|

| ISO custom bracket design/advice (Page 1/1) |

|

saving_rossi

|

MAY 05, 12:41 AM

|

|

I'm working on a 3100 SFI swap for an 85 v6. Im keeping AC, reprogramming the 3100 PCM, but I have a few things I haven't fully cleared up yet on my to do list.

I am using the stock fiero exhaust for now, just porting and welding the manifolds and flanges. EGR won't connect quite right, so I am just deleting it. I assume this would require delete plates of some sort that bolt into EGR ports.

Additionally, I am retaining AC, and using the stock 3100 AC compressor. I will eventually get lines custom done, but for now I just need everything to fit. This means I can't relocate my alternator to the AC position to retain the upper dogbone.

I could

A) design 4 corner solid mounts for the 3100 and notch the decklid/strut tower, or

B) relocate the alternator to the trunk side of the block.

I know relocation could cause issues with eating belts and might require a different size pulley/length of belt. But I'm not sure which is more effective. I like the idea of solid mounts, and I figured someone would be selling them...but this requires welding directly to the cradle, right? Both options are very involved, I just want to know what I'm getting myself into when I pick one. I imagine with the 4 corner mounts, they would have to align with already-existing bolt holes.

What I am looking for is either someone who has solid mounted a 3100/3400 before who has a solid design, or who I can pay to fabricate these. Or just general advice...should I get sendcutsend? I'm hoping to have this car started before mid june..the friend who found me the 3100 is leaving for the summer and I'd like him to see it start up for the first time.

Beyond this, I am also seeking guidance for repinning the fiero chassis harness to the 3100 PCM...curious about what this will even look like. The setup in the 3100 buick all connected together in a fuse box, and for the fiero that setup by the battery I think is whats replacing that, but I'm not sure. Wondering what will plug into what. Thanks to you all for helping, I promise I am looking through the older posts about this too.

|

|

|

fierosound

|

MAY 05, 12:48 PM

|

|

|

|

fieroguru

|

MAY 05, 07:26 PM

|

|

If you are not a skilled fabricator with some precision measurement tools, I would not recommend reworking the assessory drive or taking on a complete engine/tranmsission mount redesign.

Keep the accessory drive stock & resuse as many of the stock fiero mounts.

Once that is done, then look for options for a "dogbone", but remember it does not have to be mounted on the top and go to the chassis. It can be mounted between the engine and the cradle down low.

The reason there is a dogbone is because of the Tri-mount setup with the engine mount directly under the engine. If you have an engine mount in front of the front crossmember and then a support bar from the engine to the rear crossmember then no top mounted dogbone will be needed.

On a 4.9 swap I did once, I used an 88 lateral link as a stabilizing rod from the engine to the cradle with a forward engine mount in front of the front crossmember.

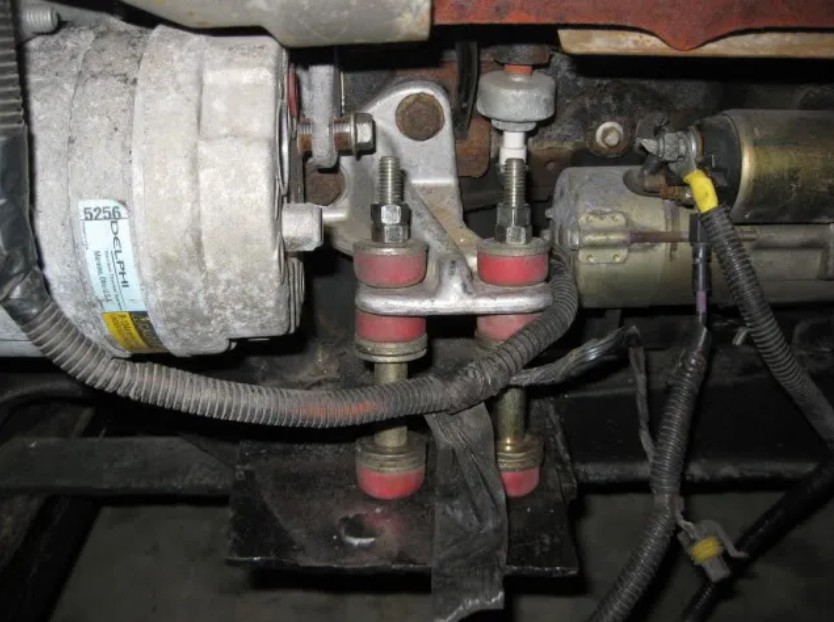

Here is the front forward mount. The bracket on the engine is stock for the 4.9 (and similar ones exist for many FWD engines). The bracket from the crossmember to the cradle is a piece of angle which can be bolted or welded in place. The mount is a GM transmission mount (not really a fan of these anymore as they really are not designed to resist significant upward force, but for stockish power applications they work OK).

Later on a buddy had a 3800/getrag swap that moved/rocked to much, it had the lower engine mount, and a 2nd engine mount in front of the front crossmember and no dogbone (alternator in the way). I replaced the forward engine mount with some sway bar links to stiffen it up and installed a cut down 88 lateral link on the rear of the engine to the cradle. Problem solved.

If you are doig this swap on an 84-87 chassis, then there are inboard rear tire rod mount brackets with a protruding studs already welded to the cradle. These could be a good staring point for a brace to the engine, just need to see what attachment points would be available on the engine.

|

|

|

saving_rossi

|

MAY 05, 08:20 PM

|

|

I am using an 84-87 chassis, it looks like there’s a good mounting point on the block for a dogbone to connect to the tie rod protrusion. Not sure if the metal is too thin or if there is even enough clearance. I’ll attach a picture[This message has been edited by saving_rossi (edited 05-05-2025).]

|

|

|

cartercarbaficionado

|

MAY 05, 10:15 PM

|

|

| quote | Originally posted by saving_rossi:

I am using an 84-87 chassis, it looks like there’s a good mounting point on the block for a dogbone to connect to the tie rod protrusion. Not sure if the metal is too thin or if there is even enough clearance. I’ll attach a picture

|

|

they put a shock on some of those near the engine mount so its probably fine?

|

|

|

saving_rossi

|

MAY 08, 01:21 PM

|

|

|

Just ran into another problem…AC compressor is in the way of the firewall-side engine mount. I’m working with some friends to fabricate a rear side cradle mounted dog bone, if I can just do that could I ignore the firewall mount?

|

|

|

fieroguru

|

MAY 08, 04:58 PM

|

|

|

The wider the mounts are spaced (front to rear), the better they will resist drivetrain movement.

|

|

|

|