|

| LS4 / F40 swap - fieroguru (Page 138/216) |

|

fieroguru

|

JUL 05, 09:12 PM

|

|

| quote | Originally posted by Syn:

Is anyone else having issue with the pictures loading? |

|

I checked a few pages and everything loads fine for me.

|

|

|

fieroguru

|

JUL 08, 10:01 PM

|

|

I was a participant in the Addco group buy on larger front & rear sway bars for the 88s:

http://www.fiero.nl/forum/Forum4/HTML/076691.html

The bars arrived on Thursday:

First order of business was to measure the torsional resistance of the two stock bars and then the addco ones to verify the gain. I made this crude test stand to lock the bars to the work table, used a pipe clamp to load one end while the other end pressed on the scale.

Here is what I came up with:

Stock Front: 169 lb/in (Addco spec'd @ 157 lb/in)

Addco Front: 243 lb/in (Addco spec'd @ 240 lb/in)

Stock Rear: 75 lb/in (Addco spec'd @ 81 lb/in)

Addco Rear: 136 lb/in (Addco spec'd @ 139 lb/in)

My measurements have the Addco bars 44%/81% stiffer than stock vs. their estimate of 53%/72%. Overall I think the torsional specs for the Addco bars are spot on (I was within +/- 3 lb/in with my measurements).

I started with mocking up the front. The supplied bushing and bracket will need to be slotted further to line up with the stock holes in the cradle:

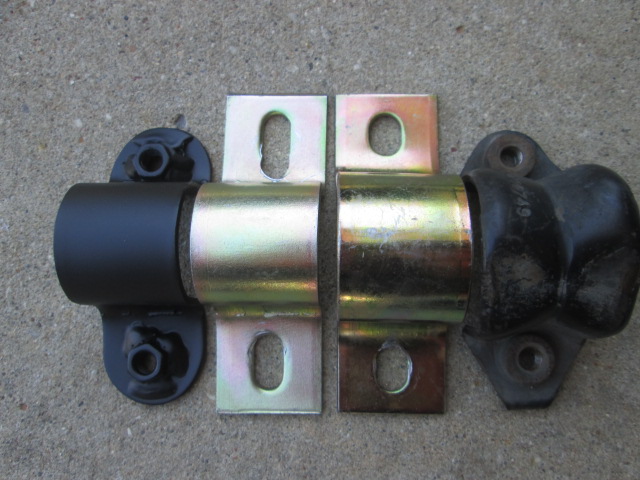

My front wheels barely clear the stock sway bar, let alone a thicker one. So I wanted to shift the sway bar as far to the rear as I could. So I ended up using the rear addco brackets (smaller), made some bushings, and then modified the bracket to accept the stock 8 mm bolts. Starting on the left in this picture: Modified Addco rear bracket, Addco rear bracket with 1 slot extended, addco front bracket, stock 88 bracket:

Installed with new bushings:

I did round the inside edge of the sway bar and ground the corner off the bump stop pad on the crossmember - there are two areas that get tight as the sway bar is shifted to the rear:

Front Installed:

The car rolls much less with just the front bar. I am hoping to get the rear bar installed on Monday.

|

|

|

KissMySSFiero

|

JUL 10, 01:48 PM

|

|

| quote | Originally posted by fieroguru:

Picked up a 12" combo miter saw and aluminum and steel blades.

|

|

What kind of blade did you get? I'm curious how this works. I've thought about it for doing my exhaust.

|

|

|

fieroguru

|

JUL 10, 10:30 PM

|

|

| quote | Originally posted by KissMySSFiero:

What kind of blade did you get? I'm curious how this works. I've thought about it for doing my exhaust. |

|

I did some research and was hoping for a 1 blade fits all solution, but the teeth for aluminum are a different grade of carbide and have a different profile than steel. So I ordered one of each, but haven't taken the time to fab up a good clamp setup yet. Maybe next weekend.

For steel, I ordered this one:

https://www.ebay.com/itm/DI...p2057872.m2749.l2649

For aluminum, I ordered this one:

https://www.ebay.com/itm/Co...p2057872.m2749.l2649

The saw has a max speed of about 4000 rpm, so I picked up a router speed adjuster and can slow the saw down some. If I go too slow, it will shut the saw off.

The saw is belt drive, so one of these days I might take the side cover off and look at options for slowing the blade speed with a pulley change, which would also increase the torque at the cut interface.

|

|

|

Jefrysuko

|

JUL 30, 11:12 PM

|

|

| quote | Originally posted by fieroguru:

The saw is belt drive, so one of these days I might take the side cover off and look at options for slowing the blade speed with a pulley change, which would also increase the torque at the cut interface.

|

|

Another trick is to use a smaller blade than the saw was designed for which will reduce the linear speed at the teeth. Of course this limits your width of cut too.

|

|

|

fieroguru

|

AUG 01, 10:31 AM

|

|

Good to see you posting again!

I might have to try that. I cut some 1" solid aluminum bar with the saw speed regulated down. The saw didn't have much torque, so I had to keep the cut pressure pretty light, which isn't necessarily a bad idea, but the cut wasn't as true as I would have liked. A 10" blade should flex less than a 12" one so that might be an option.

|

|

|

Wraith177

|

AUG 04, 02:53 PM

|

|

|

I have to say man, I admire your taste. Hoping to have pretty much the same set up, picking pieces from various LS engines. I love your work man. I can’t wait to see how fast this thing goes man! This is impressive work, please keep it going! ------------------

This signature adds .5 bhp.

