|

| 1988 2.5 Throttle Cable (Page 1/1) |

|

Fieoreos

|

MAY 06, 04:26 PM

|

|

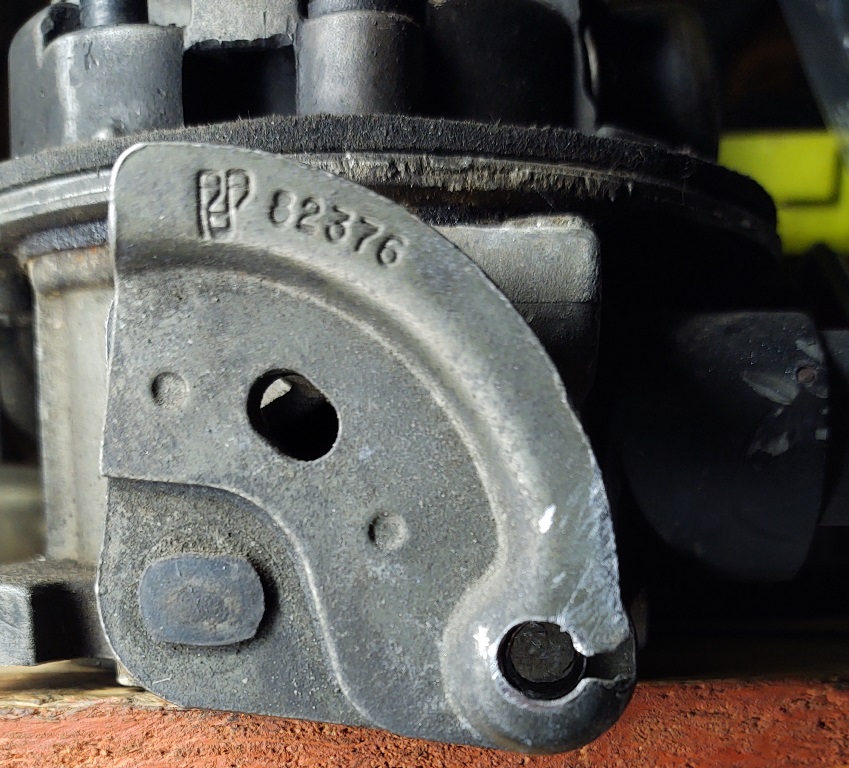

I'm looking for the short cable that connects the throttle linkage to the throttle body. My son talked me into letting him buy 3 Fieros over a year ago, and we are getting close to finishing up an engine overhaul on the first one. This car was missing everything from the block up on the engine assembly. We purchased another complete engine, BUT, it looks like we are short a cable. I've looked around online at the usual places and have come up empty handed. Any help would be great. Even a picture of a complete setup would be nice.

|

|

|

Vintage-Nut

|

MAY 07, 12:32 PM

|

|

According to the P22 parts book, these are the GM Part Numbers for 1987-1988 Pontiac Fiero 2.5L

10041795 (MT2)

10046606 ((MD9 EXC K34)

10046607 (MD9, K34)

10046608 (MT2, EXC K34)

10046609 (MT2,K34)

Of course, they're discontinued AND The Fiero Store only offers '84-'86 4cyl Throttle Cables.......

Post your need in 'The Mall' which I often comment to try member Larry Hubert and send a PM asking if he has the cable.

| quote | Larry Hubbert

If I can be of any help, please contact me on Facebook Messenger (Larry Hubbert), PM on Pennock's (Larry Hubbert) and/or direct at LHUBBERT2@BRIGHTHOUSE.COM. Also please use your true name and/or provide me with the names you use on other venues in order to avoid any confusion. |

|

------------------

Original Owner of a Silver '88 GT

Under 'Production Refurbishment' @ 136k Miles

|

|

|

theogre

|

MAY 08, 05:14 PM

|

|

Worse, only Stick cars need that short cable so getting Used part is even harder.

MD9 is TH125c & cable is 1 piece from pedal to TBI & "idle" pulley is totally Round.

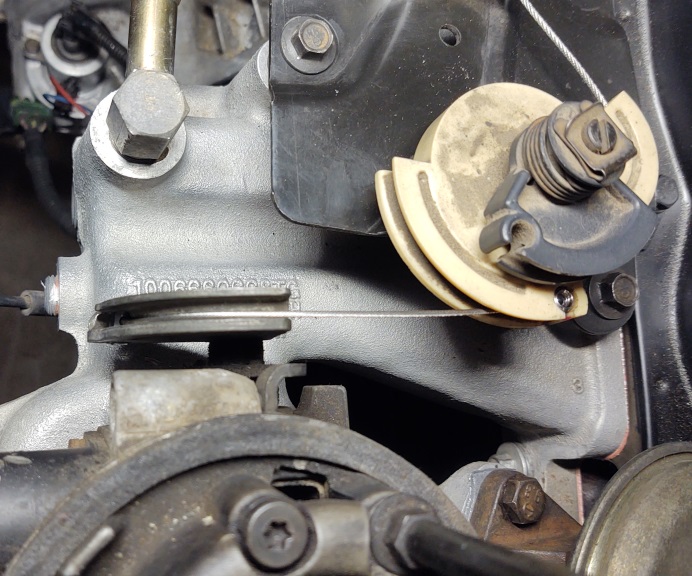

For Ref: top pulley is for Cruise servo cable that pulls the bottom pulley when active. Other "cable slot" that "runs backward" & goes "nowhere" on the this pulley set is for TV cable to MD9 trans.

Can Make a cable out of Brake/Clutch Cable for Bikes etc. The ends don't need to look nice just to keep the ends anchor.

