|

| 84 front lower ball joint ruined? (Page 1/2) |

|

AsaBergman

|

JUN 09, 07:36 PM

|

|

Took my front lower control arms to a mechanic to have the ball joints replaced. Replacement ball joints were Moog, not cheapo ones. I was unaware some original 84s had some welds holding the ball joint in. Mechanic removed the welds with a torch and 'pressed' the new ball joint in. Upon getting home and setting the control arms down on the bench one of the ball joints(without the snap ring) popped out. The sockets on both control arms are damaged.

First, without the snap ring would the ball joint be able to be popped out so easily by setting it down on a bench. Second, is the socket the ball joint presses into ruined? What are my options here? Should I have the ball joints welded in or locate new arms?

|

|

|

AsaBergman

|

JUN 09, 09:21 PM

|

|

|

|

Spoon

|

JUN 09, 09:55 PM

|

|

I've always known that those ball joints are pressed in and if a snap ring is used that is a just in case for insurance. Must of been a rookie mechanic. I've heard similar stories like that from a friend of mine. If something goes bad they can blame you for poor assembly despite their work being shoddy.

Who did this to you? You can pm me the shops name.

I'd start from scratch with 2 control arms. Who knows how hot he got them. Metal could be brittle now and subject to cracking while on the road under load.

Let them know the ball joint fell out of the arm before you had a chance to put it on the car. This could of been a deadly situation.

Spoon

------------------

"Kilgore Trout once wrote a short story which was a dialogue between two pieces of yeast. They were discussing the possible purposes of life as they ate sugar and suffocated in their own excrement. Because of their limited intelligence, they never came close to guessing that they were making champagne." - Kurt Vonnegut

|

|

|

AsaBergman

|

JUN 09, 10:38 PM

|

|

I was able to fully reseat the balljoint by lightly hitting it with a rubber mallet. I don't think the hole in the control arm provides enough 'clamping' to hold the ball joint securely anymore because from what I've seen with other cars the ball joint should not go in that easy nor be this easy to remove. Definitely not safe. The other control are has two spots of damage on the ball joint socket so likely that one's even worse.

I agree, I'm going to hunt down replacement control arms as I don't think these can be trusted anymore. The worst part about this is I'm a very strict/stubborn DIY person and this is the first time I've had a garage do any work other than tires. Should have just bought the tools.

I'd rather not share the name as I don't think the mechanic is an idiot and I quite like him, I think he just made a mistake. He didn't charge me when I picked them up so when I go back tomorrow I'm going to let him know I cannot pay him.

|

|

|

Patrick

|

JUN 09, 11:14 PM

|

|

| quote | Originally posted by AsaBergman:

Mechanic removed the welds with a torch...

|

|

I'm a little surprised that he wouldn't have ground the tack welds off, but maybe a torch is simply quicker?

When the suspension is assembled, the ball joints wouldn't be going anywhere. The spring tension keeps them well seated.

It's impossible to tell from here if the ball joint hole in each control arm is damaged enough to warrant replacing them... but if it were me, and the holes weren't loose enough to allow the ball joints to move side-to-side, I'd probably just go ahead and use them.  I guess it depends how readily available replacement control arms are. I guess it depends how readily available replacement control arms are.[This message has been edited by Patrick (edited 06-09-2020).]

|

|

|

theogre

|

JUN 10, 12:20 AM

|

|

If new joint(s) cane out just moving by hand...

The arm(s) need replacing and send the shop the bill to get it/them.

Holes need new joint pressed in them. Otherwise can, likely will, move and wallow out the hole under lateral loads.

Clip Rings w/ new BJ are just a backup to tight CA holes.

Shop Should Not used a torch to remove the tack weld. The damage done isn't just the torch hole. Heat for that goes well beyond actual torch hole to expand the metal at and likely near BJ hole.

