|

| LS4 / F40 swap - fieroguru (Page 194/216) |

|

Will

|

DEC 13, 08:09 PM

|

|

| quote | Originally posted by fieroguru:

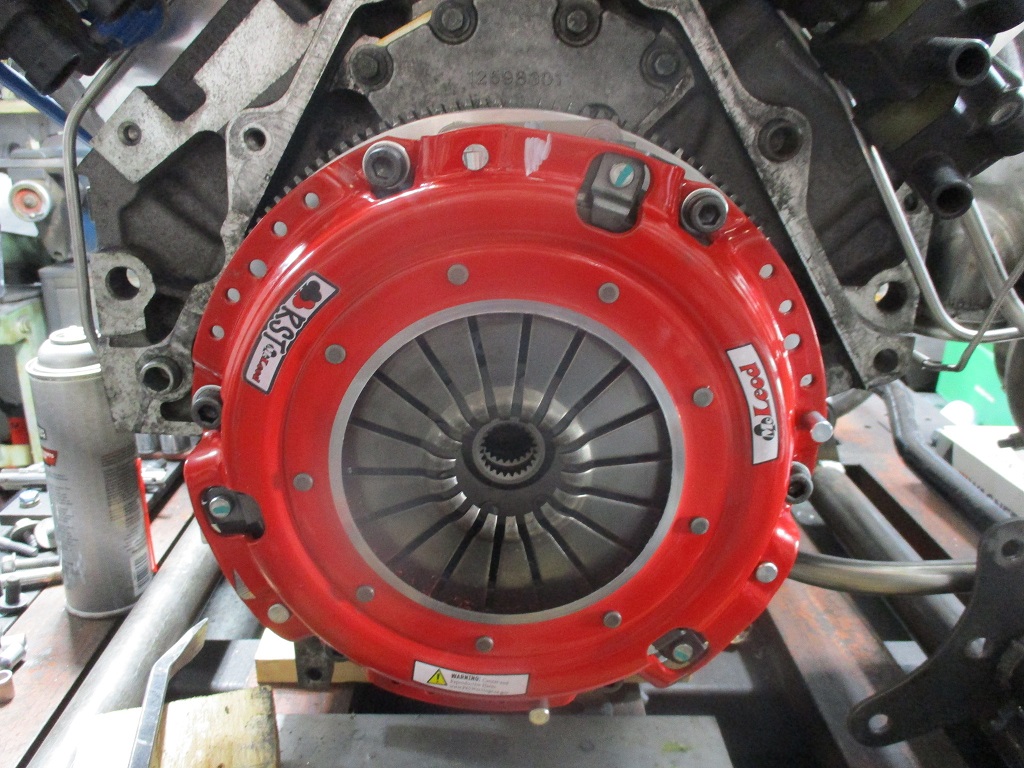

McLeod RTS 91/2" twin disk clutch, organic disks, with some slight modifications. It is a super tight fit.

This post is on page 46.

[QUOTE]Originally posted by fieroguru:

Flywheel and twin disc clutch are now done.

