|

| SBC Serpentine Accessory Belt Upgrade (Page 7/7) |

|

fieroguru

|

DEC 05, 07:49 PM

|

|

Post a pic of the tensioner. I have had a couple of these pensioners break after a couple of years, but I shimmed the belt further from the body too.

I ended up making a billet aluminum arm and installed it in the tensioner housing.

Also, did you add the stabilizing bracket to the rear of the alternator? Under WOT pulls the bracket without the stabilizer will flex and allow the belt to be tossed.[This message has been edited by fieroguru (edited 12-05-2019).]

|

|

|

V8Steve

|

DEC 16, 05:50 AM

|

|

Both the alternator and the AC compressor are secured to the block at the opposite end of the pulley.

I have a theory: The chassis dyno folks told me it happened during the last "Pull" and that the belt had been rubbing against the E-Brake cable. In looking at the failed belt and the roughly foot long strand, I wonder if that strand wrapped itself around a pulley and eventually ripped the tensioner in half. The car just came home the other day and I've not had time to take the passenger wheel off and begin inspecting.

The mounted base of the tensioner is still attached to the bracket and I'll post a photo of that one when I take it off.

PS: On the last pull, the recorded WHP was 320.

[This message has been edited by V8Steve (edited 12-16-2019).]

|

|

|

V8Steve

|

DEC 16, 12:33 PM

|

|

|

|

V8Steve

|

JAN 05, 04:34 PM

|

|

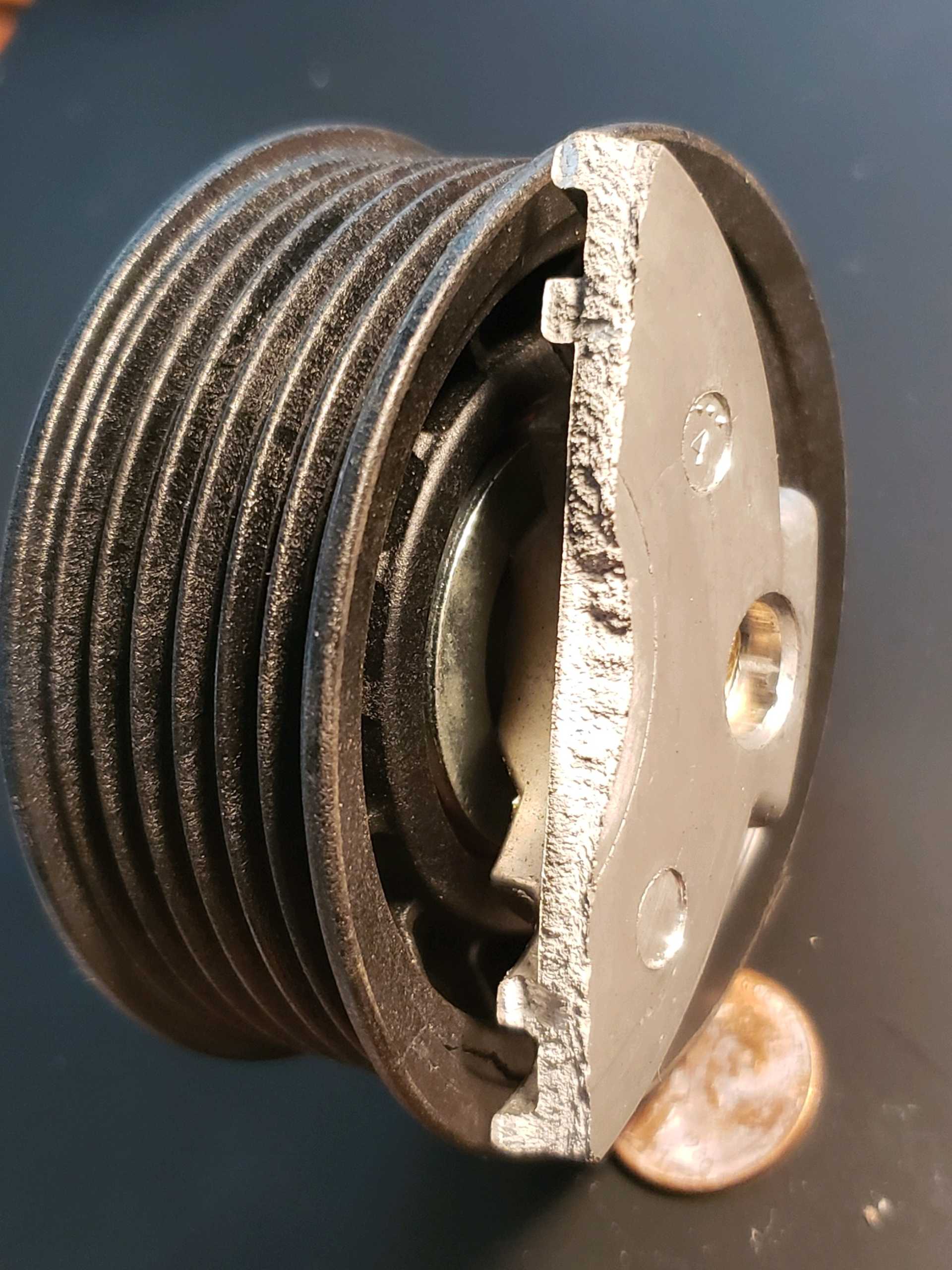

I think I found the root cause of the belt walking off the outer edge of the pulley on two different tensioners. The unit that failed on the dyno came from Rock Auto several years ago so I don't remember the brand. The new one, two weeks ago was a Duralast from Autozone. After checking the alignment and angularity of all the pulleys with a Gates laser tool, I put on the Duralast and also used a belt one size longer. All was well after a few hours of run time but then the belt began to walk off again.

