|

| LS4 / F40 swap - fieroguru (Page 135/216) |

|

Rickady88GT

|

APR 15, 12:18 AM

|

|

| quote | Originally posted by fieroguru:

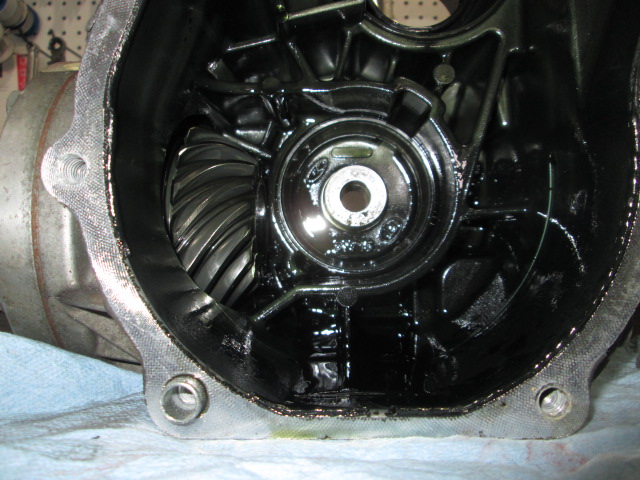

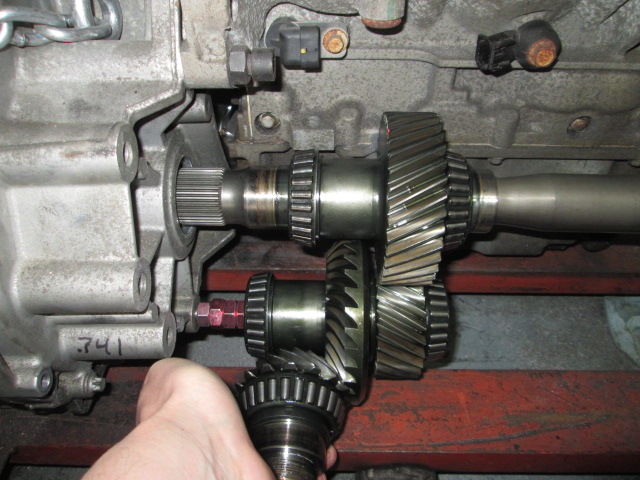

Finally took one of these Saab AWD units apart...

The center-line of the pinion gear is about 7/16" lower than the center-line of the ring gear, so flipping it 180 will raise the output shaft about 7/8". That will place it about 3 5/16" below the F40 axle center-line. The F40 axle center-line is about 2 13/16" below the crankshaft center-line, so centerline to centerline between the AWD output shaft and the engine crankshaft should be close to 6 1/8"... which means the output shaft should have room to clear the crankshaft.

Some other important info:

Splines on passenger side intermediate shaft: 27

Splines on AWD power takeoff from differential: 38

Gear teeth on hollow drive tube: 35

Gear teeth on ring gear shaft: 26

Gear teeth on actual ring gear: 31

Gear teeth on pinion gear: 15

Overall ratio has the pinion output shaft spinning 2.781 times faster than the F40 differential RPM.

I still need to collect a F40 AWD differential with the female spline shaft to drive the AWD unit as well as the front differential. |

|

I love pictures

|

|

|

Rickady88GT

|

APR 15, 09:14 AM

|

|

| quote | Originally posted by fieroguru:

Finally took one of these Saab AWD units apart...

|

|

Is there any reason for the hollow shaft of the ring gear? Does anything run through it? I understand that the larger diameter of the bearing shaft is better, but is that hollow used for anything?

|

|

|

fieroguru

|

APR 15, 10:21 AM

|

|

|

It is to allow access to one of the mounting bolts to the transaxle. [This message has been edited by fieroguru (edited 04-15-2018).]

|

|

|

Rickady88GT

|

APR 15, 09:34 PM

|

|

| quote | Originally posted by fieroguru:

It is to allow access to one of the mounting bolts to the transaxle.

|

|

Ok.

|

|

|

Rickady88GT

|

APR 19, 12:15 AM

|

|

What are the differences between the Saab and F40?

