|

| Ferrari 288GTO build (Page 37/64) |

|

dobie1

|

JUL 23, 12:23 AM

|

|

|

|

Sage

|

JUL 23, 10:40 AM

|

|

Vent looks perfect. Finding and fixing those "little" things, like variances in the lines of your bumper....THAT'S what will make your "replica" stand above the crowd.....NOT that the crowd is all that big that makes up the people that would even ATTEMPT a project like yours. You are killin' it!

Everything looks spectacular!

Keep the updates coming.

HAGO!

|

|

|

shemdogg

|

JUL 24, 11:46 PM

|

|

Yeah what he said. Wow thats looking great! Symmetry on these cars are tough. Mines definitely an "asymmetrico" lol

go go go!

shem

|

|

|

dobie1

|

JUL 29, 03:21 PM

|

|

Thanks for visiting and the positive comments Ted and Shem Always appreciate the comments.

I have company for a week right now so nothing Really happening in the build at the moment.

I’m panning on starting the Carbon Fiber Vacuum bag front hood build next week. Hope to have lots of pics And build details for everyone.

Stay safe

Wayne[This message has been edited by dobie1 (edited 07-29-2020).]

|

|

|

dobie1

|

AUG 05, 12:15 AM

|

|

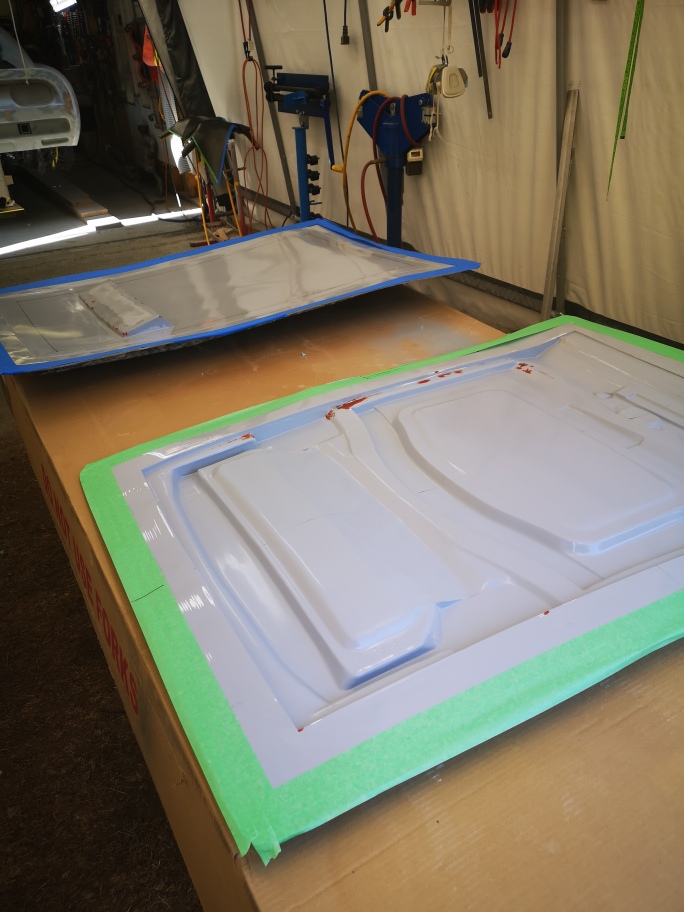

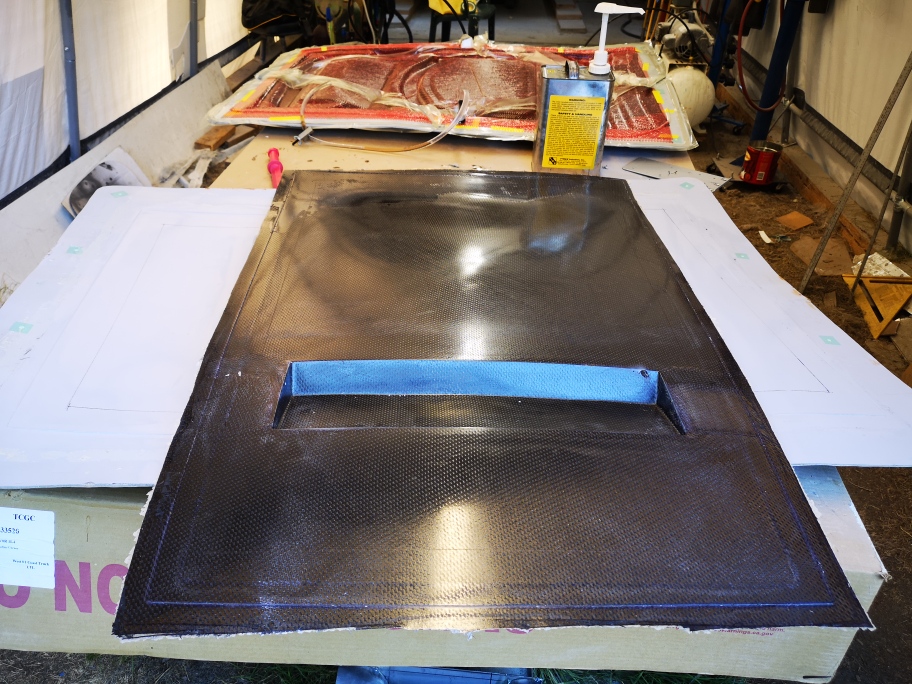

I worked on the hood mold getting it ready for doing a Carbon Fiber Layup. I lightly ground out a few minor flaws on the surface and spread some specially formulated repair putty into the areas. I sanded everything to 1500 grit finish then polished the entire surface. once that was finished I used a chemical mold sealer and then applied a chemical mold release.

The tape is applied to keep the perimeter free from free from mold release as the gum tape will not stick as well.

