|

| '87 2.5L valve cover replacement (Page 1/4) |

|

waynrayn

|

JAN 17, 01:18 AM

|

|

Hi All:

In the process of preparing to replace a badly leaking valve cover gasket, I have gone through all the archives (27 pages of "valve cover" search). I have a pretty good understanding of the job, which seems relatively simple on a 2.5 L, and don't feel I need to ask a lot of questions. However, I would like to clarify some things.

1) On the right side of the cover, the PCV valve line lifts easily out of the grommet. Maybe too easily, I think. I noticed that the end of the PCV line is not sitting straight in the grommet. It is tight up against an electrical hose underneath, and over time has tilted to the left. The right side is raised a millimeter or two more than the left. I've posted pictures of the cover, and line alongside the electrical:

https://ibb.co/vvMy9qh

https://ibb.co/wgQKFc2

I think this should be tight in the grommet, and straight. I'll get new grommets with the Felpro package, but suggestions to adjust the tight line so it's not tilted would be appreciated.

2) On the left side of the cover, the breather hose is stiffer. I take it I can just put something like a screwdriver underneath it, and pull on either end of the screw driver to force it and the grommet out?

3) I have ordered the Fel-Pro rubber gasket. Ogre and others have indicated that a line of gasket sealer- from what I have read, I am inclined to use Permatex The Right Stuff- should be applied on both sides of the gasket. I tend to agree with this, so there is less chance of leakage. But am wondering if I am setting myself up for a world of hurt, if I have to get the cover off at a future date?

I'm hoping this is it, although I may be back with a question or two mid job.

Thx,

Wayne[This message has been edited by waynrayn (edited 01-17-2019).]

|

|

|

theogre

|

JAN 17, 03:05 AM

|

|

You didn't read newer posts... view by date.

Any rubber or cork is a waste of time/money. Never use sealer with rubber gaskets.

Many will install just RTV sealer and no gasket. I never say you should even tho GM did many at the factory. More confusing Some Covers are made for this but not all. Big problem is Many people don't clean and sealers won't seal for long.

Use Felpro VS50179T PermaDryPlus that comes w/ new bolts etc. Example: https://www.autozone.com/ex...over-gasket/231525_0

If cover is damage get Dorman 264-905 (try searching stores w/o dash Dorman 264905 ) induces new screw cap etc. https://www.dormanproducts....p-48101-264-905.aspx Example: https://www.autozone.com/ex...er-engine/454149_0_0

Can try to Order both at most local parts stores and get same or next day without "FedEx" shipping cost.

gaskets do not have seals for PCV.

Loosen the bolt and/or carefully bent the tube to fit the valve better. Valve doesn't care about being install a bit off.

PCV Seals and hose get hard etc and leak a little to a lot.

left side plastic elbow is often hard to remove because seal is hard. If you get a new Dorman cover. carefully cut the old seal to get elbow out w/o breaking.

Dorman and some other made just PCV grommets but don't have # right now. https://www.dormanproducts....eyword&q=PCV+Bushing Dorman says should be 42322 1 per pack and likely you need 2------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

fierosound

|

JAN 17, 07:20 AM

|

|

The BEST valve cover gasket you want to use on the Duke is Felpro PN FEL-VS50179T as theogre mentioned.

This rubber/steel gasket has raised edges to seal properly and comes with all the hardware needed for installation.

------------------

My World of Wheels Winners (Click on links below)

3.4L Supercharged 87 GT and Super Duty 4 Indy #163[This message has been edited by fierosound (edited 01-17-2019).]

|

|

|

waynrayn

|

JAN 17, 12:13 PM

|

|

Hi Ogre / fierofsound:

Thank you for your replies. The items I have already ordered are, yes, the "New Engine Valve Cover Kit, Cap And Grommets Dorman 264-905," and the "Fel-Pro VS50179T Valve Cover Set." These items are on their way, and should be here shortly (I'm in Canada, couldn't get them locally).

I'm still unclear on using sealer on the Fel Pro gasket. In a previous post (http://www.fiero.nl/forum/A...000503-2-001000.html), Ogre said:

"On a good valve cover..... coat both sides of the gasket with either super 300 or HiTack gasket adhesive. Aviation sealer is good if you can find it. People who use only RTV are generally asking for leaks. If the cover is bent up a bit, RTV can be used with a gasket. Make sure everything is very clean or the RTV will not stick. Neither will any of the other sealers above. Do not get excessive with RTV. Peices of it can break loose and plug up oil pasages. Not a good thing. As for material..... I like the "rubber" gaskets better than cork. They take a better seal and hold it longer. they are also less prone to crush destruction."

From this, I am still thinking that I should put adhesive, whether HiTack or The Right Stuff, on either side of the Fel Pro gasket regardless?[This message has been edited by waynrayn (edited 01-17-2019).]

|

|

|

theogre

|

JAN 17, 01:35 PM

|

|

Do Not use Any type of sealer w/ felpro gasket "kit" above.

