|

| Trinten's SBC/F23 build - The work has begun! (Page 25/76) |

|

fieroguru

|

NOV 21, 08:01 PM

|

|

| quote | Originally posted by ericjon262:

I've always hated adapter plate swaps(mainly because most seem like hack swaps.), but I do love seeing the ingenuity that has gone into this build. keep up the good work.

|

|

Thanks! I like for my swaps to have a little creative flair!

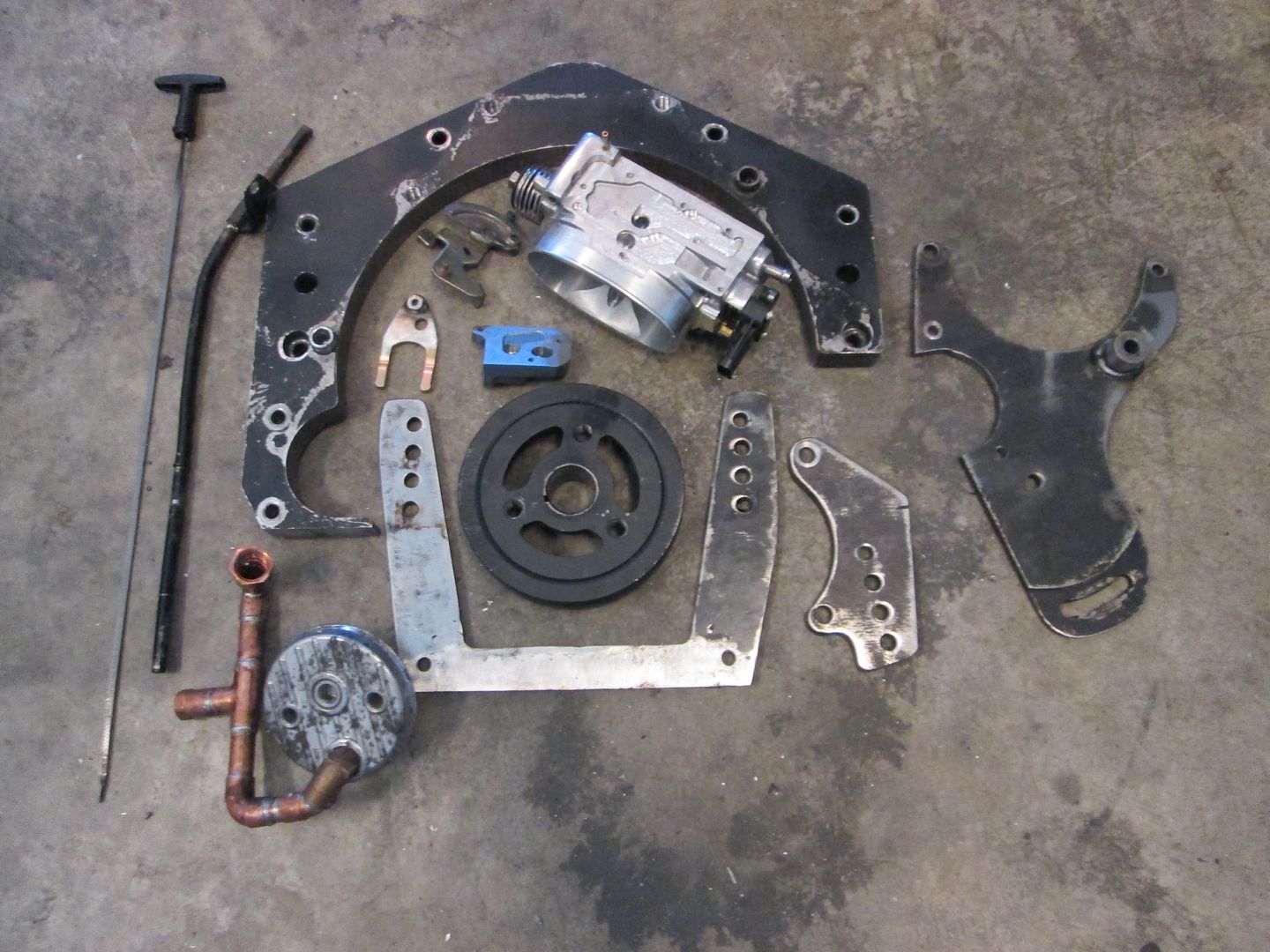

Some aspects of this swap are very similar to the last SBC I did (like the serpentine belt conversion, the thermostat housing to rigid pipe plumbing, the A/N adapters for the water pump ports on the block, the used of sheet metal heat shields, etc). Other aspects are very similar to my LS4 swap (coil packs, 4" cold air intake and use of the LS7 MAF sensor), then there are many other items with unique solutions just for this swap (F23 mounts, F23 shifter bracket, cradle mods to lower the drive train, IAC relocation, throttle cable bracket, hard lines for PCV, the headers, etc).

Hopefully over the weekend I will be able to take a picture of all the pieces I made or significantly modified for this swap, just to give an indication of the work that has been put into it.

