|

| 85 Notchie Build (Page 4/23) |

|

zkhennings

|

MAR 17, 10:26 PM

|

|

I am thinking about it! Not sure yet what the future will hold. I unfortunately took a bunch of pictures with the family camera and almost all of them have been erased besides this one... I made my valve covers different colors.... Why? I think it looks cool.

As a good tip... instead of taping off the aluminum stripes that are exposed, I put a shop towel in a sanding block like I would sandpaper, and soaked it in brake parts cleaner, then ran it across the top and it took all the paint off. Engine enamel (which these are painted with) is really really easy to take off before it gets heat cycled. I baked these in the oven once I painted them and took the paint off the stripes

So my cold start injector is deleted and there is no issues with starting.

I had the worst luck ever this weekend, I go to bleed my brakes and the 6mm line from front to back explodes. It takes so long to find a replacement because no one carries it. Finally hours later one autozone had two 6 foot pre flared sections with the wrong sized fittings. Got a coupler and the right sized fittings. Stupid fittings, 6 mm fittings wouldnt fit the 6mm line. Had to drill them out, and reflare the line. Finally got that in, bleed the rear left caliper, all is good. Then the bleeder broke off on the passenger side rear caliper. These are only a year and a half old calipers. I tried everything, welding to it, welding nuts to it, drilling it out and hammering a screw driver in there, heating it... Nothing worked

I looked on the forum and everyone had basically said on previous threads to buy a new caliper. I went and bought freeze off instead, the spray that actually freezes the bolts and cracks the rust. I did this while alternatingly heated it for around and hour, then cut an easy out to the right size and welded it to a socket, and finally it came out!

Such a successful moment. So if anyone else has stuck bleeders, I suggest the same technique. Everything else went smoothly, just a 12 hour detour really

|

|

|

zkhennings

|

APR 13, 02:48 PM

|

|

Ok just to post some updates...

I have around 250 miles on the new engine, I will take a gopro video soon and post.

Everything is running well, oil pressures are at 40 psi when warmed up at idle. There are no weird smells or sound and everything is as it should be.

I am going to need to get a new flywheel though because the one on the car right now is only half correct. All the holes are drilled but the weight is missing from the back. So it vibrates, not terribly, and way less than with the 88 flywheel, but still it vibrates. So that will be annoying to change. Anyone have an easy way of doing this? I would love to not have to drain all my coolant and replace it/ undo everything just to hook it back up. I need my car for getting to work this summer so it cant be off the road more than a weekend at a time. I think that could easily be a weekend job though.

I need a new gasket for the sunroof, and I need to get real dew wipes because the chrome ridge that goes over the door panels with these dew wipes messes up how the door skins get aligned.

Goals for this summer are as follows:

Flywheel

New rims and tires

Coilovers

New front springs

Brake upgrade (will depend on wheels I get)

Painting the floor

I would like to do a roll bar with racing seats and harnesses but I don't know how feasible that is.

Custom external gauge pod with gauges

Fiberglass door panels

New transmission (maybe f23 but most likely not)

7730 Swap

And then I want to turbocharge it or at least get that stuff going

If I cant get it done I will be making a new more stock like exhaust for my car because side exhaust is really really loud all the time.

|

|

|

zkhennings

|

MAY 05, 05:19 PM

|

|

|

... [This message has been edited by zkhennings (edited 06-05-2014).]

|

|

|

zkhennings

|

MAY 27, 09:02 AM

|

|

|

|

zkhennings

|

JUN 07, 07:44 PM

|

|

Well with the new tires with stiffer smaller sidewalls my car was scary on the highway with the poor alignment, I slotted the upper control arms to slide the ball joints back to put the wheels in negative camber vs positive camber they were in... Also I painted my swaybar and reinstalled it.

|

|

|

zkhennings

|

AUG 01, 02:20 PM

|

|

|

Lots of summer updates to be posted soon...

|

|

|

zkhennings

|

FEB 28, 02:39 PM

|

|

|

|

zkhennings

|

FEB 28, 03:13 PM

|

|

Now I'm moving onto my coilover conversion and GrandAm Brake swap. I swapped all 4 calipers with Grand Am front calipers, installed Russel stainless steel braided brake hoses, painted the calipers (well 2 of them because I decided the paint was not the best, and got the G2 epoxy caliper paint which I have yet to use).

I bought front hubs machined by Fieroguru and they worked out great! I installed new timken bearings into those and removed all the splash shields. My old rotors were gross and pitted.

