|

| LS4 / F40 swap - fieroguru (Page 23/216) |

|

katatak

|

APR 26, 11:04 PM

|

|

Your work always amazes me Guru and now all my favorite threads are in the smae place!

Pat

|

|

|

mptighe

|

APR 27, 06:13 PM

|

|

fieroguru,

Since you helped me with some info, I'd like to repay the favor. I found a place to send the F40's in for cryo and WPC treating. If you want, they'll also order and install a Quaife LSD for you. The owner Dave says it will make the tranny easily hold 450 lb tq. He's done a bunch of them for Archie over the past couple of years. Anyway, if you're interested then you can find their contact info in my thread here... Not trying to hijack your thread, keep up the good work!

http://www.fiero.nl/forum/F...ML/085180-2.html#p62

|

|

|

fieroguru

|

APR 27, 06:19 PM

|

|

Accessory drive went from this:

To this:

114" belt to 80" belt

5 idlers, reduced to 3

Alternator up top at rear of engine to down low at front

PS pump from up top to in trash can (actually just sitting on the shelf)

Lots of stuff visible on top, to just the new tension idler[This message has been edited by fieroguru (edited 04-27-2011).]

|

|

|

dobey

|

APR 27, 09:24 PM

|

|

| quote | Originally posted by mptighe:

fieroguru,

Since you helped me with some info, I'd like to repay the favor. I found a place to send the F40's in for cryo and WPC treating. If you want, they'll also order and install a Quaife LSD for you. The owner Dave says it will make the tranny easily hold 450 lb tq. He's done a bunch of them for Archie over the past couple of years. Anyway, if you're interested then you can find their contact info in my thread here... Not trying to hijack your thread, keep up the good work!

http://www.fiero.nl/forum/F...ML/085180-2.html#p62 |

|

Honestly, I think installing an LSD will probably do more harm than good, if one intends to drive the car excessively hard (fast shifting, landing back near peak tq). And especially if one has good, sticky tires on good suspension. It is much more likely for stuff to break in that condition, since the LSD actually prevents slip from happening, where it would be useful.

|

|

|

fieroguru

|

APR 27, 10:08 PM

|

|

| quote | Originally posted by mptighe:

fieroguru,

Since you helped me with some info, I'd like to repay the favor. I found a place to send the F40's in for cryo and WPC treating. If you want, they'll also order and install a Quaife LSD for you. The owner Dave says it will make the tranny easily hold 450 lb tq. He's done a bunch of them for Archie over the past couple of years. Anyway, if you're interested then you can find their contact info in my thread here... Not trying to hijack your thread, keep up the good work!

http://www.fiero.nl/forum/F...ML/085180-2.html#p62 |

|

Thanks for the info, and am sure a few will find it useful.

Cryo treating transmissions has been around for quite some time and has been done to getrags and isuzu's with favorable results, but I am not convinced the F40 needs any additional upgrading. I fully expect to shear off the stock fiero outer CV at the wheel bearing hub before the F40 will give up the ghost, so it doesn't really make since to throw more $$ at the transmission unless I am going to do the same for the axles... and the axles really would need to come first. If/when I frag my first F40, I will look at doing something different, but until then dropping any additional $$$ into an essentially disposable transmission w/o any real proof of them being failure prone to begin with just isn't in my budget nor in the scope of my engine swap.

|

|

|

dobey

|

APR 28, 10:32 AM

|

|

| quote | Originally posted by fieroguru:

I fully expect to shear off the stock fiero outer CV at the wheel bearing hub before the F40 will give up the ghost, so it doesn't really make since to throw more $$ at the transmission unless I am going to do the same for the axles... and the axles really would need to come first.

|

|

Speaking of axles, have you figured out what solution you're going with there yet? Also, going with a half-shaft should help a bit too, since the axles should be much closer in length at that point.

|

|

|

fieroguru

|

APR 28, 01:11 PM

|

|

| quote | Originally posted by dobey:

Speaking of axles, have you figured out what solution you're going with there yet? Also, going with a half-shaft should help a bit too, since the axles should be much closer in length at that point. |

|

My problem is I think about stuff too much...

Longterm, I want to stuff some wide wheels in the back and want to upgrade the bearings/CV's and would prefer to run a 4 3/4" pattern (cheap/wide wheels). In looking at the stock 88 rear upright, I noticed that the bolt pattern for the bearing is not centered in the raised portions of the casting, they are slightly inset. I have some S10 4x4 front wheel bearings and while they will not fit in the center bore of the upright, their flange pattern is very close to being centered in the raised portion of the casting. So it might be possible to bore the upright to accept the larger wheel bearing, but before reaching the final size, weld the existing bearing bolt hole shut, finish boring the upright and then redrill the 3 mounting holes. I belive the uprights are ductial iron so welding the holes closed shouldn't be much of an issue.

Another approach to use the S10 wheel bearing... the center bore is very close to accepting the first step in the S10 wheel bearing. So I could make it fit this first step, then make a spacer ring (about 1/2") to suppport the bearing and change the bearing pattern. Doing this moves the wheels outboard, but I could just shorten the lateral links and pull them back in.