Sequence of installation

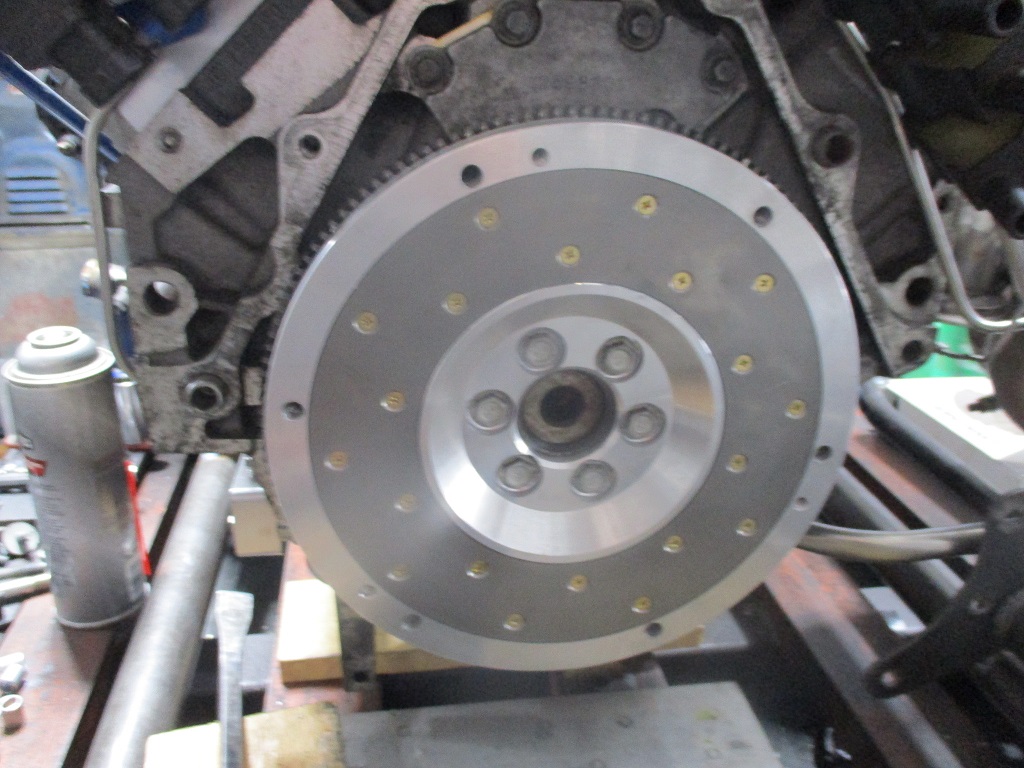

Flywheel:

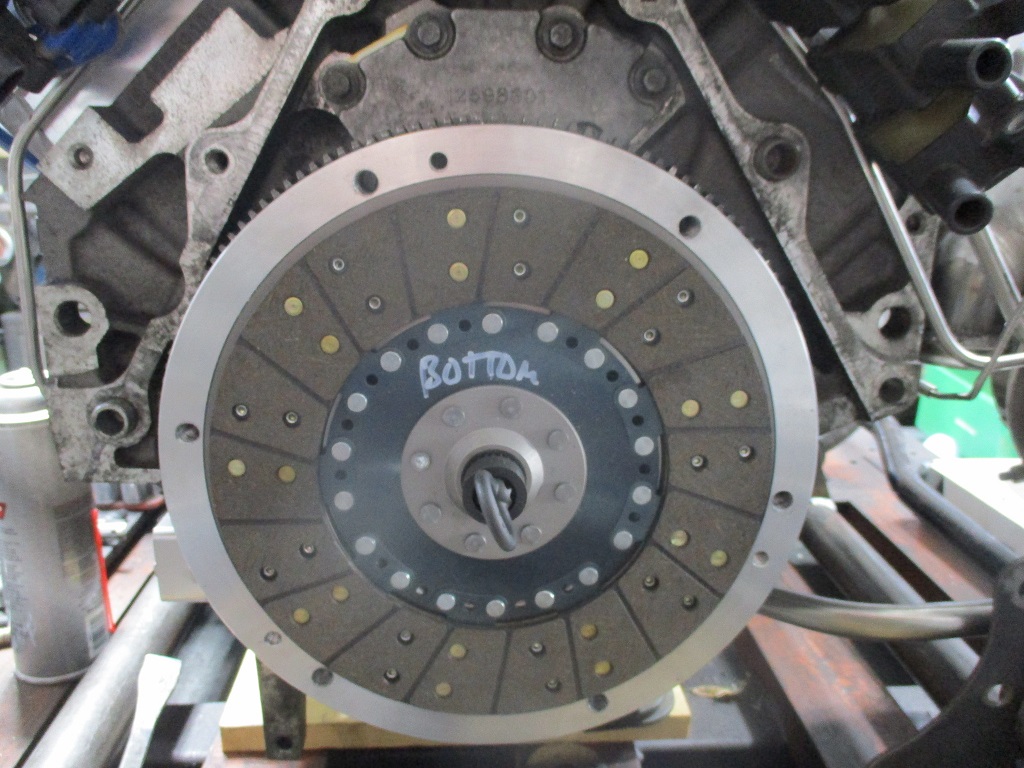

Bottom Disc:

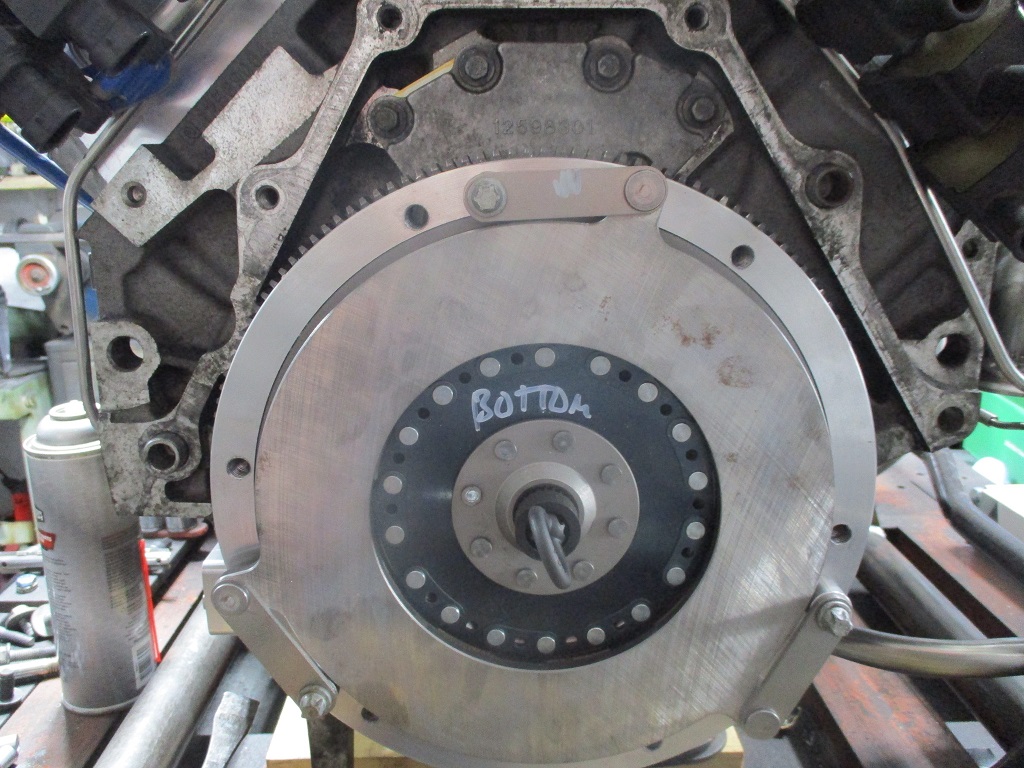

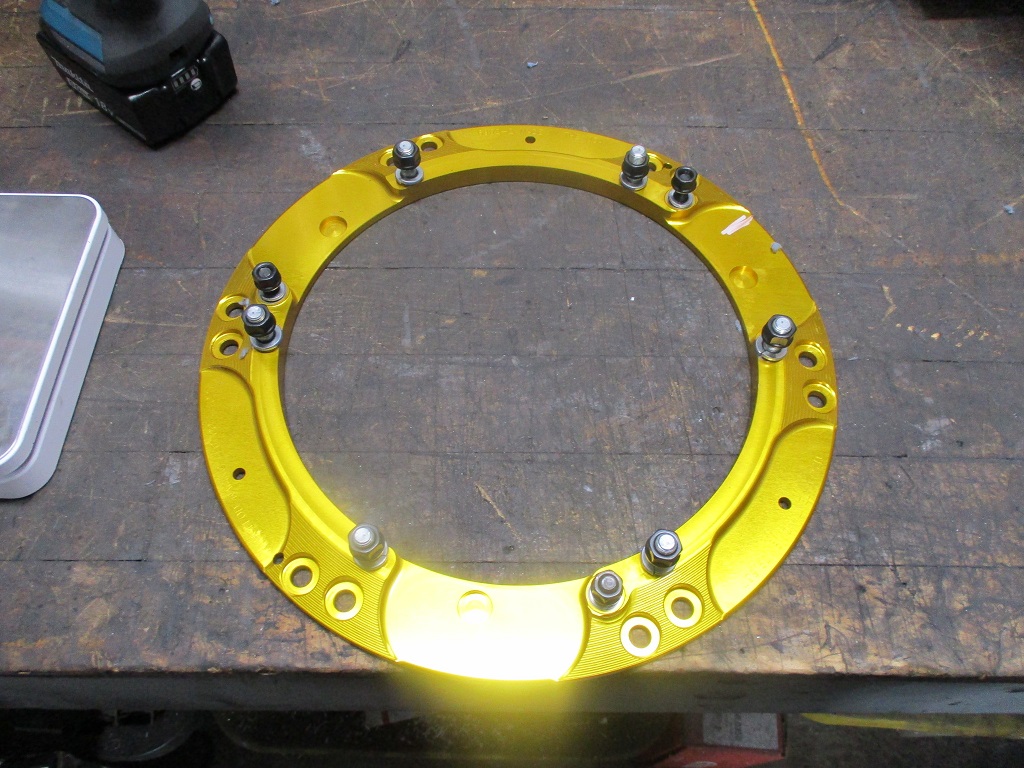

Floater Plate:

For some reason I missed taking a picture of the top disk.

