|

| LS4 / F40 swap - fieroguru (Page 17/216) |

|

fieroguru

|

MAR 21, 05:59 PM

|

|

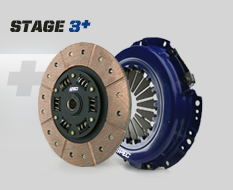

I have put a combined 45K miles on my SBC/Getrag setup with a Spec Stage 2+, Stage 3 and Stage 3+ so. These were 9 1/8" and while the Stage 2+ had the absolute best street manners, it wouldn't hold. I chose that clutch after trying the Stage 3 (sprung 6 puck). It would hold the power, but sucked with driving it daily in stop/go traffic. The stage 3+ had street manners much closer to the stage 2+ and would hold the power. Here are some generic pictures to show the difference between the Spec Stage 3 and the Spec Stage 3+

The Stage 3 was developed to improve the street manners of the Stage 3 series while still having excellent holding power.

The Clutch I am going with is a Stage 4+. The only difference between the stage 3+ and Stage 4+ is the solid hub vs. the spring hub. My old SBC setup was solid mounted and the LS4/F40 setup will be rubber isolated, so that should help smooth out the engagement. Also the 9 7/8" diameter vs the 9 1/8" should also help smooth the engagement as well... only one way to know for sure.

For the guys looking for a less aggressive clutch, Spec offers this clutch in all their various stages (which are much cheaper). AC Delco also offers a kevlar disk version as well, and Autozone sells a stock and heavier duty one (higher clamp load pressure plate).

The downside of this clutch is it will require a custom flywheel... but that is part of the F40 challenge in general.

|

|

|

fieroguru

|

MAR 21, 06:07 PM

|

|

LS4/F40 is back in for more test fits...

The relocated frame notch is going to workout just fine:

Here is the clearance to the decklid hinge box... but the water pump isn't on the engine.

Both hinge boxes are being removed. I got the idea from Jefrysuko at the 25th and hope to have that modification done in the next week. So with them going away, my aluminum firewall panel will also need to be removed and replaced:

Here is a very rough mockup of the exhaust as it would exit the rear.

Wednesday this week the wife and girls are going to Chicago to visit family for 10 days! The lack of daddy duties and noise/fume curfews for 10 days should really help speed things up a great deal!

|

|

|

fieroguru

|

MAR 23, 07:38 PM

|

|

Here are a couple more progress pics to show how the exhaust will be routing:

It is 2 1/2" coming from under the oil pan, into a flex coupler then to 3" mandrel bend into the muffler. The rear bank will come down and merge into the 3" section prior to the muffler... that one will take some time.

|

|

|

rcp builders

|

MAR 23, 09:16 PM

|

|

| quote | Originally posted by fieroguru:

I have decided on a clutch.

It will be a Spec Stage 4+ (solid hub and solid ring of friction material) of the version I just test fitted. The list price is over $600, but it includes a HTOB that I will not need, so maybe I can get the cost down some.

Yes the clutch is alittle overkill at the moment, but wanted to make sure it would hold any future upgrades (NOS, Turbo, stroker kit, or a 6.0, 6.2). |

|

Hey Guru,

First, great work!!!

Second, I have the spec 4+ with the springless hub and solid disc material. It is a very streetable clutch, it does like a little rev (maybe 1700) but will engage

very smooth with that. G/L Ray

|

|

|

Ruffy

|

MAR 23, 10:13 PM

|

|

|

unreal motor build! there is easier ways of getting 400 hp though hahaha. but seems like you got a good head on your shoulders and know what you are doing. very nice build! i cant wait to hear it and see it run on youtube or in person.

|

|

|

engine man

|

MAR 24, 01:42 AM

|

|

|

this is a great thread and a top notch build . in the futuer do you see your self having the block sleved to a bigger bore i know Darton can bring it out to 4.250

|

|

|

fieroguru

|

MAR 24, 07:50 AM

|

|

| quote | Originally posted by engine man:

this is a great thread and a top notch build . in the futuer do you see your self having the block sleved to a bigger bore i know Darton can bring it out to 4.250 |

|

I probably will not mess with resleeving the block. If decide to increase cubes, I might stroke it or just get a 6.0 or 6.2 short block. The LS4 block is actually longer than the LS4, so there is room to put a 3/16 to 1/4" adapter plate on the RWD block without increasing the overall width of the engine/transmission. You still need to shorten the crank 3mm at the flywheel and 10mm on the font, but I could drop a RWD block in with minimal rework of the existing setup.

Fuel efficiency at interstate speeds is a primary goal for this swap, so there is a better chance I would add a turbo (in the rear where the muffler is) vs. adding cubes...

|

|

|

dobey

|

MAR 24, 10:24 AM

|

|

| quote | Originally posted by fieroguru:

I probably will not mess with resleeving the block. If decide to increase cubes, I might stroke it or just get a 6.0 or 6.2 short block. The LS4 block is actually longer than the LS4, so there is room to put a 3/16 to 1/4" adapter plate on the RWD block without increasing the overall width of the engine/transmission. You still need to shorten the crank 3mm at the flywheel and 10mm on the font, but I could drop a RWD block in with minimal rework of the existing setup.

Fuel efficiency at interstate speeds is a primary goal for this swap, so there is a better chance I would add a turbo (in the rear where the muffler is) vs. adding cubes... |

|

If you do increase the cubes with an LS2/3 block, you could just swap in the LS4 crank instead of machining the RWD crank. All the LSx cranks are the same stroke, save the 4.8 and 7.0 engines which are slightly shorter or longer, respectively. If you want to stroke it, then machining the ends on an LS7 crank is probably the best bet, unless you want to spend the $$$ and go for a forged crank.

|

|

|

fieroguru

|

MAR 25, 03:49 PM

|

|

Tacked the muffler to the cradle in its proper position so I can fabricate the rear manifold tube on the bench vs. under the car.

After it was tacked, I put the cradle back in the chassis to confirm the placement clears the truck... by about 3/8":

Then it was back on the table and ended up with this merge section:

In the morning I will travel about 2 hrs from here and machine a custom aluminum LS4/F40 flywheel.

|

|

|

dobey

|

MAR 25, 04:09 PM

|

|

| quote | Originally posted by fieroguru:

After it was tacked, I put the cradle back in the chassis to confirm the placement clears the truck... by about 3/8":

|

|

Not a whole lot of room there. What are you planning for a heat shield? does it clear with the stock heat shield?

|

|

|

|