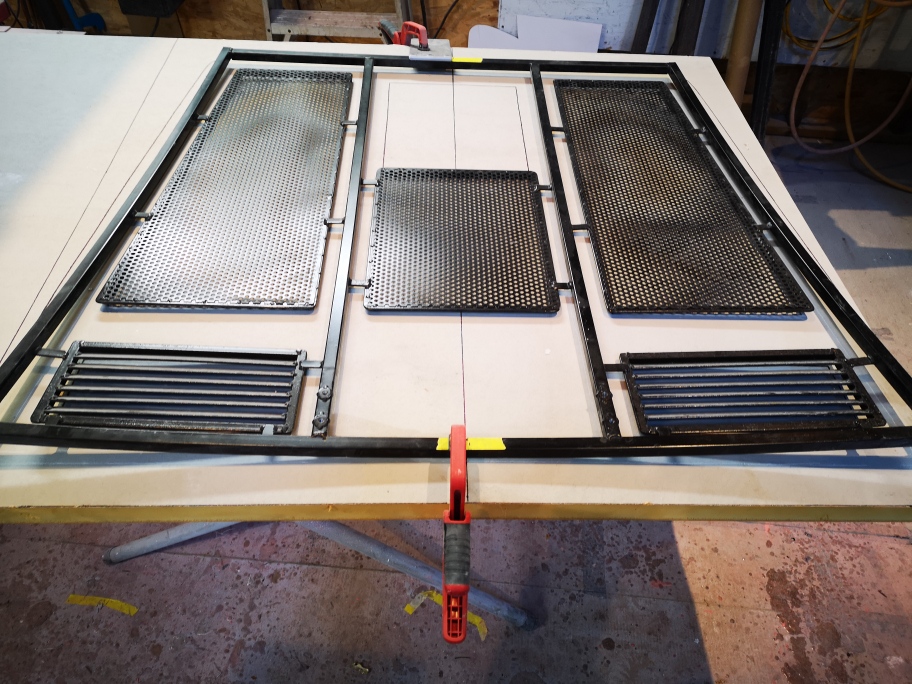

this is the steel frame removed

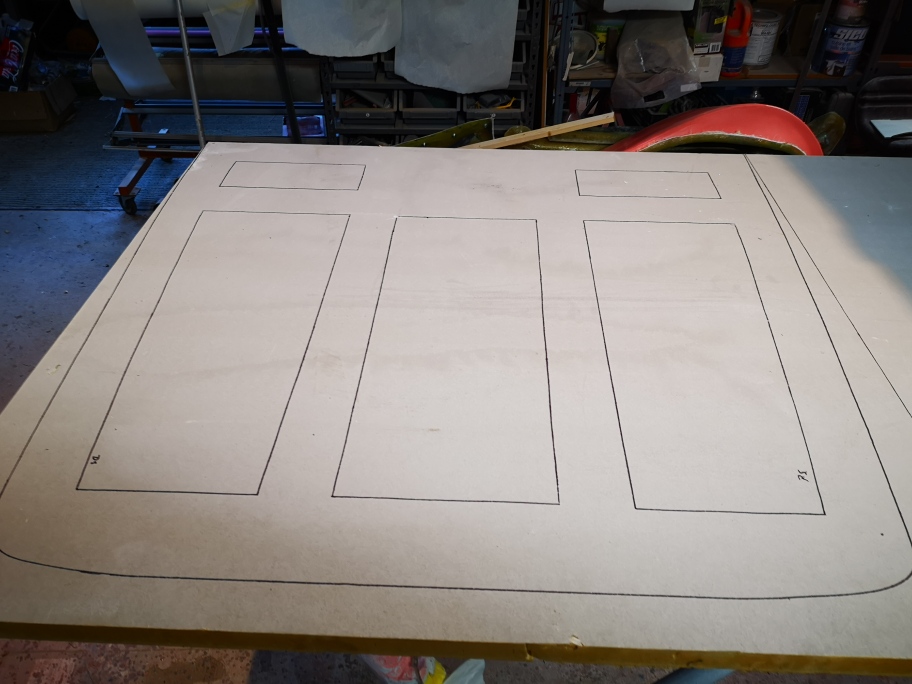

this is the cut out piece of 1 1/2" urethane foam ready to sand into shape, once that is completed I'll go through the process to make a top and bottom mold

I'll be back soon with more updates.