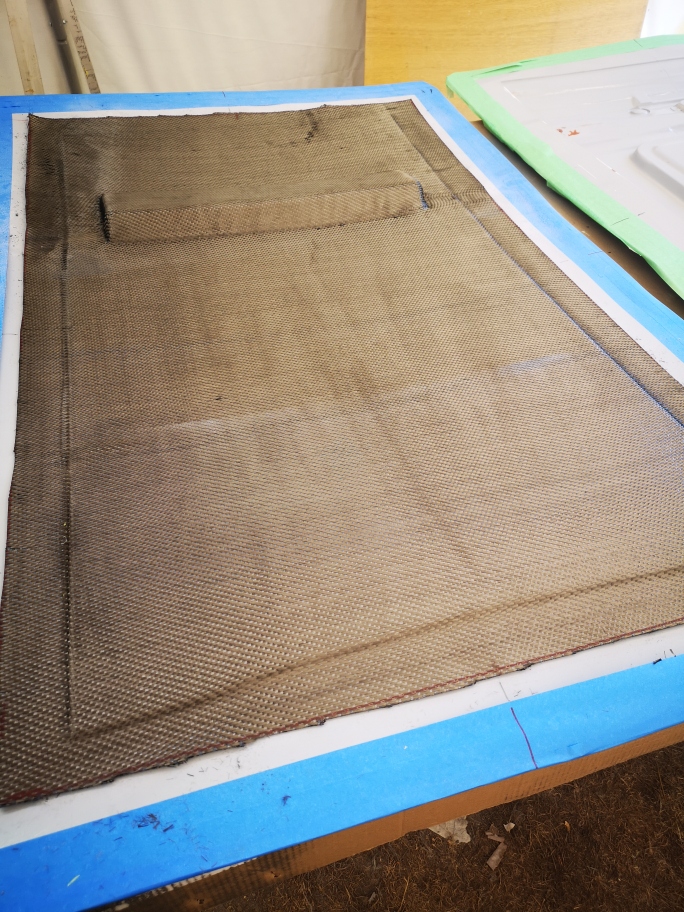

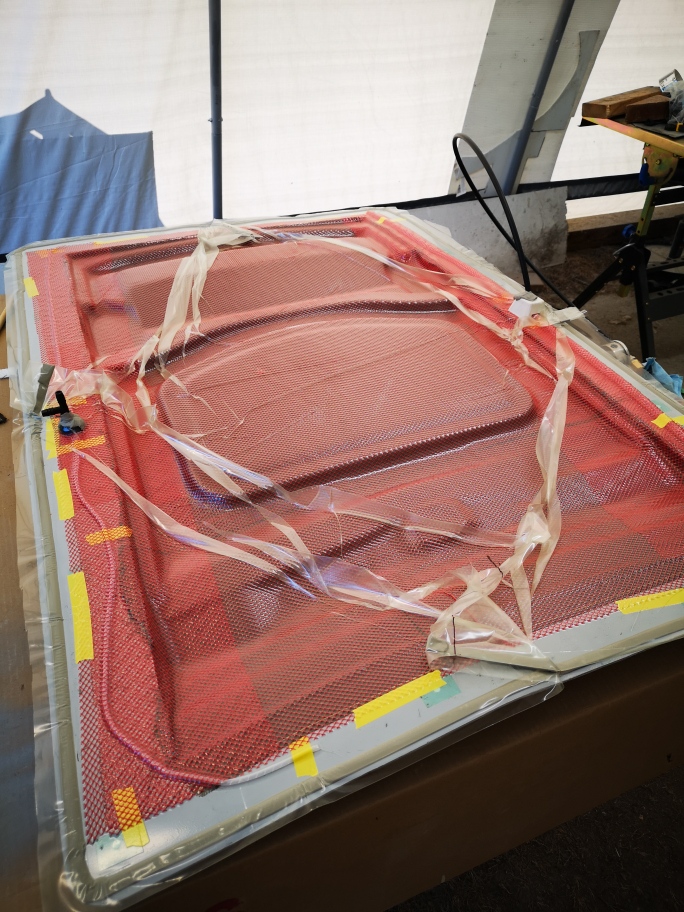

The layup is two layers of 6K 5S Carbon fibre then a layer of Lantor Soric SF ,this is a bulking material with great weight and strength it has channels over the enter surface to aid in resin flow. The sonic is 1" smaller than the width and length to allow it to be sealed in the part, then the last layer of carbon is applied.

