|

| Trinten's SBC/F23 build - The work has begun! (Page 37/76) |

|

fieroguru

|

APR 13, 10:14 AM

|

|

|

|

joshua riedl

|

APR 13, 10:32 AM

|

|

|

What about drilling and tapping an aluminum rod and bolting it in centered in the upper intake?

|

|

|

Jefrysuko

|

APR 14, 11:46 AM

|

|

You're just hitting the resonate frequency of the top portion of the plenum at idle. Just do something to change it's mass and you'll move it to a different frequency which will excite at a different rpm.

Either duct tape Paul's hand to the plenum or find something else to stick on it like a large Fiero Emblem or something of the like. If Paul was more into marketing he'd already have "Fieroguru Performance L.L.C." lazer cut out of aluminum, polished and stuck to the intake by now!

|

|

|

Trinten

|

APR 14, 11:29 PM

|

|

| quote | Originally posted by Jefrysuko:

...

If Paul was more into marketing he'd already have "Fieroguru Performance L.L.C." lazer cut out of aluminum, polished and stuck to the intake by now! |

|

Going to see if FieroGuru will give me permission to do something like that and put it on my intake. This would be awesome, and give him much-deserved credit.

|

|

|

fieroguru

|

APR 20, 06:03 PM

|

|

Back from yet another business trip and back working on the car. Only thing good about traveling is spending the evenings thinking about Fiero stuff.

The drivetrain is back out for clutch issues.

