|

| LS4 / F40 swap - fieroguru (Page 182/216) |

|

fieroguru

|

SEP 04, 09:30 PM

|

|

| quote | Originally posted by ericjon262:

I see you have no intercooler, are you planning on water/meth injection?

|

|

No plans for water/meth, just E85.

Boost will likely stay in single digits to reach my initial power goals, so I am not concerned with excessively high intake air temps at the moment.

|

|

|

Bob2112

|

SEP 04, 09:48 PM

|

|

|

Looking great as always. Any news on the LS4 water manifolds? I looked back and last I saw was a small batch last year, but sounded like there were some quality issues you didn't like.

|

|

|

fieroguru

|

SEP 04, 10:42 PM

|

|

| quote | Originally posted by Bob2112:

Looking great as always. Any news on the LS4 water manifolds? I looked back and last I saw was a small batch last year, but sounded like there were some quality issues you didn't like. |

|

That is still the case. I purchased a CNC mill for delivery in December and the long term plan is to bring all machining operations back in house. I probably won't dedicate time to fine tuning the mill until I get my car back on the road. It has been down for almost 3 years now...

|

|

|

fieroguru

|

SEP 10, 08:03 PM

|

|

While I have the Fiero pulled away from the wall, I decided to play around with the stereo setup some...

Lets recap what the current plan is: Low profile 7" GPS/NAV/Rear CameraAndroid/Blue Tooth etc.. head unit to be mounted where the aux gauges normally are.

5 channel soundsteam nano amp mounted in the dash cubby.

For the speakers, I went a little nostalgic and chose Alpine:

4" for the B pillars

5 1/4" for the Dash

6 1/2" for the Fiero Store door panels.

Then it came to the subwoofer... the under dash box that Alex4mula made would allow an 8" sub. I made a mock up from card board (1 single piece, lots of cuts, bend slices and tape). I took out the stock sub housing with the modified tang bang and started to test fit. I still need to remove a couple of brackets to get it fully into place.

However, while I was messing with that box, I thought of another option... The passenger foot well has been done before, but this is a little different take on it. Basically the box hugs the side of the center console and extends from the face of the seat to the foot well at the very front. With it being 4" deep at the seat end, it ends up being about 5" deep in the foot well as the center console frame is tapered. This style box would allow me to run a ported 10" sub down in the foot well and under the dash with a port facing up right next to the HVAC control panel.

If I wanted the sub closer to the seat, then a 12" one will easily fit diameter wise, but the mounting depth would start to become a limiting factor.

|

|

|

Will

|

SEP 12, 09:40 AM

|

|

| quote | Originally posted by fieroguru:

Then it came to the subwoofer... the under dash box that Alex4mula made would allow an 8" sub. I made a mock up from card board (1 single piece, lots of cuts, bend slices and tape). I took out the stock sub housing with the modified tang bang and started to test fit. I still need to remove a couple of brackets to get it fully into place.

|

|

I made a mock-up like that a few years ago. It can be MUCH better by relocating the convenience center and blue dingy thingy--or rather the blue dingy thingy socket if you've properly removed the blue dingy thingy--somewhere else, allowing the box to occupy that volume in a more compact box shape. That results in better volume for an 8" sub.

If you gotta have a 10 or 12, your options in a Fiero are limited.

