|

| Supernatural 3.7L 9,000RPM Project (Page 5/20) |

|

fishsticks

|

JUN 07, 08:35 PM

|

|

| quote | Originally posted by La fiera:

I don't know what injectors are you guys using on your engines but I only use these. Bosch EV1 with 4 hole. The spray pattern is not a "pencil" like the regular Fiero injectors everyone uses. These newer injectors spray like a "fan". With that said, The injector's height is strategically mounted to spray right around the intake valve, not on the stem or the intake walls but exactly in the perimeter of the intake valve.

|

|

This is actually why I raised the concern, the wider pattern seems like it will put more fuel on the walls of the plenum - specifically on the long wall closest to an injector nozzle.

How much runner length did you end up with? My guess is 3" or less.

|

|

|

La fiera

|

JUN 07, 09:21 PM

|

|

| quote | Originally posted by fishsticks:

This is actually why I raised the concern, the wider pattern seems like it will put more fuel on the walls of the plenum - specifically on the long wall closest to an injector nozzle.

How much runner length did you end up with? My guess is 3" or less.

|

|

I placed the injectors high enough to umbrella the diameter of the intake valve. The reminder fuel if any, will puddle on top of the valve to make up for the laggy throtle response. I can model this on the MegaSquirt but I can do it much easier and faster mechanically.

I didn't just came up with this intake. I've been working on this for this for 2 years.

|

|

|

La fiera

|

JUN 08, 11:24 PM

|

|

This is how the Supernatural concept was born. Here I found some old videos with the old 2.8L ! I forgot about these!! But anyways, you can even hear the sound in engine frequencies diferenciate from stock. That's when I trusted my gut to stay with the iron heads.

Stock Fiero with the old tired 2.8L with 1.6 rockers and TR1 intake.

https://youtu.be/uRf0UgHKJ9E

This is breaking in the rebuilt and upgraded 2.8L

https://youtu.be/PKi-EJPBQmw

Rebuilt 2.8L with cam, head work and same TR1 intake.

https://youtu.be/IyAIFD_LG8Y

As you can see, the interior hasn't changed much!

|

|

|

La fiera

|

JUN 08, 11:43 PM

|

|

| quote | Originally posted by Will:

I note that he didn't show the runner entries inside the plenum...  for this to work, those have to be carefully radiused and sculpted. They'll also be quite short, but probably not unreasonably short. for this to work, those have to be carefully radiused and sculpted. They'll also be quite short, but probably not unreasonably short.

|

|

You know that stock injector bong tha takes 1/4 of the intake's entry diagonal? Well, in this manifold it is gone.

|

|

|

Will

|

JUN 09, 07:41 PM

|

|

I didn't think you'd built that box and put it on top of a stock lower....

|

|

|

La fiera

|

JUN 09, 10:03 PM

|

|

| quote | Originally posted by Will:

I didn't think you'd built that box and put it on top of a stock lower....  |

|

I know, I just don't have the luxury (money) to do otherwise! I have to spend every penny wisely. This is one man operation relying on side jobs to make my toy make some po'er!. If I had the means of Fishsticks, one blows up and order another one type deal; would be a different story!  [This message has been edited by La fiera (edited 06-09-2021).]

|

|

|

fishsticks

|

JUN 10, 01:48 AM

|

|

|

|

Blacktree

|

JUN 10, 10:13 AM

|

|

| quote | Originally posted by La fiera:

You know that stock injector bong tha takes 1/4 of the intake's entry diagonal? Well, in this manifold it is gone.

|

|

That's what I like about the Falconer lower intake... no injector bungs. Also, there's no cold-start or idle air passages. So the intake ports can be bigger.

It also has a big port on the end, for crankcase vacuum. That's what the blue fitting is for.

|

|

|

La fiera

|

JUN 10, 06:15 PM

|

|

| quote | Originally posted by fishsticks:

I still think you're gonna have fuel beading issues on those smooth plenum walls.

|

|

I don't think so. There is way more injector to wall clearance than the intake I'm running now and I don't have any fuel beading issues.

This is the injector aiming straight at the valve. And the little runner that will get some fuel mist is textured.

This is the intake I'm running now. Injector is pointing directly to the intake valve.

This is looking under it, from the intake valve up the intake you can see the injector tip pointing towards it.

Outside view of the injectors orientation.

|

|

|

fishsticks

|

JUN 10, 11:59 PM

|

|

Your welds are way nicer than mine.

I agree you're fine in the runner and with injector positioning. I'm worried air rushing into the plenum is going to (partially) disrupt the spray pattern from the injectors since they're so high up and put fuel on the plenum walls.

