|

| Another Katatak Fiero Adventure! (Page 27/72) |

|

Carver1

|

DEC 23, 01:02 PM

|

|

put me in line for that Camaro.

I'll give you the Solstice as collateral. deal?.......

|

|

|

katatak

|

DEC 24, 11:36 AM

|

|

After a brief intermission due to "work", I was able to get back to the console project yesterday afternoon. My plan is to build a new (different) shift cover. This one will be the entire length of the console in an atempt to give it a smooth flat look, My goal all along was to create a console that was smooth and seamless. I am getting closer to that goal. Yesterday, I managed to get the main part of the new cover glassed and started the test fitting last night. As I was test fitting, I noticed that there is an "elevation" change from the arm rest part of the console to the AC surround. I had 2 ideas to make up the difference. One was to cut a "wedge" on each side of the cover and then slope the cover from the high point on the arm rest to the AC surround and the other was to leave it flat and build a "spacer" at the AC surround to help steady the cover. I ended up leaving it flat and at the AC end and I built in a tray to hold things!

First on the agenda was to prep the mold:

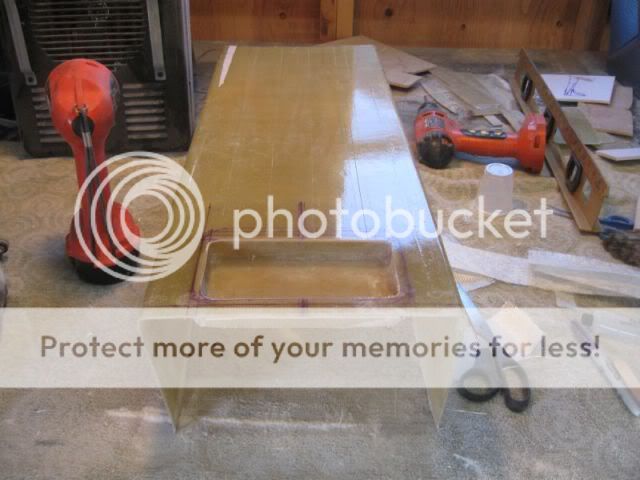

This was going to be my largest fiberglass project yet. I cut all the mat and cloth, layed out all my supplies and went to work:

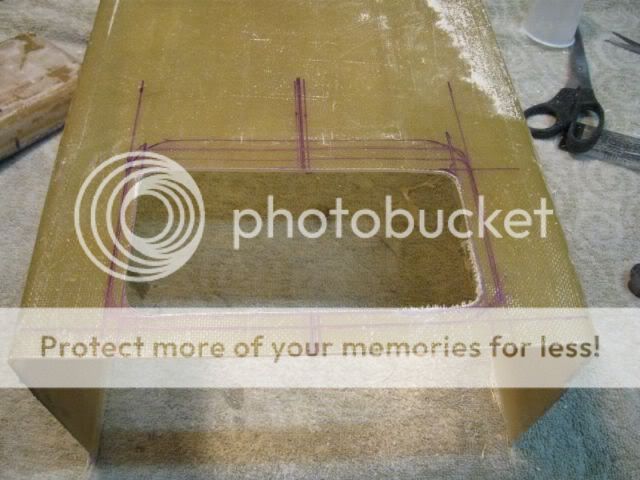

Taking shape - adding some heat to help it cure - it was about 32* and snowing here yesterday:

Now here's where I messed up. I got in a rush when I was prepping the mold. I used some epoxy to "round" the corners in the mold. The epoxy I used was old and had been sitting in my shop on the shelf for about 4 years. It was not setting and was still kind of soft. I tried to scrape it off but it was tearing the paper from the foam core. So I decided to just cover over the top with packing tape. I was in such a rush to get the glass work started, I failed to wax the side walls of the mold. Once the glass was cured, I peeled the mold off. Unfortunately, the paper came off with the part. So now I have a lot more sanding to do to get the paper off the mold. I tried a small area with my sander and 50 grit and it just balled up and plugged up he sand paper. I may have to lay another layer of mat over top to cover the paper. Just makes a lot more work but I learned a vaulable lesson. Prep, prep, prep........

