|

| 85 Notchie Build (Page 5/23) |

|

David Hambleton

|

MAR 03, 08:38 PM

|

|

Well done! You've certainly put a lot of time & energy into your project.

Have you had technical training & experience or is all this from natural mechanical aptitude?

|

|

|

zkhennings

|

MAR 04, 12:31 AM

|

|

| quote | Originally posted by David Hambleton:

Well done! You've certainly put a lot of time & energy into your project.

Have you had technical training & experience or is all this from natural mechanical aptitude? |

|

Thanks! Nope never any training before I started to seriously work on my car, I was a diesel truck mechanic for a summer after I had learned to work on my car a bit, but it was really all brake jobs, oil changes, sway bar bushings, that kind of thing. I learned everything by doing. I threw myself into an engine swap and then into an engine build and just made sure I was careful.

I have been building things for years, but now my car is my main project.

|

|

|

zkhennings

|

MAR 16, 11:24 AM

|

|

So my future plans are a turbo 3800 built on a custom cradle with custom rear suspension, custom exhaust, custom front suspension. I might do custom knuckles but I am not sure. With the 3800 I will upgrade the brakes again.

In the meantime since all that will take definitely over a year, I am supercharging the 2.8!

I have an eaton m45 I am planning on mounting where the AC would normally be, I may use an intercooler depending on how much boost I am pushing. I bought L36 injectors (22lph) which should do the job, and I am going to swap ecms with a 7730 maybe running the $58 mask for the syclone. I think I am going to stay with distributor ignition.

I want to figure out a way to run the SC off the v belt groove for AC. I do not want to run a V belt, but maybe I could turn the V belt groove off, and machine a ring that would accept a toothed belt and press that on. Then make a SC pulley. This would simplify things a lot as I would not have to figure out how to mount a pulley, and I wouldn't have to deal with extra long serpentine belts and I do not know if the grooved pulley would have the same serpentine pattern as the fiero

Looking on McMaster it appears that I should use a high torque timing belt and pulleys. Hopefully I can find a pulley that I could stick in the lathe and turn the inner diameter to fit over where the V belt was. They are steel so I could weld it on.[This message has been edited by zkhennings (edited 03-16-2014).]

|

|

|

ttt123

|

MAR 17, 07:45 AM

|

|

|

just read through you intire build.. very nice. tip of the hat to putting time into the 2.8. i'm building a 3.4l turbo currently. so at 132hp how did you feel about the cars performance?

|

|

|

woodyhere

|

MAR 17, 09:05 AM

|

|

|

I just read your thread. I really enjoyed seeing all you went through. I admire your tenacity. You saved a Fiero many would have walked away from. Isn't it funny how anything that we know isn't quite right will always come back to bit us later. I have been building cars and bikes for over 50 years and I still have to make myself check and double check before things go together. Try as I might, I still make plenty of mistakes. The trick is to man up and fix them. You have definitely demonstrated that quality. I look forward to seeing more of your work in the future. This has been a very interesting read. ------------------

woodys 427

|

|

|

zkhennings

|

MAR 19, 10:23 PM

|

|

| quote | Originally posted by ttt123:

just read through you intire build.. very nice. tip of the hat to putting time into the 2.8. i'm building a 3.4l turbo currently. so at 132hp how did you feel about the cars performance? |

|

Thanks! At 132 hp it is not slow, it has a pretty flat torque curve so it accelerates nice, actually pushes you back in your seat. A 3.4 turbo would be lots of fun

| quote | Originally posted by woodyhere:

I just read your thread. I really enjoyed seeing all you went through. I admire your tenacity. You saved a Fiero many would have walked away from. Isn't it funny how anything that we know isn't quite right will always come back to bit us later. I have been building cars and bikes for over 50 years and I still have to make myself check and double check before things go together. Try as I might, I still make plenty of mistakes. The trick is to man up and fix them. You have definitely demonstrated that quality. I look forward to seeing more of your work in the future. This has been a very interesting read.

|

|

Thanks a lot woody, I have learned so much about life working on this Fiero. I can't wait to soon have the funds to really take this car somewhere. I know that I will make sure whatever I do with it is done right from the start no matter what.

|

|

|

zkhennings

|

MAR 27, 10:11 AM

|

|

I have been working in the real world now out of college I got a job as a Mechanical Engineer and I bought an 03 WRX just like I wanted to. It ended up getting totaled (not my fault thankfully) and I picked up an 02 WRX in much better condition, though both were in good condition.

03 when I got it

It came with a bad turbo because the PO was a total idiot and put all his weight on it which torqued the housing and ruined the turbo.

Replacing the turbo

03 Totalled

New WRX

Now I was in VT (200+ miles from my house) and a timing gear blew up and trashed the motor... So I am currently re-gasketing another motor and doing the timing belt and water pump and whatnot. It was a very expensive tow home.

Doing a couple quick mods to the motor while it is out. I also have forged rods and pistons for a stroker build using the 2.5L crank in the 2.0L engine so that will happen at some point.

But for now I have been doing tons and tons of research and I have decided to go with an Ecotec 2.2 that I will turbo to 400+rwhp

Basically I hope for the Fiero that I can have a wicked fast and well handling car I can totally beat on and take to track days. I also want it to stay relatively cheap because of these goals, I wanted to do a 3800 turbo because if I ever blew it up I would be out 500$ to swap in a new junkyard motor and that is that. VS I've spent north of $2500 on trying to get a running engine in my WRX again. So that meant I was looking for an engine that holds good power stock or close to stock that I don't need to get any machining done on it to mod it if I need to.