Are there differences between the auto and manual?

|

|

|

fieroguru

|

APR 19, 11:29 AM

|

|

| quote | Originally posted by Rickady88GT:

What are the differences between the Saab and F40?

Are there differences between the auto and manual? |

|

Saab was the original application for the F40 (so there are Saab F40s, just like Pontiac G6 F40s and Buick Regal F40s). Saab's 6 speed auto is called AF40 and the AWD units between the Auto and Manual versions are very, very similar. In stock configuration they might not be interchangeable, but since I am making a new case for mine, everything should be able to be "made to work". The Saab AF40 AWD units are much more plentiful and cost less. The one I am tearing apart was $250 shipped.

Yes, there are differences between auto and manual. The intermediate axle shaft is one for sure (different GM part numbers), but it has the proper splines to engage the F40, so it might just be a length issue, but I am redesigning the case and make adjustments for any length issues. There may be other differences that I haven't figured out, but with my intent of making a custom case, I don't think they are significant.

|

|

|

fieroguru

|

APR 21, 09:34 PM

|

|

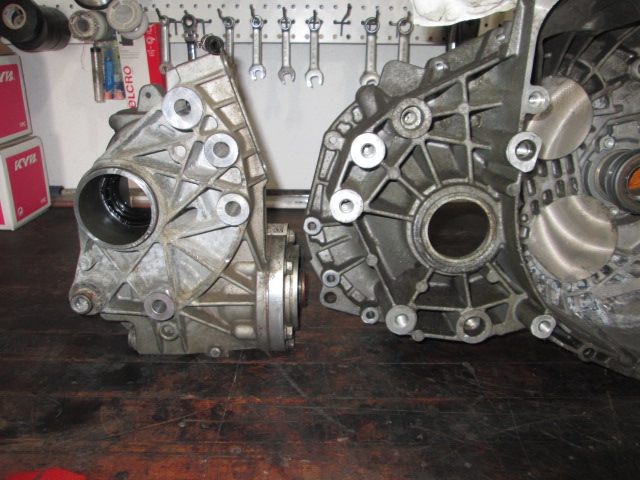

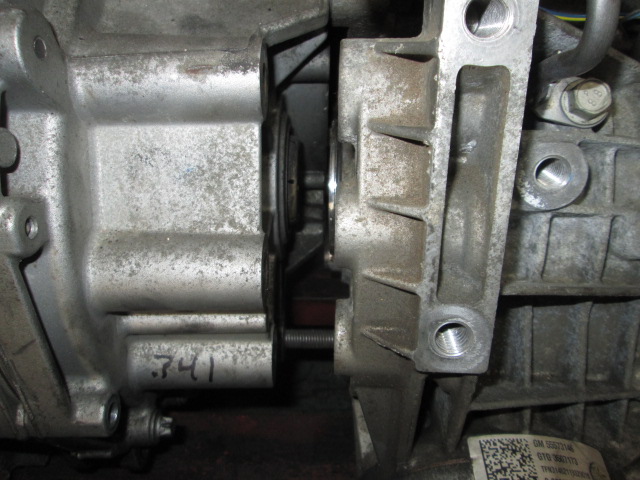

I played with the AWD unit some more today...

The bolt pattern between the AF40 AWD unit is the same as the European unit, but there are 2 interference areas. The center boss on the AWD unit is larger than the axle seal hole in the F40, so the F40 case will need to be bored. While doing that, I will need to clearance the bellhousing case about 1/8" as well:

It looks like the bolt hole that is centered inside the hollow ring gear shaft is the same between the AF40 an the G6 F40 case, but that is the only common bolt hole. There is a raised boss on the G6 F40 that is in the way, also right now the LS4 oil pan flange and the AWD case interfere by about 1/4". All should be able to be addressed with a new AWD case half. The AWD unit also sticks below the LS4 oil by by about 3/4".

