|

| The White Bug (Page 40/46) |

|

pmbrunelle

|

JUL 02, 08:13 PM

|

|

I started the anti-dive mod on my front suspension, which mainly consists of moving the forward lower control arm pivots down 3/8".

To locate the new pivot holes, I made a drill guide bushing which centers in the original hole. I then used the flat side of the guide bushing to clock the guide hole correctly.

Now that the pilot holes are drilled, I need to weld the original holes shut. Then, I can drill out the pilot holes to the correct size.

|

|

|

pmbrunelle

|

JUL 24, 01:34 AM

|

|

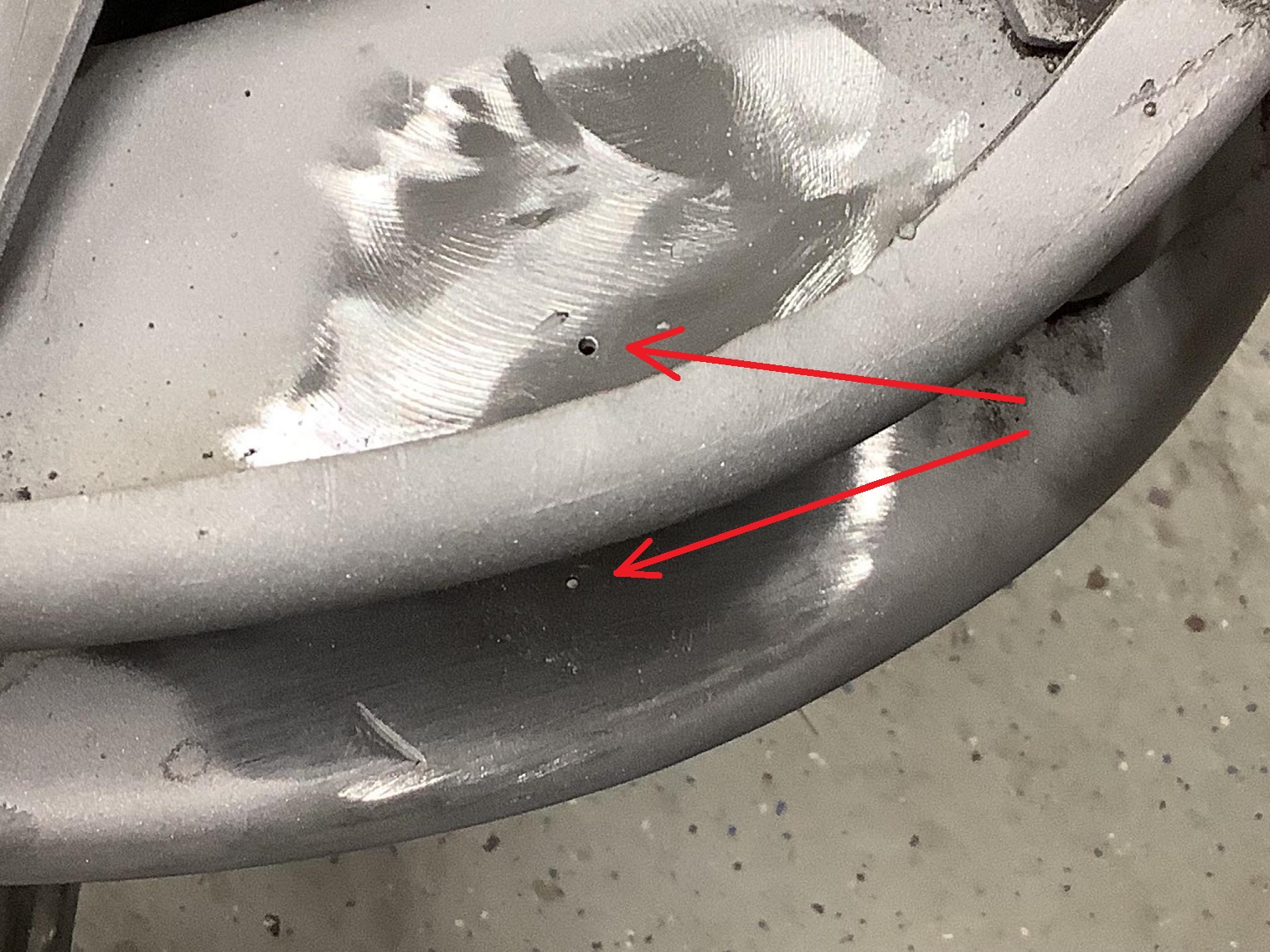

Welding the stock LCA pivot holes shut went well. Now, I can drill out the pilot holes to the correct size:

I made a plywood jig to simulate the steering rack:

As I'm moving the LCA down, I want to move the steering rack down as well. The steering rack mounts need to be cut off, shortened, and then rewelded to the crossmember.