Pressure plate:

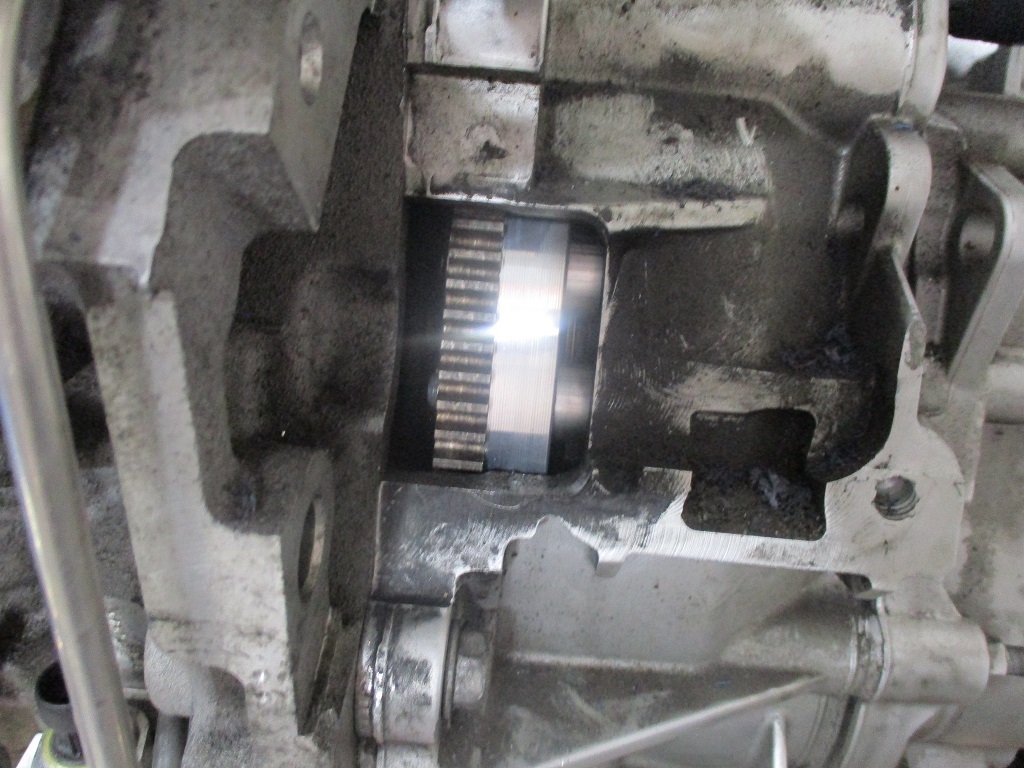

Transmission installed:

With my quest for weight offsetting for the turbo bits, the twin disc clutch is definitely heavier than my last setup.

However, like the turbo, the additional weigh is needed to hold up to 800 hp while keeping the car daily driver friendly, but the additional weight was still kept to a minimum.

For comparison, a stock 2.8 fiero setup is about 15 lbs for the flywheel and 15.6 lbs for the clutch/pressure plate = 30.65 lbs.

LS4/F40 Spec Stage 4+ combo is 11.2 lbs for the flywheel and 28 lbs total after 55K miles of use.

Stock 2000 LS1 is 24 lbs for the flywheel and 32 lbs for the clutch/pressure plate = 56 lbs and this weight is spread over a 2" larger diameter.