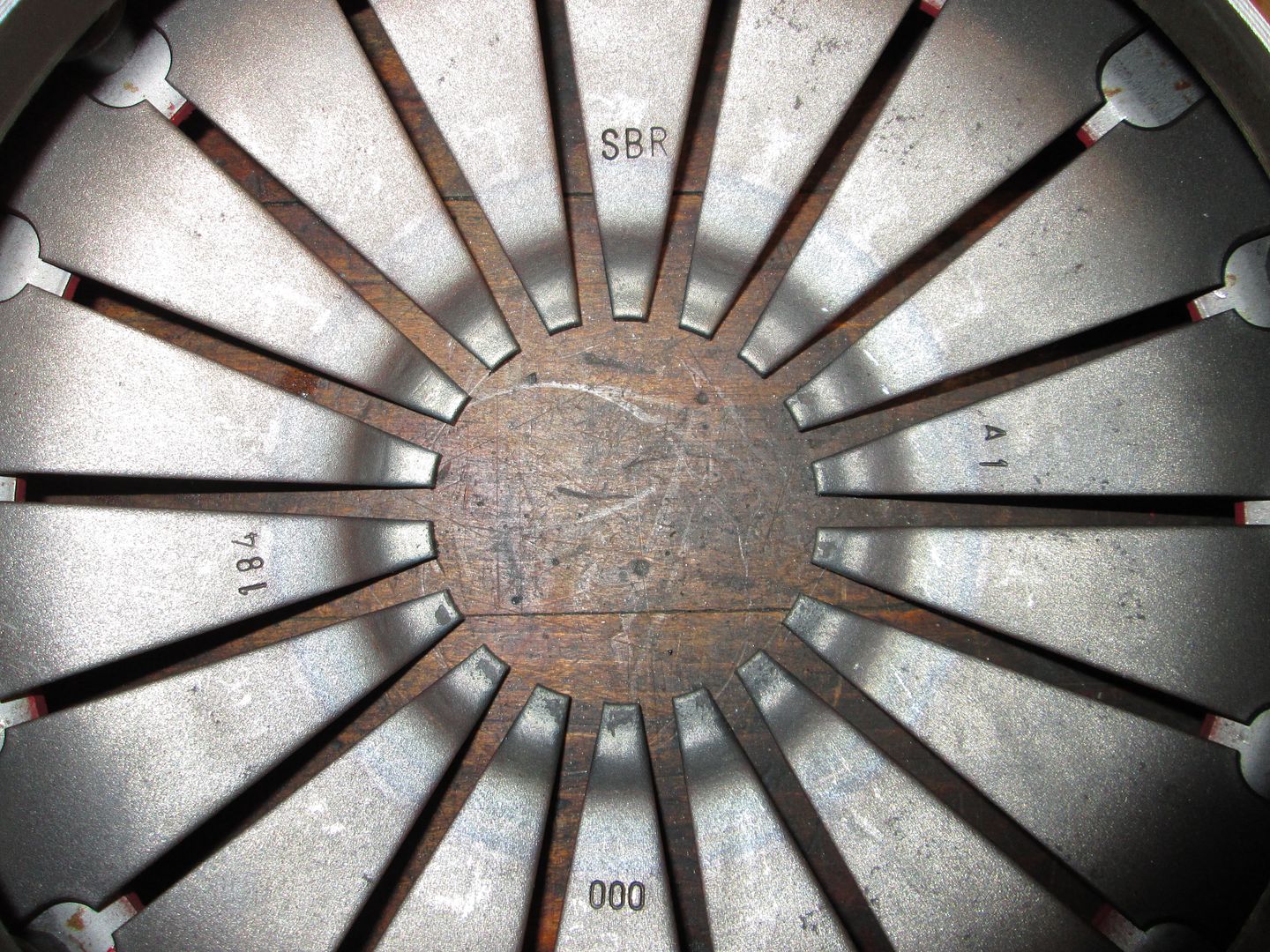

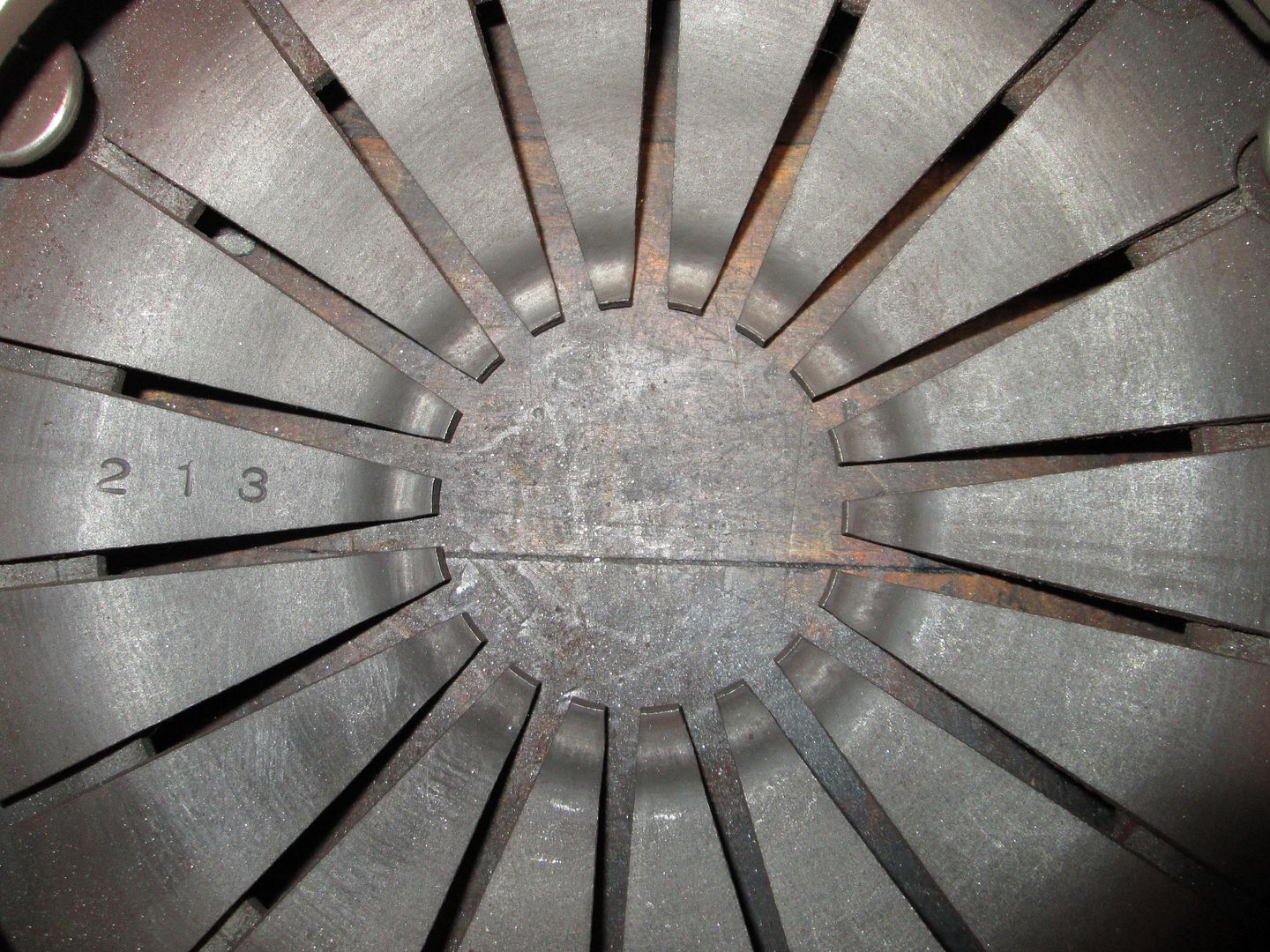

ClutchNet was supposed to ship the exact same clutch/pressure plate as the car had before, but after nearly 2 months of waiting for them, the pressure plate ended up being different. Shame on me for not taking the time to properly compare the two pressure plates. The old one was in the attic and when the new one was red and rivet style I assumed it was the same. They are different, have different clamp loads, and even place the pressure plate fingers in a different spot:

The other error on my part was I didn't bleed the HTOB prior to taking my range of motion measurements, so when the new pressure plate arrived and I checked its finger position, the range of motion looked right with slightly less room for wear vs. release. But it wasn't right and eventually over extended after about 40 miles and 8 hrs of running. FTE is the OEM supplier for the F23 HTOB and I scored a NOS unit on eBay. This one doesn't have any fluid and I will make sure my measurements are correct this time...

Having the engine out it gives me easy access to knock out a few other items.

The bad idler pulley was likely caused by pressing some 3/8" lock washers into the center of the bearing to help center it (the LS4 idler pulley is 12mm ID and I am using a 3/8" bolt for it - done this many times before). These were too much of a press fit and likely enlarged the inner race enough to cause an issue. So before I installed the new idler, I took a stack of 4 lock washers and tuned down the OD so they could easily slide into the new idler pulley. Here is a picture of the old one with the lock washers still pressed in place:

I found another source of light metal rattle (was thinking it was the A/C clutch). Instead it was the heat shield I had added between the alternator and the header primary to keep as much exhaust heat off the alternator as possible. There is about 1/4" between the two pieces and I bent the heat shield to be better centered between the two.