I used heavy duty AC Delco rotors, and bought some nice Performance Friction brake pads. Because they are made for maybe a weekend autocrosser or racer, the bedding process included heavy braking from 100+mph down to 60mph 3 times. I also installed a full sized Blazer Master Cylinder and swapped the Fiero reservoir onto it. I also had to grind the front brackets down a little, but this is common knowledge so no picture. The brakes are great, and I have the perfect amount of pedal travel. At first I had very little travel until the brakes seated themselves. I think I will do the S10 booster swap in the future, because although I can lock up the tires fine, I have to push pretty hard. This picture is not from when the brakes were first installed. As you can see I angled the brake hoses so they are never bending at a tight radius. I retained them to the struts with cushion clamps.

While I had the front hubs off I decided that I was sick of bottoming out all the time and cut my bump stops. I could get most of the way around with an angle grinder, but then cut the last bit with a dremel with a cutoff wheel. I put the grinding disk on the angle grinder and pressed it flat to the cone to make it nice and flat on the bottom to weld to. I cut around an inch of material from the bumpstop and welded them back up with flux core wire. I also added the cup pieces to the polyurethane bushings I had previously installed in the front suspension.

And my tools organized on my Fiero mat

And now for the rear coilovers. I have KYB shocks up front, and struts in the rear. I bought 350# springs from summit, as well as AFCO (?) Sleeves for monroe struts from summit.

The spring perches came off wicked easy with the angle grinder, I did them all in one cut, went most of the way through, then whacked them with a hammer and they popped right off

Then I ground them down on a bench grinder and painted them with some epoxy paint I had where I exposed the metal.

Here are the parts all slid into place

Now what I did next I had to undo, because I thought I could install the top hats upside down and get some extra travel. I didn't take pictures when I redid everything with the top hats in their regular orientation. But I tacked some 2.5 inch exhaust tubing to the top hat to center the springs. They are perfectly centered, it appears off in the picture as the paint is still wet and shiny.

I trimmed the bump stop I had on the strut to gain some extra travel

Here is the snap ring installed into the top of the sleeve. I squeezed it in there with a punch and hammer. I then RTVd over the top of it. Since then the sleeves slid down a little until they settled, they are only aluminum so I am not surprised they deformed at the bottom a little bit.

And that is that. I wish I had a picture of the ride height which I think looks very nice with the GT wheels. I also installed some camber bolts I bought from RockAuto. They came with one of the offset washers being the wrong size. I called the company who makes them to see if they could send me one, they were very unhelpful. I called RockAuto and they checked my order and immediately shipped me a whole new camber bolt for free, and it came only two days later! I was really happy and wrote them a good review.

Next up is the exhaust work[This message has been edited by zkhennings (edited 03-09-2020).]

|

|

|

zkhennings

|

FEB 28, 04:18 PM

|

|

I had a side exhaust with 2" tubing and a cheap Thrush Turbo muffler and it was loud and raspy and droned like crazy. It also made it harder to change the starter and the oil, and brought more heat against the firewall and wiring. So I decided to fabricate a new Y pipe that went the other direction over the transmission to 2.5" tubing that snakes next to the trunk, through a 3" Borla XR-1 muffler with a lifetime guarantee (pretty much, million mile guarantee, 304ss). I have a flex coupling in one side of the Y pipe, and one after the Y pipe meets the rest of the exhaust. I don't have pictures of the rest of the exhaust at the moment.

So I am planning on going 3800 at the beginning of the summer once I graduate college. I will be getting probably an 03 WRX as soon as I have the money which will be my daily driver.

Because of this, I just bought mild steel mandrel bent tubing. I spent less than $100 on all the tubing and gaskets and couplings (but more on the flex couplings). I bought smooth adapters to attach the 3" Borla to the 2.5" exhaust. I went with the 3" because with the 3800 I will be using a 3" exhaust. It was amazing practice, I got pretty decent at welding the thin tubing (16ga) I painted the exhaust with high temp header paint, but it has not done amazingly, especially in the winter here. I will repaint in the spring.

I first solid mounted the exhaust when I made it but that was a terrible idea. It sounded horrible in car, and was incredibly loud. I have since rubber mounted it with rubber exhaust mounting blocks bolted to the cradle. I made the axis of rotation of both almost perpendicular to one another, so it supports the exhaust in place with only two mounting points. The blocks are easily unbolted to remove the exhaust. I went to a local exhaust shop and picked up the blocks and steel rods that hang from the blocks for $5 a piece. They are around $15 on the internet.

For this project I did not want to be welding with .030 flux core wire. I found a great welding supply store in Boston for the hobbiest. I bought my brand new 40cf bottle outright for $100, and its only $20 to fill the tank. So much better than any of the huge industrial suppliers which is where most people I know get their tanks filled. I don't live in an area with many shops like that, I have no automotive paint stores nearby either. Just chains like autozone. Here Fieros are also expensive.

So I bought some .023 solid wire and a regulator from Harbor Freight. Honestly it works perfectly at maybe a third of the cost.

