|

| Ferrari 288GTO build (Page 35/64) |

|

RCR

|

JUN 02, 07:38 PM

|

|

Looks great, Wayne. I'm going to have to hit the lottery so I can spend more time on mine (can't wait for retirement  ). ).

Bob

|

|

|

dobie1

|

JUN 02, 11:28 PM

|

|

| quote | Originally posted by shemdogg:

Looking great as always! Got me tossing around making molds for mine, just dont know how to do it. Learning a lot watching you -good stuff!

shem |

|

Hea Shem ,glad your thinking about doing molds even if you don’t You can use molds for lots of parts and extras, I’m still learning .

Hi Bob

Retirement has it’s good and bad side to it lots of time to work on the project but the down side is a definite reduction in funds to work with.

I can’t believe how much resin these molds take , the 2oz mat is taking 40 oz of resin per layer 1 oz 32oz .

If I had known How much it takes I’d should have got a 45 gal drum ......

Wayne[This message has been edited by dobie1 (edited 06-02-2020).]

|

|

|

dobie1

|

JUN 04, 11:02 PM

|

|

|

|

dobie1

|

JUN 18, 11:40 PM

|

|

|

|

PaulJK

|

JUN 20, 06:13 AM

|

|

|

Beautiful job !!! Just a thought though ..... careful with the chin spoiler or the first speed bump it meets will take it off. Seen lots of cars going sideways into parking lots because of low chin spoilers ....

|

|

|

dobie1

|

JUN 20, 11:10 PM

|

|

Thanks Paul glad your enjoying the build ,I believe that I have 5"s of clearance but will not know for sure until I get it finished mounted wheels on and down on the ground .

Fingers are crossed!!!

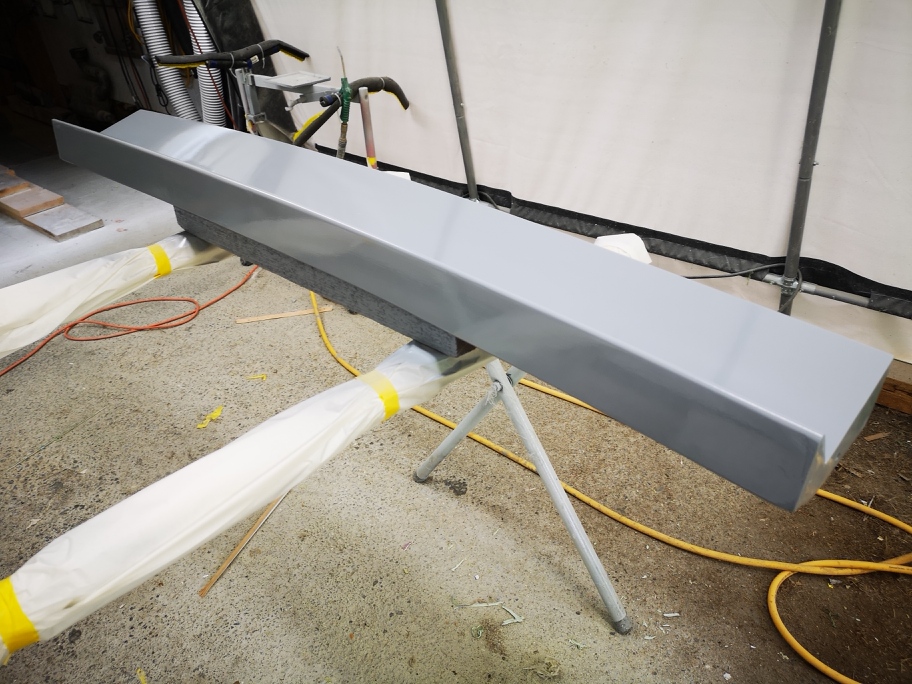

I was busy today finishing off the front spoiler ,I completed the filling and sanding to get the contours I wanted.

Then I sprayed it with Epoxy Primer came out great.

30 minutes later and heavy coat of Slick Sand

Tomorrow I'll block sand and hope to spray it with the white paint in a couple days. It's tough right now trying to find all the nuts bolts etc. that have now disappeared some where in the shop.

Dam!!

Stay safe everyone

Wayne

|

|

|

RCR

|

JUN 21, 04:29 PM

|

|

Gotta admit, Wayne. Starting to feel real lazy every time I check in. You're moving so well. Keep it up.

I'm going back in the garage to do some sanding, and filling, and sanding...

take care...

Bob

|

|

|

dobie1

|

JUN 22, 10:09 PM

|

|

|

|

dobie1

|

JUL 05, 12:16 AM

|

|

|

|

Sage

|

JUL 05, 09:29 AM

|

|

HAGO!

|

|

|

|