|

| My 1988 LFX F40 build. (Page 6/68) |

|

fieroguru

|

JAN 23, 02:31 PM

|

|

| quote | Originally posted by Daryl M:

Yes, I do get the importance and the variables involved. Thanks for the feedback. I did take all of the points you have mentioned into account when making the mounts. I would be interested in how much camber does change through the span of travel of the suspension. I can't imagine it is more than 5 or 6 degrees, but I haven't measured it. I could be way off. |

|

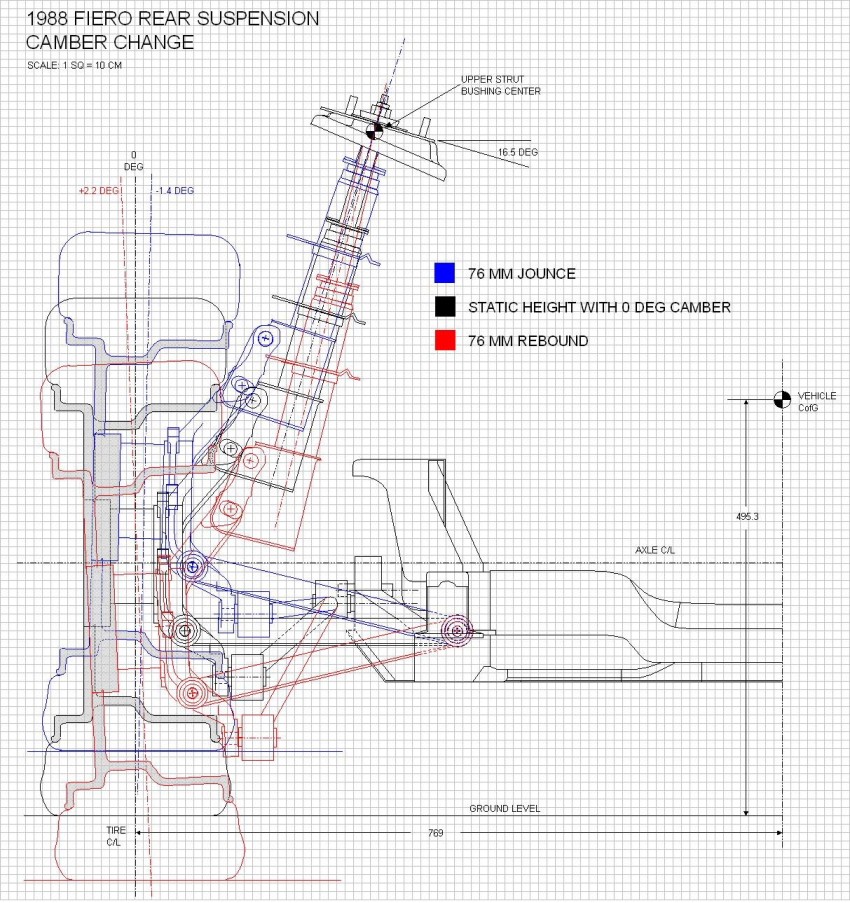

If you haven't seen it yet, check out Bloozberry's build thread in the construction zone. He took the time to document in great detail the front and rear suspension coordinates for the 88 fiero and with the help of another member Zac88GT was able to run them through a suspension analyzer program.

http://www.fiero.nl/forum/F.../HTML/000116-13.html

[This message has been edited by fieroguru (edited 01-23-2019).]

|

|

|

Daryl M

|

JAN 23, 02:47 PM

|

|

Guru

That is just what I wanted to see. If I read this correctly the camber changes about 3 degrees through the range of motion. If that is all it varies, I am golden.

Thanks for posting[This message has been edited by Daryl M (edited 01-23-2019).]

|

|

|

Raydar

|

JAN 23, 07:59 PM

|

|

| quote | Originally posted by Daryl M:

Guru

That is just what I wanted to see. If I read this correctly the camber changes about 3 degrees through the range of motion. If that is all it varies, I am golden.

Thanks for posting

|

|

What guru has not mentioned is that he offers a kit that helps to minimize that camber change. He can tell you the details.

(I have it on both of my 88s.)

I will include the link.

http://www.fiero.nl/forum/Forum4/HTML/060635.html[This message has been edited by Raydar (edited 01-23-2019).]

|

|

|

pmbrunelle

|

JAN 23, 08:24 PM

|

|

If you decide to use it, your Fiero sender is 1/4" NPT. If you need a Fiero sender, the 88 Fiero senders are considered better / more reliable, so consider that as an option.

The main difficulty I see with drilling and tapping the adapter is that in order to intersect the longitudinal passage, the hole you drill can't be very deep, so as to avoid drilling through to the other side.

Therefore, you may need to start cutting with a regular tap, and then switch over to a bottoming tap.

Edit: you could even cut a thread off the end of the tap every time you cut the hole one thread deeper.

