|

| Trinten's SBC/F23 build - The work has begun! (Page 32/76) |

|

nosrac

|

FEB 09, 09:51 PM

|

|

| quote | Originally posted by fieroguru:

Glad to see you think some of these mods are worth the effort! I think they really clean up the overall look of the engine bay.

Yes, I can supply the modified hinges with or without the reinforcing leg. I do have a few spare sets of hinges, so I just need to decide how much to charge for them and build the instruction sheet.

|

|

Put me down for a set.

|

|

|

Trinten

|

FEB 09, 10:04 PM

|

|

| quote | Originally posted by fieroguru:

Did the bolts holding the headers to the heads ever work loose. I am using the same ARP fasteners and don't want anything to work loose. The V-bands shouldn't work loose.

As for the ground clearance, only the pipe connecting the two headers is below the cradle. If it was in the center of the car, then there might be some concern about hitting it on a high crowned road. With it being as far to the side as it is, I doubt it will ever hit anything. My LS4 exhaust hangs down the same way. |

|

Nope! Those header bolts were awesome! Those things were always snug - the guy guaranteed they wouldn't work themselves loose or need to be retorqued, and he was right! Everything that came loose started at the collectors and further on back.

|

|

|

seajai

|

FEB 09, 10:32 PM

|

|

| quote | Originally posted by Trinten:

Nice! A big thanks to whoever gave you the heads up on those hinges in PM!

|

|

You're welcome

I like the stealthy look of the brace guru came up with. I had to brace mine with the engine in the car.

I think I may employ guru's design the next time the engine is out.[This message has been edited by seajai (edited 02-09-2014).]

|

|

|

Trinten

|

FEB 09, 10:49 PM

|

|

Thank you!

With the model/design/install of my strut, the decklid actually would not automatically rise on it's own, unfortunately. The strut was too horizontal. Sorta made the electric trunk popper useless. I was planning on boring out one of the rubber stoppers and putting a spring in there, to add a little upwards tension so the popper cooperates with the strut.

