|

| Ferrari 288GTO build (Page 31/64) |

|

Sage

|

MAR 01, 10:24 AM

|

|

Superlative, outstanding work!

Entire body looks great.

Unless you get yourself a chopper gun, or find a glass shop to take on the orders, I predict, you will not be able to keep up with people wanting their own out of your molds! (You're still gonna do molds....right?  ) )

Have you decided on what paint/final finish you'll be using, keeping in mind, it will be the surface your molds are made on? Just curious, As I'm sure you're aware, the molding process does really "test" the integrity of the surface used to create the pulling surface of the molds formed on it.

Ever use Duratec? When I'm doing a new mold, I generally coat the plug with gel coat, thinned 50/50 with acetone and catalyzed and shot with an HVLP gun, then soap sanded with up to about 1000 or 1200 grit wet, 3 stage buffed, then about 10 coats of mold release wax, and PVA as a final release agent . Never had one stick or "marry" a plug that way. But you're talking an entire BODY! The Duratec performs like gel coat, but works sort of like paint. Old school method always used laquer paint, but you can't even get the "real" stuff anymore. That's when we started using gel coat. Anyway, just curious, I'm sure you've got this covered, just wondering what your plan was. Hate to see you paint it all pretty like, then have that nice paint job messed up during the mold process. Guess I should mind my own business?LOL

Car looks great Wayne....I still say, you will have potential customers clammering at your door to get one!

HAGO!

|

|

|

dobie1

|

MAR 01, 10:23 PM

|

|

| quote | Originally posted by Sage:

Superlative, outstanding work!

Entire body looks great.

Unless you get yourself a chopper gun, or find a glass shop to take on the orders, I predict, you will not be able to keep up with people wanting their own out of your molds! (You're still gonna do molds....right?  ) )

Have you decided on what paint/final finish you'll be using, keeping in mind, it will be the surface your molds are made on? Just curious, As I'm sure you're aware, the molding process does really "test" the integrity of the surface used to create the pulling surface of the molds formed on it.

Ever use Duratec? When I'm doing a new mold, I generally coat the plug with gel coat, thinned 50/50 with acetone and catalyzed and shot with an HVLP gun, then soap sanded with up to about 1000 or 1200 grit wet, 3 stage buffed, then about 10 coats of mold release wax, and PVA as a final release agent . Never had one stick or "marry" a plug that way. But you're talking an entire BODY! The Duratec performs like gel coat, but works sort of like paint. Old school method always used laquer paint, but you can't even get the "real" stuff anymore. That's when we started using gel coat. Anyway, just curious, I'm sure you've got this covered, just wondering what your plan was. Hate to see you paint it all pretty like, then have that nice paint job messed up during the mold process. Guess I should mind my own business?LOL

Car looks great Wayne....I still say, you will have potential customers clammering at your door to get one!

HAGO!  |

|

Good to hear from you Sage!! I always appreciate your input and the knowledge you have from building ,molds parts etc.

Yes I’m going to build molds of the entire car . I think along time ago you told me this was going to be a plug and that I would be building molds!!

It came down to the car is a one of a kind and if I’m ever involved in a accident or mishap it will be nice to just make a new piece part.

I was planning on painting the car in a single stage polyurethane car paint, a neighbor had a body shop up until last year ended up with lots of product left over and is giving me a gallon.

No I haven’t used Duratec yet however I do have a gallon of Duratec sunblock that I was going to use to spray on my carbon fiber body that I plan on building.

I’m intrigued by the 50/50 gel coat and acetone , so are you using waxed or unwaxed gelcoat. I’m assuming waxed to get a fully hardened surface. Does the acetone not break down the gelcoat?

What Duratec do you use.

I do have a cup gun for doing the gelcoat I have been looking at a hand held chopper gun but not for the time being. I understand from reading that you can layer the two and then consolidate between layers. I’ll probably do a hand layup on the first body and if I get more than the first kit that is tentatively spoken for I’ll look at getting a chopper gun.

Thanks for your input

Wayne

|

|

|

Sage

|

MAR 02, 08:19 PM

|

|

Wayne:

The thinned gel coat can be sprayed through an HVLP gun.