|

|

|

fieroguru

|

SEP 19, 06:54 AM

|

|

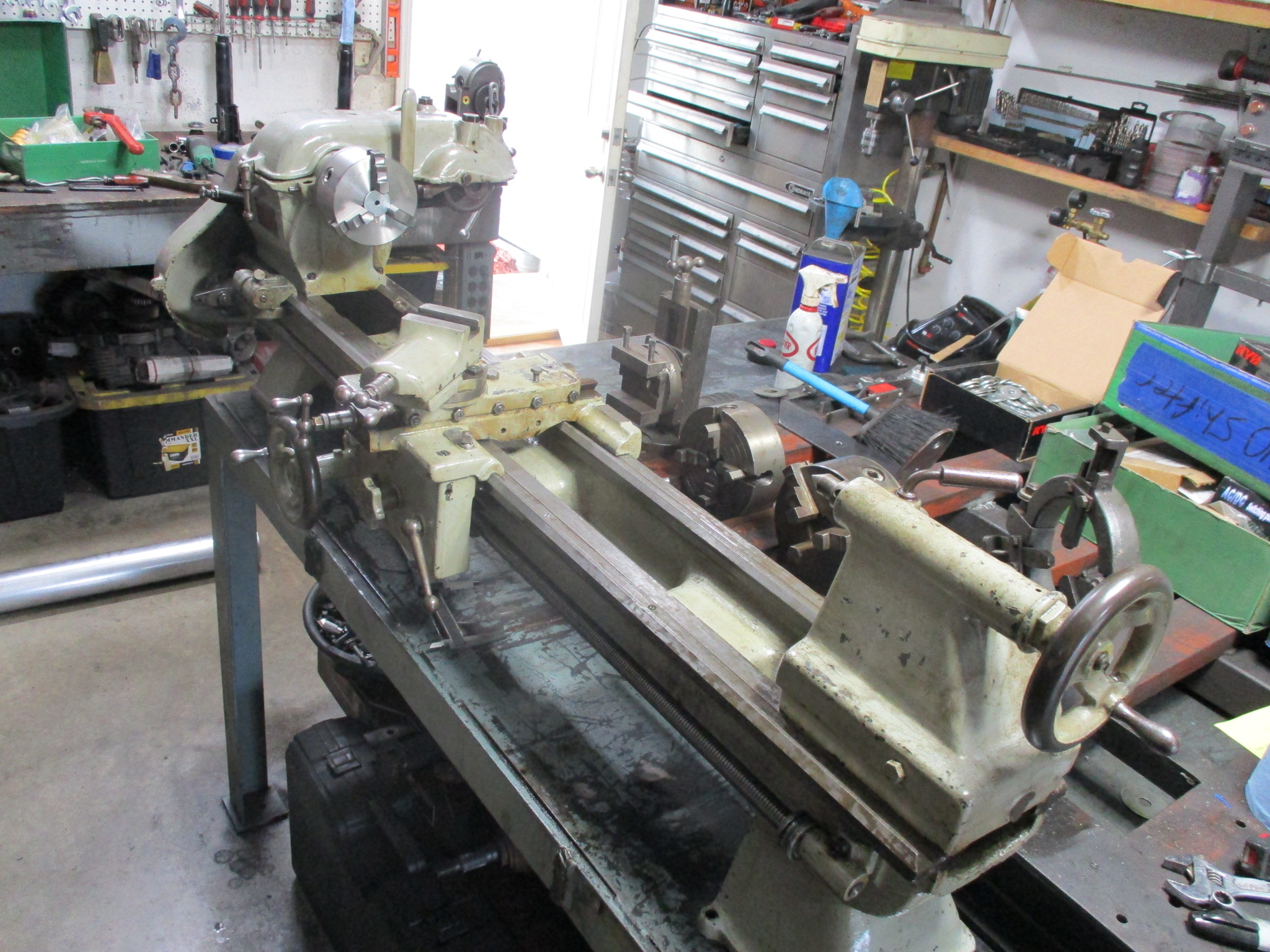

This past week a 12" Clausing 100 lathe popped up on Craigslist about 2 hours away. For some reason this 12" lathe is about 12 5/8" to the ways and a portion of the ways right by the chuck was modified to 13.5" (6.75" to the center). Since I was looking for one that would swing a thin 13 5/8 to 13 3/4 disk, I picked this lathe up and plan to use it to replace the 9" Southbend lathe and the Aamco 3000 brake lathe (working on freeing up space for the new CNC mill to arrive in Dec). I have already ordered the DROs for it and will pick up a new 120V 1ph motor for it (came with a 3000+ RPM 120v motor.

|

|

|

fieroguru

|

SEP 24, 07:45 PM

|

|

Today was a busy day getting the lathe ready...