|

|

|

fieroguru

|

FEB 11, 07:49 PM

|

|

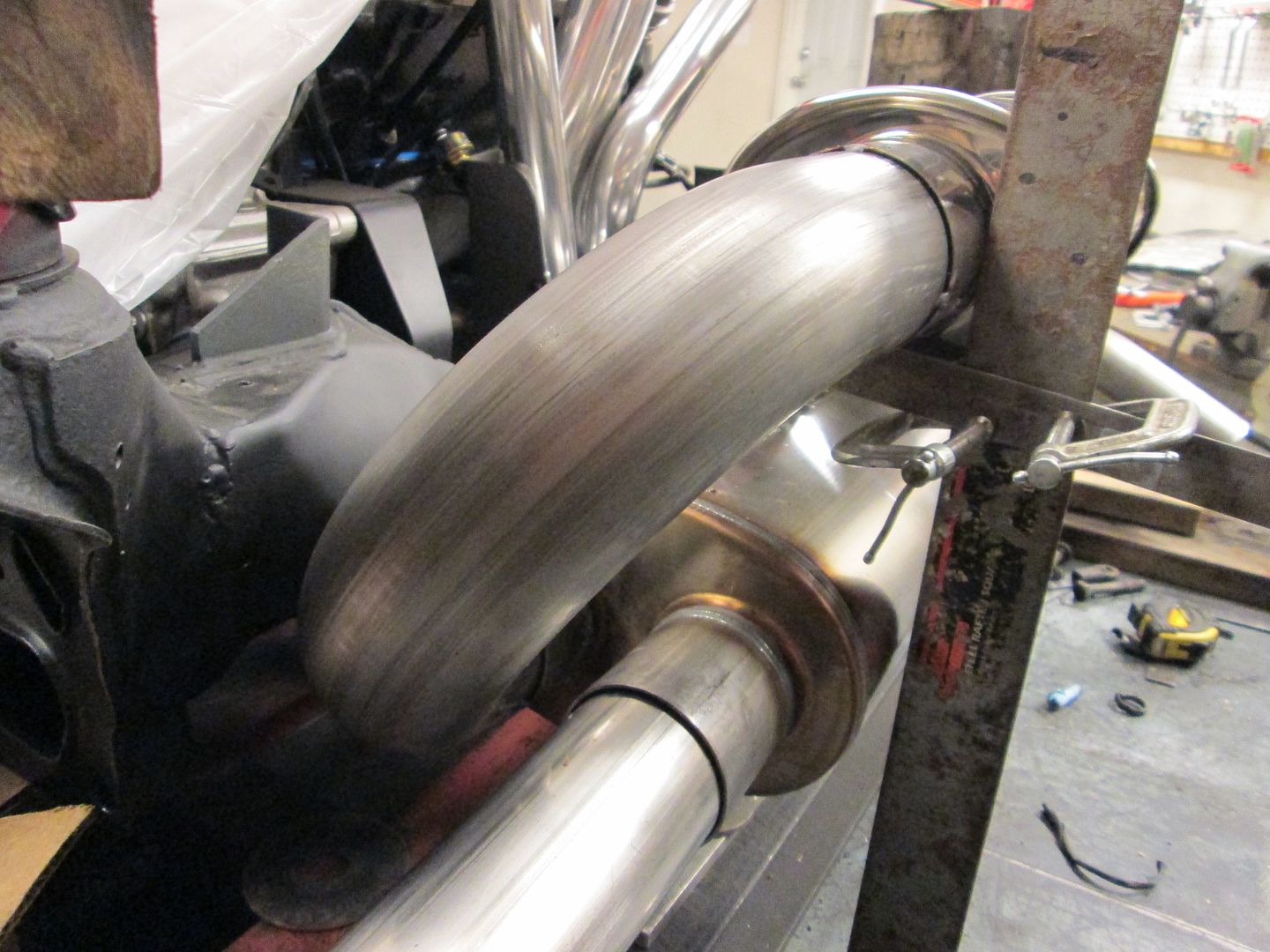

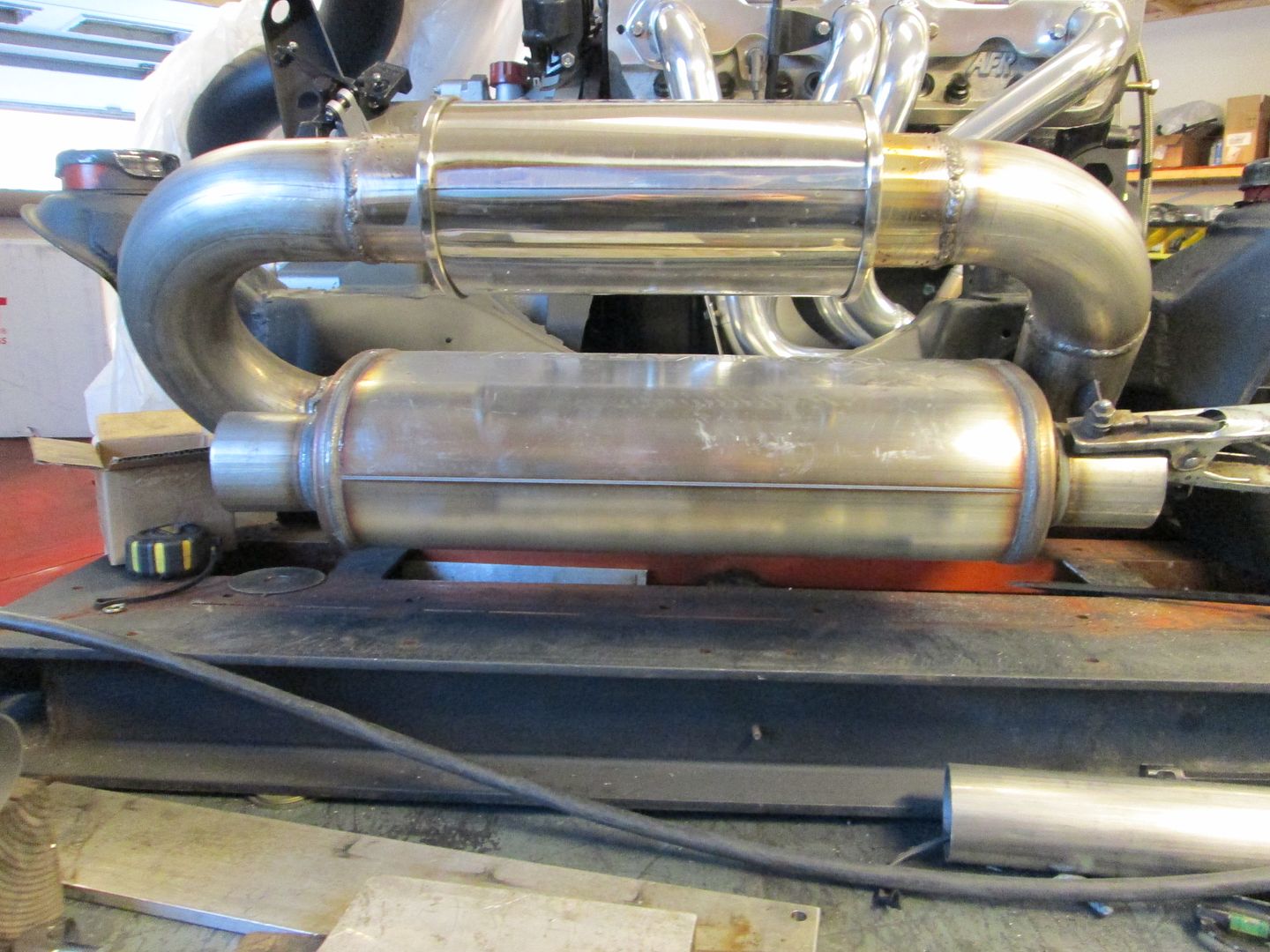

Little more progress on the exhaust. The upturn section was welded up and then the resonator was leveled and squared and tacked into place. Then the u bend and muffler were set into position and leveled and squared and tack welded in place too. Now I need to pull it all back out and weld it up solid. I still need to drill the hole for the wide band and fab up some exhaust hangers using the factory exhaust hanger bolt holes in the cradle.

The rear bumper is about 14" behind the rear cradle bolts and the bottom of the level is the approximate bottom of the trunk floor, so there is plenty of room in all directions for this to slide up into place.

This exhaust is about 3-4 feet longer than the one on my LS4 swap and it has an additional resonator. The extra length and the resonator will help quiet it down some without being a restriction.

|

|

|

fieroguru

|

FEB 13, 07:00 PM

|

|

Its almost time to put the drivetrain back into the engine bay. I finished welding up the exhaust except for the 2 1/2" pipes that go to the tips - I need it in the chassis to center and level the pipes to the body:

Here is the driver side hanger (I need to sand it down and paint the bolt on bracket):

Here is the passenger side. It will have a hole drilled for a strap that will go down and be attached to the 2 1/2" exhaust pipe on the passenger side. I didn't take a good picture of it, but the wideband O2 sensor bung was also welded on:

|

|

|

KissMySSFiero

|

FEB 13, 07:12 PM

|

|

|

thanks for keeping fieros interesting. Nice work as usual.

|

|

|

fieroguru

|

FEB 15, 07:44 PM

|

|

|

|

Trinten

|

FEB 15, 08:21 PM

|

|

That is a lot of stuff man!

Sorry you had something snap on you

I hope you guys are getting some better weather out there than we're seeing this way. Stay warm!

|

|

|

fieroguru

|

FEB 16, 07:30 PM

|

|

| quote | Originally posted by Trinten:

I hope you guys are getting some better weather out there than we're seeing this way. Stay warm! |

|

Its been cold (single digit lows most of last week) with a couple of inches of snow here and there, but nothing like what you guys where getting. Today was 39 and the start of our heat wave. The highs this next week are all above 49 degrees until next Sunday when it drops to 41.