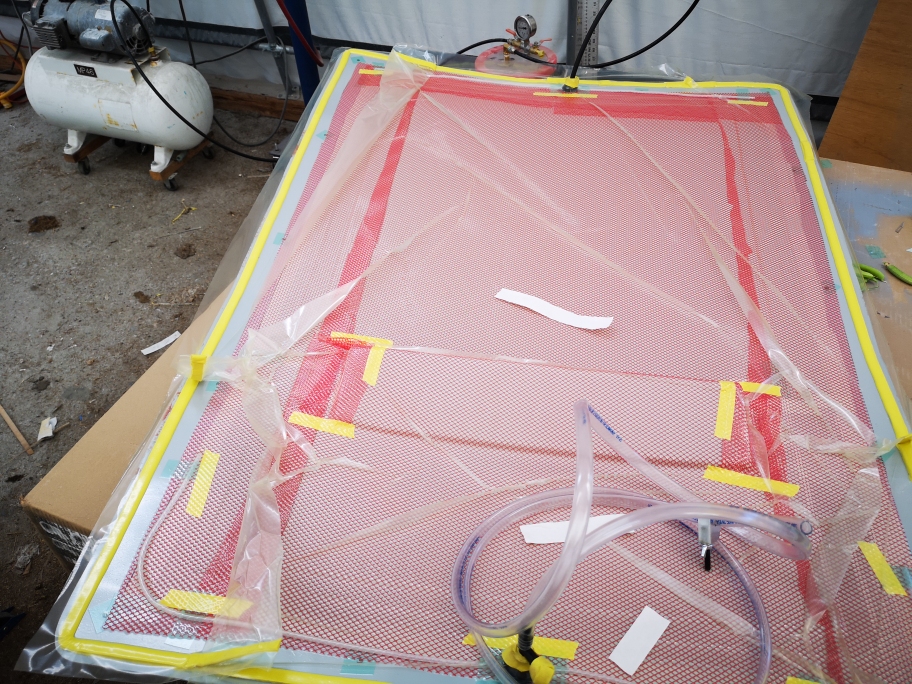

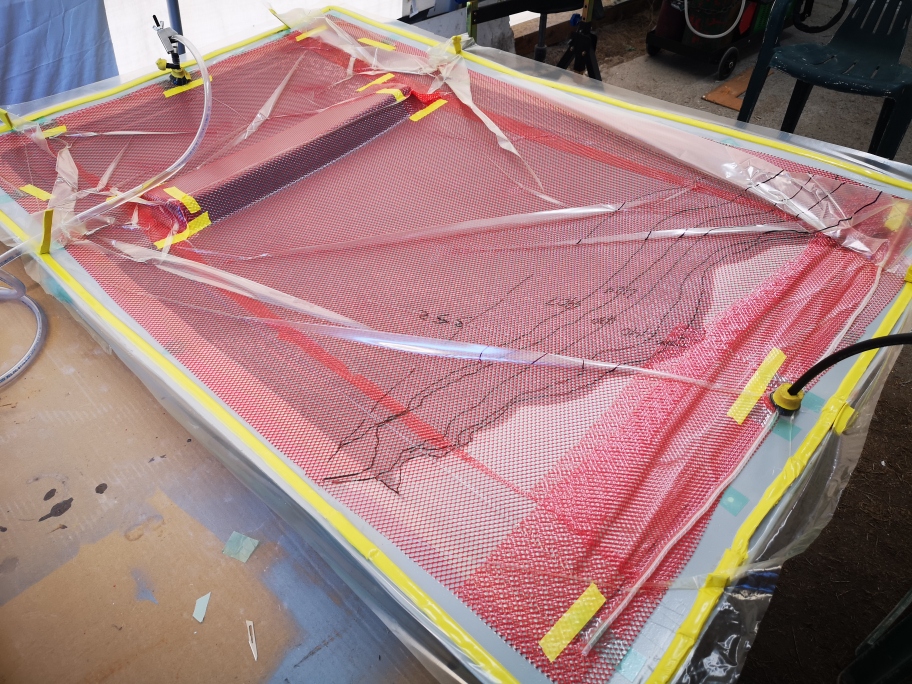

After everything was stacked up and the flow media (red layer) ,vacuum bag attached and the suction and supply lines were attached I tested for a 30" pull the supply line was released and flow starts from one end to the other.

I'll leave everything under suction for 24 hours then well see the first part from the molds. Ill layup the bottom part next then bond the two parts together

fingers crossed.!!!!

Stay safe everyone

Wayne

|

|

|

RCR

|

AUG 05, 08:21 PM

|

|

You've come a long way in your process since those beginning days, Wayne.

Everything looks fantastic.

Bob

|

|

|

dobie1

|

AUG 05, 11:27 PM

|

|

Thanks Bob

I keep evolving ,watching videos has helped in learning new techniques

I pulled the part from the top side of the hood mold , a couple small flaws but very happy over all. I'll trim it up to the outer lines and get it ready to bond to the bottom half.

I layed up the bottom half of the mold today a lot of work getting it into all the angles and ensuring no bridging ,cross my fingers.

thanks for stopping bye

stay safe

Wayne

|

|

|

dobie1

|

AUG 06, 09:48 PM

|

|

I pulled the second part from the lower mold today and trimmed it up, for the most part am very happy. I'll have to sand and prep a few areas , I also need to laminate some capture nuts on the inside for the hood hinges and lock /striker before bonding the two parts together.

