|

| Fiero GTS (GT Streched) Build thread Fast Back plus Nochie (Page 9/15) |

|

Nebraska

|

MAR 06, 01:00 PM

|

|

|

I can't remember exactly what the clearence was, but I do remember sliding a feeler gauge between the flywheel and adapter and thinking that it is really close.

|

|

|

Nebraska

|

MAR 07, 09:01 PM

|

|

|

|

Nebraska

|

MAR 07, 09:06 PM

|

|

|

Does anyone know the typical crankshaft endplay and the runout on a typical flywheel ??

|

|

|

Nebraska

|

MAR 07, 09:36 PM

|

|

|

I searched the internet to find the endplay of a northstar engine, and guess what I found here in this forum in Blooze Own: An F355 Six Speed N* Build Thread. This forum has so much information. The spec is .002" to .019" if anyone is interested.

|

|

|

bubbajoexxx

|

MAR 07, 09:36 PM

|

|

|

when i make an adapter plate I always under cut where the flywheel sits to prevent this even ones made for the porsche are cut clean trough as i did with mine on the stretch

|

|

|

Nebraska

|

MAR 09, 07:31 PM

|

|

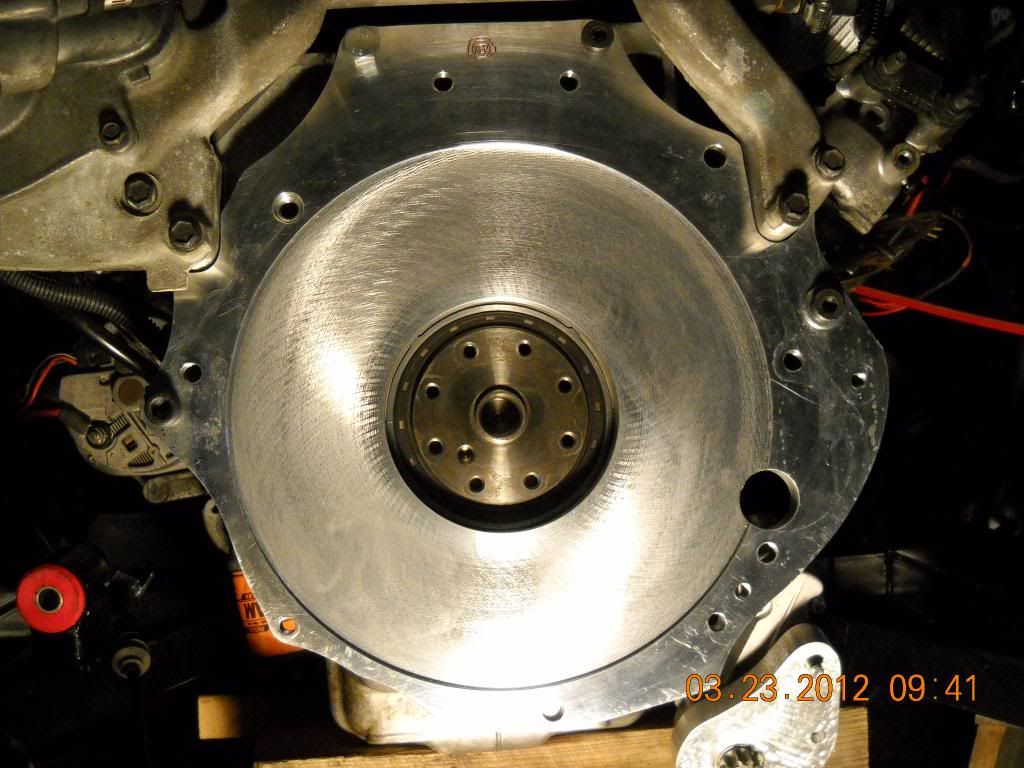

Since I did not document the trans/engine adaptation I guess I have a chance to do it now. It seems like I have to do eveything at least two times to get it right. Here is the modified adapter from Kennedy Engineering and the spacer and redrilled flywheel. I'm going to take Bubbjoes advice and machine clearance into the adapter for the flywheel. I measured the crankshaft enplay and it was .005"which is good, so I think I'll get .1" machined into the adapter just to be safe. Here are some pics before the machining.

|

|

|

Nebraska

|

MAR 16, 08:42 PM

|

|

|

Not to much progress this week, still waiting for my parts from the machine shop. While waiting and since I have the tranny out I decided to make strentghening plate for the tranny. The GT40 guys do this to make the tranny hold up to more HP. I'll post some pics when I get it done.

|

|

|

Nebraska

|

MAR 21, 08:20 PM

|

|

|

|

Nebraska

|

MAR 23, 10:43 AM

|

|

I started the reassembly, here is the freshly machined adapter with extra clearance for the flywheel mounted to the engine.

|

|

|

Nebraska

|

MAR 23, 10:50 AM

|

|

I had another issue when I removed the flywheel. The bolts were alot looser than I expexted. I forget what I torqued them to, but I think I over stretched them. Here is a pic of one of the bolts I removed compared to a new one. You can notice the deformed threads.

|

|

|