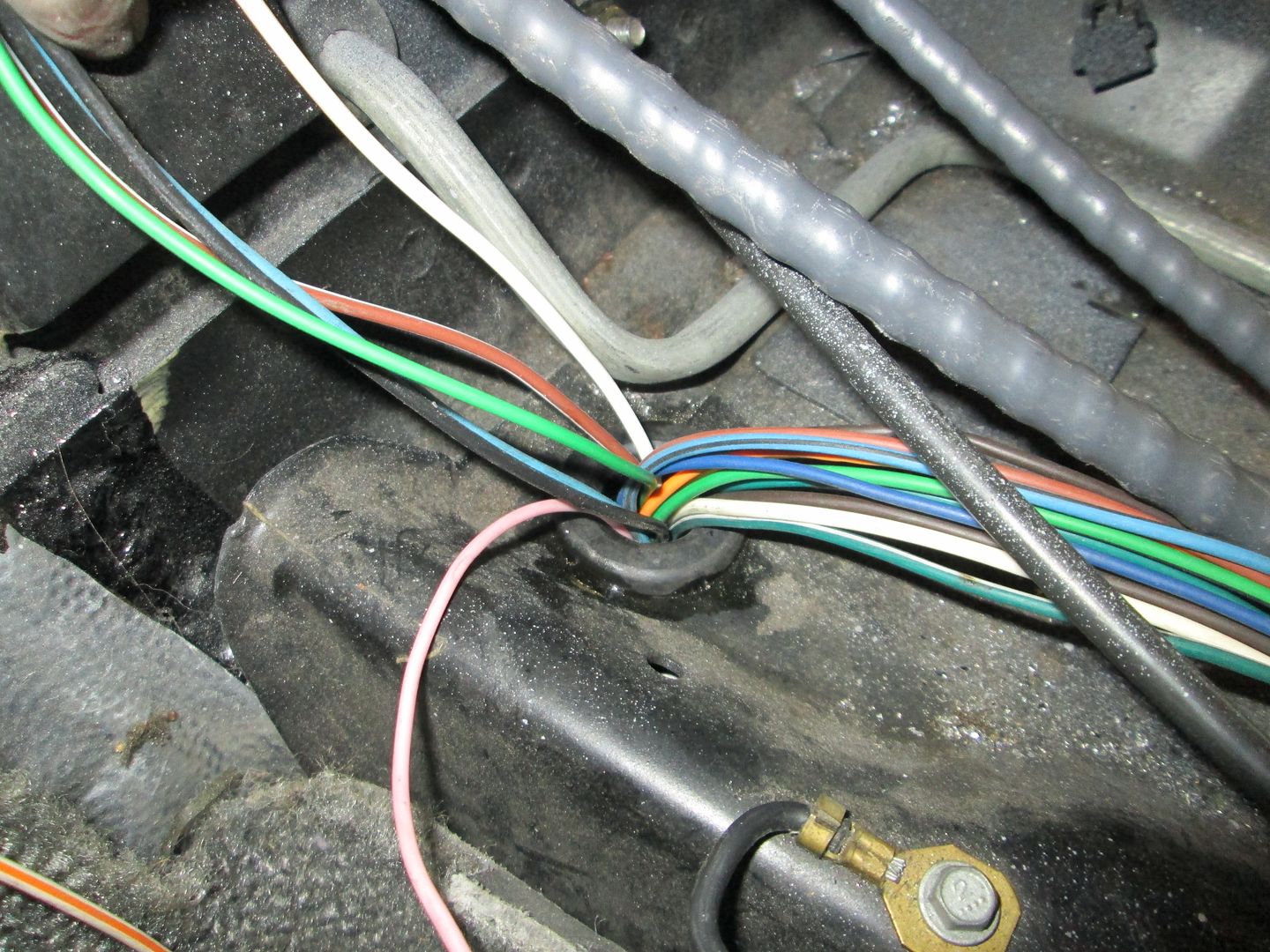

Today wasn't as productive as I would have liked, but the rear chassis harness work is done.

Drilled the access hole in the center console as well as in the side of the chassis to access the double firewall section. De-pinned the fuel pump connector and the trunk release connector so I could pass the wires through the holes, then reinstalled the connector pins. Passed the rear harness (including the 2 wires for the water pump) down into the fuel tank area, then installed 2 layers of heat shrink to protect the wires. Snaked a piece of rod through the double firewall section, tapped the harness to it and pulled it through. Once that was done I was able to reconnect the two sections of wired with western union splices, soldered, heat shrinked over the splice, then heat shrink over the entire spliced area. When splicing the harness, I stagger the spliced every 3/4" so there won't be two splices right next to each other that could allow them to run through. It also keeps the harness from being bulky in the spliced area.

I need to steal the fuel pump connector off the parts car's fuel tank so I can replace the melted one. Once that is done, the fuel tank can be installed along with the fuel filter/regulator. Then the engine/transmission will go back in.

With the weather being nice this week and since I will be traveling for work the week of Feb 24, I plan to put in some decent hours in the evenings this coming week. I would like to hear it make noise before I leave for my trip, but there is still a bunch of work that needs to be done.

|

|

|