|

| 1988 LFX Build Lessons Learned/How to (Page 6/11) |

|

MikesFirstFiero

|

MAY 11, 10:29 AM

|

|

|

What software are you using in your iPhone?

|

|

|

Will

|

MAY 11, 10:42 AM

|

|

| quote | Originally posted by RandomTask:

Yup. Already have a cart built from MACE engineering. Once I get all the electrical/mechanical issues figured out and body finished, everything is coming back out and installing a built LFX (Forged internals, cams,) and under boost. |

|

Cart? Like a shifter kart?

|

|

|

Daryl M

|

MAY 11, 11:04 AM

|

|

| quote | Originally posted by MikesFirstFiero:

I'm starting an LFX into an 88 project. Bought a wrecked 2018 Impala and have been ripping it apart. Going ot use the 6T70 automatic since I'm tired of shifting and the Impala does provide a manual shift up/down feature.

One thing I found is that the fuel pump has an external controller mounted in the trunk. In the outlet pipe at the fuel tank is a pressure sensor so the pressure is closed loop regulated. There are two lines from the fuel tank area to the engine. One is the fuel to the high pressure pump and the other (I think) is the purge line from the charcoal cannister, which is mounted on the side of the tank.

Since I've got the fuel pump I may try to adapt it to the Fiero tank, But the opening is really big and it may not fit properly. I've also heard of using a corvette fuel filter that has an internal pressure regulator. That would be much simpler but I'm not sure how the fuel sender works. Is it a canbus item? Analog? One more thing to mess with.

Your idea of using a Camaro AirCon compressor sounds good but does this require the original Fiero ECU to be retained?

For instruments I'm fitting the Impala gauge panel into the Fiero Housing. Hooking up a Canbus is much easier than figuring how to make the tach and VSS work. Turns out the 6T70 has both of these sensors internally but they are digitized. Good for me with the auto but unless someone makes a CanBus set of instruments it's a pain.

If you could I'd appreciate more photos of your motor mounting? I'm about to start that in a week or two and any advice would be welcomed. |

|

Have you test fit the Impala transmission in the cradle? When I tried it, I found that the physical size of the transmission was interfering with the cradle and would require cradle modifications I did not want. I found a low miles Saab F40 manual transmission that was a much better fit and was lighter too.

|

|

|

RandomTask

|

MAY 12, 03:17 PM

|

|

^^ I would love to see someone execute an auto version of the swap though. Would be a fantastic daily.

That said, Drive shaft shop missed another deadline. Said two weeks ago that the inners were being machined and should be finished soon. Called yesterday and the inners are suddenly -about - to be machined. Going on 4 months with this clown show operation.

