|

| 87 Fiero build for 24 hours of Lemons (Page 1/3) |

|

87FieroLemons

|

APR 20, 11:11 PM

|

|

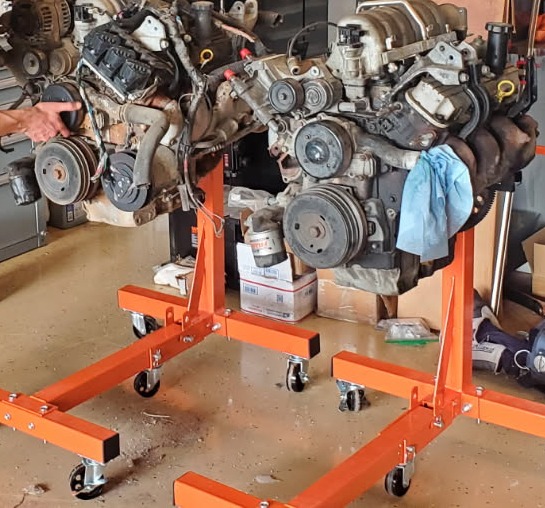

Hello Fiero Forum,

We're a team (re)building a Fiero for the Lemons series. It ran previously with a 3.4 TDC and a 282, currently we're working towards converting it to a L26 3800 with an F23 5 speed. We've sourced a couple engines, though we're unsure at this point of their mechanical state. We also have four F23 transmissions, two cavalier, one FY1 and one M84 (junkyard sent us the wrong one). No one on the team has any experience with Fieros so this will likely be a thread of many questions. I appreciate any and all help.

To start, my understanding of the coolant elbows is that they only feed the heater core. If so, I'd like to remove them entirely and bypass the heater core by threading each inlet and running a short hose between to maintainbypass flow. I found a few mentions indicating this has been done, but I'm struggling to find actual documentation of it beyond some specs such as thread size and type (3/4" and 1" NPT) and a warning about the metal being thin. Anyone have any further details?

Secondly, are there any recommendations for a cable throttle body besides the northstar 96-99 or 2k+? We're running a Microsquirt for engine management and the stepper motor IAC eats up a significant amount of I/O on the ECM. The MAF sensor also appears to be a frequency type which is incompatible with our ECM, although we'd like to be able to run a blended MAF/MAP setup, it isn't strictly necessary. I suppose the ideal setup would be a 75mm cable throttle body with a 2 or 3 wire PWM IAC valve and a lip to mount intake tubing so we can run an in-line voltage-based MAF, if we decide to run a blended MAF/MAP setup.

I'm sure we'll have many more questions to come as the build progresses. We're also currently debating how we want to frankenstein the transmissions to get our 3.63 FDR while getting the cavalier bellhousing and maintaining reasonable mounting options, if anyone wants to weigh-in on that, I'm happy to hear it.

[This message has been edited by 87FieroLemons (edited 04-21-2025).]

|

|

|

Patrick

|

APR 20, 11:32 PM

|

|

| quote | Originally posted by 87FieroLemons:

I'd like to remove them entirely and bypass the heater core by threading each inlet and running a short hose between to maintain bypass flow.

|

|

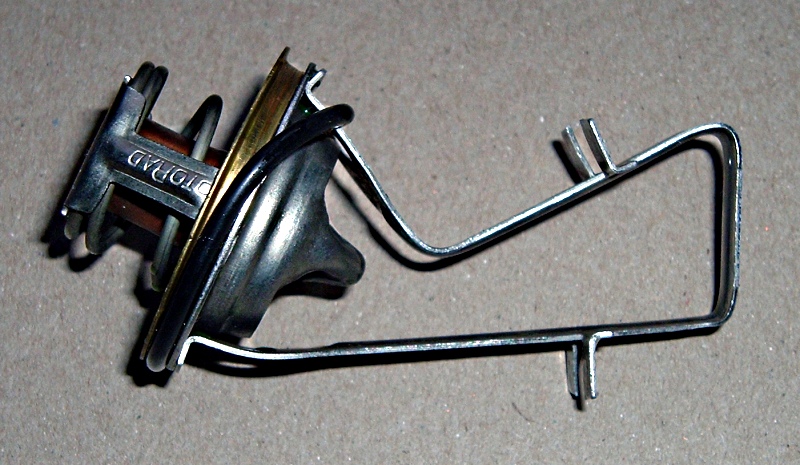

I just wanted to comment on the necessity of maintaining enough flow for the bypass. I found out what happens when the bypass flow is restricted too much when I temporarily bypassed a leaky heater core with too small of a fitting used to connect the hoses. It resulted in excessive pressure against the thermostat.