Install Dry and follow directions in the kit using the right "washers" w/ the gasket.

High Tack and Super 300 Sealers can work on cork and rubber but you must clean all oil or they often won't work either.

RTV Silicon and related "casket eliminators" will fail when you fail to clean off all oil/grease on parts. These are never to be used w/ most gaskets and ones require that often only in some spots like many oil pan sets you use a little at gasket joints. Most people use way too much of the product then push out by the gasket and the "Boogers" can cause big problems like blocking drain holes under valve covers on most engines not just Fiero 2.5l "Duke."

Even the "kit" likes clean parts but not like above that will fail for even a very thin film of oil you can't see on surfaces to seal.

Using added sealers then final clean should be alcohol or brake clean on a clean rag then wipe everything the sealers touch.

Another example: The 2.5l timing cover over the gear set often can't use a gasket to the block, oil pan or both. GM had several version of the timing cover for this engine family. When you have non gasket versions, You use RTV silicon and careful cleaning on all parts and wait a day or more to "dry" or you will have a leak and often sooner. Cover to block you use a thin line of sealer. Cover to pan then often use more because your filling a big gap but not so much will squeeze out.

|

|

|

waynrayn

|

JAN 17, 01:49 PM

|

|

Hi Ogre:

Thanks very much, that's very clear now.

I did happen to find this short (3:33) video from Fel-Pro, discussing use and misuse of adhesives on their gaskets:

https://www.youtube.com/watch?v=bfqZ_lwk2j0

Regards,

~W~

|

|

|

waynrayn

|

JAN 17, 11:37 PM

|

|

Hi Ogre:

"... left side plastic elbow is often hard to remove because seal is hard. If you get a new Dorman cover. carefully cut the old seal to get elbow out w/o breaking."

When you say "old seal," do you mean to cut the grommet on the left side? How?

Thx,

~W~

|

|

|

theogre

|

JAN 18, 10:24 AM

|

|

Yes, Cut the old grommet if needed. any small knife should do. you likely not need cut all the way to make it give up pressure on the elbow.

Can try carefully pull and twist the elbow so barb end inside the cover can work itself thru the rubber.

You don't force the elbow any other way likely prying w/ whatever or likely will break it.

If cover is off the engine, clean so oil doesn't get on everything and "sit" on it or attach to engine again to hold while you cut/pull/twist the elbow.

|

|

|

waynrayn

|

JAN 18, 01:46 PM

|

|

That's great, thanks very much. Very clear.

~W~

|

|

|

waynrayn

|

JAN 22, 06:11 PM

|

|

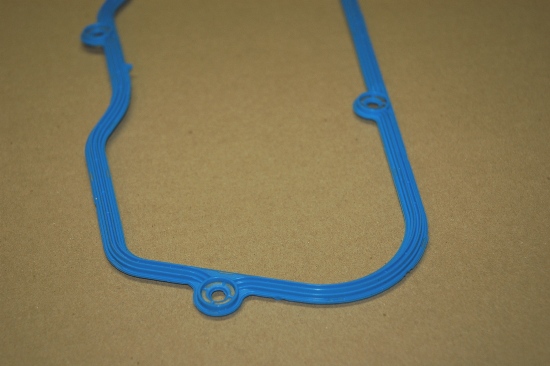

So... The parts, correctly chosen and labeled ("New Engine Valve Cover Kit, Cap And Grommets Dorman 264-905," and the "Fel-Pro VS50179T Valve Cover Set") have arrived.

However, looking at them, the design of the gasket and the new valve cover are not making sense to me.

The gasket has an impression around four of the bolt holes, meaning it narrows, and is not consistently thick. Also, the new cover flange has gaps ("divot"?) in these four areas too.

I've provided pictures of this:

1) Gasket narrowing: https://i.ibb.co/xGZwMF7/1.jpg

2) Flange divot: https://i.ibb.co/MZDnnWz/2.jpg

3) Gap because of gasket thickness narrowing: https://i.ibb.co/ygHTx3Y/3.jpg

I've also tried using the provided force spreaders (I think these are the force spreaders), as it seems the impressions in the gasket might be designed for them. It's better, but they leave a gap also.

Pictures 4 and 5, to show what I tried:

4) https://i.ibb.co/xHRHvky/4.jpg

5) https://i.ibb.co/LQvsRt0/5.jpg

I understand I'm doing something (several things?) incorrectly here. Obviously the gasket and cover flange are designed this way. But it makes no sense to me, in terms of sealing oil inside.

Could someone please explain what my mistake is?

Thanks very much,

Wayne[This message has been edited by waynrayn (edited 01-22-2019).]

|

|

|

|