Couple of things to remember.....you have to use about 5 times as much MEKP (catalyst) as you would normally with just gel coat alone.

You don't have all the time in the world to shoot it, and the gun has to be thoroughly cleaned immediately, for obvious reasons. I don't use gel coat with wax in it, but you DO have to spray a coat of PVA on the gel coat after you put it on your plug.

You know that it cures in the absence of air, so it has to be sealed (which is what the wax would do if it was in there) and the PVA does that just fine. If you don't put the PVA coat on after the last coat of gel, it's not going to cure and will remain a gooey mess.

After putting the PVA on and letting it kick, (I usually give it at least overnight), you can start sanding.....if it went on pretty smooth you can start with #400 and work up to as fine/smooth as you want the surface to be. I usually go up to at least #800, but have gone as much as #1500.

The plug surface is going to determine your mold pulling surface, at least the start of it.

When you get finished sanding, then you start buffing. I usually go 3 stages up to machine glaze finishing compound. There are many products out there that will do the same thing, but I generally use McGuires. You can order specific mold polishing compound from most fiberglass supply houses too. Buffing can be an "art". The method I use combines the compound with clean water, never let your surface get "dry"...when you get to the point you're almost done, you're using mostly just water....and a GOOD buffing pad. I like wool, but I'm old school, I guess. There are foam pads now, that will pretty much do the same job, but to me, they are harder to use. I guess it's a matter of what you're used to.

The same process is followed on the mold pulling surface, (I use tooling gel coat, and I'd think you should too...it withstands much higher curing temps, that you encounter when parts you put IN the mold are kicking..), i.e., sand, sand, sand, buff, buff, buff.

Also, I generally do the orange (or black) tooling gel coat as the pulling surface, after building that up sufficiently, (15 -20 mils), I put a "tracer" coat of white gel coat on about half that thick, but only because that's the way I was taught to do it. If you ever sand through to the tracer coat, you know you might be making a new mold soon, or doing some mold repair!

Anyway, there's lots of vids out there walking you through mold making, everybody has their own little "tricks" they like to use, and you can always look the process up on some of the supply house sites, like Fiberglast.com...their stuff is expensive, but they do have more than a few tutorials and lots of info on doing all sorts of composite work, including mold making.

So, there's another cent and a half worth of trivia. Hope some of it helps you a little.

You might just be ok with your original plan using the polyurethane single stage. Its mostly a matter of creating an effective barrier coat between the plug and the mold. Parting wax is what I count on 99% of the time and it generally works, but when MAKING a mold, or using a new mold (less than 10 pulls) I will also use the PVA, or Fibrelease, usually PVA. Some of the old timers used to use Johnson's Floor Wax and it worked too!

Doing the gel coat finish is very labor intensive and time consuming....and you are doing an entire body! You might be another year just prepping to lay the mold up!LOL I think I'd probably figure out a way to use the paint! You have to basically do the same process with the Duratec, but it IS cheaper than gel coat, but not by a lot.Duratec

Given the caliber of your work on this project, there's no doubt you will produce stellar molds, which will produce stellar parts!

Keep the updates coming.

HAGO!

P.S. Don't forget the 10 coats of wax on the plug, after the sanding/buffing, before the PVA.

Same thing on the mold before using it for the first time.....and oh yea....it should probably cure for at least 10 days or so.

Not "Hard and Fast" rules, but ones that I've always followed with good results.[This message has been edited by Sage (edited 03-02-2020).]

|

|

|

dobie1

|

MAR 09, 10:43 PM

|

|

|

|

dobie1

|

MAR 26, 08:40 PM

|

|

Well I hope everyone is safe and not infected with Covid 19.

I have been in isolation working on the build, Luckily I am retired so no real reason to leave our home other than for food.

