|

| Chrysler 3.5 HO V6 swap (Page 11/33) |

|

bmwguru

|

DEC 27, 04:45 PM

|

|

|

|

tesmith66

|

DEC 29, 08:10 AM

|

|

Love the sheet metal work. You should convert that fuel pump bump into a door or removable panel for easy access. My Grand Prix had an access panel and it was very, very nice when I had to replace the pump.

Good work!!!------------------

1986 SE Aero coupe.

3.4 DOHC swap is complete and running, now just have to finish the rest of the car...

|

|

|

seajai

|

DEC 29, 09:10 AM

|

|

Thanks everyone for the great compliments, it really means a lot to me. This is my first venture into metal work and I'm happy it's turning out as good as it is.  I thought about making a fuel sender access door but the almost 6" diameter fuel sender would have required me to cut out too much of the structure of the tunnel. I thought about making a fuel sender access door but the almost 6" diameter fuel sender would have required me to cut out too much of the structure of the tunnel.

|

|

|

seajai

|

DEC 30, 12:33 PM

|

|

Got my cover made. Used rivnuts on the frame and attached the cover with #10-32 screws. Think I'll use foam weathertrip to seal it up.

[This message has been edited by seajai (edited 09-28-2023).]

|

|

|

seajai

|

DEC 30, 10:49 PM

|

|

Got the throttle cable hooked up today. I ended up moving the cable pass-through over to the left about 9" from its original position, exiting just above the main cross beam.

The stock Fiero cable was about a foot too short and had a different end on it than the Chrysler, and the stock Chrysler cable was only 3' long. My solution, hook the two cables together. First off, I built a bracket to attach the cables. Second, I cut off the ends of the cables and housings. Luckily both the Chrysler and Fiero cable housings were .250" outside diameter which allowed me to use standard plumbing compression fittings to attach them to my bracket. My fittings came with a small tube designed to slide inside plastic line to keep it from collapsing, I used one of those to crimp the cables together and added some solder to strengthen the connection. I'll probably make a plastic cover to pretty it up a bit.

[This message has been edited by seajai (edited 09-28-2023).]

|

|

|

PBJ

|

DEC 31, 09:15 AM

|

|

Was not sure what I was going to see when I first saw the thread title. I am impressed, very nicely done!

Pete------------------

88 3800 turbo...10 sec Quarter Mile Member.

|

|

|

carnut122

|

DEC 31, 10:34 AM

|

|

|

I'm glad to see you're progressing.

|

|

|

fieroguru

|

DEC 31, 10:58 AM

|

|

Way to think outside the box! I really like the firewall tweak and the throttle cable solution.

My only suggestion for the throttle cable setup would be to make the bracket from C shaped material (like 1x1 tubing with one side removed) with the top/bottom and visible side closed and the open part to access the cables placed along the valve cover. That way the bracket by design keeps the "mystery" hidden, but everything would still be accessible by removing the bracket. I would also suggest some cable slits at the threaded holes so if need be you can remove the cable from the bracket without having to undo their crimped/soldered connection.

Keep up the good work!

|

|

|

JohnWPB

|

DEC 31, 12:27 PM

|

|

| quote | Originally posted by seajai:

Plan on attending a few more shows for 2013. Is there a date set yet for Frazee? |

|

Wow, totally missed this thread till now. I just read every post, all 3 pages to catch up, and subscribed to the thread. Saying this is an ambitious build is an understatement! I do hope you bring it to Frazee in July, as I would love to see it in person![This message has been edited by JohnWPB (edited 12-31-2012).]

|

|

|

seajai

|

DEC 31, 03:34 PM

|

|

| quote | Originally posted by fieroguru:

Way to think outside the box! I really like the firewall tweak and the throttle cable solution.

My only suggestion for the throttle cable setup would be to make the bracket from C shaped material (like 1x1 tubing with one side removed) with the top/bottom and visible side closed and the open part to access the cables placed along the valve cover. That way the bracket by design keeps the "mystery" hidden, but everything would still be accessible by removing the bracket. I would also suggest some cable slits at the threaded holes so if need be you can remove the cable from the bracket without having to undo their crimped/soldered connection.

Keep up the good work! |

|

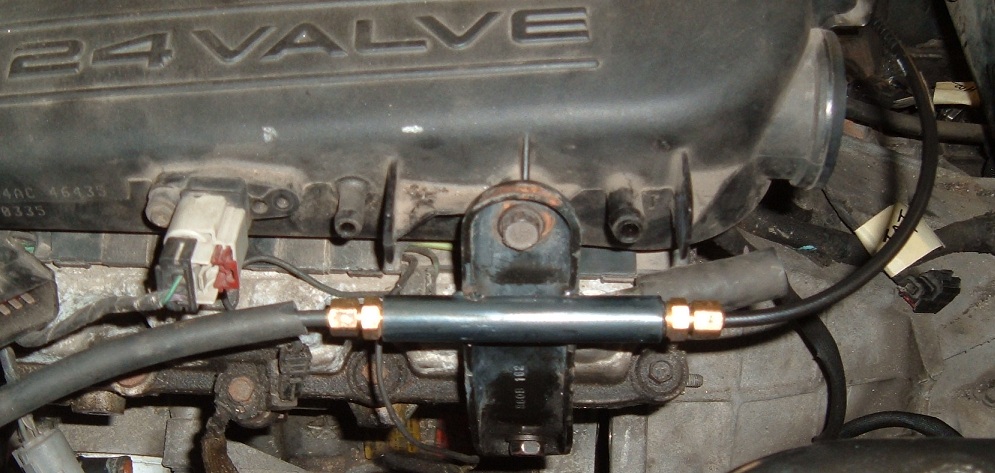

Thanks for the suggestions, it's great having another pair of eyes to look at something. I wasn't completely happy with how it turned out, and your suggestions got the ol' brain cells cooking. So I re-thought the design and here is throttle cable version 2.0. I used a piece of steel plumbing pipe welded to the factory bracket and I cut a slit on the bottom side of the pipe to insert the cable. I'm much happier with this look. Now on to the shift cable!

[This message has been edited by seajai (edited 09-28-2023).]

|

|

|