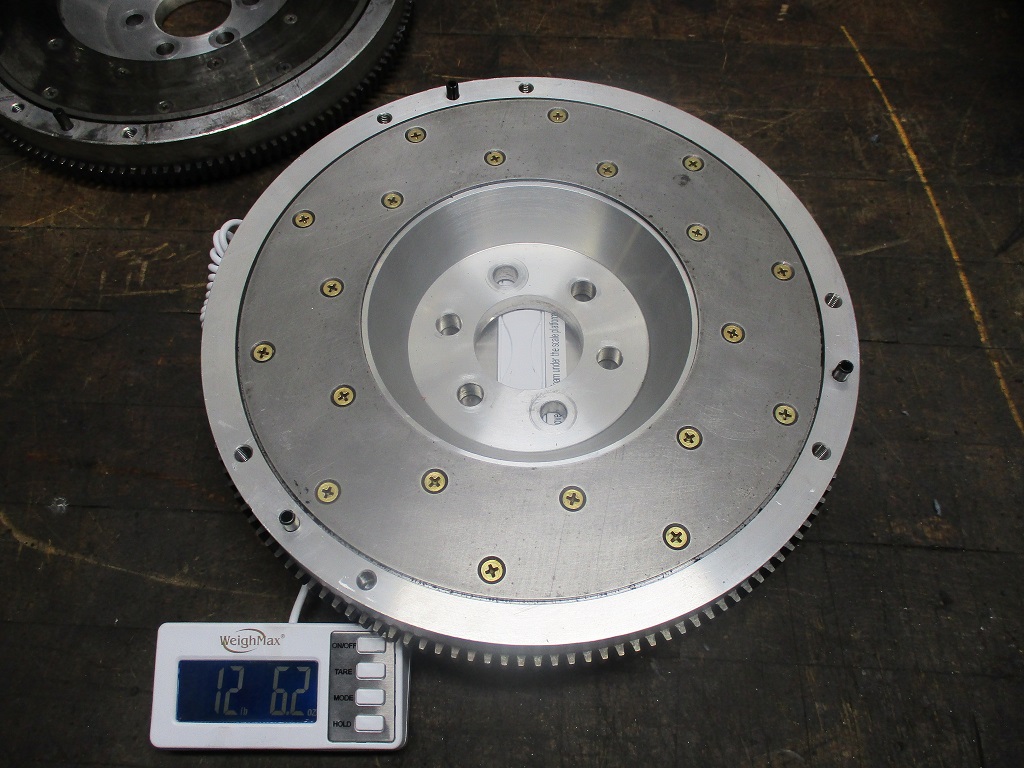

LS4/F40 flywheel/twin disc clutch combo is 13 lbs for the flywheel, and 21 lbs for the clutch discs, floater plate, pressure plate and all bolts. = 34 lbs So the setup will be about 3.5 lbs heavier than stock Fiero and 22 lbs lighter than a stock LS1 clutch setup.

The clutch did come with this plate so that it could reuse the stock flywheel/pressure plate bolt patterns... I tossed it as it wasn't needed. This saved 2.5 lbs off the clutch kit as delivered.

Here is a history of my LS4 flywheels:

Original prototype (after 55k miles) - fabricated with manual lathe and mill:

CNC version of original from small batch run:

Protype of the twin disc version - fabricated with manual lathe and mill:

The twin disc version is heavier as there is minimal material taken off the backside:

Now it is pretty much time to start cleaning things, sand blasting them and starting to make then look pretty.

|

|

[/QUOTE]

Ahh, cool. Thanks!

I have a PowerTrain Technology 7.25" dual disk. They list organic disks, but really don't want to sell them. It's weird. They steered me toward a unit with the thinner cerametallic disks. That's ok with me, as it let me package the assembly inside a 282 bellhousing without making a flywheel from scratch. We'll see how easy or otherwise it is to drive.

How does the throw out distance compare to the F40 HTOB range or to a stock clutch?[This message has been edited by Will (edited 12-13-2023).]

|

|

|

fieroguru

|

DEC 13, 09:32 PM

|

|

| quote | Originally posted by Will:

How does the throw out distance compare to the F40 HTOB range or to a stock clutch?