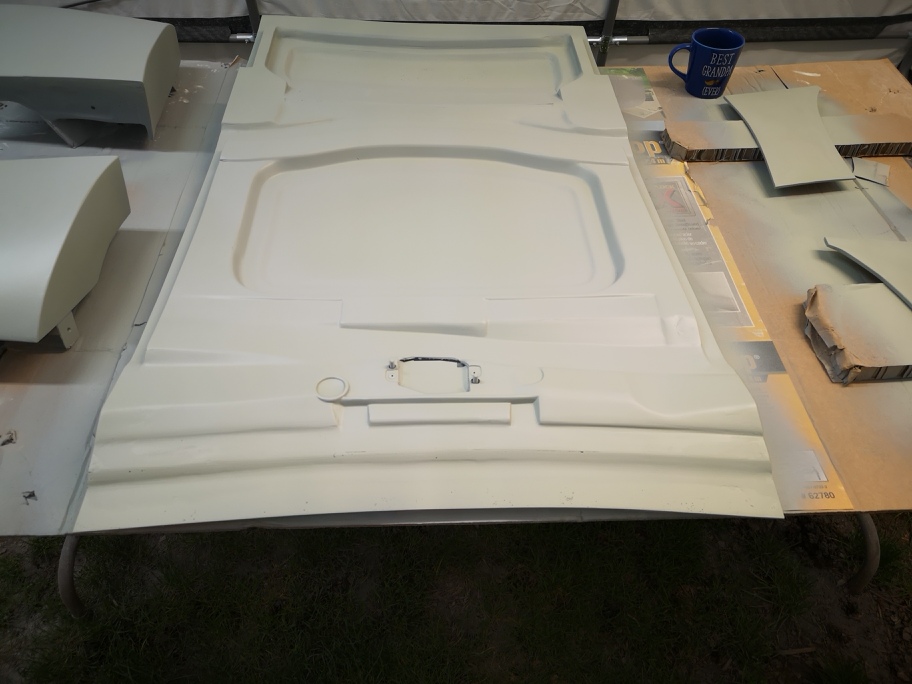

I have been busy I've taken all the panels off the car and finished them all individually and then remount each piece to ensure they all fit perfectly, very time consuming.

My hope is by taking these extra final steps before painting , the parts I produce will fit Exactly as the originals.

There was a lot more sanding and finishing than I thought was needed. But when your going to make molds its has to be close to perfect, what ever isn't perfect will end up in the parts.

Here are a few shots of the door panels and one of the fender running boards.

The weather is still bit cool so it is taking a bit longer for the parts to dry, so it will be a few days to get everything done.

Thanks for looking and please be safe and social distance in these times.

Wayne[This message has been edited by dobie1 (edited 03-27-2020).]

|

|

|

wftb

|

MAR 26, 10:09 PM

|

|

|

Amazing work. Been following this thread a long time. You are a source of inspiration. ------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms

|

|

|

RCR

|

MAR 28, 09:18 PM

|

|

Looks great, Wayne.

stay safe and good health.

Bob[This message has been edited by RCR (edited 03-28-2020).]

|

|

|

dobie1

|

MAR 28, 11:00 PM

|

|

Thanks WFTB , I always appreciate people taking the time to stop by the build. comments are always appreciated.

Good to hear from you Bob!

Don and I were talking today and hoping to see a post on your build we hope things are getting back to normal for you.

TTYS

Wayne

|

|

|

dobie1

|

MAR 30, 10:31 PM

|

|

A bit of a update.

The weather isn't really cooperating ,it's really cool and moist from the rain. The parts I primed the other day although chemically dry hadn't really dryed to a point I could sand yet. So switched it up and setup and Primed a few more pieces.

I'set up for the fenders and center fill today so will spray tomorrow. On a side note I finally got my DeCups spray system, thanks to Amazon during this uncertain time.

I'm looking forward to a easier clean up with the ability to paint at all angles.

Thanks for visiting.

Wayne

|

|

|

dobie1

|

MAR 31, 10:20 PM

|

|

I got to use the DeKups today , I really like the system!! The cleanup went really fast only needed to clean the gun, there are consumable waste but I'll continue using the system going forward.

I was given a bit of insider technic from a neighbour for spraying Slick Sand which is very thick to spray adding 10% full poxy reducer to the mix thins it down and lays it very flat.

It sure is nice having it back in one colour again ,i'll start to sand tomorrow the previous parts I sprayed the other day. Starting at 320 grit then to 400, If everything goes according to plan the next will be spraying paint. It's not the colour I'd like to see the car in (White) but free paint makes it a easy decision.

Here are a few shots

Thanks for looking

Wayne

|

|

|

|