|

| So my Fiero died... (Page 6/12) |

|

steve308

|

AUG 08, 08:47 AM

|

|

|

Tubing bender and a piece of brake line to make what you need. You really should adapt a stock fan shroud for the aftermarket fan if you can locate an old OE fan assembly. You tube shows you how.

|

|

|

Cliff Pennock

|

AUG 08, 10:02 AM

|

|

| quote | Originally posted by steve308:

You really should adapt a stock fan shroud for the aftermarket fan if you can locate an old OE fan assembly. |

|

Yes, but getting any OEM part here in The Netherlands is next to impossible since there are no junked Fieros AFAIK. And very seldomly, people part out their Fiero. In fact, I have seen it only once in the past few years.

|

|

|

RWDPLZ

|

AUG 08, 10:03 AM

|

|

I'd be concerned about the straight cut lines leaking a bit, but they should be fine to get the car back home a few miles. Ideally you'd want to flare the ends, so they look like the ends on the radiator.

I'd also make sure to use hose that's rated for transmission fluid, no telling what was in there before if it isn't marked.

|

|

|

Fie Ro

|

AUG 08, 12:05 PM

|

|

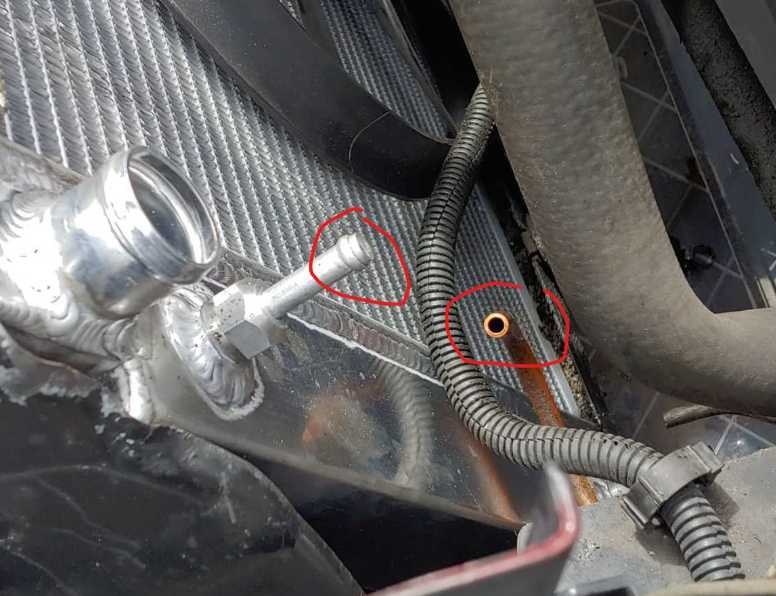

Remove that nipple thing, it is pointing the wrong way already, you probably can find a 90 degree elbow with the same threadsize and a hose adapter at a normal hardwarestore. No need to make it more complicated.

That looks like a screw they put in to prevent the radiator from draining after they broke the tube and forgot to remove it when installing the rubber hose.

|

|

|

theogre

|

AUG 08, 01:23 PM

|

|

Fix:

1. again, need solder bumps etc so rubber won't slide off.

2. just bent the trans line back some so rubber has a bigger radius to bend. or use a "weak" spring outside of rubber for bending tighter radius. Spring stay there. Or use both if needed. Proper J1532 hose needs 6-8 inches or more radius to bend w/o pinching w/o extra support. A little tighter w/ support.

3. If save the hard line bend, use compression fitting to joint bottom part. Will still need to bend bottom section for clearance.

4. Look like the fan "body" edge will fit under w/ some effort w/o distortion when done. If fan "body" won't clear, If you cut/grind the rad frame only cut bare minimum to fix that problem. Or use spacers on the mounting screw points.

|

|

|

Patrick

|

AUG 08, 02:45 PM

|

|

I'm certainly not suggesting that flaring the ends of the metal tubes or adding a bit of solder to them is a bad idea to help keep the hoses on, but the fluid pressure through the transmission cooling lines is minimal. I simply double-clamped the hoses on a repair I made to the transmission cooling lines on my '86 GT years ago and it's never had an issue.

|

|

|

ArthurPeale

|

AUG 08, 05:03 PM

|

|

| quote | Originally posted by Cliff Pennock:

I cannot simply use a single rubber hose, since it will pinch:

So any tips before I start? 😊 |

|

I don't see why you couldn't use the single rubber hose - add some more slack with a slightly longer hose, with a strain relief. It's not high pressure, so as long as your line isn't kinked, you should be all set.

|

|

|

theogre

|

AUG 08, 05:55 PM

|

|

| quote | Originally posted by Patrick:

I'm certainly not suggesting that flaring the ends of the metal tubes or adding a bit of solder to them is a bad idea to help keep the hoses on, but the fluid pressure through the transmission cooling lines is minimal. I simply double-clamped the hoses on a repair I made to the transmission cooling lines on my '86 GT years ago and it's never had an issue. |

|

May not "blow off" now because so low pressure or other reasons...

If the line(s) get a little to completely crush/pinched then enough pressure to blow off and quickly drain the Trans while you drive.

Remember Oil Dumping method in cave to change AT oil? In takes < ~ 15 minute to pump the trans dry.

Yes, the trans may may shift "wrong" etc w/ restricted flow but better then running out of trans oil on the highway.

And Ignoring other possible problems causing an oil slick on the road...

Short straight sections w/ minimum gap to span is different then any big gap w/ or w/o bending the hose too.

Just Heat cycling can cause failures in later setup.

It takes very little pressure to blow off any hose w/o something to "lock them" in place.

Trans oil, Coolant, and more lubes the joint and no clamp alone should be trusted.

In back and even w/ OEM setup, the oil cooling hoses often leak or @ minimum move from oil and external heat and vibration and stop moving only when the clamps are @ the "Blow off" Stops on the hard lines.

Even w/ J1532 hose can have problems in the long term because also gets heat from Exhaust on Fiero and many others for trans section. Is why Many OEM have hard lines going into the heat exchanger directly. Is Part of why the Loop section of rear rubber for Fiero has the loop to side of trans to help keep exhaust heating to nothing. But still fails long term @ ends to trans short lines. I recently bought new J1532 to replace that section again. And while there likely add some heat shield too to block Exhaust IR hitting them. (That's on top replacing the Duke's huge "Pebble Bed" Cat w/ current smaller better Cat.)

|

|

|

RWDPLZ

|

AUG 08, 09:19 PM

|

|

| quote | Originally posted by Patrick:

I'm certainly not suggesting that flaring the ends of the metal tubes or adding a bit of solder to them is a bad idea to help keep the hoses on, but the fluid pressure through the transmission cooling lines is minimal. I simply double-clamped the hoses on a repair I made to the transmission cooling lines on my '86 GT years ago and it's never had an issue. |

|

I've used un-flared line with a hose, and it leaked, slowly. Was able to drive 7 hours home on it adding fluid once.

|

|

|

Patrick

|

AUG 08, 11:13 PM

|

|

| quote | Originally posted by RWDPLZ:

I've used un-flared line with a hose, and it leaked, slowly.

|

|

Two clamps at each end of hose?

My '86 GT has been stored for years, and to be honest I haven't even looked under the decklid for ages... but i drove that GT for a couple of years after splicing in a length of hose, and it never leaked at all. Maybe I should buy a lottery ticket?

|

|

|