Quick Example: Find a brake cable w/ 1 factory "barrel" end to use on plastic pulley (so 1/2 the work is done) then figure out metal pulley end where can mod the pulley as needed to anchor that end.

Might be able to make a tight loop for TBI end & use a nail as the "barrel." Or maybe just hook the pulley but file out sharp areas where cable hits. Crimp/solder a small steel tube to make the loop.

Or drill 1 or 2 small holes in a nail to fit the cable then "crimp" the hole(s). 2 holes carefully done will make very hard to pull out even before you "crimp" 1 or both holes w/ a punch.

Or just use longer cable thru the TBI cable section then into 2 or more holes you drilled in the middle section & maybe a small screw to finally "clamp" the end so stay put.

The ends see "static" loads once installed & barely or never see full tension of the cable as part of pulley carries most cable load except maybe @ very end of travel @ WOT.

Barrel & other ends are easy @ the factory etc but often ways to get around the factory ends. But in this case, don't use Solder like many on YT etc does to make important/critical ends. that only good for things like lawn mowers etc.

Gas Pedal should be around same height as brake pedal when the cable(s) are right. But often Fiero Gas Pedal has problems too so can't trust that. Like the Pivot Block & arm section passes thru is way worn making the pedal to sit lower. see https://web.archive.org/web...~fierocave/cable.htm

But I don't have pics of the block mostly because all black & no easy way to see where is worn in a pic. The Arm & metal bracket is easy to see when you remove the block.

------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave[This message has been edited by theogre (edited 05-08-2024).]

|

|

|

Fieoreos

|

MAY 13, 04:55 PM

|

|

|

|

cartercarbaficionado

|

MAY 13, 06:00 PM

|

|

| quote | Originally posted by Fieoreos:

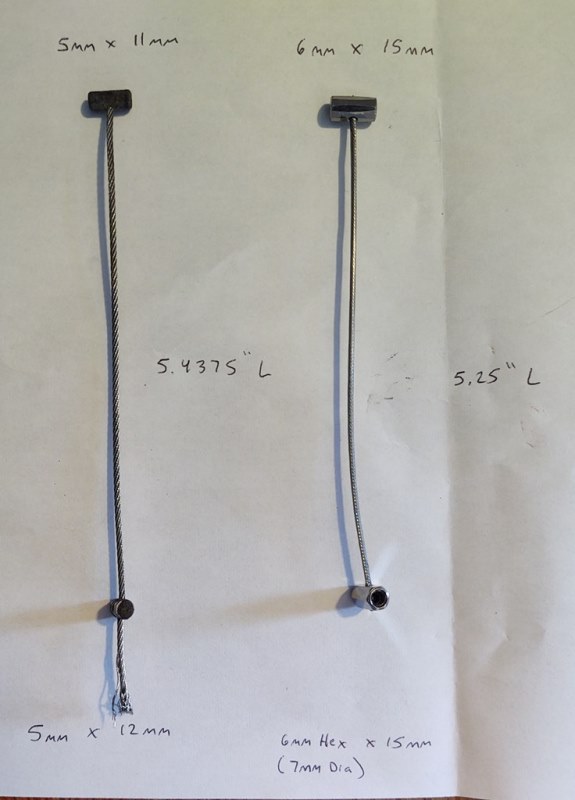

I jumped down several rabbit holes and came to the same conclusions. The parts are not available new, and bicycle cables could be used to fab up a new temporary cable. My biggest hang up was navigating the names and types of cable ends. I thought I had the lingo down until I stepped into my local bike shop. They were not familiar with the terms I used, and started talking about gyros, and modulevers. The word I heard repeatedly was knarp. I guess knarps are what I needed. So I bought my knarps and a piece of cable for about $9 and headed home.

I fiddled around with the movement of the throttle, and the pedal to get an idea of how long the cable should be. Then I used a piece of string and a screw with the throttle wide open, and the pedal to the floor to double check the length. I made the cable a little long just to be safe. The knarps have a set screw so shortening the cable is easy. I mounted the knarps at 90 degrees from each other to match what I thought the cable layout should be. I didn't have an OE cable or picture of one for reference. The hole in the throttle body was a little small for the new hexagon shaped knarps so I drilled it out, and filed the knarp some. I put the new cable in, and, it was too long. No big deal, move the knarp and clipped off the cable. At about 5.25" long the cable seems about the correct length. Hopefully the new cable will hold together.

|

|

from a mountain biker and car enthusiast, please lock tight and tighten the absolute living crud out of those and always carry spares, also sometimes the shops just call em ends for whatever reason, you can for future reference on another one of these use a brake or shift cable and then only one bolt on end to make a cable and that the factory ends are lead and can be made of pipe solder if you want a factory look like I did on my specialized zee performance comp z4 during its restoration

|

|

|

theogre

|

MAY 13, 08:40 PM

|

|

Good call w/ 90° def for the ends as way short cable likely doesn't last twisted a lot.

When I pull the throttle cable for auto trans, I install pulley first then TBI both w/ minimum twisting for same reason.

Might should have left the cable a bit long then put a solder ball so never get the end off in case screw gets lose.

Also found extra pedal assem & better light & camera updated pedal broke again for problems w/ the "bearing box."

|

|

|

Fieoreos

|

MAY 22, 09:13 PM

|

|

I did find a cable at a pick and pull the other day, well sort of. Our car is a manual, and I found an '87 Pontiac 6000 with a 2.5L and an automatic, the 6000 has a long once piece cable. I clipped the cable off and brought it home. The OE cable fits like it should, but is about 3/16" longer than the one I made. I tested it out and it doesn't open the throttle all the way. So I'm sticking with the one I made. The OE cable will be in the car just in case.

|

|

|

theogre

|

MAY 22, 09:52 PM

|

|

|

|

|