|

|

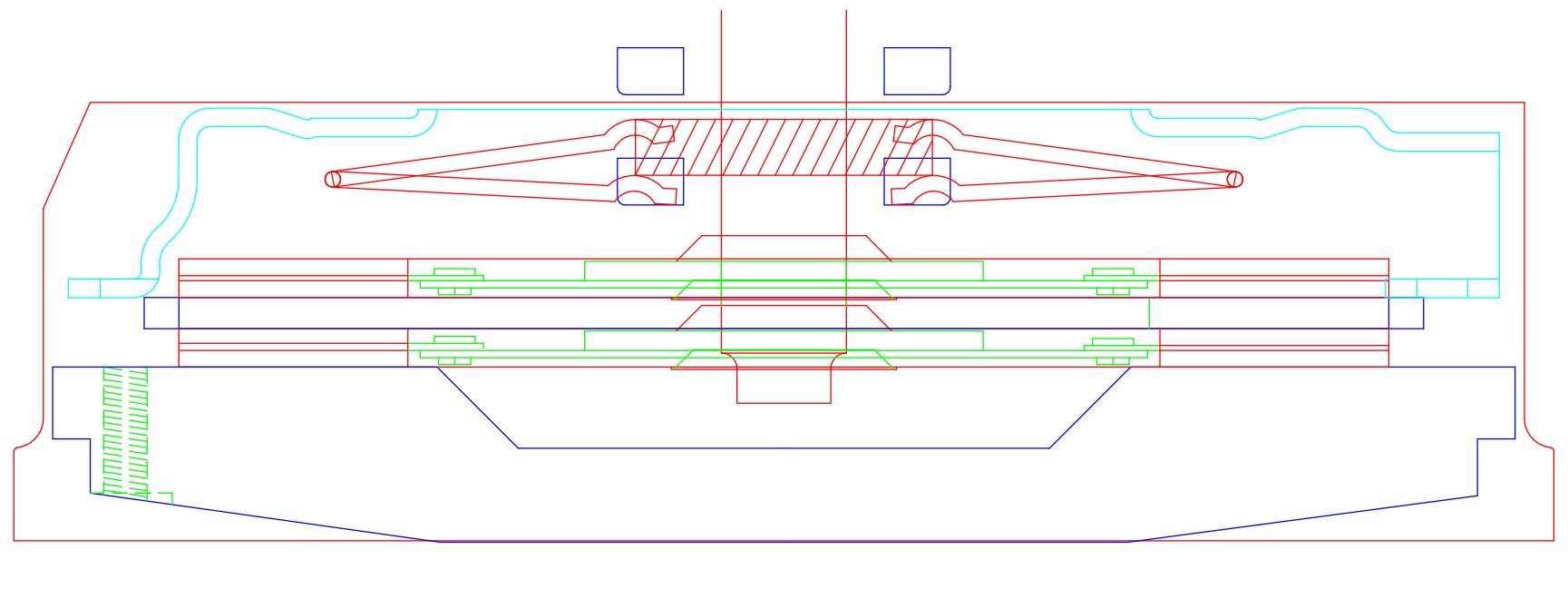

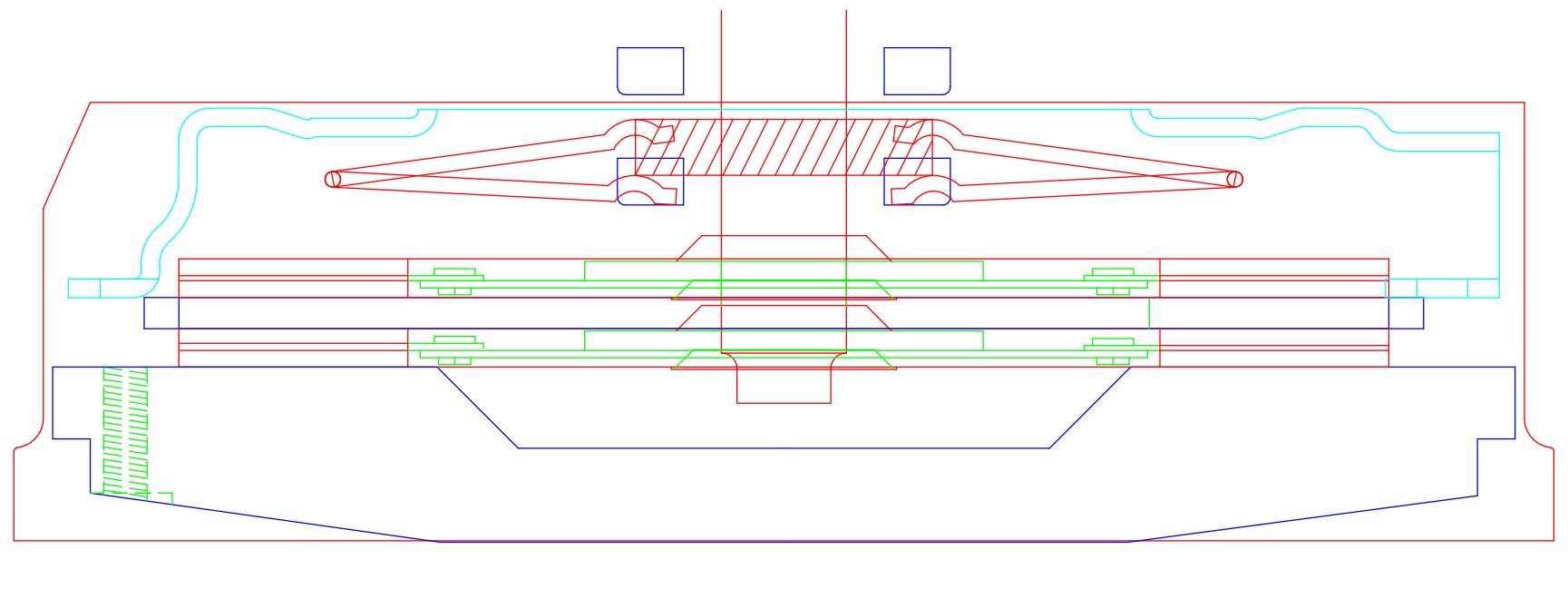

In this layout the 4 rectangular blocks in the upper center represent the F40 HTOB at full compression and full extension.

The positions of the pressure plate fingers are with the pressure plate bolted into position and the recommended throw to release the clutch. I spent a fair amount of time dialing in the thickness of the flywheel to ensure full spline engagement on the discs and in combination with the height of the flywheel to pressure plate spacers to position the pressure plate fingers optimally. Release is about 1/2 pedal travel and the clutch starts moving the car from a stop with the pedal about 1" off the floor. I have a Rodney clutch master with adjustable banjo and my clutch pedal is pretty much flush with the brake. I could adjust the clutch pedal higher.

When I start driving the car to work in the spring, I will likely have to leave my work boots at work and change into them at work. Size 13E work boots are a little snug with the pedals. Right foot barely fits past the brake pedal and console area to reach the loud pedal. Left foot on the clutch rubs the wheel well carpet quite a bit as well. My normal shoes work much better.

|

|

|

dskebo

|

DEC 14, 11:54 AM

|

|

does the car smoke under hard acceleration while driving? Blue smoke? I'm just curious if the turbo can scavenge the oil without backing up.