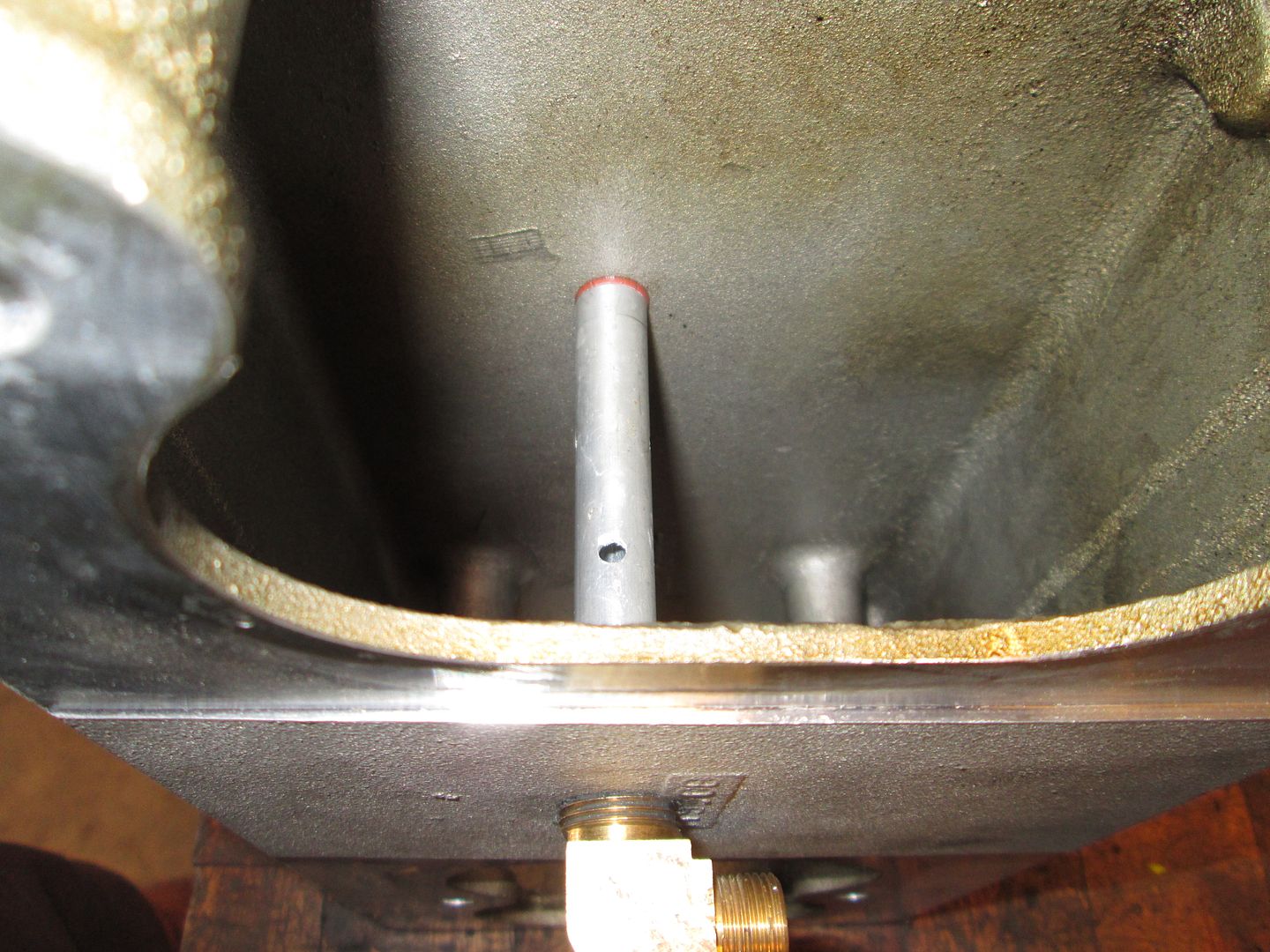

For the intake plenum vibration, I adapted Joshua's suggestion but kept it completely invisible. Once the plenum was off, I removed the brass PCV fitting from the bottom center and bored it to accept a 1/2" aluminum tube:

Pressed in an aluminum tube, drilled 4 air holes in it for the PCV, cut it to precise length and added a plastic cap to the top:

Threaded it back into place and this tube now pushes up the center of the plenum by .008" and should keep it from vibrating.