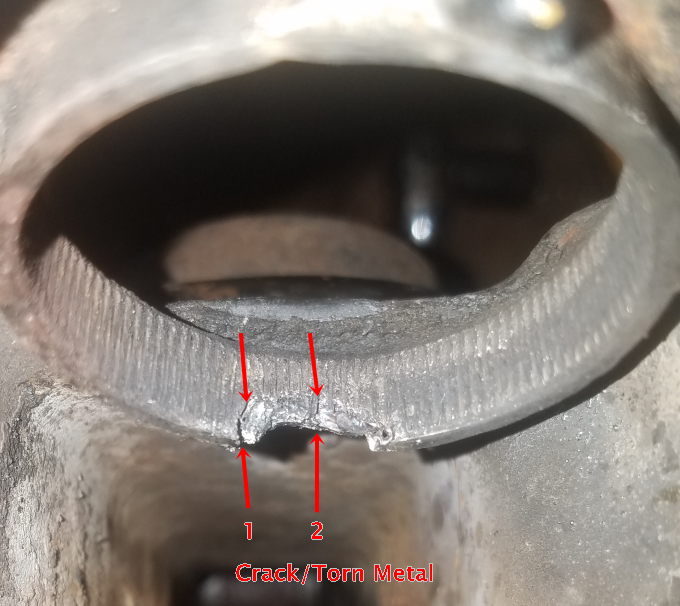

I copy the second pic to "zoom" on damage area... I see Two cracks... This is the Original Size, crop to 680x606 and save as png to save details & notes. If needed copy to local PC w/ larger screen to see. (I didm't have to use Software Zoom or anything else because picture is big and good.)

Likely because he party welded them in or fail to "cut" OE weld then press torn them apart.

Likely the BJ hole is distorted from heat and/or press operation to remove old BJ.

Actually look like missing metal was torn off and if true still attach to old BJ because edge right side and "arch" look torn not melted.------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

AsaBergman

|

JUN 10, 12:26 AM

|

|

| quote | Originally posted by Patrick:

I'm a little surprised that he wouldn't have ground the tack welds off, but maybe a torch is simply quicker?

When the suspension is assembled, the ball joints wouldn't be going anywhere. The spring tension keeps them well seated.

It's impossible to tell from here if the ball joint hole in each control arm is damaged enough to warrant replacing them... but if it were me, and the holes weren't loose enough to allow the ball joints to move side-to-side, I'd probably just go ahead and use them.  I guess it depends how readily available replacement control arms are. I guess it depends how readily available replacement control arms are.

|

|

Thanks for the response. The ball joints don't have any side-to-side play and can't be pushed out by hand. Far as I can tell the holes in the control arms are still perfectly circular.

I contacted someone selling a whole front suspension near me, waiting on a response. If not I'd have to get arms from ebay or the fiero store(which is a little too pricey for me at the moment). This is the most I've disassembled a car(entire front suspension) at once so I'm very paranoid about all this. I appreciate the response from you and Spoon.

|

|

|

Patrick

|

JUN 10, 12:41 AM

|

|

| quote | Originally posted by AsaBergman:

I contacted someone selling a whole front suspension near me, waiting on a response. If not I'd have to get arms from ebay or the fiero store(which is a little too pricey for me at the moment).

|

|

The Ogre probably posted while you were typing out your response. Heck, I've got an extra set of front control arms from an '86 GT you could have for free... but the shipping across the country and across the border would probably cost a lot.

|

|

|

AsaBergman

|

JUN 10, 01:20 AM

|

|

The other control arm. This ball joint was actually in pretty tight, couldn't knock it out with light taps like the other.

Ogre,

On second look at that control arm it does appear to have a very small crack and definitely looks like the metal was torn. This arm would only get worse if I used it.

Patrick,

I appreciate that very much but not only would shipping cost a ton it would also take much longer than expected. Luckily Fieros are far more common here in Pennsylvania than where you are, just a matter of finding time to pull parts at a yard.

Both arms are getting junked. Unfortunately I can't say much to the garage as it's a small town and I need inspections done somewhere. Atleast now I know I'm not foolish for doing my own work.

|

|

|

theogre

|

JUN 10, 02:06 PM

|

|

This is relatively easy even for very Nubes....

Replacement CA may have tack weld BJ or Not. GM seems to stop that in later years.

If true, can use Dremel w/ "heavy duty" cutoff wheels like PN 420 20pc or Reinforced 456 10pc but the are 1-1/2" vs 15/16" for normal and heavy duty.

Can use "EZ Lock" series too but cost more and bigger like reinforced wheels.

If you have variable speed tool, slower speeds may work better.

Can use thin "normal" wheels but easier to break them. Most Grinder tips often don't work for this job.

⚠️ All needs safety glasses/goggles because when then break, often shatters and goes everywhere.

Can buy "kits" that have some of different wheel, grinders, sanding, etc. that might help if you need arbors etc too. or even Tool kit w/ various bits/tips.

If buying new tool at minimum get 3 speed tool.

Could use HF etc tool tips and so one but often won't last long vs real Dremel tool. Some tips/wheels are cheap and may not last either. Grinder color matter for Dremel but others may not be same type even if same color.

B&D RTX™ 3-Speed Rotary Tool is good and easier because of locking "arm" to hold to change tips even w/ one hand.

Press tool like many tools are "Free w/ Deposit" at AZ and others. Most are 30 day to get 100% money back or you own it.

AZ shows what is available at each location. Change store online to find. Might need to call around stores for other chains.

|

|

|

|