Picked up new 1750 RPM 120V motor

Ordered dual pulley for motor (2" and 2 1/2") - this will give me 300, 500, 627, 833, 1045, 1741 rpm options

Wired up motor to on/off switch

Created captive nuts for the motor mount stands

Mounted motor on mount stands and clamped them to the table

Clamped the lathe to the table

Test ran lathe

Installed new chuck backing plate

Trued up backing plate

Installed chuck and verified trueness

Installed cross side DRO (fabricated 2 brackets, drill/tap several holes)

Modified the bed of the lathe in non-critical areas to fit a RWD LS flywheel

I still need to fab up everything for the main DRO and some chip guards for the DRO rails, then it will be time to start cleaning up the 9" one so it can find a new home.

|

|

|

fieroguru

|

OCT 02, 09:08 PM

|

|

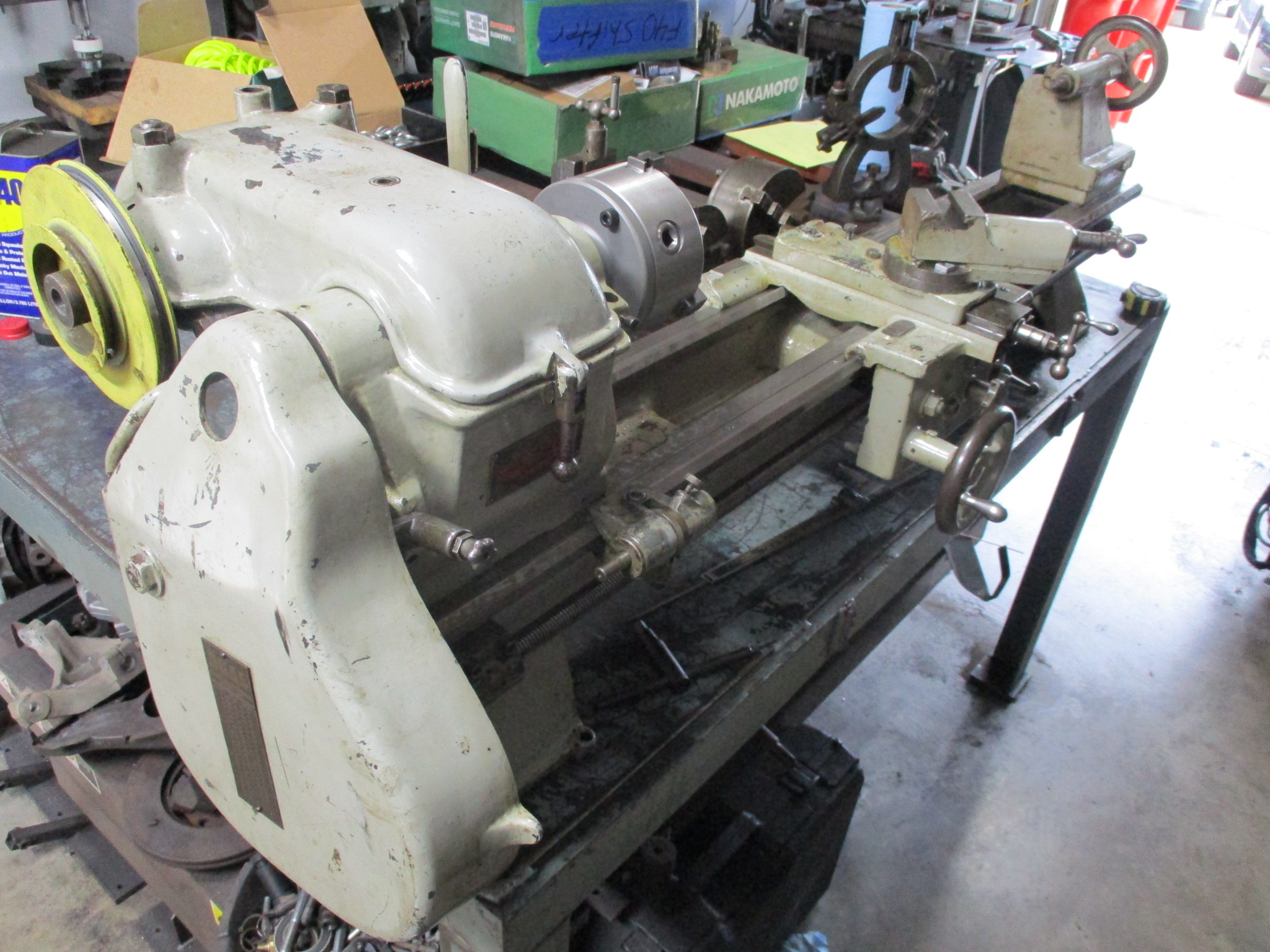

After doing some tests with the Clausing, it was time to clean up the 9" Southbend and find a new owner. Here it is all cleaned up. I listed it pretty much as you see it here with everything shown.

