|

| General question about welding up and redrilling a hole on a spindle??? (Page 1/3) |

|

qwikgta

|

MAY 07, 01:10 PM

|

|

So years ago, Arautt Motor Sports (AMS) purchased from Held the rights to produce and sell suspension / brake parts. This is not a thread about AMS or Held. For a short period of time, AMS was selling dropped spindles that had the hole for the outer tie rod drilled incorrectly, they were drilled upside down. So while they looked good, when you installed them you found out that the outer tie rod would not fit into the hole unless you turned it 180' and had it going down into the hole from the top, vs going up from the bottom.

I'm not sure if just running them that way would cause any issues, I guess if the steering could turn full left to right and didn't bump into the swaybar or hit the calipers at any time during movement ?????

I just found out that the 88 i'm driving daily has a set of those mis-drilled 1" dropped spindles on it, however, they were installed upside down, so instead of dropping the front 1" it has raised the front 1". Funny thing is the PO had installed Rodney Dickmans 1" dropped ball joint on it, so in the end it just stayed - even.

Now that i know this, i plan to swap the spindles and get the full drop on the front that I'm looking for.

SO here is the question: After swapping will is be an issue to run the steering rack w/ the outer tie rods upside down, or should I get the spindles re-drilled?

And, has anyone ever had a machine shop weld closed the/a hole and re-drill it? Is it possible? Or should I just turn the outers 180?

Thanks in advance.

|

|

|

fierosound

|

MAY 07, 01:57 PM

|

|

A picture is worth a 1000 words. Do you have any?  [This message has been edited by fierosound (edited 05-12-2020).]

|

|

|

IMSA GT

|

MAY 07, 03:10 PM

|

|

I don't see an issue running them upside down as long as they clear everything and you don't notice any excessive angles/stresses on the end joints when you steer to full lock.

I'm more concerned about the structural integrity of the entire part. As Fierosound mentioned, can you post a picture of the entire spindle? I need to see if these are Held or Arraut spindles. There is a huge difference in safety between the two.[This message has been edited by IMSA GT (edited 05-07-2020).]

|

|

|

ltlfrari

|

MAY 07, 03:27 PM

|

|

Stock position is with the tie rod end beneath the steering arm on the knuckle, so if you install the knuckles the correct way up, the tie rod end will be on top.

So the question is, will the toe rod hit the sway bar (or anything) else with the suspension in full compression?

If not then I think you'd be ok putting them in upside down otherwise not.

At worst you'd have a bit of up slope on the tie rods when the car was on the ground vs being pretty parallel if mounted correctly but I cannot really see tha causing any major problem given the angle would not be that far off.

------------------

Anything I might say is probably worth what you paid for it, so treat it accordingly!

Dave

www.ltlfrari.com

|

|

|

olejoedad

|

MAY 07, 07:35 PM

|

|

|

Keep in mind the hole is tapered. [This message has been edited by olejoedad (edited 05-07-2020).]

|

|

|

pmbrunelle

|

MAY 07, 07:40 PM

|

|

| quote | Originally posted by ltlfrari:

At worst you'd have a bit of up slope on the tie rods when the car was on the ground vs being pretty parallel if mounted correctly but I cannot really see tha causing any major problem given the angle would not be that far off.

|

|

Bumpsteer?

| quote | Originally posted by olejoedad:

Keep in mind the hole is tapered.

|

|

Also, the castle nut needs a machined face to bear against.

|

|

|

fieroguru

|

MAY 07, 09:51 PM

|

|

We need pictures of this... if the entire spindle was installed upside down, the wheels have to be wonky.

The kingpin angle, different size ball joint tapers top and bottom, brake caliper position... lots of significant challenges to install a spindle upside down...