The O2 sensor bungs came in today, so I will try to have the headers complete Friday and should be able to ship them to the coaters early next week.

|

|

|

fieroguru

|

NOV 23, 02:08 PM

|

|

Welded the o2 sensor bungs to the headers:

Then I started taking everything apart. The engine is back on the stand:

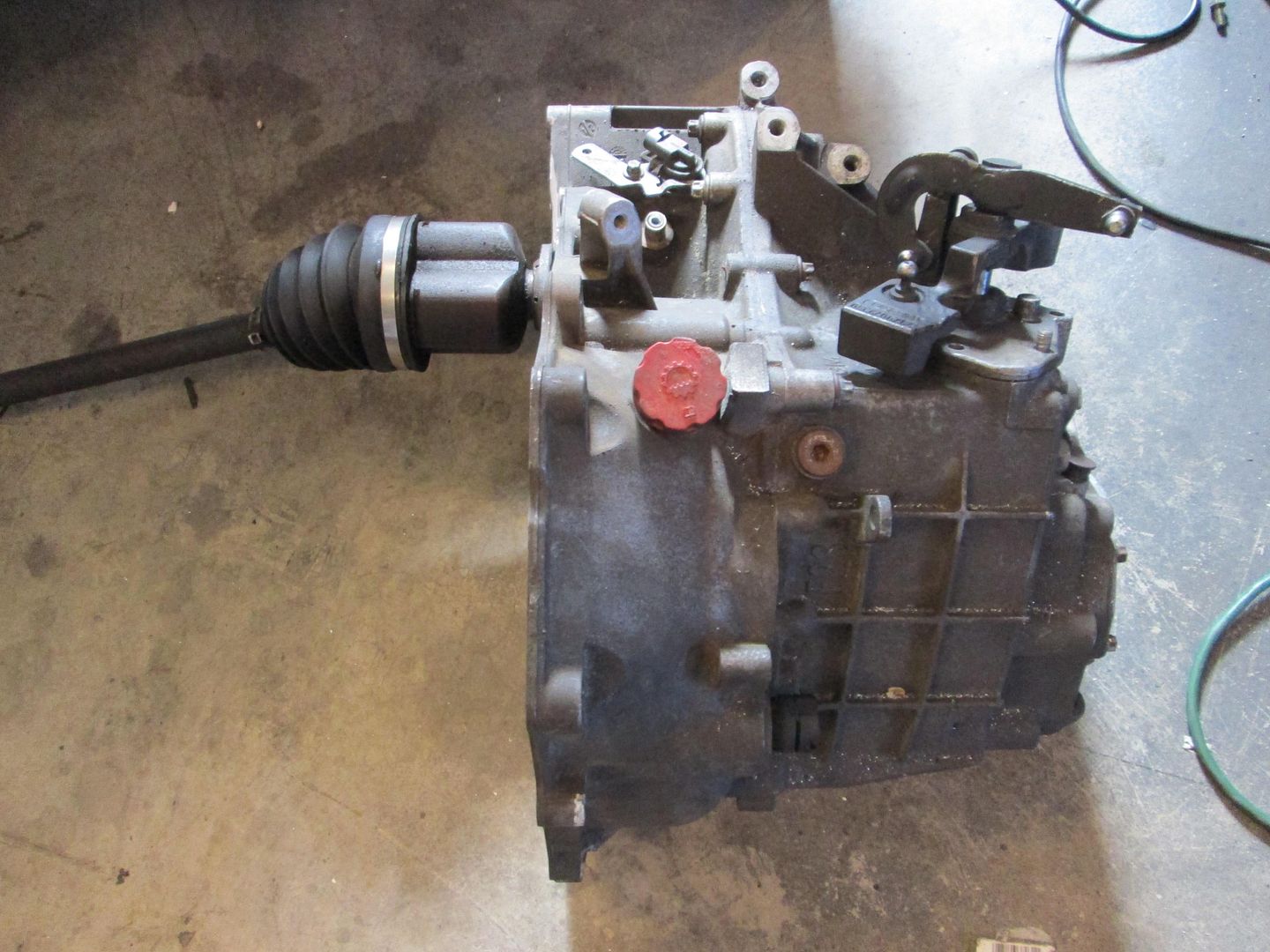

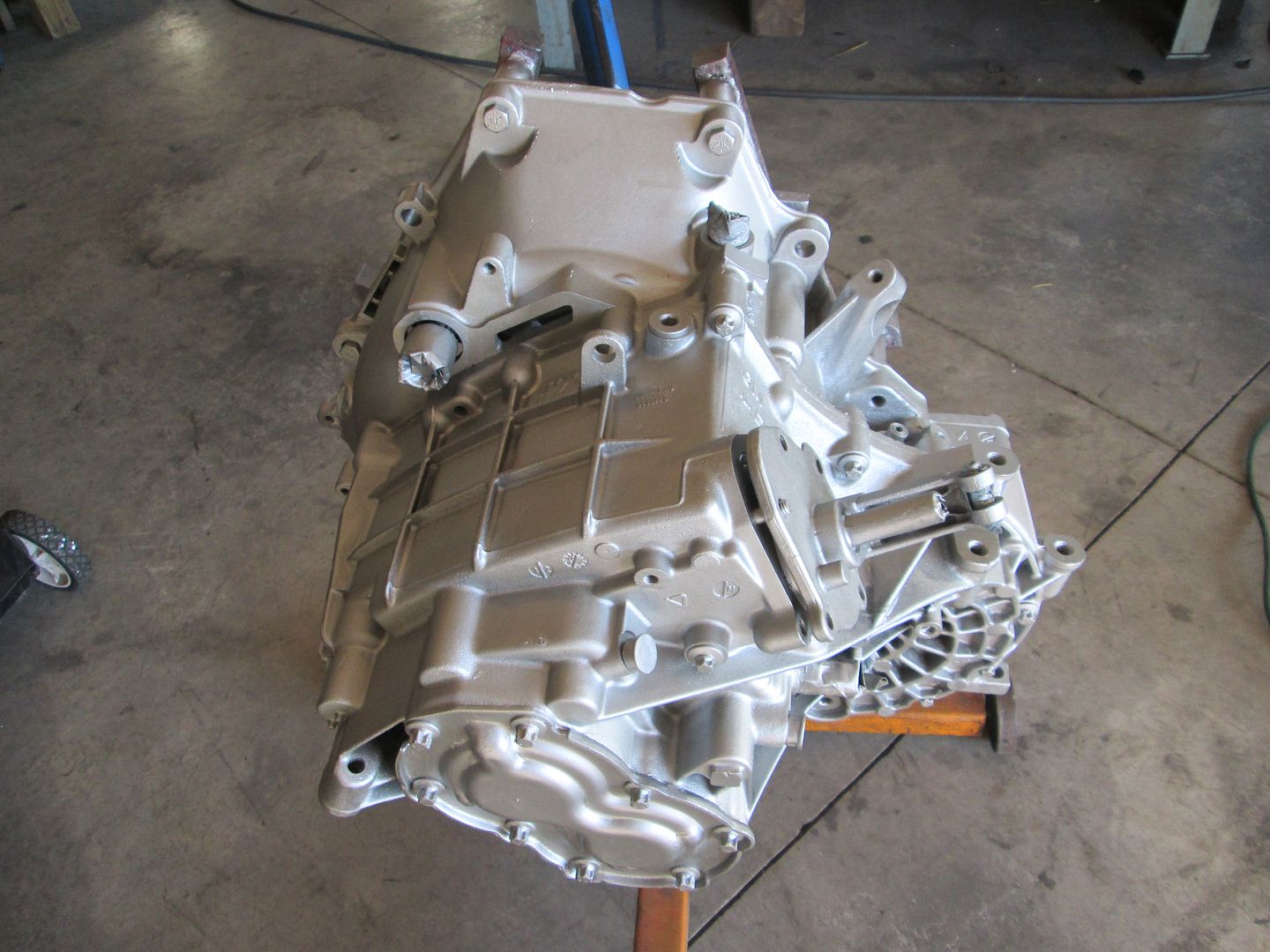

Transmission hanging out on the floor:

Here is everything I fabricated for the swap (except the engine and transmission brackets that are welded to the cradle):

Here is everything that I have modified in some manner (throttle cable and the fittings for the water pump ports on the engine not shown):

|

|

|

fieroguru

|

NOV 24, 07:56 PM

|

|

Just been sanding, cleaning and priming...

Several more parts are still drying.

|

|

|

fieroguru

|

NOV 25, 08:10 PM

|

|

The stack of primed parts is getting larger:

The headers boxed up and shipping them to the coaters on Tuesday.

|

|

|

CowsPatoot

|

NOV 28, 08:05 PM

|

|

I jumped in to complain about the lack of updates and discovered it was moved to the construction zone.

The fact that the passenger side axle still hasn't been removed kind of bothers me. Is that an issue that should be dealt with while everything is apart? Or just wait till it breaks and assume the worst?

|

|

|

fieroguru

|

NOV 29, 01:30 PM

|

|

| quote | Originally posted by CowsPatoot:

The fact that the passenger side axle still hasn't been removed kind of bothers me. |