| | CLICK FOR FULL SIZE |

[This message has been edited by Patrick (edited 04-21-2025).]

|

|

|

87FieroLemons

|

APR 20, 11:58 PM

|

|

| quote | Originally posted by Patrick:

I just wanted to comment on the necessity of maintaining enough flow for the bypass. I found out what happens when the bypass flow is restricted too much when I temporarily bypassed a leaky heater core with too small of a fitting used to connect the hoses. It resulted in excessive pressure against the thermostat.

|

|

Yes, I've definitely read about this happening, collapsing the thermostat. Any recommendation on a minimum diameter? I am definitely concerned about keeping the engine cool. The previous 3.4 TDC seized from overheating. The biggest struggle in this series with Fieros seems to be the cooling system. The best recommendations I've read are a mixture of a coolant swirl pot and bypass hoses in critical spots to allow for air to separate itself from the system. Not going to pretend I understand any of that well enough to implement it as of yet, but I'm trying. The other, less conventional idea is moving the radiator much closer to the engine.

|

|

|

Brian A

|

APR 21, 12:00 AM

|

|

Very cool! Best wishes.

It will be fun to watch the build! Post lots of photos!!!

There is a nice Fiero Lemons car that runs here in the San Francisco Bay Area. It does quite well.

I have a 1987 Fiero GT track car but don't race it.

|

|

|

cartercarbaficionado

|

APR 21, 12:27 AM

|

|

| quote | Originally posted by 87FieroLemons:

Hello Fiero Forum,

We're a team (re)building a Fiero for the Lemons series. It ran previously with a 3.4 TDC and a 282, currently we're working towards converting it to a L26 3800 with an F23 5 speed. We've sourced a couple engines, though we're unsure at this point of their mechanical state. We also have four F23 transmissions, two cavalier, one FY1 and one M84 (junkyard sent us the wrong one). No one on the team has any experience with Fieros so this will likely be a thread of many questions. I appreciate any and all help.

To start, my understanding of the coolant elbows is that they only feed the heater core. If so, I'd like to remove them entirely and bypass the heater core by threading each inlet and running a short hose between to maintainbypass flow. I found a few mentions indicating this has been done, but I'm struggling to find actual documentation of it beyond some specs such as thread size and type (3/4" and 1" NPT) and a warning about the metal being thin. Anyone have any further details?

Secondly, are there any recommendations for a cable throttle body besides the northstar 96-99 or 2k+? We're running a Microsquirt for engine management and the stepper motor IAC eats up a significant amount of I/O on the ECM. The MAF sensor also appears to be a frequency type which is incompatible with our ECM, although we'd like to be able to run a blended MAF/MAP setup, it isn't strictly necessary. I suppose the ideal setup would be a 75mm cable throttle body with a 2 or 3 wire PWM IAC valve and a lip to mount intake tubing so we can run an in-line voltage-based MAF, if we decide to run a blended MAF/MAP setup.

I'm sure we'll have many more questions to come as the build progresses. We're also currently debating how we want to frankenstein the transmissions to get our 3.63 FDR while getting the cavalier bellhousing and maintaining reasonable mounting options, if anyone wants to weigh-in on that, I'm happy to hear it. |

|

my 2.8 is running 5/8 inch heater hose and the oem fittings for the heater, ugly but functional, my solution to the smaller size was a few more hose clamps, the correct way to do that would probably be finding a 5/8s to 1/2 adapter or sautering a bigger fitting on inplace of the smaller one

honestly? no. you can modify the throttle body to make it cable driven though depending on the style (did it on a 07 triton to get it working in a 80s truck even though it hurt me very much to put that junk in that f150)

as for the overheating? ford taurus fan. moves 4000 cfm ir something ridiculous and solved a overheating 350 in a fiero with a stock rad, plus a 454 swapped s10 (looking forward to doing it myself)[This message has been edited by cartercarbaficionado (edited 04-21-2025).]

|

|

|

Patrick

|

APR 21, 01:18 AM

|

|

| quote | Originally posted by 87FieroLemons:

Any recommendation on a minimum diameter?

|

|

You might get away with 1/2", but considering that the two I.D. hose sizes on the heater core are 5/8" and 3/4", you probably should go no less than 5/8" to be totally safe.

|

|

|

eph_kay

|

APR 21, 04:00 PM

|

|

Very excited to see this car getting back on the track. Since you are running a Microsquirt you need to look to see if MS2 coding accepts a MAF table, I honestly haven't looked, the only MAF Megasquirt set up I have done was MS3 code. Also since you are planning a 3800 the cool thing about their ignition system is you get to use the original ICM and only require a single output from the Microsquirt to control timing, the cranking bypass isn't super needed for a race car, ive done one 3800 powered buggy that way. If you have questions there is a weird thing with that ICM when tuning, every time you flash the ecu it think the ICM has had an error and goes to base timing, so you need to restart the car each time you flash a tune or you will be at static 10 degrees advanced, that took awhile to learn

New is the throttle body, you can get a Northstars throttle body, drive the IAC in to fully closed and work it with just the throttle screw since again you are a race car, if you want you can then set up a 2 or 3 wire PWM IAC externally routed to the intake past the throttle body and use the FIDLE off the Microsquirt

As for that car, I actually did the original wiring harness on the stock ecu and helped with the Microsquirt as well and ran the car one race. The motor actually died from the water in the block freezing from what I understood not from overheat at a race, I do think they had one engine fail early in the cars career from overheating, but by the time I was a part of anything all of that was sorted out

The 3800 heater core lines, since you won't likely be needing or using a thermostat shouldn't have any problem with both of them being capped, in theory you will have plenty of flow through the factory thermostat housing and the factory water pump and timing cover. Some of the 3800sc swaps I have done we used the lower intake manifold to feed coolant to the heater core, some of the buggy swaps I have done we capped all those ports, no issues with overheating, and Buggy's are hard to keep cool

Chris

|

|

|

Patrick

|

APR 21, 04:06 PM

|

|

| quote | Originally posted by eph_kay:

The 3800 heater core lines...

|

|

Oh... I somehow missed that this was going to be swapped over to a 3800 (and possibly without a thermostat).  My experiences with a 2.8 may not then apply here. My experiences with a 2.8 may not then apply here.[This message has been edited by Patrick (edited 04-21-2025).]

|

|

|

87FieroLemons

|

APR 21, 07:27 PM

|

|

| quote | Originally posted by Brian A:

Very cool! Best wishes.

It will be fun to watch the build! Post lots of photos!!!

There is a nice Fiero Lemons car that runs here in the San Francisco Bay Area. It does quite well.

I have a 1987 Fiero GT track car but don't race it. |

|

We're definitely aware of a couple other teams that run these cars with some success. It's our first venture into road racing, much less Lemons. Our family has a bit of a background with drag racing but that's a very different world. I'll see what I can do about getting some photos posted.

| quote | Originally posted by cartercarbaficionado:

my 2.8 is running 5/8 inch heater hose and the oem fittings for the heater, ugly but functional, my solution to the smaller size was a few more hose clamps, the correct way to do that would probably be finding a 5/8s to 1/2 adapter or sautering a bigger fitting on inplace of the smaller one

honestly? no. you can modify the throttle body to make it cable driven though depending on the style (did it on a 07 triton to get it working in a 80s truck even though it hurt me very much to put that junk in that f150)

as for the overheating? ford taurus fan. moves 4000 cfm ir something ridiculous and solved a overheating 350 in a fiero with a stock rad, plus a 454 swapped s10 (looking forward to doing it myself)

|

|

We're more concerned about air developing in the system from boiling the water. With such a long cooling system and cast iron heads, it seems like there's a high likelihood. We do need to source another fan and I am aware of some of the junkyard favorites (Taurus, Lincoln MK VIII, etc.).

| quote | Originally posted by Patrick:

You might get away with 1/2", but considering that the two I.D. hose sizes on the heater core are 5/8" and 3/4", you probably should go no less than 5/8" to be totally safe.

|

|

| quote | Originally posted by Patrick:

Oh... I somehow missed that this was going to be swapped over to a 3800 (and possibly without a thermostat).  My experiences with a 2.8 may not then apply here. My experiences with a 2.8 may not then apply here.

