|

| Lifter preload (Page 2/2) |

|

Lilchief

|

JUN 03, 03:00 AM

|

|

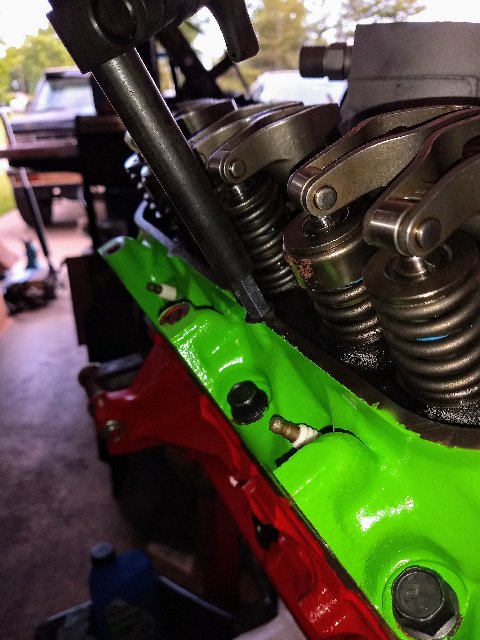

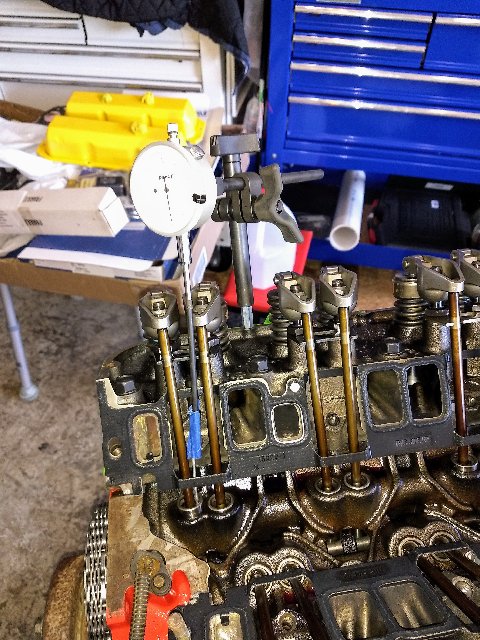

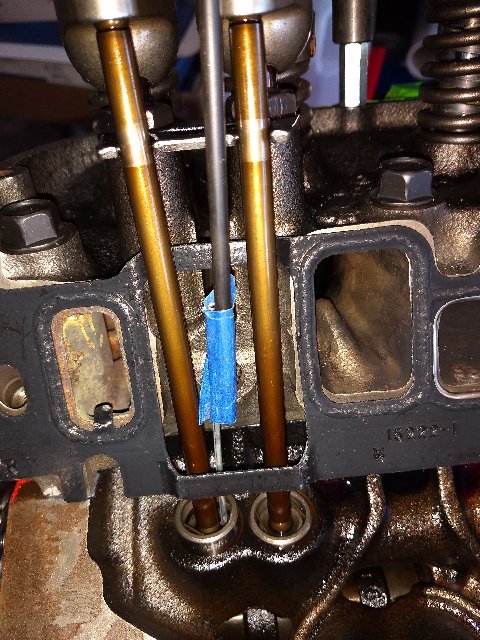

Here's some pictures of how I adjust my valves. I'm actually showing 2 methods same principal. I had to retap an althread coupling to a metric size to go in to the valve cover bolt hole. Just set the dial to zero and turn till the needle starts moving, being careful not to push down on the fulcrum (?) half round washer thing under the nut. Set to desired turns or thousanths of an inch. The compcam timing degree kit is where I got dial indicater from. I degreed the ARI cam and came out right on the money, .421/.444 llift.

This is actually for my s10. I think the intake is better than the fiero intake. The throats at bored to fit a 4.3 tbi which equals 60mm, runners are bigger and a whole lot shorter. Hope this helps someone.

|

|

|

Blacktree

|

JUN 03, 11:11 AM

|

|

With hydraulic lifters, you don't need to be very precise with lifter pre-load (not like a solid lifter). There's a pretty wide margin. And as long as it falls in that margin, you're OK. But ideally, the plunger will be in the center of its range of motion. Since you have a measuring device, you can measure that. Find out how far the plunger travels until it bottoms out, and divide that distance by 2. That will be your preload. It'll put the plunger exactly in the middle.

That said, I prefer to use zero lash plus 3/4 turn. I've seen a valvetrain get loose enough to clatter (after fully broken in) when I used only 1/2 turn of preload.

|

|

|

|