|

| How to Remove Coolant Plug from Head (V6) (Page 1/1) |

|

robmox

|

NOV 29, 02:42 PM

|

|

Hello, everyone!

I'm working on an engine swap, and I'm nearing the finish line.

My next big issue is that the machine shop put what appears to be the temperature sensor in the head and the coolant plug for the head in the wrong spots. I went to remove the coolant plug (I have a set of plumbing coolant plug wrenches), and it wouldn't budget. I cranked on it with the breaker bar, and then tried the breaker bar. I'm afraid to put heat on it.

But, does anyone have suggestions for how to remove this coolant plug from the head?

Alternatively, I may just rewire the plug for the sensor and route it back to the front of the engine. The one issue with this is that the coolant pipe runs right past it and it looks to be in the way.

Let me know your thoughts.

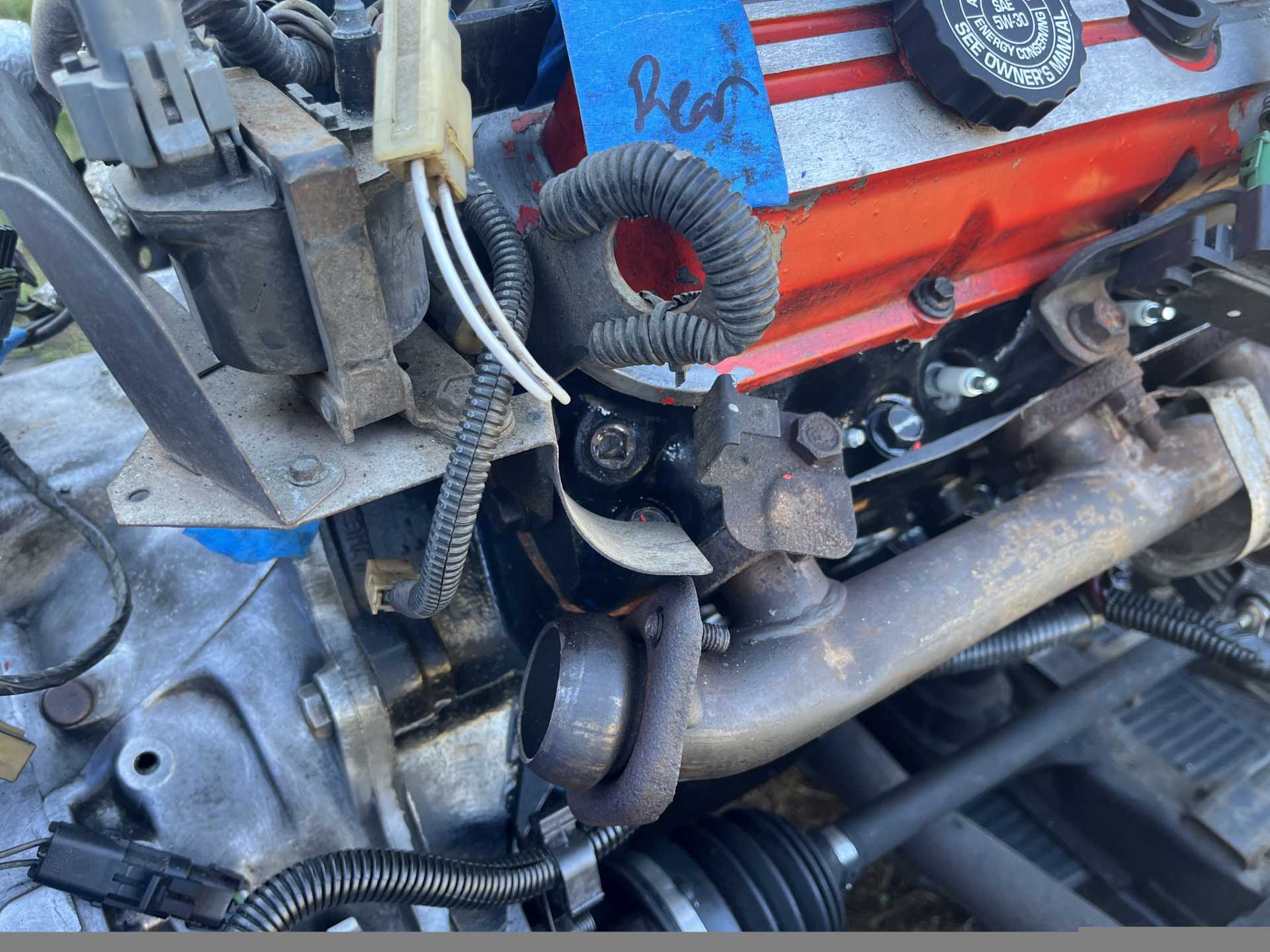

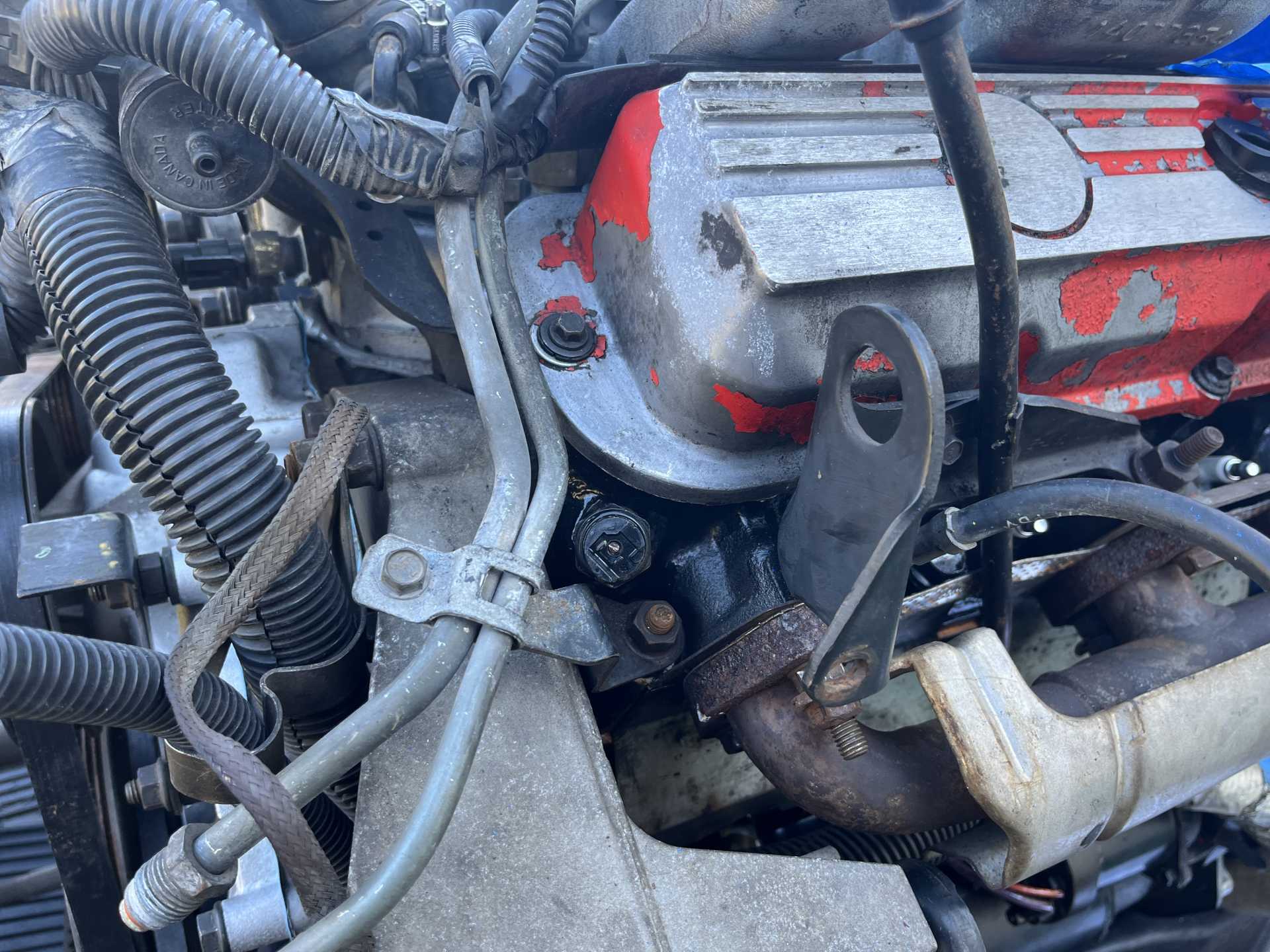

The plug in question:

The sensor:

The coolant pipe that impacts the sensor:

|

|

|

82-T/A [At Work]

|

NOV 29, 07:41 PM

|

|

| quote | Originally posted by robmox:

Hello, everyone!

I'm working on an engine swap, and I'm nearing the finish line.

My next big issue is that the machine shop put what appears to be the temperature sensor in the head and the coolant plug for the head in the wrong spots. I went to remove the coolant plug (I have a set of plumbing coolant plug wrenches), and it wouldn't budget. I cranked on it with the breaker bar, and then tried the breaker bar. I'm afraid to put heat on it.

But, does anyone have suggestions for how to remove this coolant plug from the head?

Alternatively, I may just rewire the plug for the sensor and route it back to the front of the engine. The one issue with this is that the coolant pipe runs right past it and it looks to be in the way.

Let me know your thoughts. |

|

That plug is really hard to remove. I think you already know, but the coolant plug "socket" is just a 3/8" socket extension. The best way to remove that is to slowly work the plug back and forth. Sounds crazy, but work it back and forth (meaning, tighten it, and then loosen it). Tightening it helps break the threads free in the other direction. It likely has some thread locker on it, including sealer as well. Just keep working it back and forth until it starts to break free. No real easy way to do it other than to take the whole head off and send it off to a machine shop.

|

|

|

Patrick

|

NOV 29, 07:50 PM

|

|

| quote | Originally posted by robmox:

My next big issue is that the machine shop put what appears to be the temperature sensor in the head and the coolant plug for the head in the wrong spots.

|

|

I suspect at some point in that engine's life, the heads were removed (with the temperature sensor and coolant plug already in place)... and then reinstalled on the opposite sides of the engine.[This message has been edited by Patrick (edited 11-29-2024).]

|

|

|

sleek fiero

|

NOV 29, 08:44 PM

|

|

|

If you heat the plug with a propane torch and then let it cool it will destroy thread locker/sealant and shrink the plug. Also sometime hitting with a punch that fits in the hole for the wrench will help break the threads free. sleek

|

|

|

fierofool

|

NOV 29, 09:07 PM

|

|

|

That's a common situation when swapping in a 3.4. The plug and temp sensor are in opposite heads than the Fiero. Fortunately, that was caught on my swap, so the heads were removed, new head gaskets installed, and the heads were swapped from side to side. If you can get a 3/8 drive impact extension and an impact, a little tightening and loosening as 82-T/A described. Maybe a little heating and cooling, too.

|

|

|

cliffw

|

NOV 30, 10:41 AM

|

|

| quote | Originally posted by 82-T/A [At Work]:

The best way to remove that is to slowly work the plug back and forth. Sounds crazy, but work it back and forth (meaning, tighten it, and then loosen it). Tightening it helps break the threads free in the other direction. It likely has some thread locker on it, including sealer as well. Just keep working it back and forth until it starts to break free. |

|

Absolutely. Tighten a tad first, and then loosen a tad the other way. Again in that procedure just a little bigger tad. I learned this from an ASE certified lifelong mechanic friend of mine. In my case, I broke a bolt head off using a bigger hammer, and had to drill a hole dead center (mine was a 90o drilling operation in tight quarters), then use a tap and die set.

Another option is to use an impact wrench. I can not find my hammer blow driven one but it applied just one impact per hammer strike. You can use a cordless one but don't keep impacting in only one direction.

|

|

|

fierosound

|

DEC 02, 12:21 PM

|

|

|

|

Notorio

|

DEC 12, 11:22 PM

|

|

|

Rob, please let us know what worked (or didn't work) for you ...

|

|

|

|