Also, I suppose that the sender would point upwards, and that looks close to the exhaust pipe, so it may need a shield.[This message has been edited by pmbrunelle (edited 01-23-2019).]

|

|

|

Daryl M

|

JAN 24, 12:31 AM

|

|

| quote | Originally posted by pmbrunelle:

If you decide to use it, your Fiero sender is 1/4" NPT. If you need a Fiero sender, the 88 Fiero senders are considered better / more reliable, so consider that as an option.

The main difficulty I see with drilling and tapping the adapter is that in order to intersect the longitudinal passage, the hole you drill can't be very deep, so as to avoid drilling through to the other side.

Therefore, you may need to start cutting with a regular tap, and then switch over to a bottoming tap.

Edit: you could even cut a thread off the end of the tap every time you cut the hole one thread deeper.

Also, I suppose that the sender would point upwards, and that looks close to the exhaust pipe, so it may need a shield.

|

|

Good info! Thanks! I will need to prefit the adapter so I know which side is up when tight. I was hoping there would be somewhere else on the engine to pull oil pressure from, but I don't see an obvious place and I've gotten no tips from the forum, so I guess I just have to fit both sensors in that small space.[This message has been edited by Daryl M (edited 01-24-2019).]

|

|

|

fieroguru

|

JAN 24, 09:22 AM

|

|

| quote | Originally posted by Daryl M:

Good info! Thanks! I will need to prefit the adapter so I know which side is up when tight. I was hoping there would be somewhere else on the engine to pull oil pressure from, but I don't see an obvious place and I've gotten no tips from the forum, so I guess I just have to fit both sensors in that small space.

|

|

Have you tried to remove the oil filter housing? Once it is off, you might see another oil boss, or a flat part that would be easier to tap for a sensor. Depending on how the housing seals to the block, you might be able to make a flat spacer and drill/tap it for the second oil sensor. You might also find that some of the other oil filter housings from other high feature engines are easier to add an oil sensor port to.

There are also spin on filter extensions that allow room for oil cooler as well as oil ports. One of those might fit the filter assy as well.

You can also inspect the sides and ends of the block looking for caps or plugs that might have access to the oil galleys in the block.

So there are several other paths you could explore to mount the 2nd sensor.[This message has been edited by fieroguru (edited 01-24-2019).]

|

|

|

Will

|

JAN 24, 03:12 PM

|

|

| quote | Originally posted by Daryl M:

Will, are you saying that using one transducer to feed the ECM and the stock Fiero gauges will not interfere with one another? |

|

The ECM input will have an impedance ~100k ohm. It won't interfere with the gauge. Does the ECM control a variable displacement oil pump based on this sensor's output? I haven't heard of the LFX having a variable displacement oil pump, but I could be wrong.

So GM has finally started giving the ECMs an oil pressure sensor? All other applications I've seen run the oil pressure sensor wires straight to the dash. I guess if they go to the ECM, then the ECM can put them on the CANBus for the instrument panel to read. If that's all it does, hook them both up to the same sensor.

However, if the ECM controls a variable displacement oil pump, then you probably want to find a spot for another sensor. I don't know if GM would have made significant updates to the sensor in order to make it reliable or precise enough to control the pump.

Basically almost all (if I say "all", FieroGuru will find one that doesn't...) GM oil pressure senders are essentially the same: 0-90 Ohms, just like a fuel level sender. How they're packaged isn't relevant to how they operate. The Caddy Northstar and Olds Aurora units, for example, had larger pipe threads than the other units GM built. Weird.[This message has been edited by Will (edited 01-24-2019).]

|

|

|

Daryl M

|

JAN 24, 09:36 PM

|

|

Will,

Thanks for the info. That's what I love about this forum. I learn so much.

|

|

|

thesameguy

|

JAN 25, 01:03 PM

|

|

| quote | Originally posted by fieroguru:

There are also spin on filter extensions that allow room for oil cooler as well as oil ports. One of those might fit the filter assy as well.

|

|

I like the sandwich plate idea - a small external oil cooler might not be a bad idea. Setrab/Mocal makes a sandwich plate with a built-in thermostat.

You could also use a manifold block, but there's a good chance you'd need an adapter or to rethread one since you probably won't find one with the threads you need. Most manifolds are aluminum, so rethreading is pretty easy. Just be sure the sensors you are using a two wire sensors, as an aluminum manifold will offer a crap ground path.

|

|

|

Daryl M

|

JAN 25, 10:08 PM

|

|

| quote | Originally posted by thesameguy:

I like the sandwich plate idea - a small external oil cooler might not be a bad idea. Setrab/Mocal makes a sandwich plate with a built-in thermostat.

You could also use a manifold block, but there's a good chance you'd need an adapter or to rethread one since you probably won't find one with the threads you need. Most manifolds are aluminum, so rethreading is pretty easy. Just be sure the sensors you are using a two wire sensors, as an aluminum manifold will offer a crap ground path.

|

|

The sensors have 3 wires.

|

|

|

|