|

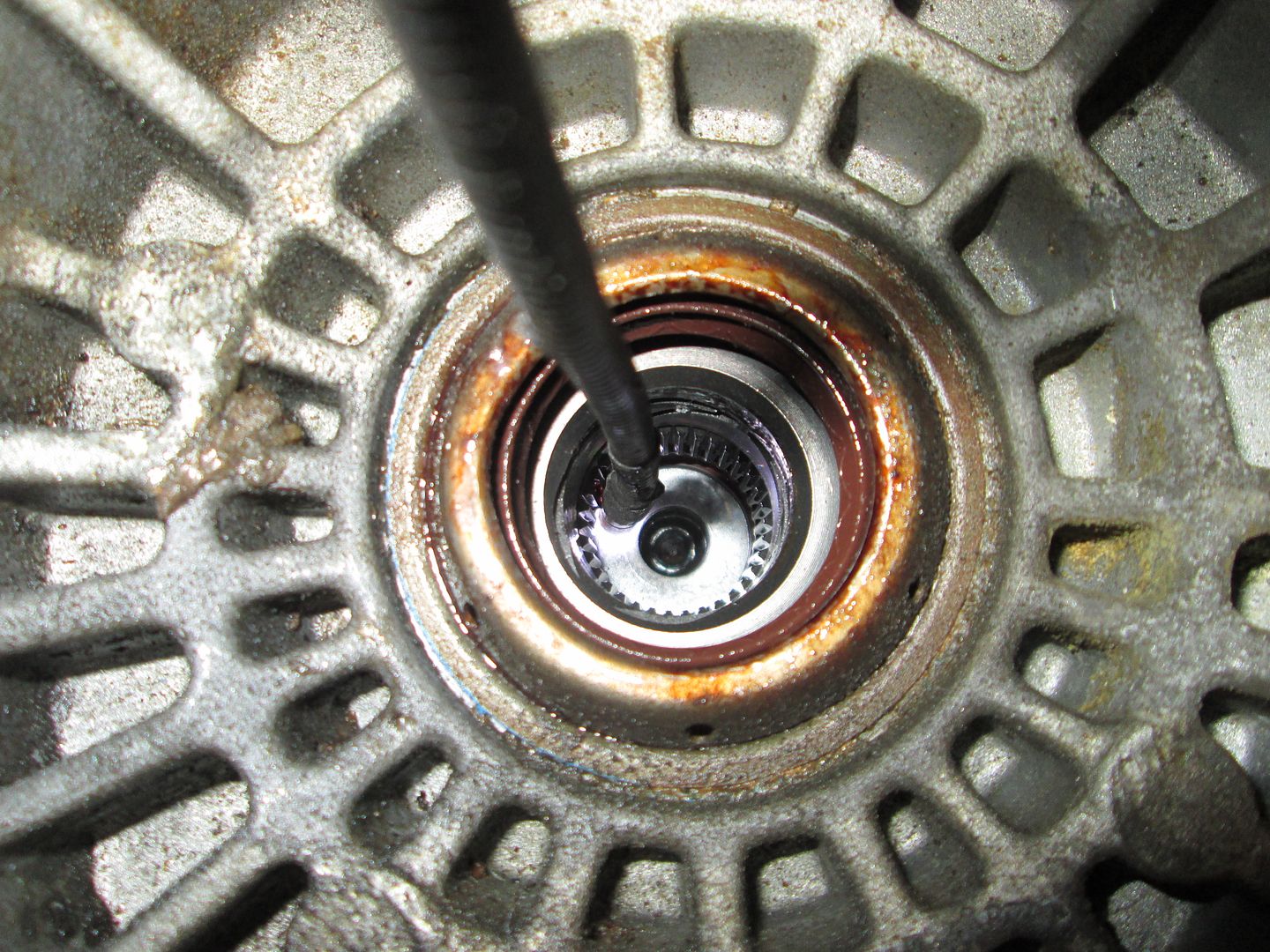

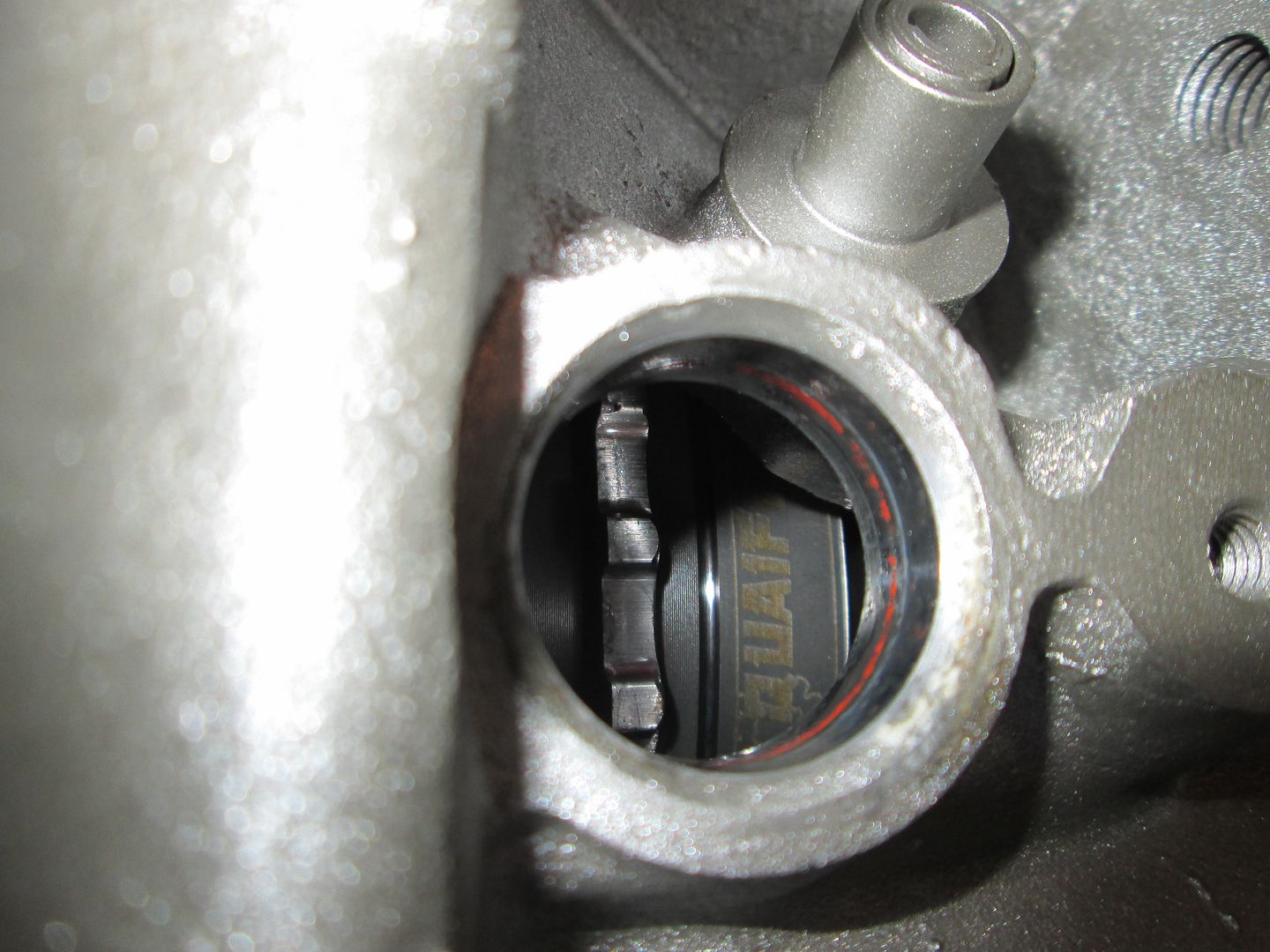

It had tried several times over the course of the built to remove the axle and discussed the issue with Vince. He didn't want me to break the transmission getting the axle out, and it wasn't too much of an inconvenience keeping it in, so I stopped messing with it, and just worked around it. While I had the transmission on the bench taking apart the shifter arms, I looked down the other side of the differential expecting to see a cross shaft blocking access to the other side. I was quite shocked with I saw this:

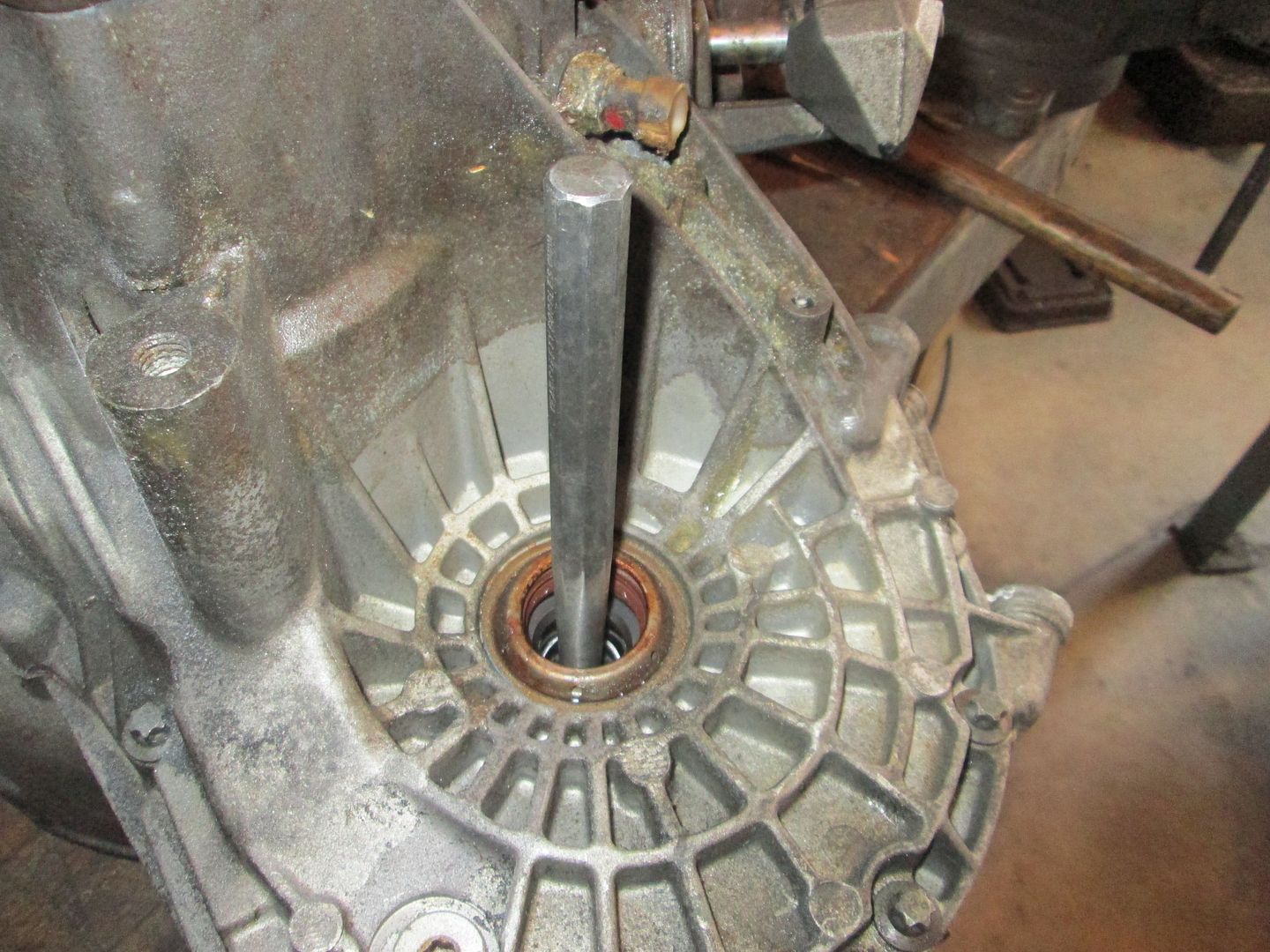

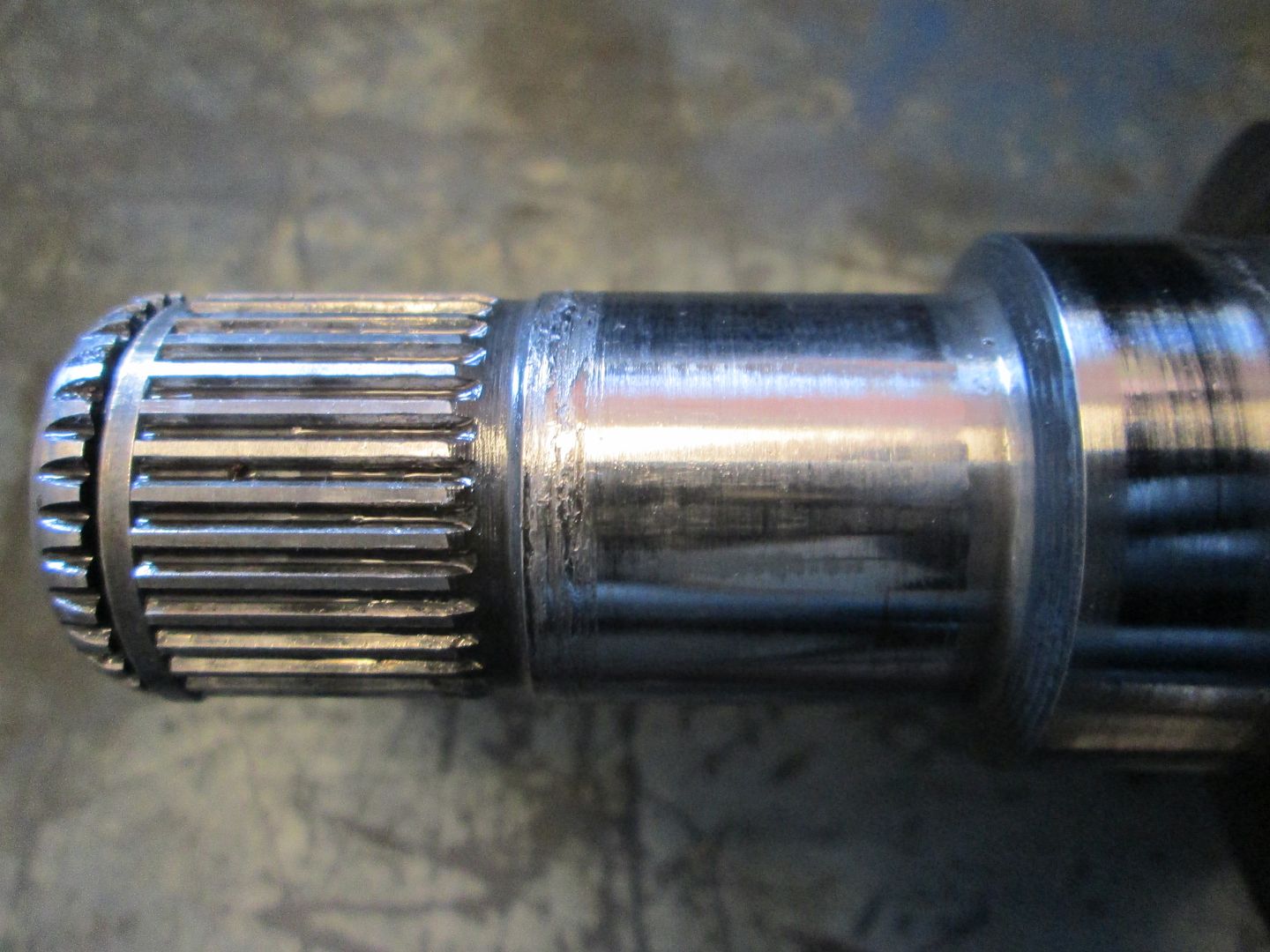

Through the small hole is the end of the tripod for the other side... Which means I can use this method to try one last time to remove the axle:

It didn't come out without a fight, but it is now out. You can see all the way through the hole in the center:

I suspect this is what was causing the axle to want to stay put. Not real sure what caused it, but I will just use another axle when it goes back together:

Been busy cleaning/scrubbing the transmission in preparation for painting...