|

|

Understood! Any and all information is welcome. The 3800 does bring unique challenges but the Fiero is kind of a challenge irrespective of powertrain.

| quote | Originally posted by eph_kay:

Very excited to see this car getting back on the track. Since you are running a Microsquirt you need to look to see if MS2 coding accepts a MAF table, I honestly haven't looked, the only MAF Megasquirt set up I have done was MS3 code. Also since you are planning a 3800 the cool thing about their ignition system is you get to use the original ICM and only require a single output from the Microsquirt to control timing, the cranking bypass isn't super needed for a race car, ive done one 3800 powered buggy that way. If you have questions there is a weird thing with that ICM when tuning, every time you flash the ecu it think the ICM has had an error and goes to base timing, so you need to restart the car each time you flash a tune or you will be at static 10 degrees advanced, that took awhile to learn

New is the throttle body, you can get a Northstars throttle body, drive the IAC in to fully closed and work it with just the throttle screw since again you are a race car, if you want you can then set up a 2 or 3 wire PWM IAC externally routed to the intake past the throttle body and use the FIDLE off the Microsquirt

As for that car, I actually did the original wiring harness on the stock ecu and helped with the Microsquirt as well and ran the car one race. The motor actually died from the water in the block freezing from what I understood not from overheat at a race, I do think they had one engine fail early in the cars career from overheating, but by the time I was a part of anything all of that was sorted out

The 3800 heater core lines, since you won't likely be needing or using a thermostat shouldn't have any problem with both of them being capped, in theory you will have plenty of flow through the factory thermostat housing and the factory water pump and timing cover. Some of the 3800sc swaps I have done we used the lower intake manifold to feed coolant to the heater core, some of the buggy swaps I have done we capped all those ports, no issues with overheating, and Buggy's are hard to keep cool

Chris |

|

Chris, very cool to run into someone who's familiar with this car.

We definitely intend to maintain the microsquirt. All the documentation I've read seemed to indicate that microsquirt and MS2 support MAF standalone or blended MAF/MAP. However, B&G firmware supports frequency MAFs but only on a specific pin and MSExtra firmware doesn't support them at all. So, seems like a voltage MAF, if any, is the safest route. This is my first time wiring/tuning an engine so I welcome any advice you have to offer.

As to the throttle body, I'm not sure it's in our interest to maintain MAF but my counterpart purchased a 96-99 northstar throttle body whose front is designed only to connect to it's bolt-on MAF. The more I research the more I think we may need to just toss it and push forward in a different direction. Ideally a 75mm +/- that comes stock with a PWM IAC to avoid unnecessary complexity. I definitely want to try and reduce I/O requirements for items that aren't offering us a speed or reliability advantage, my teammate has even discussed boost in the future so the more pins available in the future, the better. We don't have an adapter plate as of yet, so we're not committed and I think we should be able to fab one ourselves.

It's interesting to hear your recounting of the engine failure. We were told it had seized from overheating, although I would be unsurprised to hear it sat and froze. We've definitely discussed the pain it is likely going to be, cycling coolant and water constantly, to be in compliance with Lemons' requirements while keeping the cooling system from electrolysis or freezing.

I hadn't necessarily considered eliminating the thermostat. We're pretty green to this, so I won't pretend to know if that's common or the accepted practice. My initial concern would be dramatic temp swings, from leaving track to pitting and being back on track, making thermal cycling a problem for expansion sensitive items (rings, gaskets, etc.). Considering how often we're going to have to pit with a relatively meager fuel capacity, it may be quite a few temp swings although I acknowledge your experience doesn't reflect that.

|

|

|

eph_kay

|

APR 21, 10:31 PM

|

|

| quote | Originally posted by 87FieroLemons:

Chris, very cool to run into someone who's familiar with this car. |

|

Yeah I can't take credit for the build, but Adrian and Keith did awesome with the set up and it was a blast with the TDC in there on track

| quote | Originally posted by 87FieroLemons:

We definitely intend to maintain the microsquirt. All the documentation I've read seemed to indicate that microsquirt and MS2 support MAF standalone or blended MAF/MAP. However, B&G firmware supports frequency MAFs but only on a specific pin and MSExtra firmware doesn't support them at all. So, seems like a voltage MAF, if any, is the safest route. This is my first time wiring/tuning an engine so I welcome any advice you have to offer. |

|

What you will likely learn is MAF tuning isn't enough more accurate for 90% of builds to need it and you will be able to do a Speed Density tune that is more than adequate. My VW Rabbit has a VR6 with turbo with motorcycle throttle bodies, I used a MAF on the build as I was quite happy with how MAF tuning goes with HP tuners on the 3800sc swaps I had done, with MS3 code the MAF table is its own table, then you build a MAP table that is a modifier for the MAF table, then when you tune the MAF table you can't use Autotune, you have to data log the runs, then pull the log into Megalog Viewer and looks at a histogram plot to find where the MAF is off by, then hope you haven't compensated in the MAP tune for a MAF issue and chase your tail. Its much easier to just go full Speed density, of the 35 megasquirts I have installed only 1 uses MAF, a couple use Alpha N(TPS only) but most use Speed Density tables

| quote | Originally posted by 87FieroLemons:

As to the throttle body, I'm not sure it's in our interest to maintain MAF but my counterpart purchased a 96-99 northstar throttle body whose front is designed only to connect to it's bolt-on MAF. The more I research the more I think we may need to just toss it and push forward in a different direction. Ideally a 75mm +/- that comes stock with a PWM IAC to avoid unnecessary complexity. I definitely want to try and reduce I/O requirements for items that aren't offering us a speed or reliability advantage, my teammate has even discussed boost in the future so the more pins available in the future, the better. We don't have an adapter plate as of yet, so we're not committed and I think we should be able to fab one ourselves. |

|

You will not find a single PWM IAC built into a throttle body that I logical to use, Ford has it on a few things, but its big and clunky and large ford throttle bodies tend to be expensive, plus the Northstar(not the one you have, the next generation unit) fits to the fiero v6 throttle cable with such little modification its a no brainer

| quote | Originally posted by 87FieroLemons:

It's interesting to hear your recounting of the engine failure. We were told it had seized from overheating, although I would be unsurprised to hear it sat and froze. We've definitely discussed the pain it is likely going to be, cycling coolant and water constantly, to be in compliance with Lemons' requirements while keeping the cooling system from electrolysis or freezing. |

|

If I understand the story correctly years ago a local ish dealership ended up having 3.4 TDC crate motors cheap, they popped up at a few different locations around the same time, which is why you see so many of them out there. They built the car with a complete Z34 donor car with the TDC and the getrag 284(I think thats the number). That motor was run for a long time but I think it's the one that overheated and seized. I bought a few of the crate motors, Adrian bought a few of the crate motors, well maybe 1 and I bought 2, but he ended up buying both of mine from me. So one went into the car(I think its the current engine you have in the car) it ran for years and many races, its the car that got the Microsquirt installed onto, and it went up until the drained block had just enough water in it to crack the block while the car was parked over one winter.

| quote | Originally posted by 87FieroLemons:

I hadn't necessarily considered eliminating the thermostat. We're pretty green to this, so I won't pretend to know if that's common or the accepted practice. My initial concern would be dramatic temp swings, from leaving track to pitting and being back on track, making thermal cycling a problem for expansion sensitive items (rings, gaskets, etc.). Considering how often we're going to have to pit with a relatively meager fuel capacity, it may be quite a few temp swings although I acknowledge your experience doesn't reflect that. |

|

Not sure if no thermostat is the exact answer, but if you run a controller on the fan(I use Hayden 3653 mounted in the front to trigger the ground trigger form the original AC wiring of the car to activate the fan) they you can run your fan on a switch and on the controller, turn the switch of when you go to the pits and the fan will cycle keeping the temp within check, you will be surprised having the radiator at the front it will be super efficient, and being disconnected from engine its even more efficient. Then you will be putting enough heat into the system that the short amount of driving from track to pit to refuel you won't lose too much temp and won't have the car running some of the time so I don't think you need to worry about much. There is a theory that gets proven on different engines where if the thermostat isn't in the system the size of that point of flow is too big and will flow TOO much coolant too quickly not giving enough time for the radiator to dissipate the heat and people will put a flat plate with a smaller hole in it to restrict flow to keep the coolant from flowing too quickly. I would imagine the extra length of line in a mid engine application will slow flow a little, and the fact that you are going to be staying between 3k and 7k rpms 90% of your time you are going to be flowing ALOT of coolant and I doubt the "non restricted" flow will cause any problems, but it will be a play it by ear kind of situation

Chris

|

|

|

|