It became clear that the tensioner pulley goes out of alignment when swung down to receive the belt. While the tensioner body doesn't move, it's obvious that the moveable part is shifting out of alignment when the spring is energized and holding the belt. One the belt is on the pulley, that pulley is no longer parallel to the upstream pulley nor is the angularity correct. You can see the moveable part of the tensioner shift outward away from the main body while the pulley itself is beginning to go off course .[This message has been edited by V8Steve (edited 01-05-2020).]

|

|

|

V8Steve

|

APR 18, 05:10 PM

|

|

|

|

V8Steve

|

APR 18, 05:37 PM

|

|

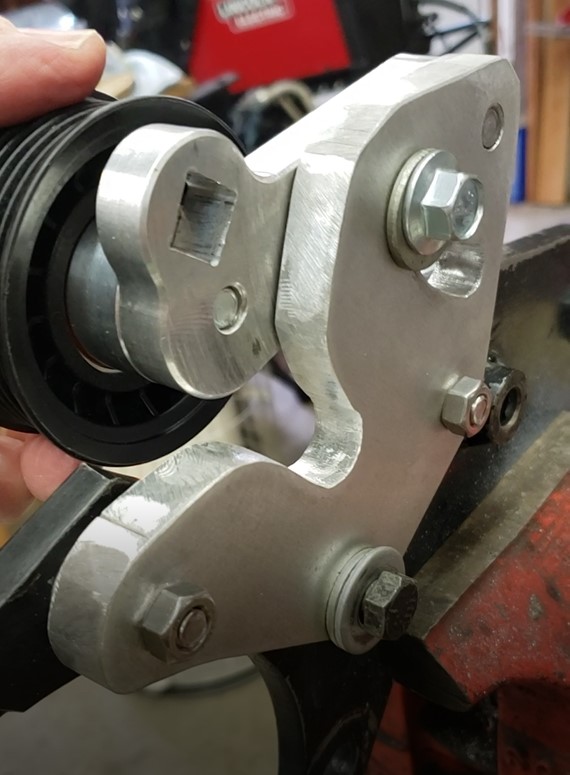

The wooden model was notched to clear the alternator body and drilled to utilize the same mounting holes as the previous tensioner. I wanted to have a 3 point mounting like the ICT bracket so I added a 3rd tapped hole in the swing arm. Then I removed the alternator and did a test fit in the car. All OK.

The next step was to buy some billet aluminum. Along the way I also used a vernier to to calculate any required standoffs to line up the pulleys. McMaster-Carr supplied the standoffs and a selection of shims to be used later.

Here's the DIY billet mounting plate:

Just for comparison the photo below shows the adjustment slot, the breaker bar slot for tightening, etc. of the DIY bracket compared to the original ICT bracket.

Here's the back side:

Everything is done, new paint on the scuffed up arm, etc. I know the alternator was always true/plumb and checked with a laser relative to the harmonic balancer, neighbor pulleys, etc. so I'm confident in the next step which will be putting it back together with the McMaster-Carr spacers and shims, all done on the bench.

Then, back in the car for hopefully the last time. If there is still a belt walking problem it will be much easier to fix. With this ICT robust setup, there will be no flexing or "moving out of true" like the two automatic tensioners that were poorly made and caused belt walking.

|

|

|

V8Steve

|

MAY 10, 11:28 AM

|

|

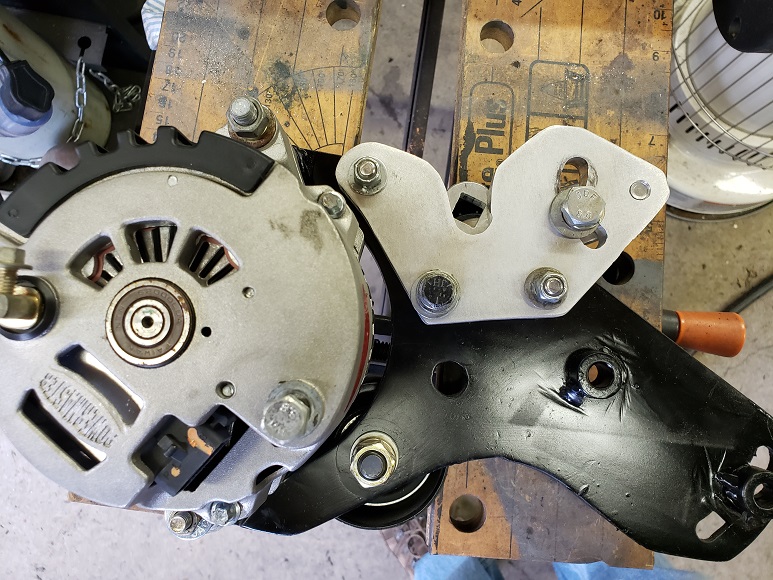

Here it is, ready to go back in the car. I checked it with a borrowed laser and found the manual pulley to be dead on with the alternator throughout the entire travel range. It's not possible to check it against the harmonic balancer when installed but I know from earlier when the motor was out of the car, the alternator was dead on with the balancer. In fact, everything was well aligned except the automatic tensioner going out of "true" when the little arm on it moved. If the manual tensioner is now true with the alternator, I'm confident it's indirectly well aligned with the harmonic balancer, especially since it has zero flex. The manual tensioner billet base is secured at three rigid points.

So now I hope this problem is behind me.

Here's the back side. The square hole in the moveable part is for a 1/2" drive to tension the belt. The ICT product is very well made.

Everything is on with self locking nuts, etc. The tapped hole in the steel arm has blue Loctite.------------------

88GT 355 CI Sequential Holley Multiport , AFR milled 180, Dyno'd at 427 HP, 320 WHP

anderson@gdsconsulting.com

|

|

|

|