|

| LS4 / F40 swap - fieroguru (Page 122/216) |

|

Neils88

|

DEC 01, 05:38 PM

|

|

I'm drooling.....  Can't wait to see it installed! Can't wait to see it installed!

|

|

|

Trinten

|

DEC 01, 08:59 PM

|

|

What process did you use to size your turbo and find one with the right map?

Some years ago I had started the planning for a turbo on mine, and worked out gobs math around it to "plot" it, then just spent a few hours looking through turbo maps to find turbos where the dot was in the right place.

The guy I've been talking to do the turbo work said it was waaaay to big of a turbo, and I'd be wasting a lot of it's potential. When I showed him all the math work, he said it made sense, but the turbo was still too huge and it would be blowing off quite a bit. He said he'd install whatever I wanted, but he had other recommendations. He has a history of working for speed shops, and has a brutal Grand National that he built up himself...

So... just wanted to understand your process and get your opinion.

|

|

|

dobey

|

DEC 01, 09:44 PM

|

|

| quote | Originally posted by Bob2112:

I'm finally starting to look for an engine and I was wondering if you would recommend a Gen III or Gen IV from an ECM standpoint. My understanding is that mechanically the engines are the same, but that with the Gen IV you have to do more conversions in the programming which can lead to less accuracy. Given the DoD didn't get working with you F40, I'll probably go with a DoD delete from the start and just rebuild the engine while I'm at it. Give all that, I'm thinking Gen III would be the way to go. Any thoughts?

|

|

There are no Gen III LS4s, but as fieroguru said, the 05-06 engines have the earlier ECM which can be a little easier to deal with. They are still Gen IV engines though.

|

|

|

fieroguru

|

DEC 02, 08:23 AM

|

|

| quote | Originally posted by Trinten:

What process did you use to size your turbo and find one with the right map?

Some years ago I had started the planning for a turbo on mine, and worked out gobs math around it to "plot" it, then just spent a few hours looking through turbo maps to find turbos where the dot was in the right place.

The guy I've been talking to do the turbo work said it was waaaay to big of a turbo, and I'd be wasting a lot of it's potential. When I showed him all the math work, he said it made sense, but the turbo was still too huge and it would be blowing off quite a bit. He said he'd install whatever I wanted, but he had other recommendations. He has a history of working for speed shops, and has a brutal Grand National that he built up himself...

So... just wanted to understand your process and get your opinion. |

|

I spent a lot of time on LS1tech in the Forced Induction section reviewing 5.3L turbo builds and dyno charts on car with a manual transmission. Part of the issue is focusing strictly on compressor maps as that is only 1/2 of the turbo. The turbine side is equally as important, and can become a restriction well before the compressor runs out of cfm, but there are no equivalent maps for those. So I was focused on sizes of the wheels on both sides and comparing the dyno results to find the approximate sizes that produced power curves that were in line with what I was looking for.

Small physical size (better for packaging), quick spool (boost below 3K), oem reliability, and moderate power levels were my goals. Unfortunately, the S369sx-e is too new of a turbo so there are not a lot of installs with dynos... but it is about the ideal size for what I was looking for.

The next step is to get a turbo specific camshaft that matches the specs of the turbo. I will probably call up a couple of vendors and see what they recommend, but I am leaning toward a stage 2 turbo cam in the 218/223 .598/.571 range.

|

|

|

FOREVER88

|

DEC 03, 01:58 PM

|

|

|

|

fieroguru

|

DEC 05, 06:18 PM

|

|

Since the car is pretty much stored for the winter, I have started to use the trunk area to store parts as they arrive:

