|

| LS4 / F40 swap - fieroguru (Page 15/216) |

|

fieroguru

|

MAR 15, 08:51 PM

|

|

|

I was planning to go the 4 speed shifter route since I have a couple of them on the shelf.

|

|

|

JPH87

|

MAR 16, 01:30 AM

|

|

| quote | Originally posted by Isolde:

Simple. They suck. Look how they dump. Look at the oval outlet. They're not even iron. And yours are writing checks that your LS4 can't cash. No sleeper-ness to them. No stealth value.

I've already shown that the '00-'02 F-car LS1 manifolds are a truly excellent fit. N/A, they're proven to be only 12 HP less than 1.75" long-tubes on a 400 RWHP build. Less than 12 on a 600 RWHP turbo build. They're durable, nicely styled, cheap, easy to get, and they offer heat shields on both. They can be extrude honed. Edelbrock makes tubular versions, albeit way overpriced. What's not to love? |

|

You would rather have iron over stainless? wow I think guru made a good choice here the ls7 manifold is more of a header than a manifold bang for the buck I don't think you can beat them for the $100 he paid. With the way he is fabing the dumps thats going to look way cool. You would be suprised at what checks LS4's can cash with a little work.

|

|

|

av8fiero

|

MAR 16, 07:51 AM

|

|

| quote | Originally posted by Isolde:

Simple. They suck. Look how they dump. Look at the oval outlet. They're not even iron. And yours are writing checks that your LS4 can't cash. No sleeper-ness to them. No stealth value. |

|

What do you base this on? They're lighter, They're Stainless and NOT cast iron, NO v8 fiero is a sleeper, and even if they do cost a little low end punch, who cares. It's not like ANY v8 fiero ever had any trouble getting off the line. So they may be too big for a basically stock LS4, but had you read his thread completely, you would know he's planning future power upgrades for the engine. Going this route eliminates his need to design and build a second exhaust system

|

|

|

Tony Kania

|

MAR 16, 09:50 AM

|

|

Guru....

Your craftsmanship is stunning. Your ideas original. And your build is just amazing. Your craftsmanship is stunning. Your ideas original. And your build is just amazing.

Tony

|

|

|

fieroguru

|

MAR 16, 11:19 AM

|

|

Thanks for the support and kind words guys!

Hopefully I there will be more progress pictures in a few days.

|

|

|

fieroguru

|

MAR 19, 02:12 PM

|

|

I was able to stop by the junk yard and get a used clutch from the application I think will result in the largest possible clutch. The transmission was already pulled, so 6 bolts and it was mine (plus $30).

The pressure plate surface is about 9 7/8"

Here is a stock Fiero 9 1/8" clutch for a visual reference:

It was much easier to pull the F40 off the 4.3 setup (no mounts on the tranny), so I used it to take some rough measurements:

With the clutch disk on the input shaft, the flywheel face can be between 1 5/8" and 1 7/8" deep into the bell housing and retain 100% spline hub engagement as well as not make contact with the HTOB sleeve.

The pressure plate has a protruding lip by the torque bands and it is 1 1/4" from the flywheel face. This part could make contact with the differential bulge deep in the bell housing. The differential bulge at the OD of the pressure plate is about 3" to 3 1/16" deep into the bell housing.

So with the flywheel at 1 5/8" thick, and the pressure plate lip another 1 1/4" into the bell housing (2 7/8") there should be ample clearance to the differential bulge at 3". A flywheel thickness at 1 3/4" would place the place the pressure plate notch at 3.0". The clutch fingers on this clutch (with some washers on the disk to account for some wear) are at 1.75" from the flywheel surface (same as the overall depth of the pressure plate). With a 1 5/8" flywheel, the clutch fingers would be at 3.37" which is within the HTOB range of motion from 2.675" to 3.582 with the midpoint of travel being 3.129". This should give the clutch release fingers about .20” of movement to the rear as the clutch wears and about .7” of clutch release travel w/o the HTOB over extending.

This was the first clutch setup I looked into, but it will not work with my fidenza flywheel due to the pressure plate bolt pattern on the pressure plate and the machined edges of the flywheel. In this picture, one of the pressure plate bolt holes lands on the full size portion of the flywheel edge, but the other one is in the clearanced portion. So I had initially discarded this flywheel setup.

So I have decided to just make a new flywheel and ditch the flex plate/spacer/flywheel setup I currently have. These parts have already been purchased for the new flywheel:

|

|

|

fieroguru

|

MAR 19, 03:12 PM

|

|

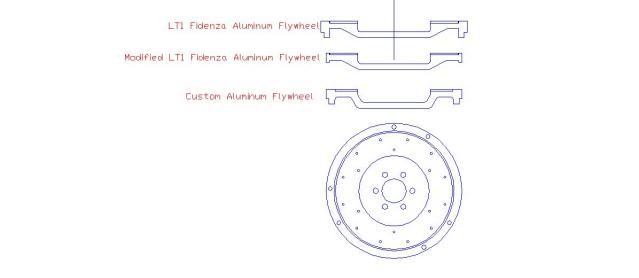

Here is a rough general shape of my new flywheel:

|

|

|

Raydar

|

MAR 19, 04:53 PM

|

|

|

|

fieroguru

|

MAR 19, 07:30 PM

|

|

| quote | Originally posted by Raydar:

What is the application? While the large diameter will help, it certainly doesn't have a lot of friction material.

Compare it to the Fiero Store Ram clutch. (It's advertised as 9 3/4 but is really 9 5/8.) It seems to have a lot more friction material.

I know that you may want something more substantial than this, but I chose it solely because of it's larger friction surface. I understand the clamping load is a bit higher too.

I wasn't happy with my Spec 2. Figure I'd go with something larger but less exotic.

|

|

I am not sharing the application for this clutch just yet, but it is a non-GM application. It is a stock application and Spec offers a Stage 3+ version for it off the shelf. Now that I know it will fit, I want to give them a call and see what the stage 3+ version is rated for (needs to be 450 lb-ft +) and if it can be had with a spring less hub.

It would be nice for the clutch material to be wider, but it can't be w/o changing to a completely different clutch setup and the available applications with 23x1 spline and 9 7/8" diameter are very, very few. Some are ruled out due to the raised pressure plate, some because the bolt pattern for the pressure plate will not fit within the material available on the flywheel, some for price or pressure plate design (porsche).

An industrious person could mix/match the previous clutch disk I was using with a non-raised pressure plate of the needed size, but I am looking for a stock clutch/pressure plate combo that already has some upgraded versions available. I wanted to go the largest diameter possible... plus I normally take the hard way...

In the last month I have learned way more than I ever wanted to know about the various clutch/pressure plate combinations across the imports and domestic applications.

|

|

|

fieroguru

|

MAR 19, 07:36 PM

|

|

I pulled the Blue 88 in and slid the engine/tranny/cradle under it to start mocking up and locating the remaining portion of the exhaust. Here are the parts for the rear most portion of the exhaust:

Yes, I know the stock fiero tips are not stainless steel and probably a restriction... but I use them on all my personal swaps, so they are staying. Once the muffler location is locked down, then the 3" inlet will be tapered to meet up with the 2 1/2" from the front. The rear manifold section will be last and the most complicated as it must taper from the LS7 manifold and then merge into the 3" section of pipe before the muffler... lots of cutting/fitting.

|

|

|

|