The AF40 passenger side intermediate shaft is 1 1/8" longer than the cobalt SS intermediate shaft. This is very good. When I first did my LS4/F40 swap, I lengthed the Saab intermediate shaft (same as the cobalt one) by 1 3/8" so I could use the stock G6 axle shaft on the PS. This means this intermediate shaft will work with my current axle setup.

I also started to play with the new rebuildable tapered fron wheel bearings for the 88s from Rodney. http://rodneydickman.com/ca....php?products_id=427

I took them apart to repack the bearings with mobile 1 synthetic grease, so I took a picture of the flange shaft of the new bearing vs. an OEM 88 one.

The bearings are all back together now and I am waiting for the paint to dry... I might even get around to installing them on Sunday.

I also installed some 2014+ 18" Silverado wheels on my Colorardo. I had to bored the centers to fit the enlarged Colordado hub. Now I need some lower profile tires and drop the truck about 3" (yes, lowered 4x4...)

|

|

|

Will

|

MAY 05, 07:51 AM

|

|

| quote | Originally posted by fieroguru:

It looks like the bolt hole that is centered inside the hollow ring gear shaft is the same between the AF40 an the G6 F40 case, but that is the only common bolt hole. There is a raised boss on the G6 F40 that is in the way, also right now the LS4 oil pan flange and the AWD case interfere by about 1/4". All should be able to be addressed with a new AWD case half. The AWD unit also sticks below the LS4 oil by by about 3/4".

|

|

If you only get one, that's the one to have.

|

|

|

fieroguru

|

MAY 06, 02:03 PM

|

|

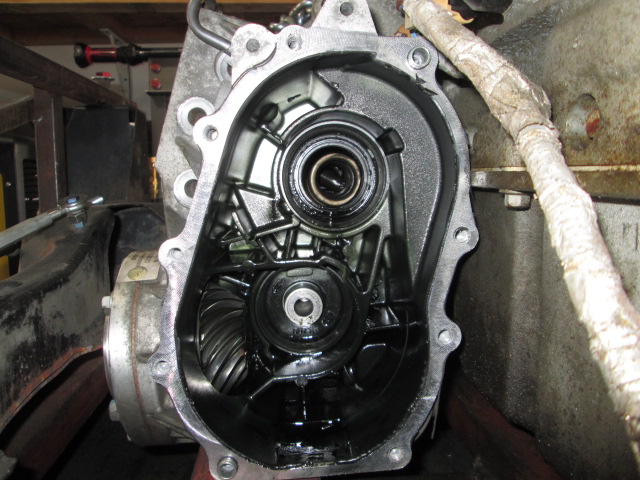

Took the passenger side axle shaft out of the AWD unit. It is interesting as one end is male and one end is female. The really nice thing is it is just the right lengths to be used with a stock G6 driver side axle (with the CV end swapped to the Fiero CV).

I also took the pinion gear out of the bearing housing cap. The pinion housing is hollow with female splines for the drive shaft to attach to.

I started to test fit the gear shafts to the engine and transmission and quickly found another interference issue. The excess flange on the oil pan interferes with the gear. Interesting that the pan has a notched area show and that is what I need to remove for the gear to clear.

Once the oil pan was clearanced, I made some crude bushings so the gear shafts would center on the passenger axle as well as a long bolt that is threaded into the common hole at the gear shaft center.

I need to remove the oil pan on the mockup engine to test fit the pinion in the forward facing position.

|

|

|

fierogt4e

|

MAY 20, 04:50 AM

|

|

As I read this AWD section for the second or third time I see a separate gear case to move the output farther towards the passenger side. Sort of a transfer case. It would keep it simple I think.

You could use 2, 3, or 4 gears depending on how far, and the direction of rotation you need to clear the AWD unit and the engine sump. Angle it up or down a little if needed. Bolt it on over the pinion support, using the 7 AWD pinion support bolts. And with a bracket on the output end.

This way you could adjust the ratios to work with whatever you find for a front diff.. 50:49 will give 2% over drive I think. This gives you more options. More easily replaced if damaged.

Best of all separate cases could be put in your store for hill chimers, rally, off road, kit-cars, and so on.

AWD Fiero! That's just cool.

P.S. Slam that 4X4!

|

|

|

|