Well the 2.2 Ecotec is a very robust motor. All this info is from a GM document.

Swap in performance valve springs from GM and redline increases to North of 7500 RPMS with no machining of the head.

Block and crank and oiling and water pump are all very robust and only need to start being changed past ~700hp

Basically I have to pull off the oil pan, pull the head, replace valve springs, put in new forged pistons and rods, get a headgasket and button it back up and it is done. Probably have to do a quick hone myself while I am in there but that is it. It has huge weight savings over a 3800, almost 200lbs. You really feel that weight in the rear, especially when the rear gets loose. Well I like to drive a loose car and it is scary with all that weight in the rear, decreasing that will allow the car to snap oversteer much more gently and controllable.

Other benefits include that it is very easy to work on, easy to replace pistons and what not while the engine is in the car, and I will be able to do a nice turbo setup without such a cramped engine bay.

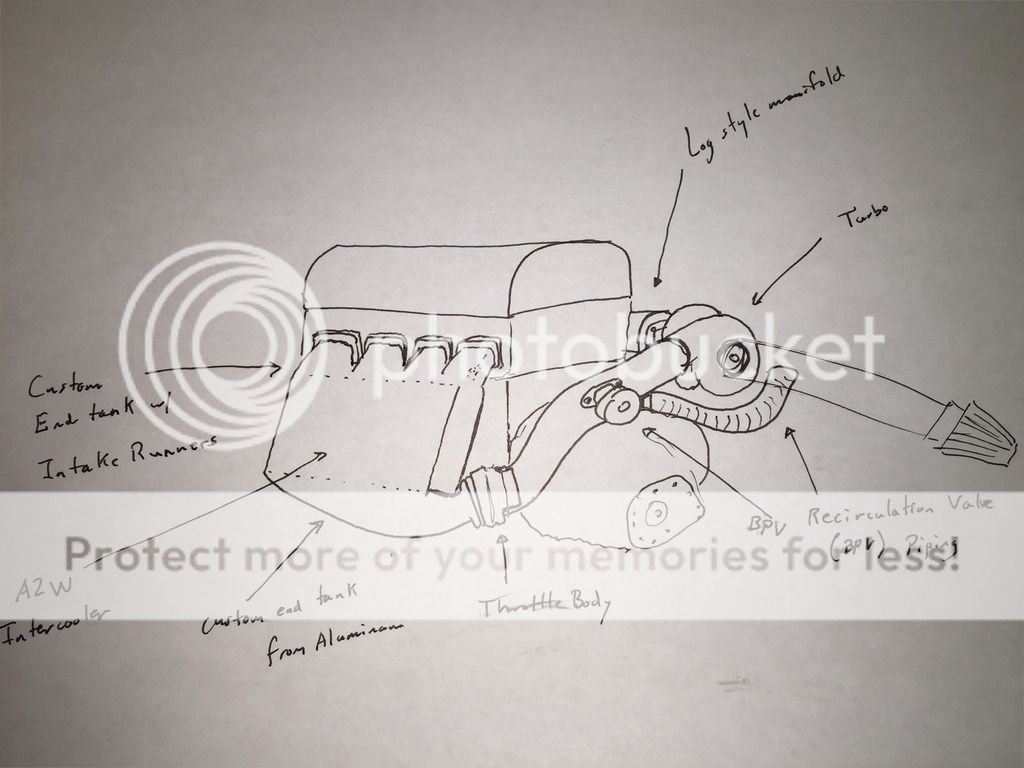

I plan on doing a few cool things, I want to buy a W2A core from Bell intercoolers, Corky Bell's company. I can get the core size I need for around $300 and it is amazing quality, as a finished intercooler it could cost north of $700. I plan on building the intercooler into the intake manifold. So one end tank of the intercooler will have the throttle body on it, and the other end will go right into the runners. This should increase throttle response a ton and decrease lag a lot as well, and it will essentially control the temperature of the entire intake manifold. Also with where it is placed in the engine bay it will get lots of cool air from under the car to further help keep temps down. I plan on a log style header to put the turbo right at the transmission, so it has a short boost line to the throttle body that goes over the transmission, and there is where I will incorporate either a BOV or BPV or a hybrid valve.

Here is a sketch to show what I am talking about more clearly:

[This message has been edited by zkhennings (edited 03-27-2015).]

|

|

|

BrittB

|

MAR 28, 02:29 PM

|

|

|

Won't the intercooler require it's own fresh air source instead of the normally higher temperature air found in the engine compartment?

|

|

|

BrittB

|

MAR 28, 02:34 PM

|

|

| quote | Originally posted by woodyhere:

Try as I might, I still make plenty of mistakes. The trick is to man up and fix them. You have definitely demonstrated that quality. I look forward to seeing more of your work in the future. This has been a very interesting read.

|

|

You never get to a point of not making mistakes, experience makes you more efficient at fixing them quickly!

This build with the planned system looks very cool, I'm happy to follow along and wish you much success!

|

|

|

zkhennings

|

MAR 30, 09:59 AM

|

|

| quote | Originally posted by BrittB:

Won't the intercooler require it's own fresh air source instead of the normally higher temperature air found in the engine compartment? |

|

It will be a water to air intercooler so it's cooling ability comes from a dedicated coolant source separate from engine coolant. I might ceramic coat the outside to further insulate it from underhood temps.

Anyone selling a Tig that can do aluminum?

|

|

|

|