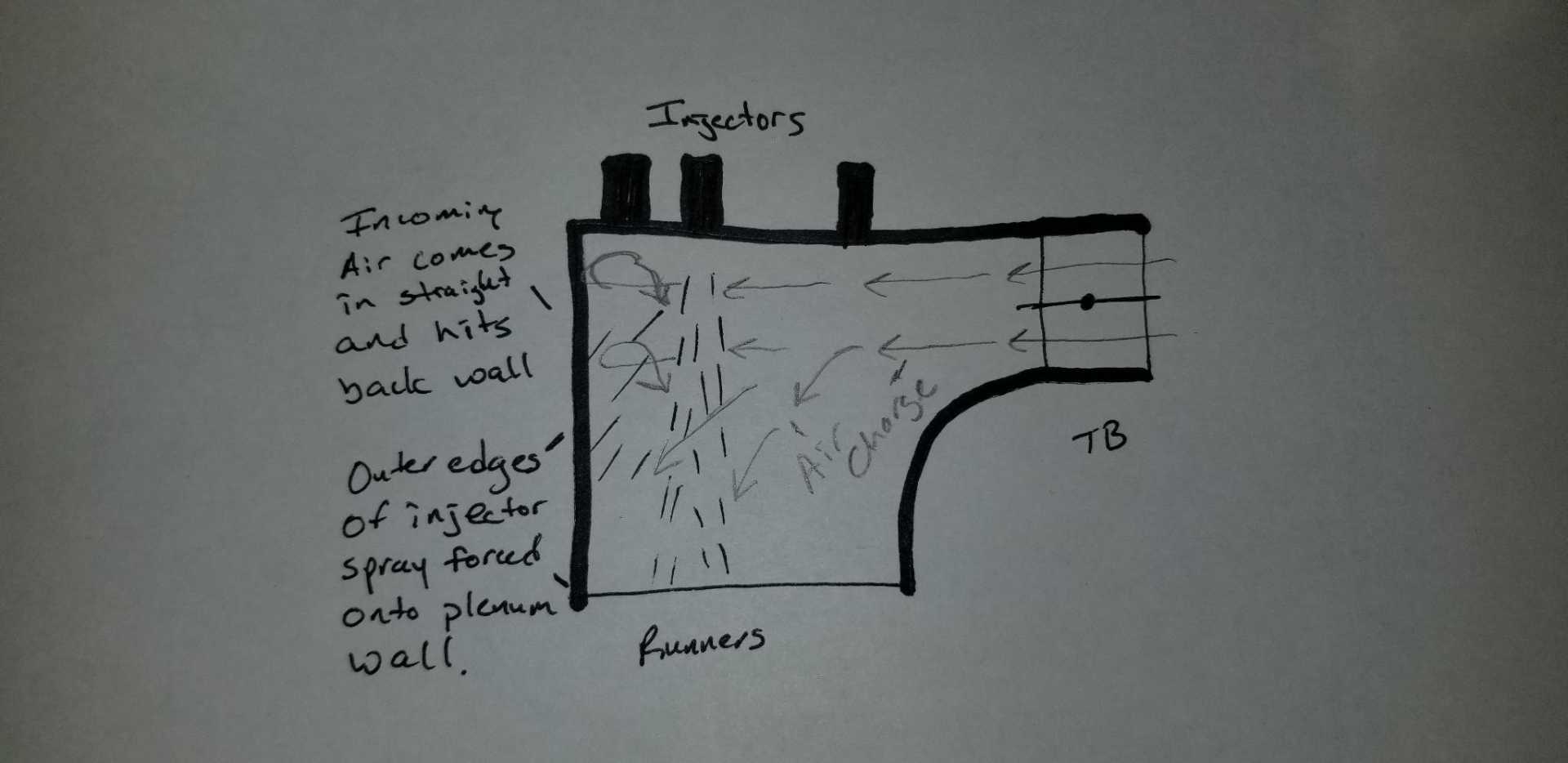

I have made the world's worst diagram illustrating what I suspect will happen. I apologize in advance for it.

Basically, incoming air is going to ignore the radiused part of the plenum below the TB and head straight for the back wall. You see a similar effect in cylinder head ports, which is why a lot of shaping is done to the ceiling, and sometimes the floor is raised.

I think that airflow is going to push fuel to that back wall, and possibly the other walls of the plenum.

Do I think your design is somehow critically flawed and doomed to failure? Not at all. In fact, I could be flat out wrong. If it were my intake, I'd stick the nozzle of a sand blaster inside there and give the plenum walls a little texture just in case. That's all I'm saying.

Your first manifold appears to have the injectors in the runners still, so I don't see this issue coming up.

Over all, I think you may run into a scenario where the front cylinders run rich and the rear cylinders run lean, and you may have to play with injector timing to compensate. You've given up the individual cylinder tuning of port injection in exchange for charge cooling like a carb or TBI would have.[This message has been edited by fishsticks (edited 06-11-2021).]

|

|

|