While researching this I have also been thinking about the G6 F40 axles... I have a set on the shelf and they come with a 30 spline at the wheel bearing. They already are a larger diameter (potentially stronger) than the stock fiero size stuff so I looked to see what wheel bearings came with 4 3/4" and 30 spline = C5 rear wheel bearings... I haven't confirmed that the diameter of the 30 splines are the same, but I do know the C5 stuff would come with ABS sensors and cost quite a bit more than the S10 ones currently setting on the shelf.

The largest diameter for the CV/bearing spline is from the later model 33 spline (3800 SC, N*, and most mid to full size FWD applications). I have a couple of these outboard CV's on the shelf as well and they would probably result in the strongest CV assembly. But the bearings that accept the larger 33 spline CV's do not come in the 4 3/4" pattern, but in the 115mm and others... and I am not sure I want to deviate away from the 4 3/4" pattern.

Right now, I am anxious to get this thing running, so I will most likely table the bearing/CV upgrade and just use the modified corsica tripod/axle for the DS (same one I built for my SBC/F40 swap) and take my two Saab intermediate shafts and make a longer one the needed length to allow a stock length G6/F40 axle to work (just need to swap out the CV end with a fiero one). Or I could use one of the Saab axles on the shelf as well since they have the fiero size outboard spline... this would save me from needing to swap the ends (a true factory axle assembly) and they are far more common and cheaper than the G6/F40 parts. Either option would allow my setup to run stock axle shafts and make replacement easier in the event I break one. If I happen to break the custom tripod housing or the custom length intermediate shaft... then I will probably go with a custom set of axles at that point using the largest components I can find.

I ordered the material to make the inner sleeve for the intermetiate shaft last night, so hopefully I will get started on it soon.[This message has been edited by fieroguru (edited 04-28-2011).]

|

|

|

dobey

|

APR 28, 01:21 PM

|

|

Haha. I know what you mean. I am trying very hard to keep myself from buying another car for a project right now. Don't need any more right now. The 2 I have is enough.

I was also wanting to use wider wheels/tires on mine, and the 4.75" bolt pattern, but I think I just want to get it running and in the car right now, and then go from there. Getting into changing all the suspension is just going to make it take much longer to get done.

I definitely am looking forward to see what your ideas for using the stock G6 axles with the extended half shaft come out like. You're doing a great job on everything so far. Awesome as always!

|

|

|

fieroguru

|

APR 30, 03:51 PM

|

|

The accessory drive is finished. Completed all the final welding for all the brackets, idler pulley standoff and the slight notch in the front crossmember:

Then I made a small bracket so the dipstick tube will attach to the front manifold:

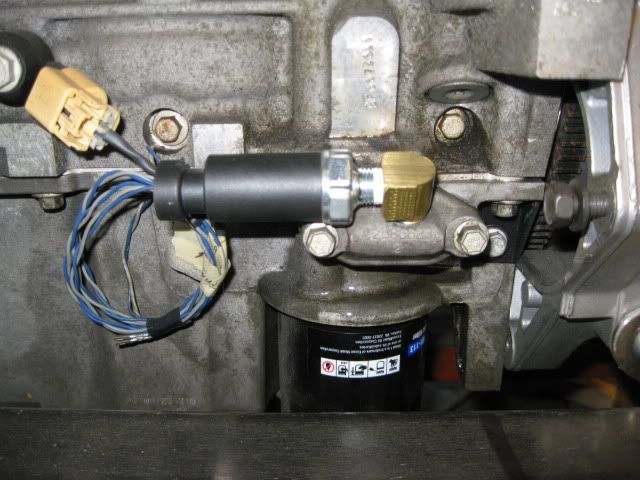

Drilled and tapped the oil bypass cover for the oil pressure sending unit for the gauge:

Relocated the temp sensor to the rear bank by cyl 8. This is the hottest cylinder and tends to be the first cylinder to detonate and kill the engine if excessively abused. Adding the 4 corner vent tubes will help eliminate hot spots, but I would rather have the ECM start pulling some timing in the event that cylinder 8 starts to get hot.

I am planning to drill/tap the coolant sensor hole by cyl #1 for the temp sender for the gauge. Still need to order a new fiero temp sensor.

Ran the welder out of Ar/CO2... so can't do any welding for the rest of the weekend. This should allow me to focus on the harness and other odds/ends for a couple of days.

|

|

|

dobey

|

APR 30, 06:03 PM

|

|

| quote | Originally posted by fieroguru:

Relocated the temp sensor to the rear bank by cyl 8. This is the hottest cylinder and tends to be the first cylinder to detonate and kill the engine if excessively abused. Adding the 4 corner vent tubes will help eliminate hot spots, but I would rather have the ECM start pulling some timing in the event that cylinder 8 starts to get hot.

I am planning to drill/tap the coolant sensor hole by cyl #1 for the temp sender for the gauge. Still need to order a new fiero temp sensor.

|

|

Isn't #8 on the other side, and #1 the one nearest the passenger side strut tower? I think you need to move that sensor to the other side if you want the #8 cylinder.

|

|

|

|