Stay safe

Wayne.

|

|

|

dobie1

|

JAN 31, 11:31 PM

|

|

|

|

Sage

|

FEB 01, 09:26 AM

|

|

Parts look GREAT!

I LOVE this stuff!

HAGO!

|

|

|

RCR

|

FEB 04, 09:19 PM

|

|

Bob

|

|

|

dobie1

|

FEB 04, 11:32 PM

|

|

|

|

dobie1

|

FEB 07, 10:50 PM

|

|

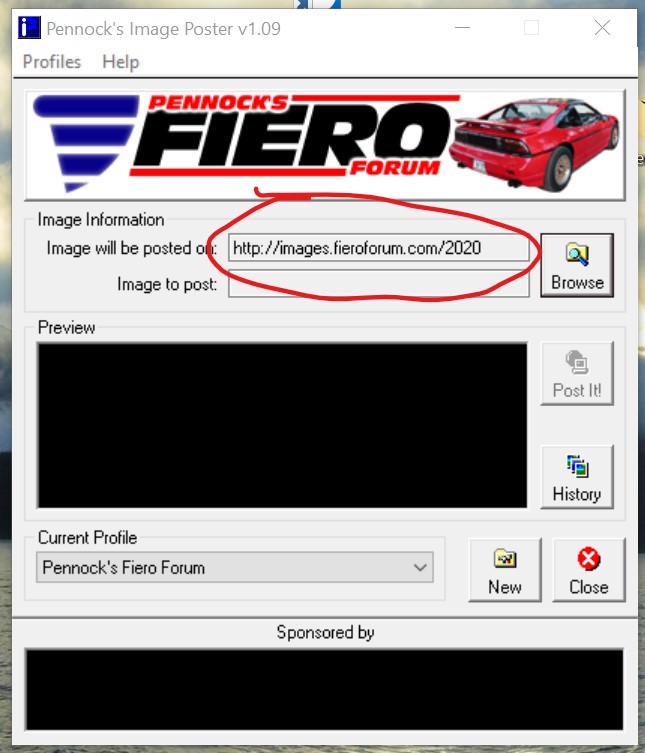

I'm hoping someone can help me , I've been using the Pennock's PIP to post pics but its not letting me , it's saying it can't find the server.

Am I doing something wrong, any help would be appreciated .

Regards

Wayne[This message has been edited by dobie1 (edited 02-08-2021).]

|

|

|

V8Steve

|

FEB 08, 07:13 AM

|

|

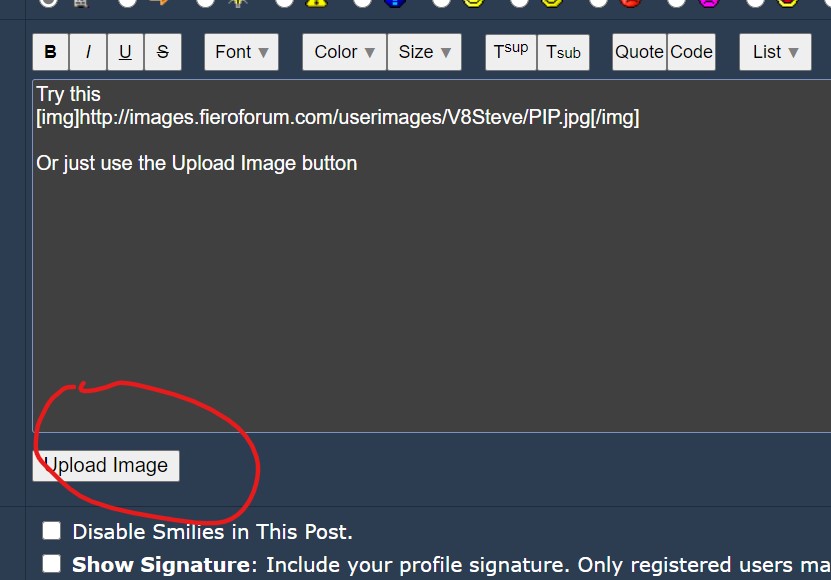

Try this

Or just use the Upload Image button

|

|

|

dobie1

|

FEB 09, 10:25 PM

|

|

|

|

|