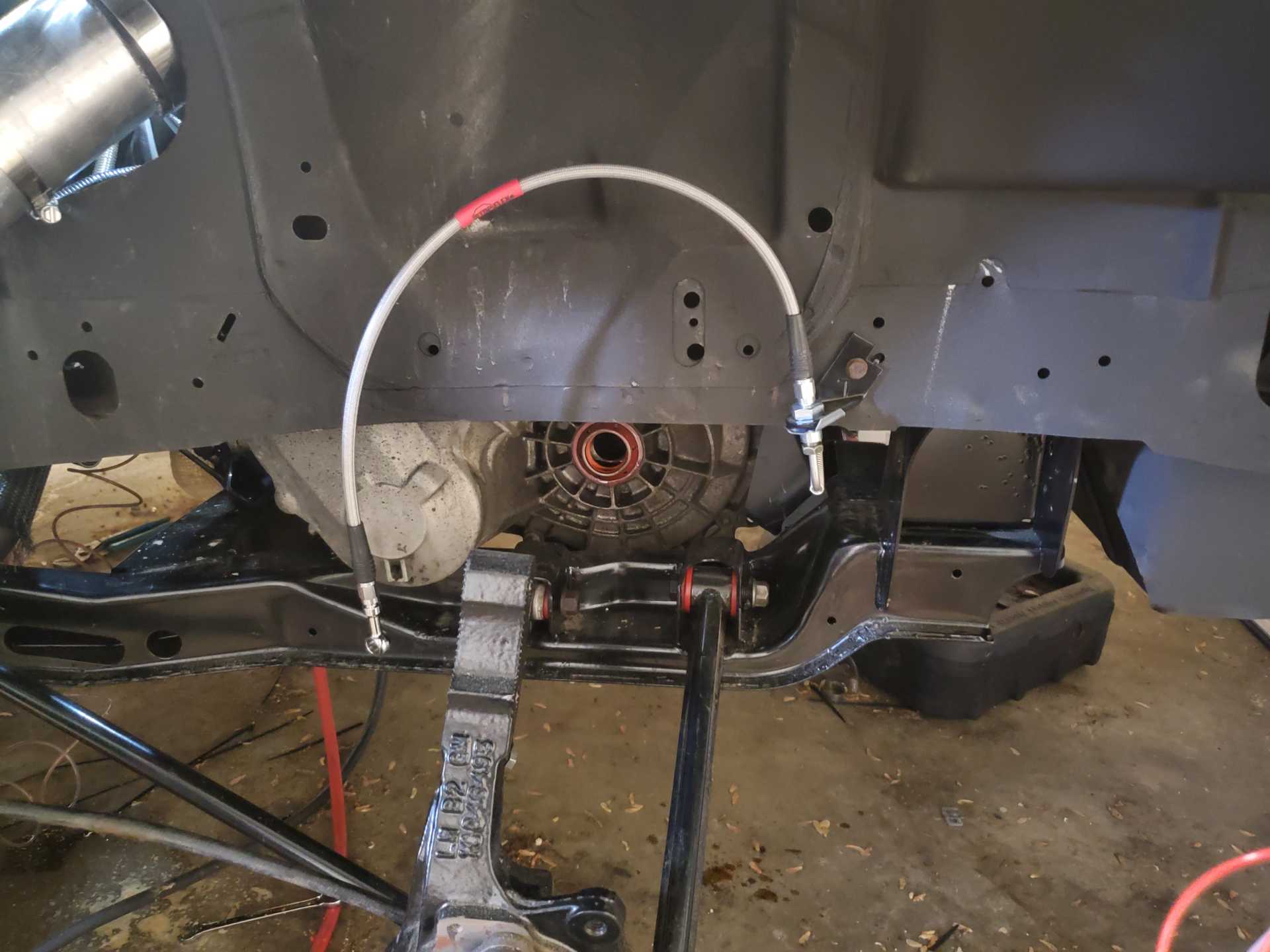

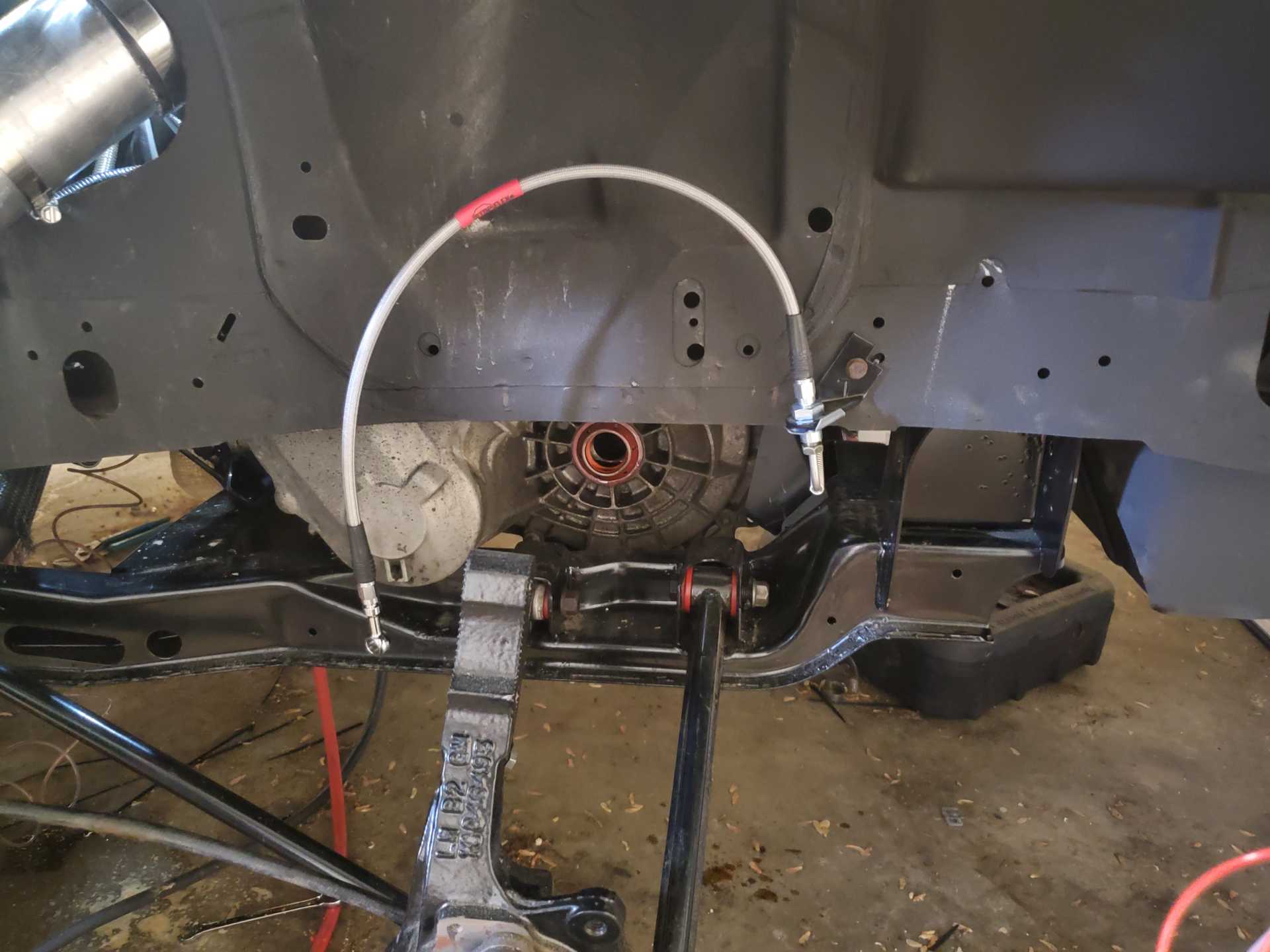

So called up a company I actually like dealing witb (fiero store) and bought some new SS hard lines and hoses. Back half installed. Front half goes in when I drop the front suspension to put in the powder coated one and redo the bushings.

|

|

|

Daryl M

|

MAY 12, 05:07 PM

|

|

| quote | Originally posted by RandomTask:

^^ I would love to see someone execute an auto version of the swap though. Would be a fantastic daily.

That said, Drive shaft shop missed another deadline. Said two weeks ago that the inners were being machined and should be finished soon. Called yesterday and the inners are suddenly -about - to be machined. Going on 4 months with this clown show operation.

So called up a company I actually like dealing witb (fiero store) and bought some new SS hard lines and hoses. Back half installed. Front half goes in when I drop the front suspension to put in the powder coated one and redo the bushings.

|

|

Absolutely! I didn't mean to come across like a negative Nelly, but these kinds of things always seem easier in you're head. Better to know the issues going in.

|

|

|

RandomTask

|

MAY 18, 02:36 PM

|

|

The Drive Shaft Shop in Salisbury NC is an absolute clown show of an operation. I spoke with them in Dec about some custom axles for my setup. They said they were actually working that project internally and would have something available in 4-5 weeks.

Contacted them 5 weeks later and they said they had to work on some other stuff. I asked if I sent them my inners and outers and provided lengths req'd, how long it would be; they stated 4-5 weeks.

I did just that. They rec'd my parts on Feb 9. It is now May 18th and they still aren't done. I keep getting excuses, and bullshit reasoning for delays. Things have gone from "They are getting machined as we speak." to two weeks later "[same part] is -ABOUT- to get machined." Communication is poor. Guy in charge of my order keeps ducking my calls, hiding behind his assistant. (BTW, I only call once a week to two weeks to get a status update). Started talking to other people with some high HP builds and they all had the same experience.