When in doubt, gun it.

84 2m4 —in progress to— 84 2m8sc

1984 Fiero, LS4, Procharger, F40 6speed

|

|

|

Bob2112

|

SEP 13, 03:28 PM

|

|

Hi guru - I'm finally getting around to disassembly of my LS4 donor car. Aside from obvious engine bay, engine and transmission area sensors and such, is there anything else I should be sure to not get rid of on the car? Just wondering if there is anything the LS4 computer will be looking for that is located in non-obvious places.

|

|

|

fieroguru

|

SEP 13, 09:44 PM

|

|

| quote | Originally posted by Bob2112:

Hi guru - I'm finally getting around to disassembly of my LS4 donor car. Aside from obvious engine bay, engine and transmission area sensors and such, is there anything else I should be sure to not get rid of on the car? Just wondering if there is anything the LS4 computer will be looking for that is located in non-obvious places.

|

|

Make sure to keep the pedal and harness.

There is a sensor on the brake booster as well if you want to hook it up (only needed for DoD/AFM).

I would take all the harnesses out of the car so you will have lots of spare wires if needed.

Also, If you want to add more features to your Fiero, you might consider keeping the BCM and related harnesses.

Nearly everything not engine related can be removed from the tune, so that is another option as well.

|

|

|

fieroguru

|

SEP 30, 09:49 PM

|

|

Travel commitments for work have been insane... but I have been making slow progress on a few fronts.

Got some new shoes for my truck... 245/55/18. The 2wd performance version of the truck came with 235/50/18 which was the look am going for, but opted to get something just a little bit taller. They are still shorter than the 265/70/18's that came with the wheels from a Silverado. Now it needs lowering and I have a 3" lowering kit for it. When I lower it, I will take off the lower door bars as well. After lowering, I plan to upgrade it to 2009+ brakes (2004-07 had to fit under 15" wheels)

After 5 years, I am getting bored with the power of the LS4/F40 car, so the easiest way to get more power is to delete DoD/AFM and install a more performance oriented camshaft. I have started to collect the needed parts for the DoD/AFM delete. These are the parts I purchased from GM Parts Direct

12557840 Vibration Damper Bolt $3.61

12586481 Camshaft Gear $16.61

12595365 Push Rod Guides $6.45

12598832 Cover $32.02

12633906 Cover $79.41

17800568 Bolt Kit $28.65

12646386 Timing Chain $36.61

12630223 Water Manifold Gasket $3.84

12594171 Manifold Gasket $10.50

12589226 Head Gasket $24.86

I picked up the Delphi brand LS7 lifters from ebay, but they were shipped in a small cardboard box with the roller ends down. The first one I pulled out has a burr of something as the roller will sometimes lock up. I am going to order some OEM LS7 lifters from GM Parts Direct.

I have had 2 custom camshafts spec'd for this car:

NA camshaft: 222/226 .604”/.604” 113+3

Turbo camshaft: 221/225 .597/.600 112+4

The NA one was spec'd to reduce overlap and improve low end torque and drivability. The additional lift and the more aggressive lobes (than the lazy DoD compatible lobes) is supposed to push the combo over 400 whp. The turbo one was spec'd to match the 369SXE turbo I have for the car with a taget of 600 whp. The camshafts are virtually identical, so I am going to go with the turbo one as that is the future state for the car. I will also run some BTR platnum .660" springs. I am hoping to order the camshaft in the next month.

R&D Efforts:

I picked up a 2004 5.3L RWD engine for mockup as well as a windowed LS3 loaner from a friend. Purpose of these two engines is to better understand the differences between the LS4 and RWD engines as well as RWD cast iron vs. RWD aluminum. The first think I determined was the difference between the crankshaft flanges and the block between the LS4 and the RWD engines. If the adapter plate is kept at this dimension (less than 3/8"), then I can use the same flywheel clutch setup on both the LS4 and RWD LS engines.

Lastly, started working on a new brake kit, which uses a rotor that has never been used before.

This one is targeted at the stock 88 Formula/GT wheels group. I found a 11.7" brake rotor that clears the nose of the lower a-arm, clears the upper a-arm, and fits the rear wheel with clearance to spare. I just need to test fit in behind an 88 front formula/GT wheel. This rotor would provide a 17% improvement in brake caliper leverage, while letting people keep their stock wheel setup.

This kit is a very tight fit...

You likely won't be able to see it through the wheels, but there isn't much room:

Caliper clearance to inner rib (this is where the front wheel could cause an issue). I can still pull the calipers toward the hub some to gain additional clearance):

Caliper clearance to the backside of the wheel:

Clearance to the lower a-arm nose:

With the suspension resting on the stock bump stop and the suspension turned to full lock, everything barely clears the upper a-arm (alignment settings might change this clearance):

I removed the bump stop and raised the suspension even more to simulate extreme lowering. Under this condition, nothing touches, but it is very, very close. :

That is it for now...

|

|

|

|