|

|

|

fieroguru

|

DEC 07, 08:38 AM

|

|

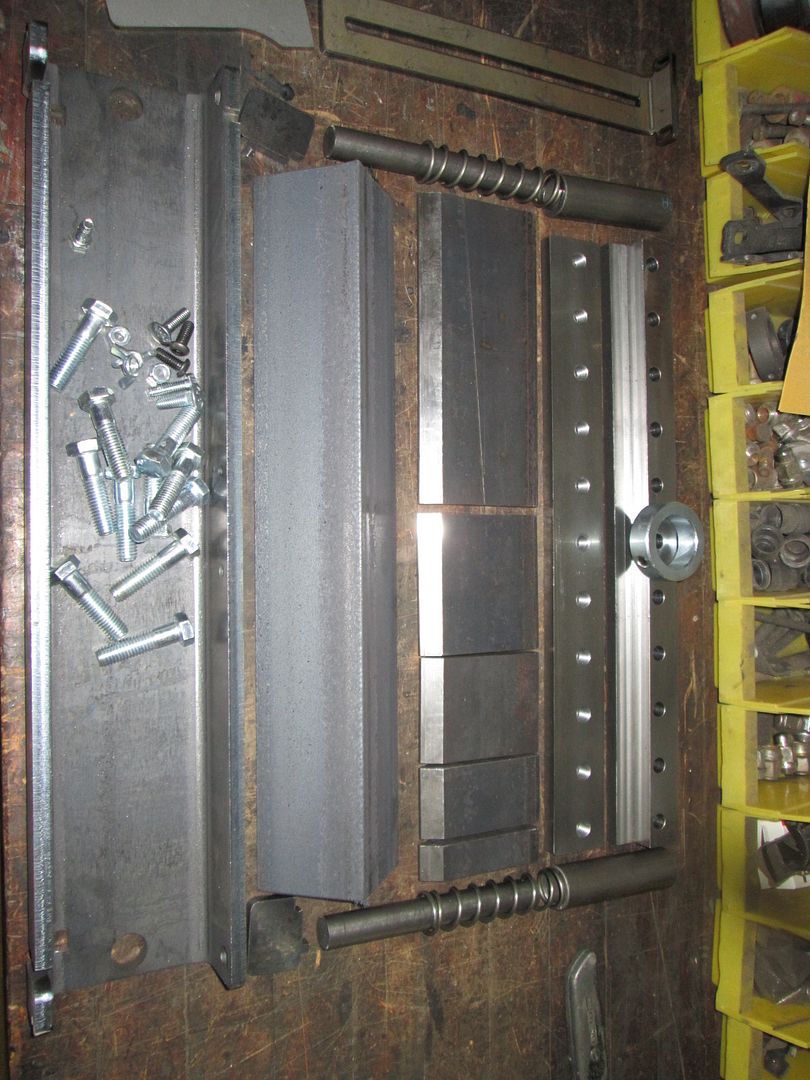

Yesterday, I cleaned the garage and eventually got busy putting together the SWAG Offroad finger press.

Some assembly required...