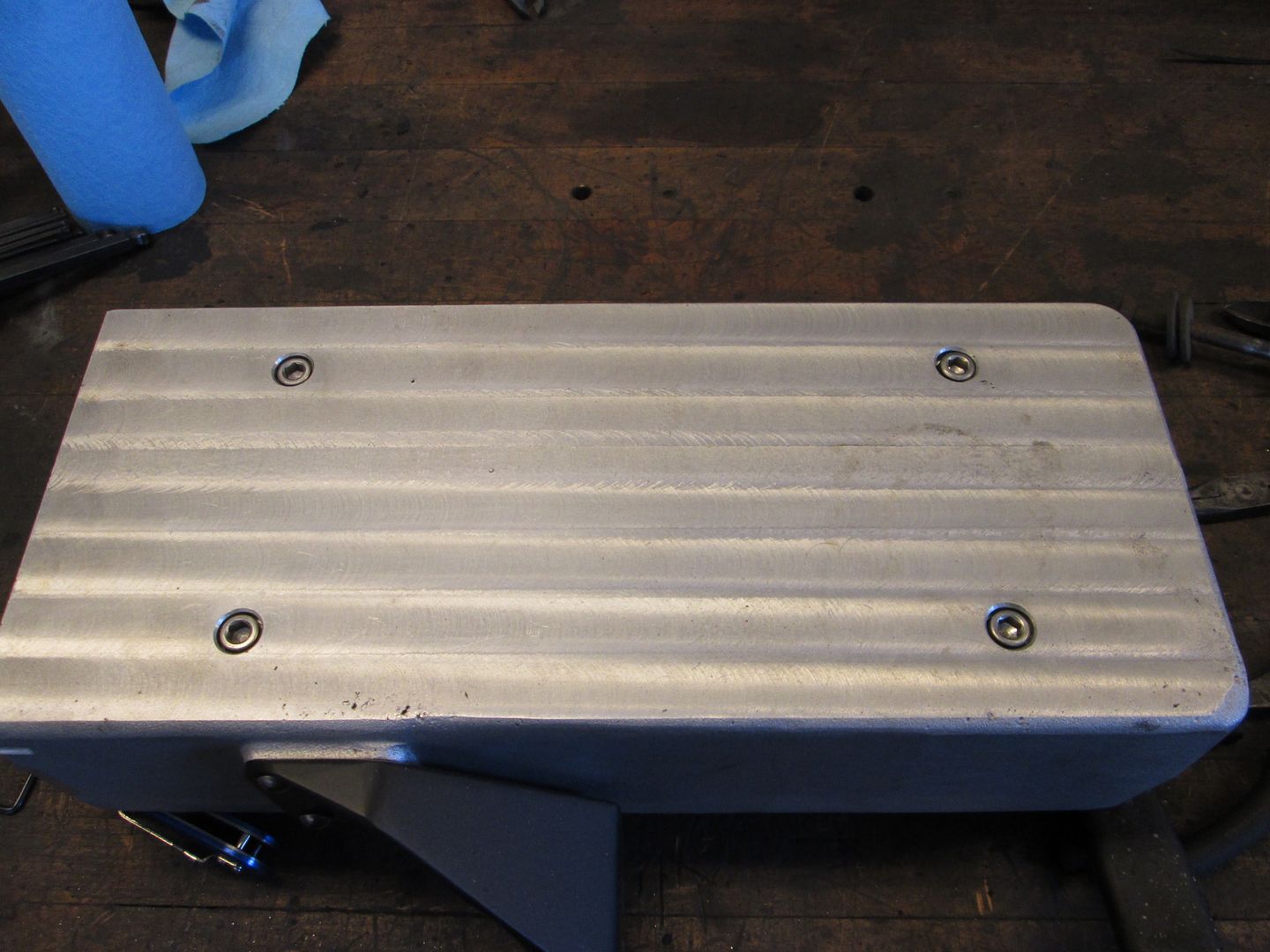

The other thing I fixed today was upper plenum bolts. The two on the PS had deeper holes in the plenum and were recessed about .14" further than the other side. So I turned up some spacers to fit under the bolt heads to take up the excess space:

If you look closely at the picture of the inside of the plenum, you will see some oil residue from the PCV system. I have ordered a catch can to install down by the transmission to keep as much oil as possible out of the intake.

While I have everything out, I will also mod the cradle slightly to improve room around the rear V-band. I have installed and removed it a couple of times in the car, but more room would make it much easier to do.[This message has been edited by fieroguru (edited 04-20-2014).]

|

|

|

KissMySSFiero

|

APR 28, 03:32 PM

|

|

anything new on this?

What gearing is on this F23? Is it the 3.94 FD?

|

|

|

fieroguru

|

APR 28, 05:59 PM

|

|

| quote | Originally posted by KissMySSFiero:

anything new on this?

What gearing is on this F23? Is it the 3.94 FD?

|

|

Waiting on ClutchNet to send a replacement pressure plate. They sent the wrong one (not high enough clamp load) the first time.

It has the 3.94 FD.

|

|

|

Trinten

|

APR 28, 10:23 PM

|

|

Yeah, Clutchnet said they would replace the pressure plate for free - didn't even need to send back the old one, however since that talk, it has been a communication blackout. I've called them every business day at an appropriate time and left messages to no avail.

At this point I'm going to file a BBB and then just get the SPEC that FieroGuru recommended to me. If Clutchnet does eventually send me the right pressure plate, then I'll have my backup handy.

Since they said not to bother to send back the wrong pressure plate (which is probably at, or only slightly above, stock -- Guru would need to chime in there), I guess I can put it up in the market here, but not sure how well it'd work with another clutch.

|

|

|

sleevePAPA

|

APR 28, 11:02 PM

|

|

|

|

Trinten

|

APR 28, 11:12 PM

|

|

Yeah, I really *really* liked my first clutch/pp from them. The salesperson I spoke to when I first did business with them was --- not great. I emailed them, and Oleg emailed me back within an hour apologizing and saying he'd make it right. I called back, he took my order, showed up promptly and was exactly what it should have been.

But this time... just not thrilled with the customer service. Such a shame, too. I thought they had a great product. Anyhow, I'm going to go with SPEC this time around and see how it holds up!

I'll be ordering the SC883F, clamping pressure is good for up to 515 pounds of torque, which will do great for the time being. I am going to call and see if I can get different clutch material than the organic, maybe they have an equivalent to the multi-puck ceramic setup I had, or a carbon/ceramic. People say they don't engage well, but (excluding first gear), I found engagement to be pretty smooth.

I'd go with kevlar, but I'm worried about this two-part scenario: I glaze it from stop-and-go, and when I try to 'burn the glaze off' with hard use, I overheat the thing and ruin it. lol That would be my luck.

|

|

|

|