just a side note the original hood that I molded weighed 59 lbs, the new one at this point is 10lbs !!!! the extra hardware and misc glues might add a couple pounds.

Stay safe

Wayne

|

|

|

PaulJK

|

AUG 06, 11:19 PM

|

|

| quote | Originally posted by dobie1:

just a side note the original hood that I molded weighed 59 lbs, the new one at this point is 10lbs !!!! the extra hardware and misc glues might add a couple pounds.

|

|

Wow. OUTSTANDING ! I have a dumb question - will the finished hood be red like the rest of the car or carbon fiber looking ?

|

|

|

Sage

|

AUG 07, 07:24 AM

|

|

Fabulous!

Wayne, you have surpassed everything I've seen up to now regarding DIY composite fabrication! OUTSTANDING job!

That hood looks great...and 10-12 pounds?????REMARKABLE!

The bagging is something I've always been "curious" about, and I've seen it done before, but not ever really tried it myself. Stellar work bud.

I still say, you're gonna be "swamped" with guys wanting to buy your kit. Your investment in making molds should pay off handsomely, provided you have time to fill all the orders!

Can hardly wait to see this masterpiece finished and fully assembled, in color. Will be awe-inspiring for sure.

Keep up the good job, and keep the updates coming!

HAGO!

|

|

|