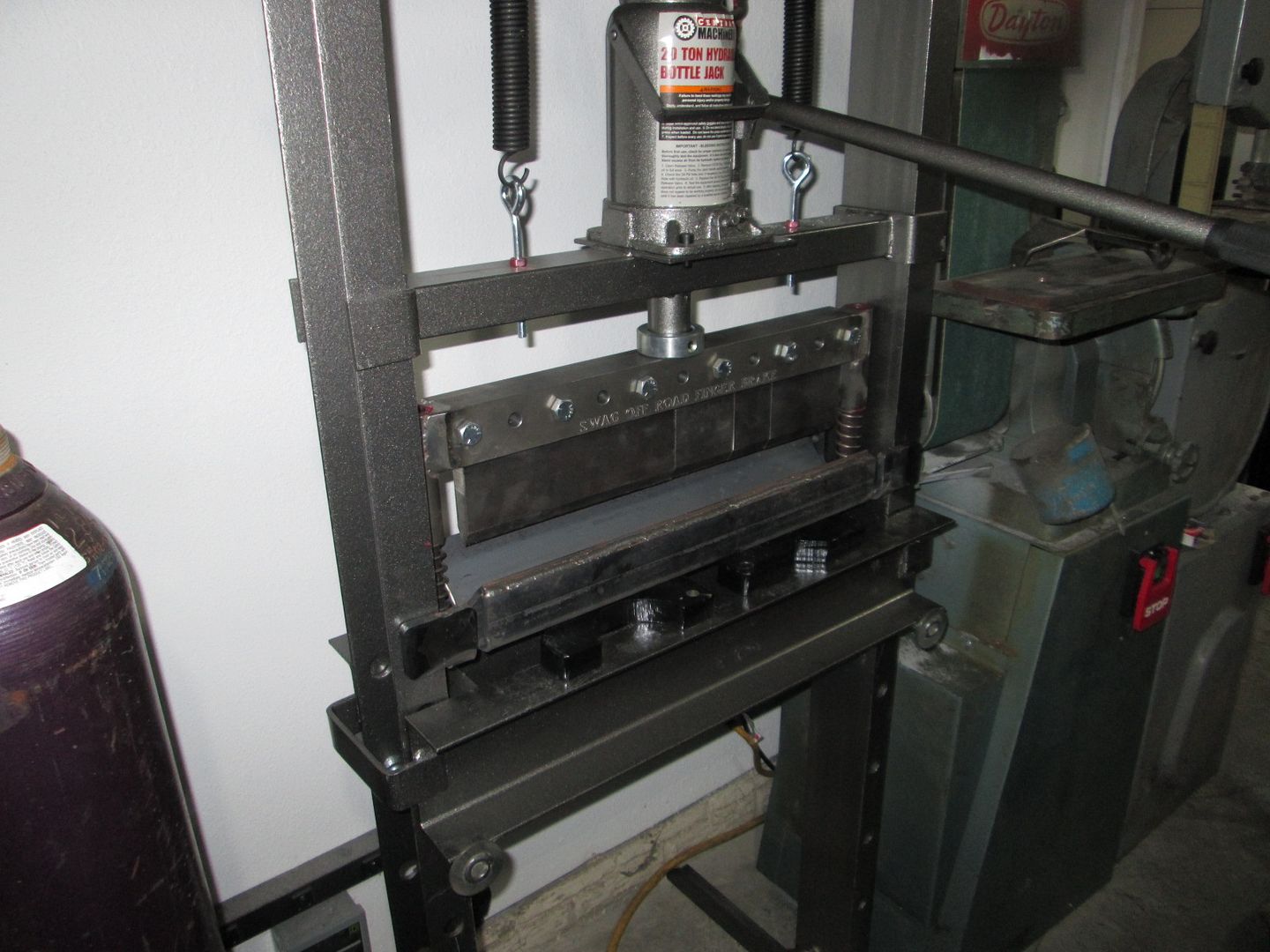

Assembled:

|

|

|

RacerX11

|

DEC 07, 12:43 PM

|

|

|

Looks good! I have the non-finger version. You will love it for making brackets and such. Looks like you also picked up a set of the laser-cut press plates?

|

|

|

fieroguru

|

DEC 07, 07:28 PM

|

|

| quote | Originally posted by RacerX11:

Looks good! I have the non-finger version. You will love it for making brackets and such. Looks like you also picked up a set of the laser-cut press plates? |

|

Those came with the shop press... not real confident they are any good. But they were plasma cut vs. cast so who knows.

I already have a few modifications I want to make.

** Drill the top portion of the slide shafts so I can pin the brake in the down position to make it easier to install and remove from the press.

** I have several scraps of 5" x 18" 1/2" plate and thinking about welding 1 or 2 of them to the underside of the base as well as welding in some positioning tabs to lock it into the c-channel base. Or drilling holes in the side clamp tabs and through the uprights on the shop press to bolt it in place.

** Also not a fan of the lock collar on the top (too much slop), so I might make something a little tighter and taller.

** Buy or make some inserts for the base to make tighter bends...

|

|

|

fieroguru

|

JAN 22, 06:49 PM

|

|

It was 60 degrees yesterday, so I put the air filter, intake tube, and wheel well liner back in and drove the car around town for a couple of hours. I really love driving this car, but below 40 the tires are no good and in winter there is a lot of salt on the roads...

I had the filter and air intake tube off to test fit the turbo, but I didn't like any of the areas. With the 6 speed cables and LS4 starter location, here was one of the options, but I really wasn't feeling it.

I think I will cut the bottom of the trunk, then the turbo, intercooler, and all associated plumbing will be hidden and not clutter up the engine bay.

From Thanksgiving until 2 weeks ago, most of my free time was spent finishing our basement bathroom. When we purchased the house, the bathroom was studded in and had all the drains installed below the concrete. We had a contractor run all the copper lines, install the bath tub, wire the electrical boxes for the lights, and install the drywall and tile. I did all the painting, caulking, grouting, hooked up the lights, installed the toilet, vanity, sink, mirror, towel racks, pictures, and built in shelves, and all the trim... My wife put the rest of the towels and supplies in there. So now when guests stay in the spare basement bedroom, they have their own full bath!

This is the last major house project for the wife, so the garage expansion is next, but probably won't start that until 2019.

|

|

|

|