I temporarily welded a steel tube to the crossmember, touching the edge of the plywood jig. This is a reference, so that when I reweld the steering rack mounts to the crossmember, the left-right positioning will be correct.

|

|

|

pmbrunelle

|

AUG 04, 10:53 PM

|

|

Since I am lowering the steering rack, the notch for the steering column clearance needs to move down, weakening the crossmember.

Therefore, I prepared some laser-cut reinforcing plates for the front crossmember.

I'll weld them on shortly.

|

|

|

pmbrunelle

|

AUG 10, 01:29 AM

|

|

The steering rack moved down by 0.5" appears to fit without issues.

This was a test fit:

With the crossmember (temporarily) in place, I tack-welded Will's spherical bearing shells to the lower control arms:

Fieros don't appear to have been built with much precision. The LCA pivots on the right side of the car were spaced ~4 mm closer together than those on the left side of the car. I don't think this car was ever in an accident. The size of the mill and drill pads gives an idea of the spaceframe's tolerances.

|

|

|

fieroguru

|

AUG 10, 07:08 AM

|

|

| quote | Originally posted by pmbrunelle:

Fieros don't appear to have been built with much precision....

The size of the mill and drill pads gives an idea of the spaceframe's tolerances.

|

|

I have seen at least 1 car where the hole for the mill and drill pads was outside of the pad area.

The whole purpose of the mill and drill was to achieve good panel alignment (cosmetics) without needing to catch up to their peers with their metal design, stamping and assembly processes.

|

|

|

ericjon262

|

AUG 14, 12:02 PM

|

|

|

your progress looks great! there are times I wish I had built my car more or less in "stages" instead of all at once. I find myself with less things that are finished, and more things that individually need attention. In your case, the steps of your build all seem much more complete before you move onto the new step. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

82-T/A [At Work]

|

AUG 14, 12:53 PM

|

|

The more times I see your white Fiero, the more and more impressed with it I become. You've done such a good job... it's 100% the product of an engineer. I'm so glad you're keeping it stock looking. It's such a striking design, and with the effort and work you're putting into it... it's going to be such a fantastic car.

|

|

|

Will

|

AUG 14, 02:34 PM

|

|

| quote | Originally posted by pmbrunelle:

With the crossmember (temporarily) in place, I tack-welded Will's spherical bearing shells to the lower control arms:

Fieros don't appear to have been built with much precision. The LCA pivots on the right side of the car were spaced ~4 mm closer together than those on the left side of the car. I don't think this car was ever in an accident. The size of the mill and drill pads gives an idea of the spaceframe's tolerances.

|

|

There's a locating pin on the crossmember, but only on one side. I thought the bolt holes on the other side were slotted, so maybe there's some room to bump it around to get the two sides closer before you finish weld them.

Or maybe you already have and this message is too late

|

|

|

pmbrunelle

|

AUG 15, 01:20 AM

|

|

| quote | Originally posted by ericjon262:

your progress looks great! there are times I wish I had built my car more or less in "stages" instead of all at once. I find myself with less things that are finished, and more things that individually need attention. In your case, the steps of your build all seem much more complete before you move onto the new step.

|

|

I like to take bite-sized chunks that aren't overwhelming. But, there's no one way to modify a car!

| quote | Originally posted by 82-T/A [At Work]:

The more times I see your white Fiero, the more and more impressed with it I become. You've done such a good job... it's 100% the product of an engineer. I'm so glad you're keeping it stock looking. It's such a striking design, and with the effort and work you're putting into it... it's going to be such a fantastic car. |

|

Glad you like it!

In about two weeks, the car should be running again with new tires/wheels/brakes/suspension. I'll see how I like it then.

| quote | Originally posted by Will:

There's a locating pin on the crossmember, but only on one side. I thought the bolt holes on the other side were slotted, so maybe there's some room to bump it around to get the two sides closer before you finish weld them.

Or maybe you already have and this message is too late |

|

On my 1985 Fiero, there is no locating pin. There are four bolts holding the crossmember to the underside of the frame rails. One bolt hole on the crossmember is close-fitting the the bolt. On the opposite side of the car, a slot on the crossmember (again, close-fitting to its bolt, along its short dimension) blocks rotation. Together, the hole and slot dully define the crossmember's position in 3 degrees of freedom. There is no adjustment available (not without changing the locating concept).

The UCA position is determined by the crossmember. Caster is determined by the relative fore/aft positioning of the UCA versus the LCA. To get the caster approximately correct and equal on both sides, I positioned the LCAs relative to the crossmember. The LCA positioning relative to the body-mounted pivot ears was a consequence of the aforementioned procedure.

I got the bearing shells TIG-welded by a guy near my parents' place:

In retrospect (I often realise these things AFTER completing the job), I should have adjusted the (relatively bendable) rear body-mounted pivot ears with a BFH to make things appear more symmetric between both sides. Oh well, I didn't do that! My mods don't always end up perfect, but that's OK. The mistakes remind me of the human element involved (myself)...

I'll give you some feedback (not right now though) on the bearing shells, over in the bearing shell thread.