Only reason I went w/ DSS is they stated they would build me a complete axle with the specs I wanted. I figured a 2 week penalty (most companies can build the shafts in 2-3 weeks) and a couple hundred dollars for a complete unit was worth it.

It's obvious it's not. Just get the shafts made by the numerous companies out there that can do this and save yourself the grief. AVOID THE DRIVE SHAFT SHOP.

I had to move the car to the street to make room in my garage for the race car (upcoming race in Aug).

|

|

|

Trinten

|

MAY 18, 04:07 PM

|

|

Oh man, this is really sad to hear. I had spoken with them a few years ago (never purchased) and their pre-sales stuff seemed really on-point. It's terrible that they are ducking you. Another industry was telling me that because of COVID, they had to reduce how much staff they had on the manufacturing floor, so their production was down almost 60 percent. I don't know how big the facility is for DSS, but if this was the case I would have hoped they'd just tell you.

I guess I'll start looking for another custom axle shop. I am just a few hours away from them, if they have Saturday hours, I can try to drop in there for you! Much harder to duck a customer when they are standing at the counter. lol

|

|

|

Will

|

MAY 18, 04:52 PM

|

|

|

That sucks to hear about DSS... I'm semi-interested in some of their products. I have a pair of the Ecotec racing output flanges for the 4T65E-HD that also fit the Getrag when used with an intermediate shaft. DSS's 33 spline hub flanges for C5/6/7 Corvettes could work at the outer end once I swap to Corvette hubs. From there, just send the flange-to-flange measurements and they send back bolt-in CV axles. Sounds like a great way to spend $2000 to move the weakest link inside the transmission... but not if they can never deliver the axles.

|

|

|

Raydar

|

MAY 20, 02:48 PM

|

|

| quote | Originally posted by RandomTask:

The Drive Shaft Shop in Salisbury NC is an absolute clown show of an operation.

|

|

Sounds a lot like another outfit on the <ahem> West Coast.

|

|

|

msweldon

|

MAY 23, 11:32 AM

|

|

| quote | Originally posted by Raydar:

Sounds a lot like another outfit on the <ahem> West Coast. |

|

Add ClutchNet and that speedshop in Michigan that does ecotec builds and swaps and LF3/4 reprogramming... 😉

|

|

|