I love the way it sounds nice design.

|

|

|

fieroguru

|

DEC 14, 08:39 PM

|

|

| quote | Originally posted by dskebo:

does the car smoke under hard acceleration while driving? Blue smoke? I'm just curious if the turbo can scavenge the oil without backing up.

I love the way it sounds nice design. |

|

Thanks!

No smoke (blue or otherwise) once I got the tune dialed in.

|

|

|

fieroguru

|

DEC 27, 05:50 PM

|

|

It will be a few more weeks before I am back working on the car... The Saturday before Christmas I sprained my left ankle really bad falling down some steps. Dr. says I need to let it heal and wear a boot for the next several weeks, which will limit my garage time for a bit.

I did need to finish something before Christmas, so I hobbled around in the garage long enough to finish this for Sara!

|

|

|

fieroguru

|

JAN 14, 08:59 PM

|

|

I am getting around better with my ankle, so spent some time in the garage today.

Installed heat shield, stiffer wastegate spring, exhaust and the smart rearview mirror. Then I started the car and let it idle for about 30 min.

Maybe next weekend I can install the new zero-lash end links.

|

|

|

fieroguru

|

JAN 21, 07:26 PM

|

|

My ankle is getting better...

On Wednesday this week the boot was trades for an ankle brace and now I am back wearing my normal shoes/boots.

Here is a picture with the heat shield installed from last weekend. It has about 1/8" gap to the compressor as well as to the turbine heat shield.

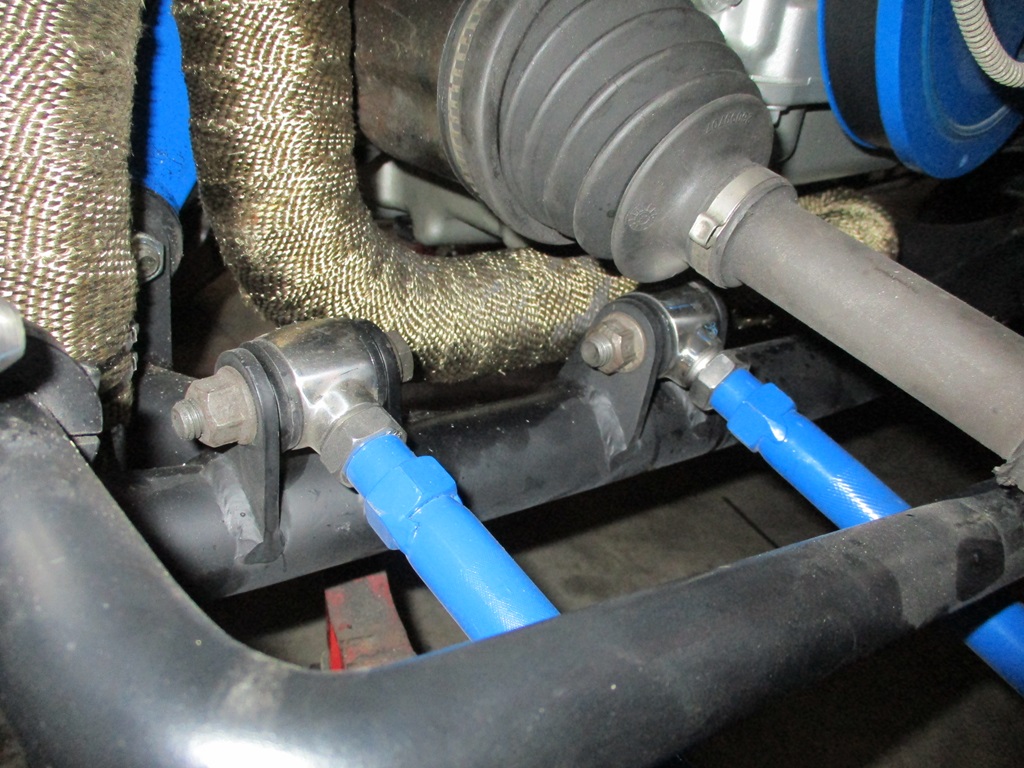

Worked on the lateral links and sway bar links this weekend.

I tried some new poly ends from Speedway motors earlier this year. They looked awesome, but the lateral links move to much front to rear as the suspension cycles, so they were binding and needed to be replaced before one snapped. At least 1 of them was bent when removed, so perfect timing. The driver side ones were pulled and rod ends put back in, but with a rubber boot this time. We will see if I they last more than 10K miles this time.

The zero-lash rod ends from the original swap are likely in a tote somewhere... The would have been too short anyway, so ordered the longest ones from Rodney. Once they arrived, they also were too short for the relocated sway bar, so took them apart and made them longer.