Makes we wonder what they modified to make it work and what all you would need to modify back to do it right.

|

|

|

qwikgta

|

MAY 08, 11:23 AM

|

|

OK, so this is what I know. The spindle is AMS, a friend of mine and I both ordered them from AMS within a few days of each other. He ordered two sets, one with a 1" in drop and the other with a 1.5" drop. Both of our packages arrived w/in a few days of each other. I had significant issues with my order, (not going into all of that) and I noticed that the taper for the tie-rod was drilled upside down. I contacted AMS and sent them back. Got another set and the taper was correct, however, the spindle was made incorrectly, in other words, it lacked the bracing that connected the tie-rod end to the spindle, and so I sent them back for a third set. Third set arrived and had issues but they were cosmetic and so I kept them.

Months later my friend took his car to a shop to install his 1.5" dropped spindles and had the same "upside down" issue. He sent those back and received another set, done correctly. The other set (1" drop) was sitting on his shelf and sat there for another 6 months or so. That set, the one in question, was purchased by the PO of my 88 GT. That set is the one he installed. I can only assume that he used the tie-rod taper as his guide to which side of the car the spindle needed to be installed. So, if that is true, then he put them on the wrong side.

in this pic, you can see that the brake is at the 8' o'clock position, when it should be at the 10 o'clock posit.

here is a close up of the driver side. In a dropped spindle, the centerline should be higher up with more of the distance from center being below the centerline. In this picture the centerline looks to be on the lower side, backwards right?

remember in this picture, the spindle is sitting on a 1" rodney balljoint.

Thoughts??[This message has been edited by qwikgta (edited 05-08-2020).]

|

|

|

qwikgta

|

MAY 08, 11:31 AM

|

|

| quote | Originally posted by fieroguru:

We need pictures of this... if the entire spindle was installed upside down, the wheels have to be wonky.

The kingpin angle, different size ball joint tapers top and bottom, brake caliper position... lots of significant challenges to install a spindle upside down...

Makes we wonder what they modified to make it work and what all you would need to modify back to do it right. |

|

Yes, if the spindle had any kingpin angle built into it, but I don't think they do, if so, its very slight. Also, not sure if being installed on top of a 1" dropped ball joint helps that b/c it has a lot of flex w/out contacting the lower A arm.

|

|

|

qwikgta

|

MAY 08, 11:37 AM

|

|

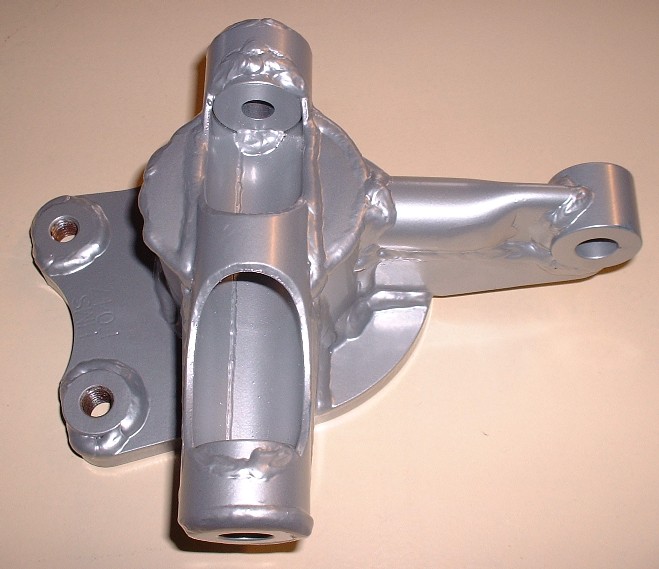

here is a pic of a dropped spindle, very similar to mine. if this picture represents the installed position, then you can see that the centerline is above the spindle center. if this is also the driverside spindle, then mine is upside down.

I always identified these with the two large scallops used to allow the balljoint nuts to be installed. I called the upper the "small" scallop and the bottom the "large". in the above pic, the small is on top, the large on the botttom.

in my pic from two posts above, the small is down, the large is up, again, a reason I think they are upside down.

Rob[This message has been edited by qwikgta (edited 05-08-2020).]

|

|

|

|