Trimmed and test fitting:

Trimmed some more. Once the cover fits where I want it, I will build a "cover for the rear console that will match up with this cover. Then I will glass the 2 parts together to form one part. The only visible seam will be at the AC surround and I think I can blend that to be nearly invisible.

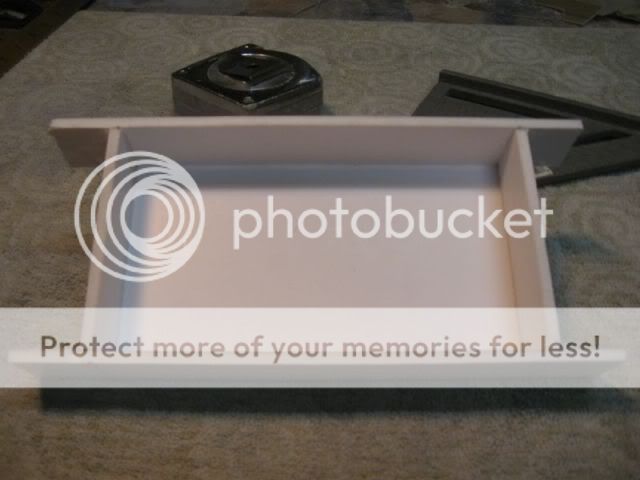

The next step was to build the tray that will set between the shifter and the AC surround. The "lid" off the 1 gallon can of resin was a perfect model - props to Archie for sharing that little tip - look around the shop for something that will work for a mold to make the part - "The Miura Project":

I layed it out to see what I was getting into:

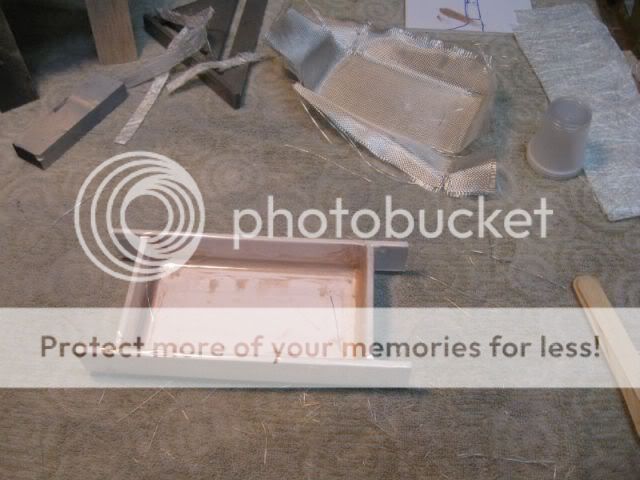

Then I made a mold out of foam core for the tray:

Mixed up some filler to lay in the corners to round them out:

And layed in the glass:

Trimmed up the tray:

Cut the hole. I cut the hole about 1/4" smaller than the tray. Once it's all one piece, I will snad the lip down so that it matches the inside of the tray and blend it all together:

Fit up and clamped in place:

Joined together. This was about 12:30 last night:

As of this AM:

And in the car:

Merry Christmas and Happy New Year!

Pat

|

|

|

katatak

|

DEC 24, 11:39 AM

|

|

| quote | Originally posted by Carver1:

"The man said Tada" |

|

Now that's funny right there. I was sitting in an airport Tuesday night and I watched a comercial for a cell phone. Now I get it......lol. It only took 3 days for me to get it! I must be getting old!

MXHNY![This message has been edited by katatak (edited 12-24-2009).]

|

|

|

Sofa King

|

DEC 25, 02:04 AM

|

|

P,

Even with a little extra foam core it still looks great! You've got my interest going - where are you headed with the final design? hmmmmm???? The use of the resin lid - brilliant! Archie is good - really good. It sparked ideas for my own armrest and glove box. DANG IT! I want to go out to the garage and work on the console.

Question: Could you have used the plastic lid from the resin instead of creating a new one? Was the lid too big, too wide, etc? It looks really sharp so far!