After Tuesday this week, the daily highs will be in the upper 40s and lower 50s for 2 weeks, so I would like to be done with the other side of the suspension by next weekend so I can take it for some more turning runs.

|

|

|

fieroguru

|

FEB 04, 07:11 PM

|

|

Last weekend I picked up 4 42x48 sheets of 1/8" steel to replenish my metal inventory. Then put the plasma cutter to work replenishing inventory of Lateral Link Relocation Brackets and the F40 Shifter Kit.

My youngest had some interest in the CNC plasma, so I walked them through the cad layout, sheet cam tool selection and g-code generation, then using Mach 3 to run the plasma table. Here is the end result. I am told it is some kind of video game.

This weekend I was able to finish up installing the rod end lateral links and zero lash end links on the passenger side. From there it was time to align the car. 1/2" conduit with precise hole locations, 0.025" welding wire, some spare rotors to hold everything in place, then square the assembly to the wheel centers, then align. Only worried about rear toe and thrust angle this time.

Then I took the car out for a spin. My left ankle is about 80% and I am still wearing the brace, but didn't have any issues driving the car! Only put about 20 miles on it then put it back in the garage.

Back to working on the interior... I picked up a new steering wheel, but will have to modify it. I also wasn't feeling the center portion of the wheel and wanted something more custom. Here is the start too the new steering wheel center:

Still need to weld up all the slots, smooth everything back down and then work on the insert.

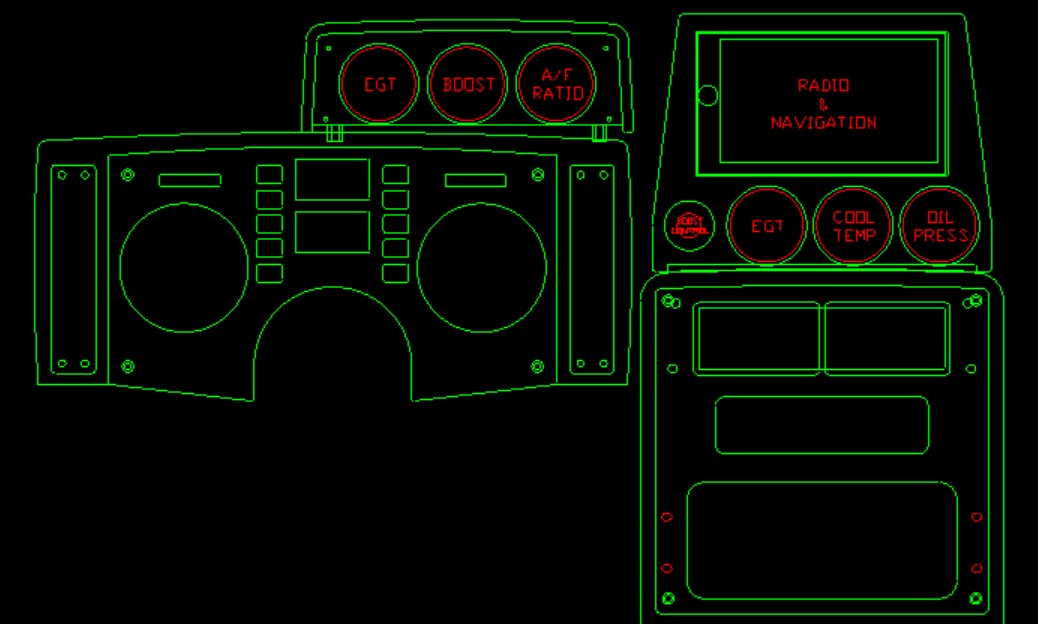

The current thought for all the gauges and 2din nav unit. Factory aux gauge housing with 3 gauges mounted over the instrument cluster and about 6-10" forward from the face of the instrument cluster. Then a custom housing where the aux gauges were to house 3 gauges, the manual boost control knob, and the 2DIN radio/nav unit.

[This message has been edited by fieroguru (edited 02-04-2024).]

|

|

|

Trinten

|

FEB 06, 06:54 PM

|

|

Nice, and if I asked this before I apologize, did you find gauges small enough to fit in the GT gauge pod? I see you're making a customer fascia for it which is cool.

I have a transmission temp digital gauge that I took apart, and it will fit in the space and display 95% correctly through the stock fascia, just haven't figured out a way to mount it in there yet.

So if there is a brand/series you can recommend and share how you'll mount the gauges in there, it would be appreciated it.

|

|

|

fieroguru

|

FEB 06, 09:43 PM

|

|

Vince, I cut out the prototype this evening. Just some slight modifications and it will be ready for install.

Most of my aftermarket gauges are the glowshift brand. They seem to barely fit, but fit they do. Most of these 2 1/16" gauges have a U bracket that bolts to the back of the gauge to hold it tight against the plate. I plan to install all the gauges on the plate, then install the plate in the housing. I will trim these U brackets down as they don't need to be as long as shown.

|

|

|

|