|

|

|

fieroguru

|

NOV 29, 05:39 PM

|

|

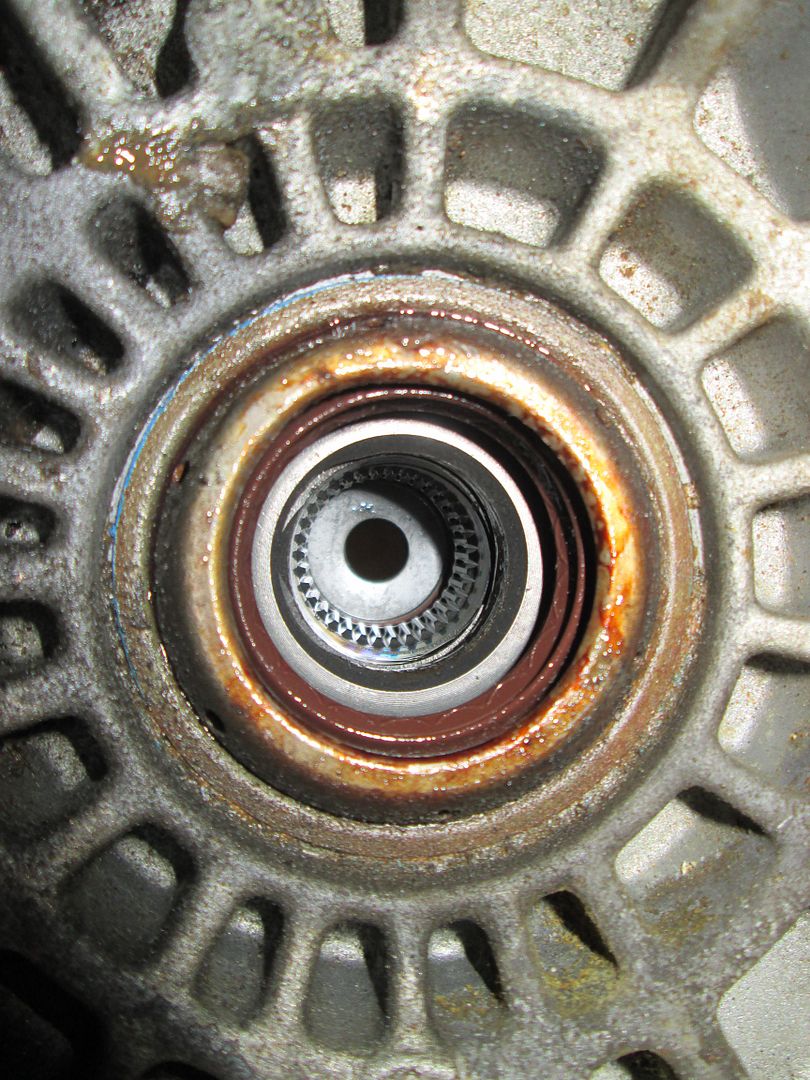

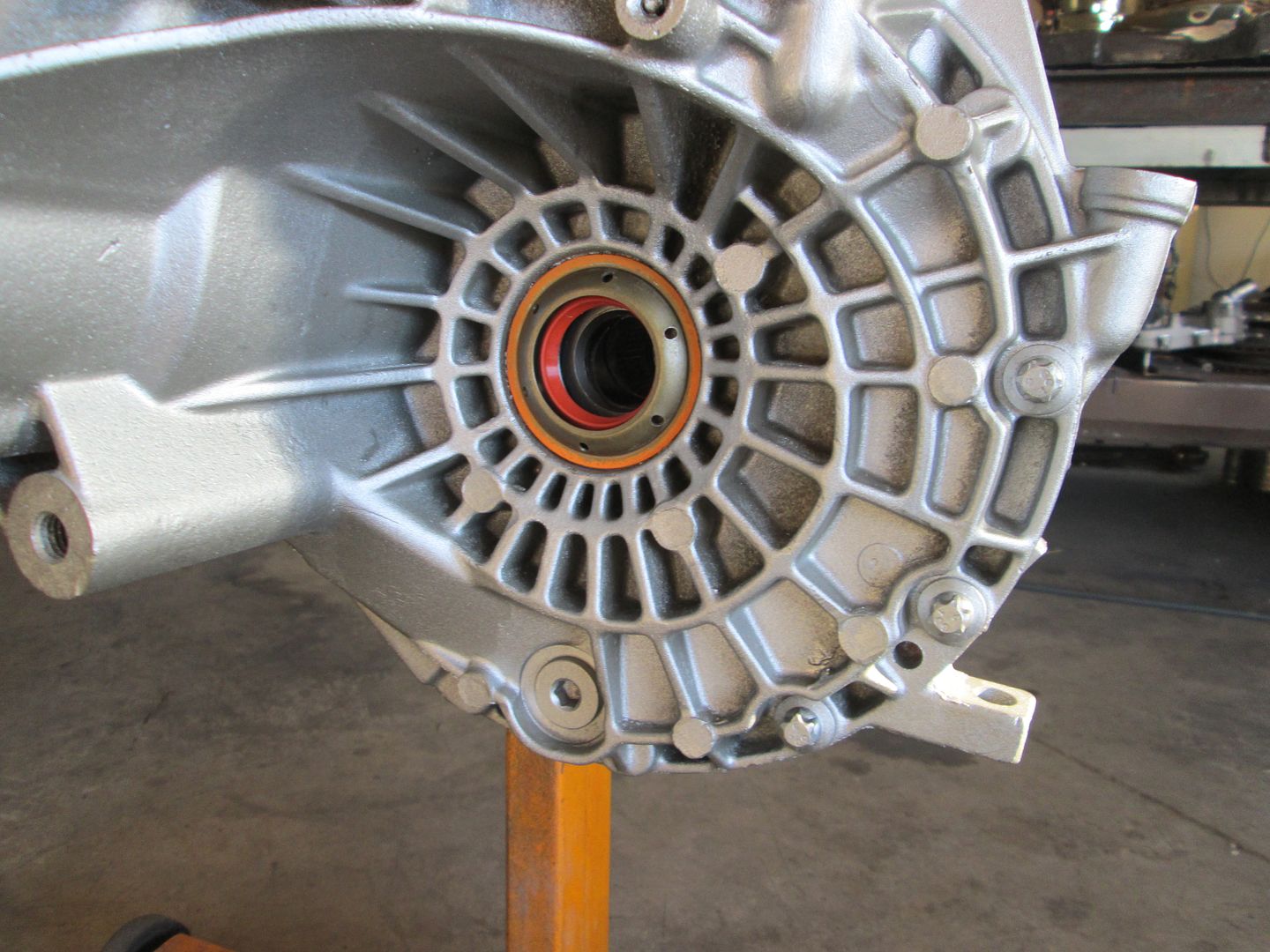

It was odd that there wasn't a cross shaft for the spider gears in the diff, so I pulled the VSS sensor and took a look