|

| Diagnosing, repairing and calibrating Fuel Sender (Page 1/1) |

|

fierobear

|

OCT 31, 04:53 PM

|

|

Recently Toddster wrote up as part of his Formula restoration the clean up and calibration of the fuel sender unit in the fuel tank. Some details weren't clear to me, so I'll ask my questions here...

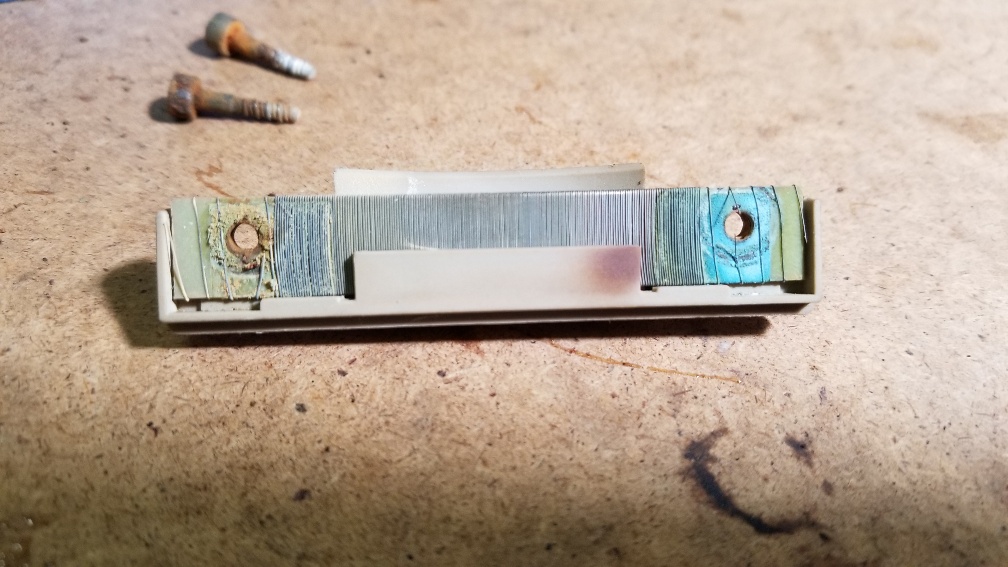

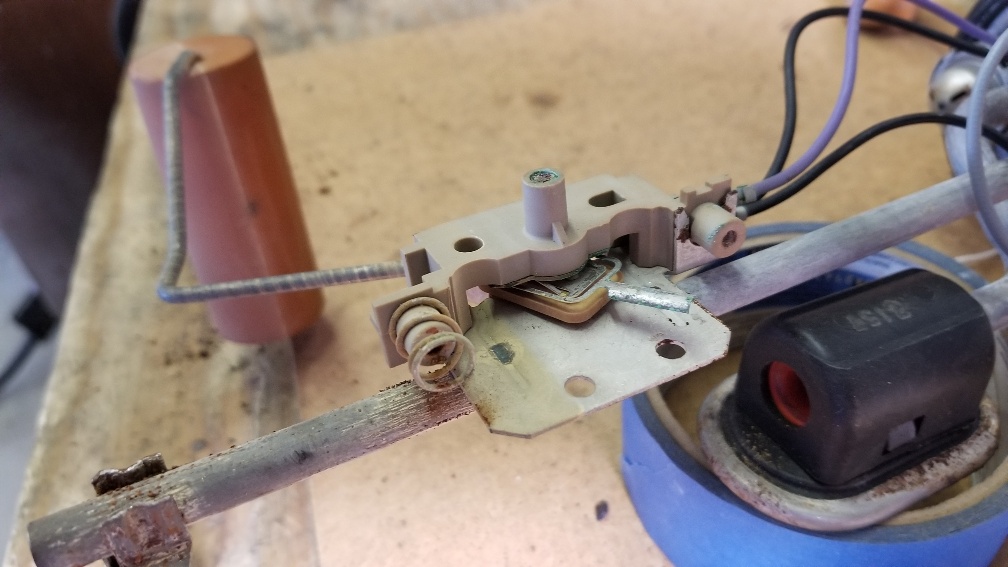

1. Where are the contact points on the Torx screws? Is it the flat plate, the very thin wires, or both?

2. How is contact continued from the screws through to main sending wires?

I plan to remove all rust and corrosion from all the parts of the sending unit, then do the calibration. I want to make sure I clean up everything that has corrosion and is preventing a good signal.

On the subject of calibration, how does adjusting the Torx screws affect resistance? Shouldn't there be just one place they can be tightened to? Too tight, they scrape the wires. Too loose, they are an open?

|

|

|

freedom0226

|

NOV 01, 07:21 PM

|

|

|

i just did this on my tank. search the archives there is a couple of great step by step instructions on how to do it. first i dip my entire sending unit in vinegar bath for a day or two and try to remove the coil strip as you already did and be verrrrry careful to not brake the copper lines as this will interrupt your readings. lighly try to sand them down with a fine brush or fine sand . if you can clean it all up well and reassemble you should be able to get some ohm readings now 0-90 ohms is the spec. Let me know if you cannot find the older write ups i mentioned and i can send you the link later on. WORST case scneerio you an either pay the $ 250 for a new sending unit from the fiero store OR get a 0-90 unit from ebay for $30 bucks and fabricate it on the OEM sending unit. You will also find a thread on that as well . its been done before. Let me know how i can help you

|

|

|

|