Merry Christmas, buddy![This message has been edited by Sofa King (edited 12-25-2009).]

|

|

|

katatak

|

DEC 26, 12:05 AM

|

|

| quote | Originally posted by Sofa King:

P,

Even with a little extra foam core it still looks great! You've got my interest going - where are you headed with the final design? hmmmmm???? The use of the resin lid - brilliant! Archie is good - really good. It sparked ideas for my own armrest and glove box. DANG IT! I want to go out to the garage and work on the console.

Question: Could you have used the plastic lid from the resin instead of creating a new one? Was the lid too big, too wide, etc? It looks really sharp so far!

Merry Christmas, buddy!

|

|

Thanks Greg........

The lid was the perfect size except it had a couple "steps" in it that would have made it a pain to glass over. The mold I made was a little smaller and more shallow too - better fit. You would not believe all the things I have been "measuring" to use as a mold! I look at things differently now that I am in the middle of a glass project. Got some more stuff cooking - actually curing right now. Whne I finish it this evening, I'll post it up.

Hope you and yours had a great Christmas!

Pat

|

|

|

katatak

|

DEC 26, 12:42 AM

|

|

|

|

katatak

|

DEC 26, 01:29 AM

|

|

A couple more thoughts - need some feedback.

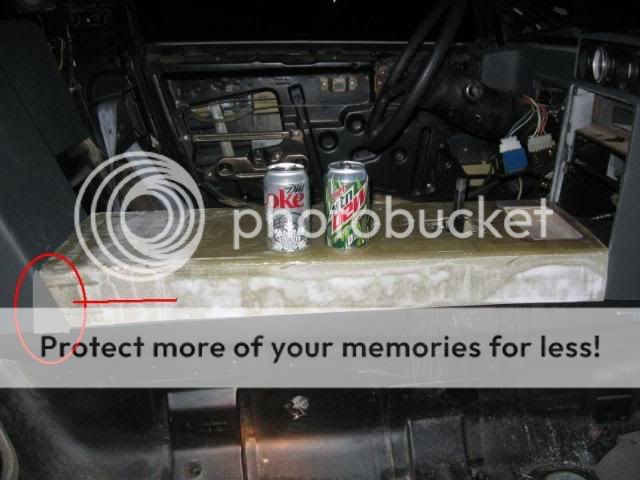

I am thinking that I should trim the rear end of the shift cover at an angle that matches the angle of the rear console (red circle) and I am thinking about cutting in some cup holders on the right side of the shift cover. I think there is enough room so that when shifting, I will not be banging the cans/bottles in the holders? I'll have to measure to see how deep I can recess them. I may not be able to get them deep enough? Give me your thoughts/ideas/comments.

"MCaHNY"

Pat

|

|

|

Rick 88

|

DEC 26, 05:30 PM

|

|

Do the angle cut. You probably won't notice it with the seat in place but it will make you feel better. On the cupholders make sure they hold a "Big Gulp".

|

|

|

Sofa King

|

DEC 26, 06:41 PM

|

|

| quote | Originally posted by katatak:

I am thinking that I should trim the rear end of the shift cover at an angle that matches the angle of the rear console |

|

P,

GREETINGS from Las Vegas! Hope you had a great Christmas and Santa was good to you? The console is looking really sharp so far! Where are you going with this final design? I think you should go with the angled cut. From a design perspective it works even though you won't see them because of the seats.

| quote | Originally posted by katatak:

I am thinking about cutting in some cup holders on the right side of the shift cover. I think there is enough room so that when shifting, I will not be banging the cans/bottles in the holders? I'll have to measure to see how deep I can recess them. I may not be able to get them deep enough? Give me your thoughts/ideas/comments. |

|

Good call - I like cup holders. LOL You might have or want to glass in an existing dual cup holder - I don't think there is enough room under the console? Although your new console did raise it a bit. I would still consider finding a dual holder and working it into the final design - anything to avoid an unnecessary fabricating and sanding. Go to www.thefind.com and type in dual cup holder. I found a few that might work for ya.

DANG IT! I really want to get home and start working![This message has been edited by Sofa King (edited 12-26-2009).]

|

|

|

Sofa King

|

DEC 26, 06:45 PM

|

|

| quote | Originally posted by katatak:

|

|

Who's that spying on you? Is that the shop foreman crackin the whip?

|

|

|

|