inside. It has a limited slip (and a good one at that)!

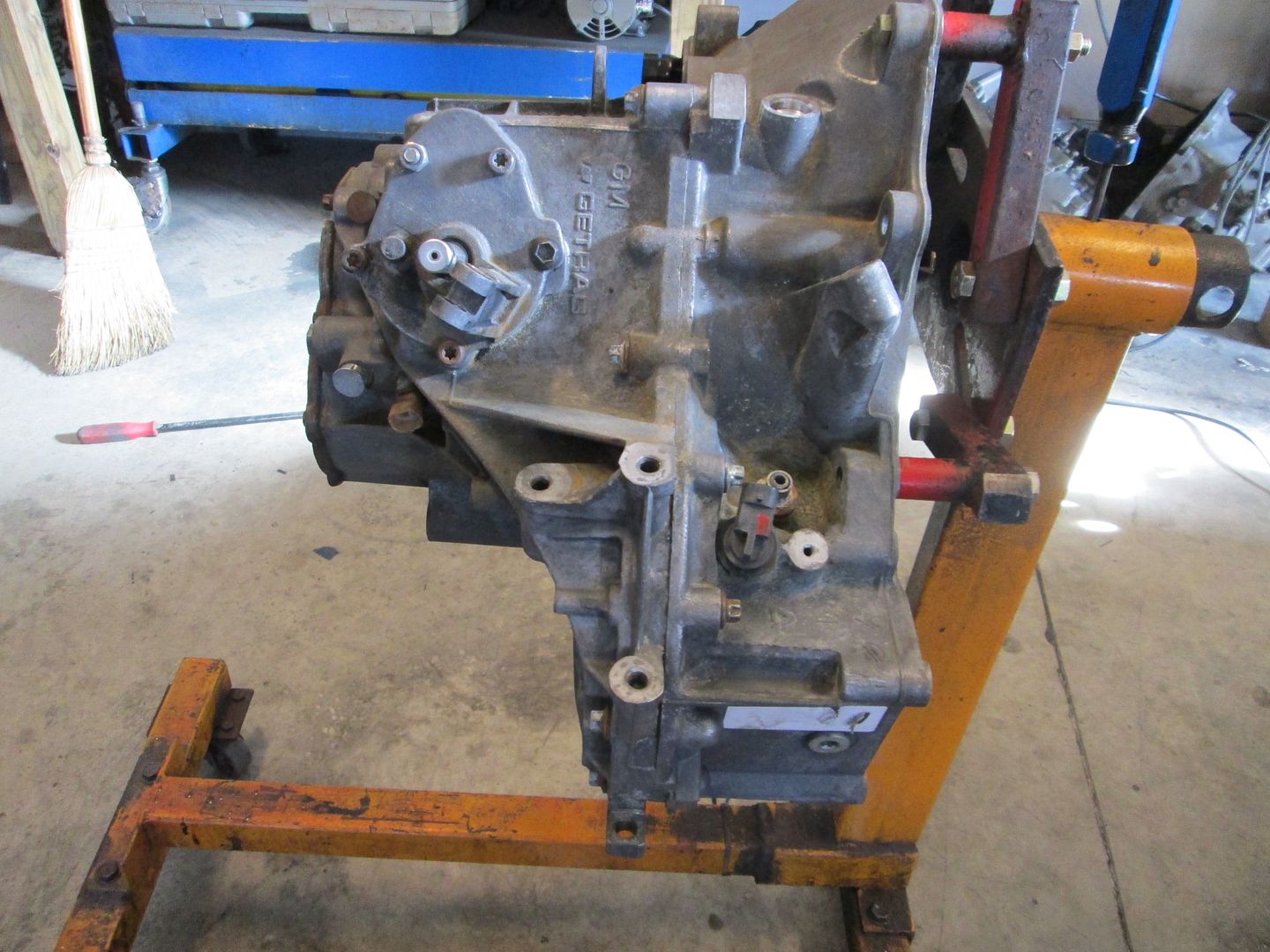

After the transmission was cleaned, I put it on the engine stand a wire brushed it some more to remove as much oxidation from it prior to painting it:

Taped off or capped off everything that should be painted and then painted it:

New Axle seals:

Then I reworked the shifter arm. I added some weld to build up some areas, ground everything smooth and removed the other side that wasn't needed any longer:

Cleaned and primed the shifter levers as well as the VSS bracket. I used tape to cover the ball studs, shafts and the square section that has a bushing slide in:

|

|

|

fieroguru

|

NOV 30, 05:41 PM

|

|

Sanded the coolant crossover tube and primed it:

Same with the cold air intake:

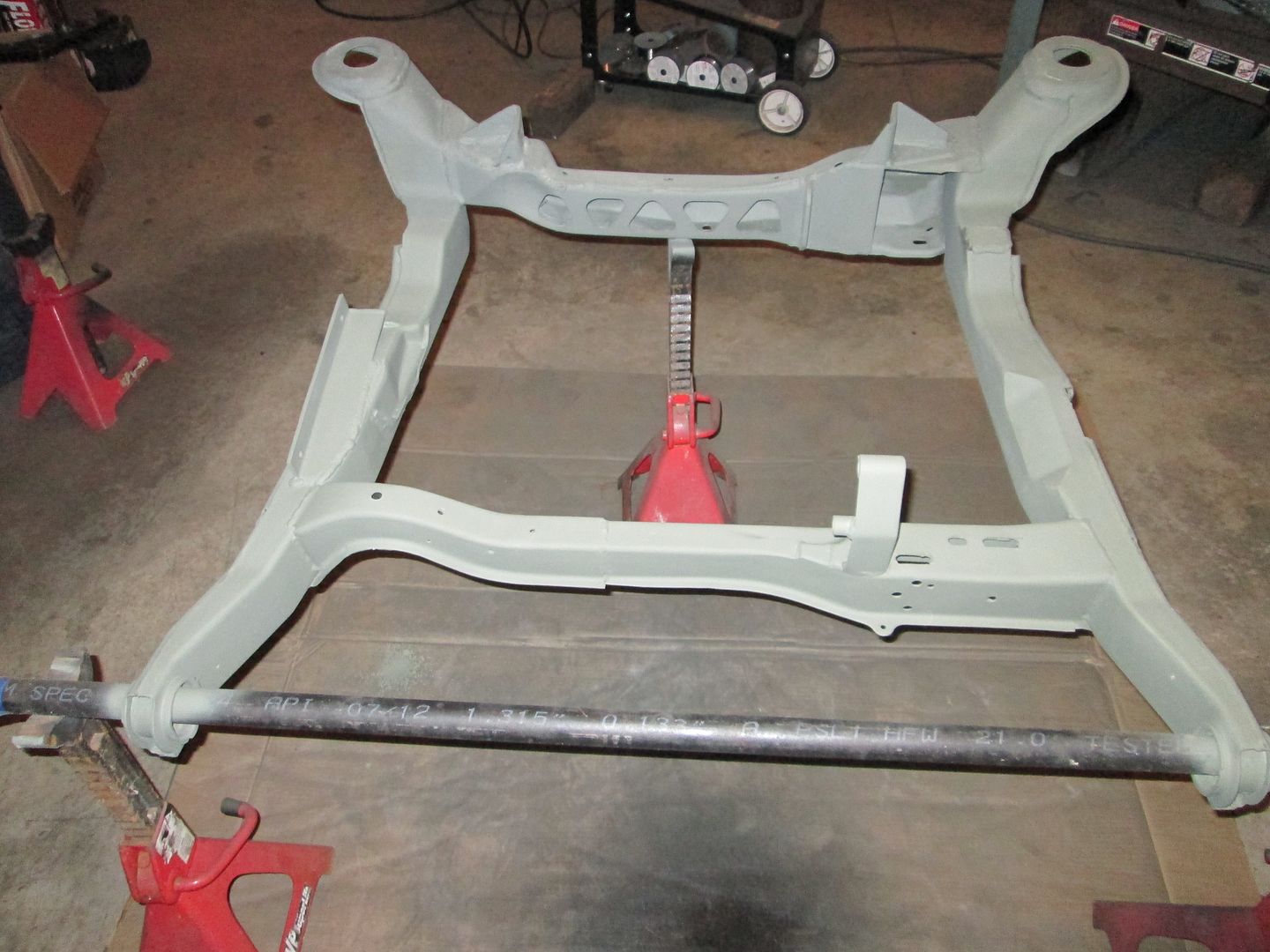

Still working on wire wheeling the cradle:

|

|

|

fieroguru

|

DEC 01, 06:57 PM

|

|

The cradle had a layer or two of paint, then topped with POR15 (which doesn't stick to paint or clean metal for that matter), so it was a pealing mess. I ended up wire brushing the whole thing down to bare metal:

Then primed it with self etching primer like all the other parts:

I think on Tuesday I will mix up some black paint and have a little parts painting party...

|

|

|

Jims88

|

DEC 02, 06:55 PM

|

|

WOW that's some serious wire brushing!

Turned out nice though!

|

|

|

|