I must have asked to little for it, had full asking price in cash in my hand in under 24 hours... It went to a good home.

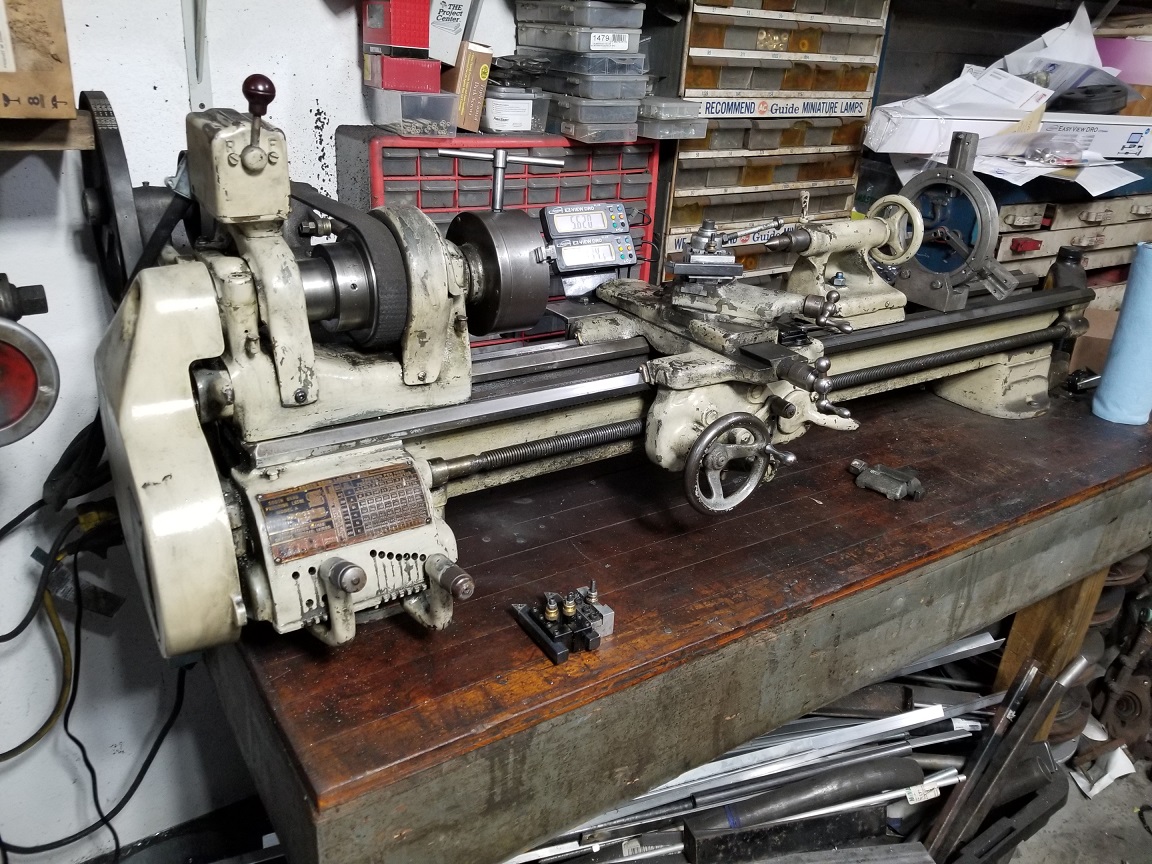

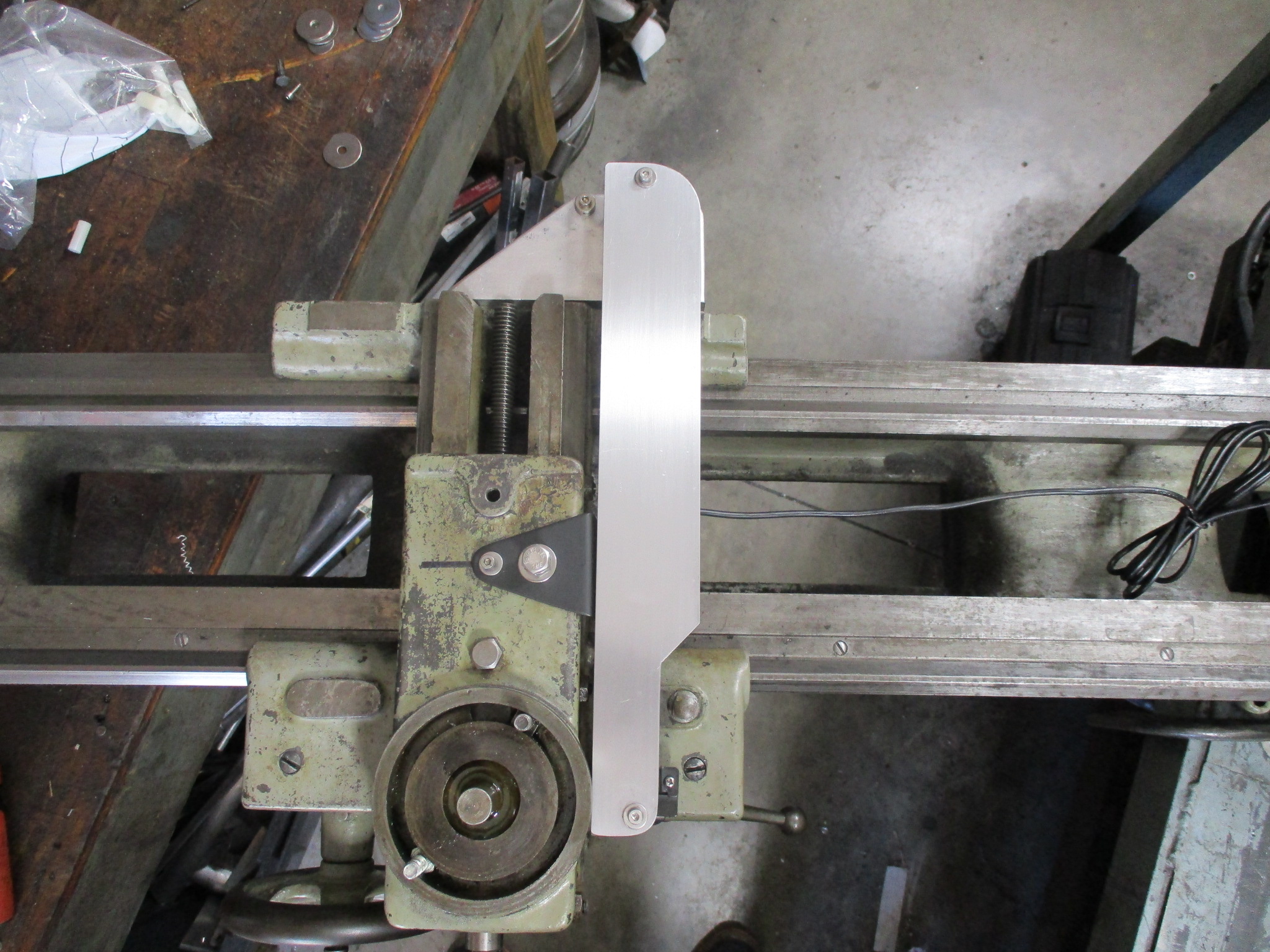

This weekend I finished up most of the DRO install on the Clausing. Similar install as I did on the Southbend, but took the extra step to add some chip shields for them. I found it easier to access both sides of the lathe with is spanning the walk way between the bench and the metal table.

After the DROs were mounted, The lathe was moved over to the work bench that would be its final home. I am still working through the final placement of the lathe as I would like to install a tool box for all the tooling against the wall and relocate the two sets of bins. The motor will be mounted under the bench (just shown on top so I could check belt alignment as well as where the mount holes would be), so I need to add some wood supports on the bottom side. I also need to find a spot to mount the DRO readouts as well as the start/stop button.

The new tool post and holder also arrived. A little larger than I needed, but all steel and will be very sturdy. You can also see I am in the middle of modifying a dual 2.6" pulley to a dual 2.6" and 2.0" pulley.

If everything goes to plan, I should be all done with the lathe replacement by the end of next weekend...

|

|

|

fieroguru

|

OCT 09, 05:16 PM

|

|

The lathe replacement project is pretty much done at this point.