WOW! I had gotten so used to my aweful flux core that I forgot how it feels to weld when you can actually see the bead and don't get splatter everywhere! I managed to put down some nice welds on the exhaust tubing. I would weld around a third of the circumference at a time, grind it flat where I ended the bead to give a nice already sealed surface to continue. This allowed me to put down some pretty flat welds. Now here are pics and excuse the quality. The exhaust is awesome by the way. It is loud, but sounds amazing, almost exotic. I picked up a ton of seat of the pants HP from doing this (maybe 10). I have no restrictions in the exhaust, and the firewall is much cooler. I have had no problems with trunk heat even on long drives.

Box of parts including Muffler and the shape of the mandrel bent tubing I bought.

Here is what I made for where the 1.5" tubing meets the 2.5" tubing. I slipped dowels into the 2.5 inch tubing and hammered the middle together to form the shape I welded the 1.5 inch tubing to.

Here is the O2 sensor screwed into the bung, I made a major mistake here and screwed the O2 sensor in without letting it cool fully after welding, and it SHATTERED the thread in the O2 sensor. I had to destroy the O2 sensor to get it out and royally screwed up the thread in the bung. I was really bummed, but a quick search found that Autozone sells O2 thread repairers, which is pretty much a massive short tap with a square opening for a 3/8 inch wrench. It worked great and I was able to save the bung.

Here is how the welds came out at medium heat, lower feed, and me making loops

This picture is the tubing welded to the cup ends from the stock Y pipe. I cut them off to reuse them.

And here is the routing. The rest of the exhaust was not done at this point. I do not know if anyone else has done this before. Most likely.

And that's all for now, I bought some snow tires and have been enjoying my Fiero in the snow

[This message has been edited by zkhennings (edited 03-09-2020).]

|

|

|

zkhennings

|

MAR 03, 05:50 PM

|

|

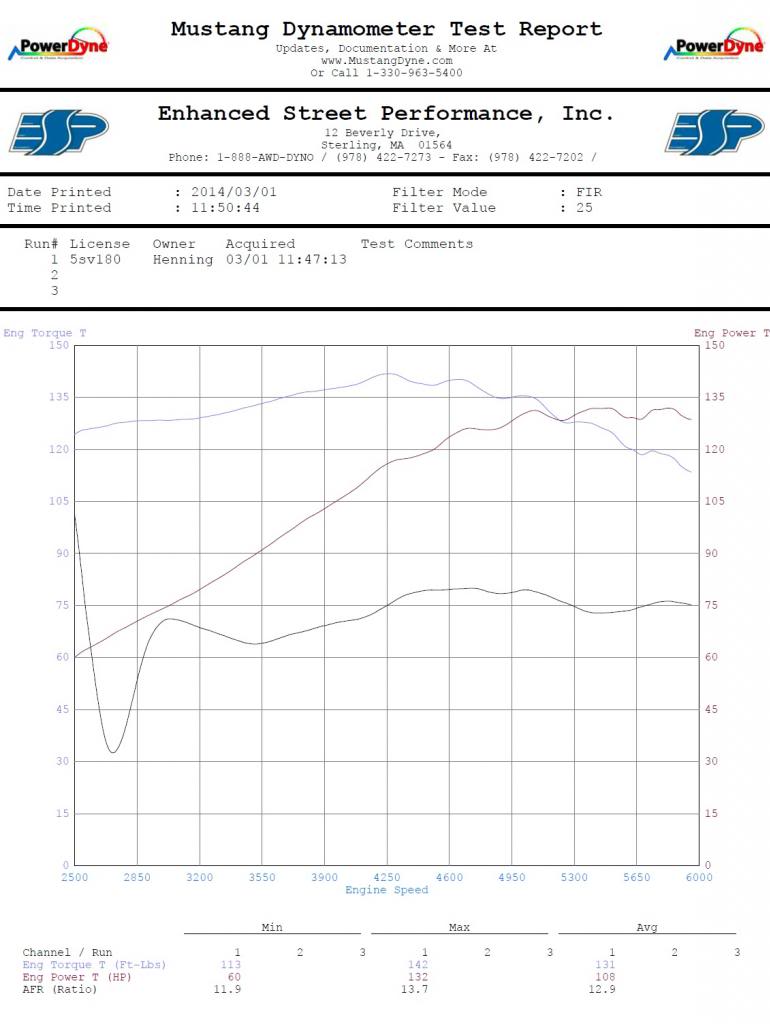

I got my car Dyno'd over the weekend at ESP in Sterling, MA. The dyno used was a Mustang Dyno. Because I am making max power at such high RPMs compared to stock, I can't wait to see if there is a noticeable increase in power when I modify my intake and bore my throttle body!

[This message has been edited by zkhennings (edited 03-09-2020).]

|

|

|

|