********************************************************************************

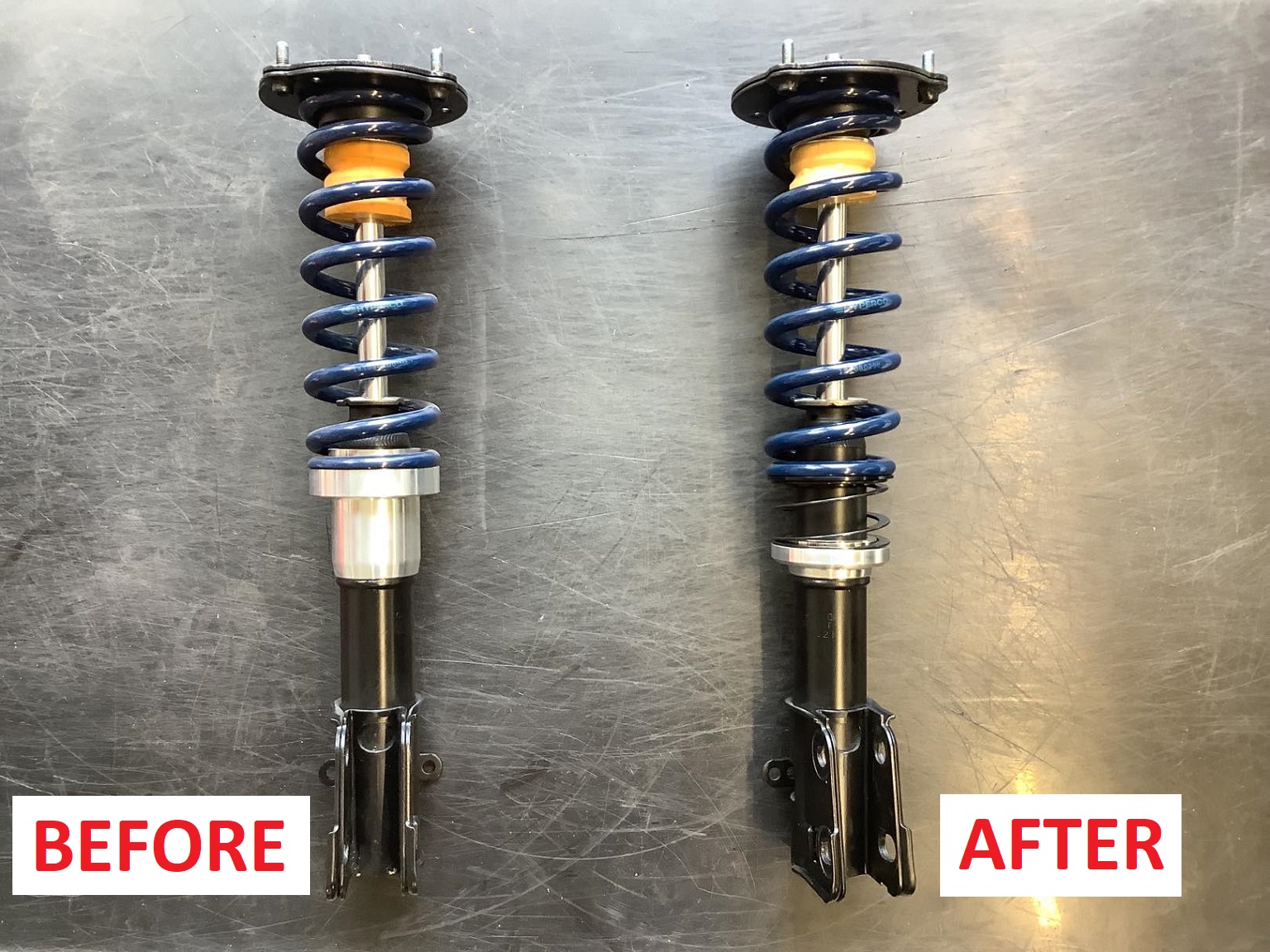

I goofed with my initial rear strut setup. I had a 400 lb/in spring, just barely preloaded. I eventually figured out that the rear of the car would end up way too high.

To correct the situation, I lowered the spring perch on the strut, and then to take up the play of the spring at full droop, I inserted an Eibach helper spring.

Expected ride frequencies are:

Front 1.75 Hz

Rear 2.07 Hz

|

|

|

ericjon262

|

AUG 16, 02:01 PM

|

|

| quote | Originally posted by pmbrunelle:

Since I am lowering the steering rack, the notch for the steering column clearance needs to move down, weakening the crossmember.

Therefore, I prepared some laser-cut reinforcing plates for the front crossmember.

I'll weld them on shortly. |

|

I too did not notice a locating pin on any of the three 84-87 crossemembers I have handled, that might be an '88 feature.

the later crossemembers have a similar reinforcement to your laser cut parts. my 85 had a non-reinforced crossmember as well, I swapped one from an 87 in when I did my anti-dive modification, while I didn't know there was a difference before I started the modification, I did welcome the extra bracing, your design looks well executed.

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

|