Finished the motor mount frame under the table.

Verified and purchased proper length of belt.

Determined location of start/stop and fabricated a bracket to hold the box.

Made tube/threaded rod to hold the DRO displays.

Bolted the lathe to the table.

Setup all my cutters in the new holders and set the holders to the right height.

The 26x18 aluminum cookie sheets for chip trays came with lots of perforated holes, so I sent them back and order a new set.

|

|

|

fieroguru

|

NOV 26, 03:17 PM

|

|

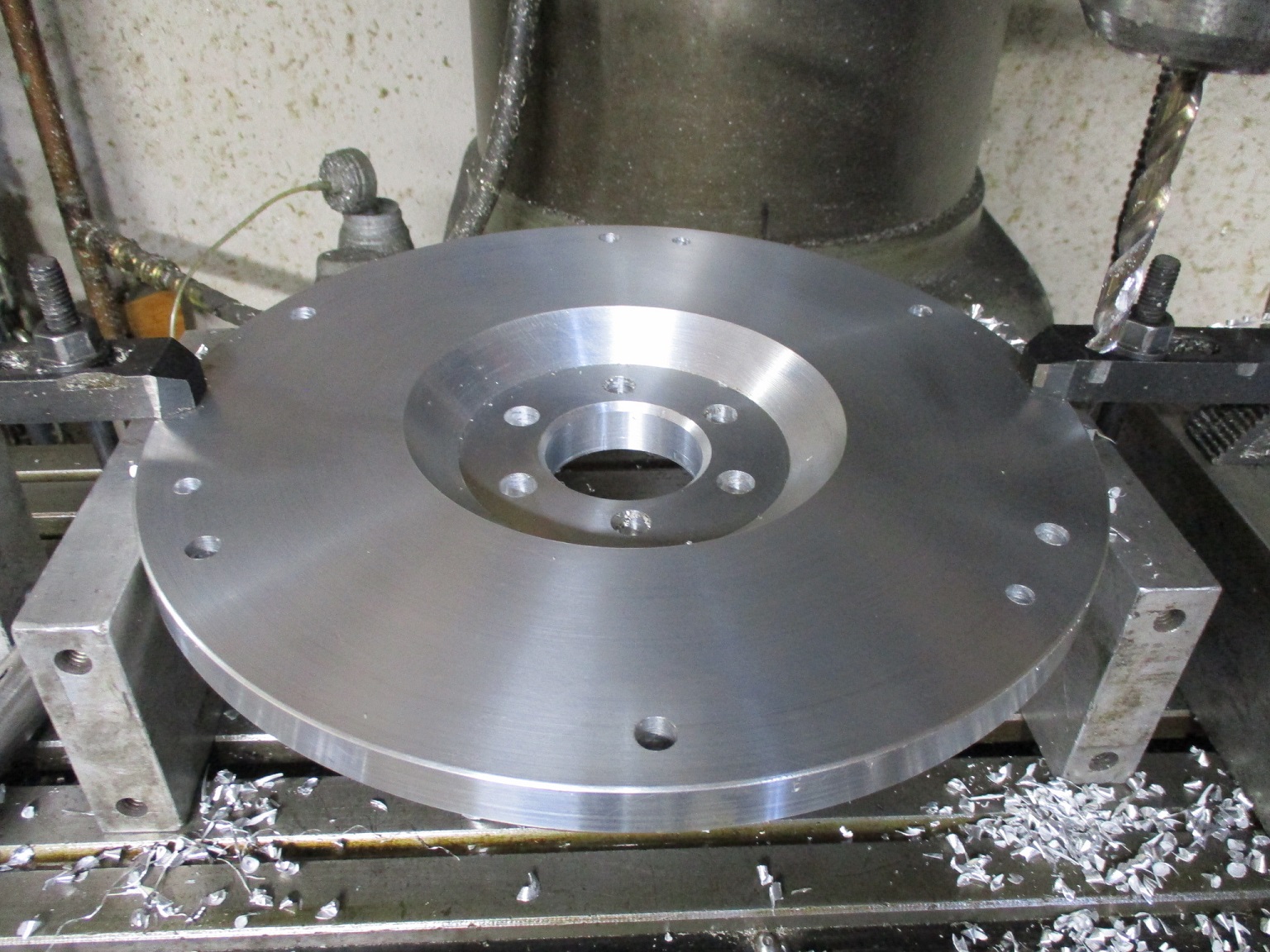

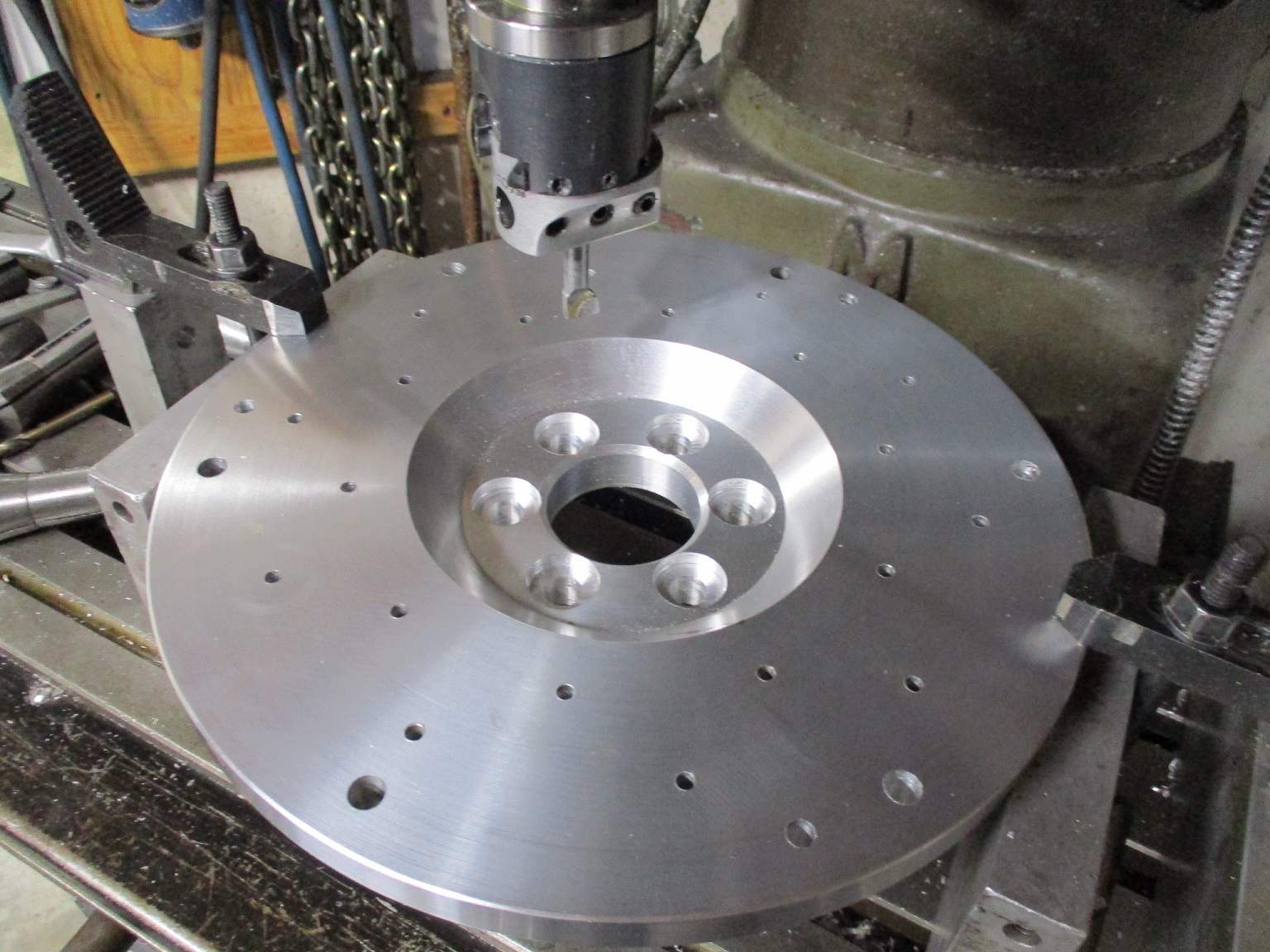

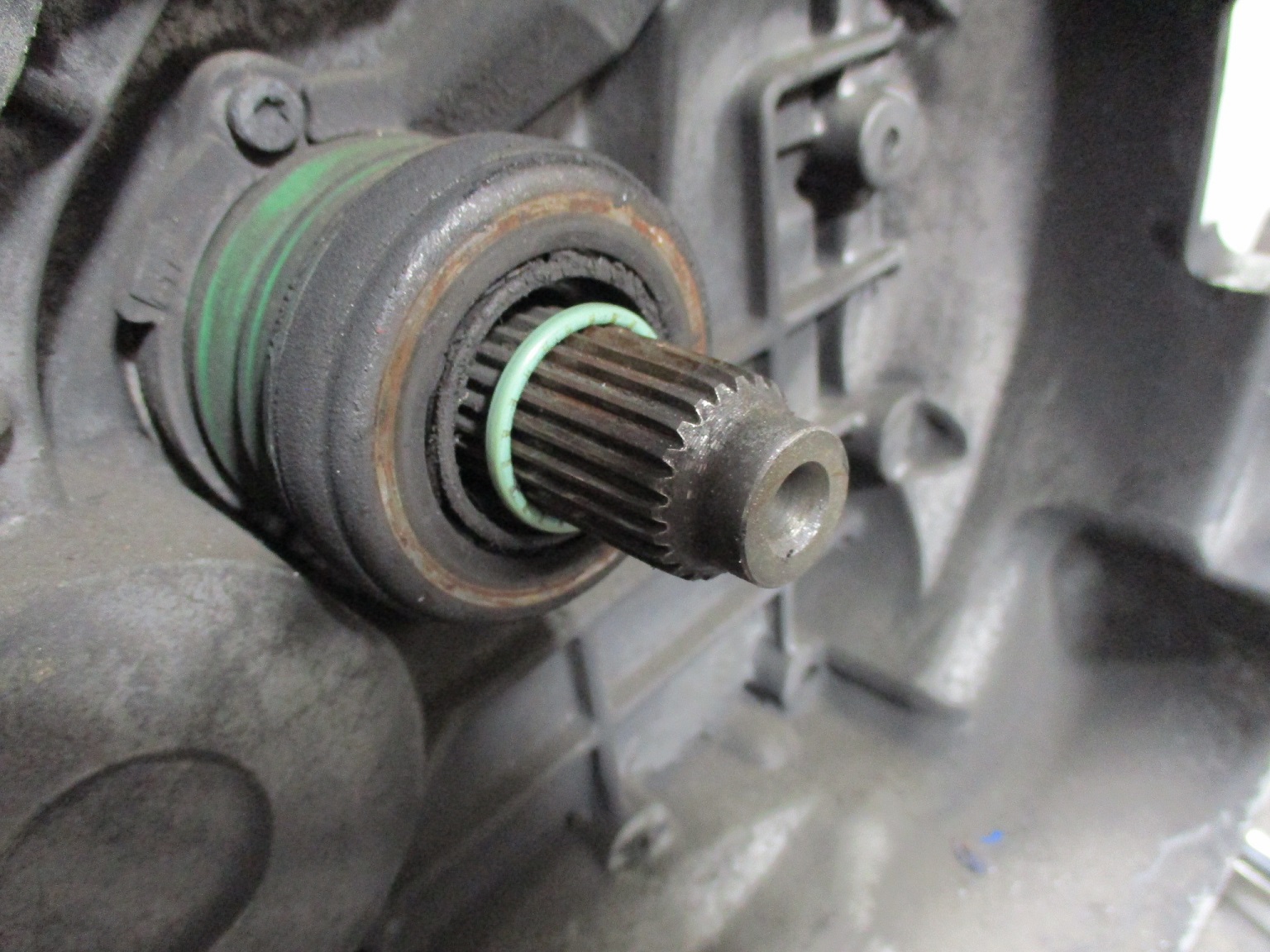

The 12" lathe has been busy - and this was a primary reason for upsizing...

New custom flywheel for dual disc clutch.

It is a super tight fit, but with a couple of minor modifications to the pressure plate, I was able to get full spline engagement on both discs as well as adequate finger clearance for wear.

This clutch uses organic clutch material like OEM for good drivability and is rated for 800 hp, which should hold the 550+ rwhp I plan to throw at it.

|

|

|

|