|

| The White Bug (Page 38/46) |

|

zkhennings

|

MAR 13, 05:44 PM

|

|

|

I imagine that was kind of scary.

|

|

|

ericjon262

|

MAR 13, 09:14 PM

|

|

I kinda wish you had taken pictures of that setup in the lathe. I have drop spindles on my car, and they actually have significantly less material to machine off, it's a big part of the reason I want to make custom spindles for the car so that the calipers mount securely to a machined face. Mine will probably use unit bearing hubs in 5x114.3 so I can have the largest wheel selection options.

I'm looking forward to hearing how your suspension mods work out!------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

pmbrunelle

|

MAR 14, 07:46 AM

|

|

Fieroguru, I've seen you post on the forum that using the as-cast surface is ill-advised. I would have probably come to that conclusion on my own, but I give you 5% credit!

********************************************************************************

With a big/solid enough lathe, there won't be vibration/scariness. This also assumes you keep the RPM down, like below 100 or less. In a marginal case, you could add a counterweight.

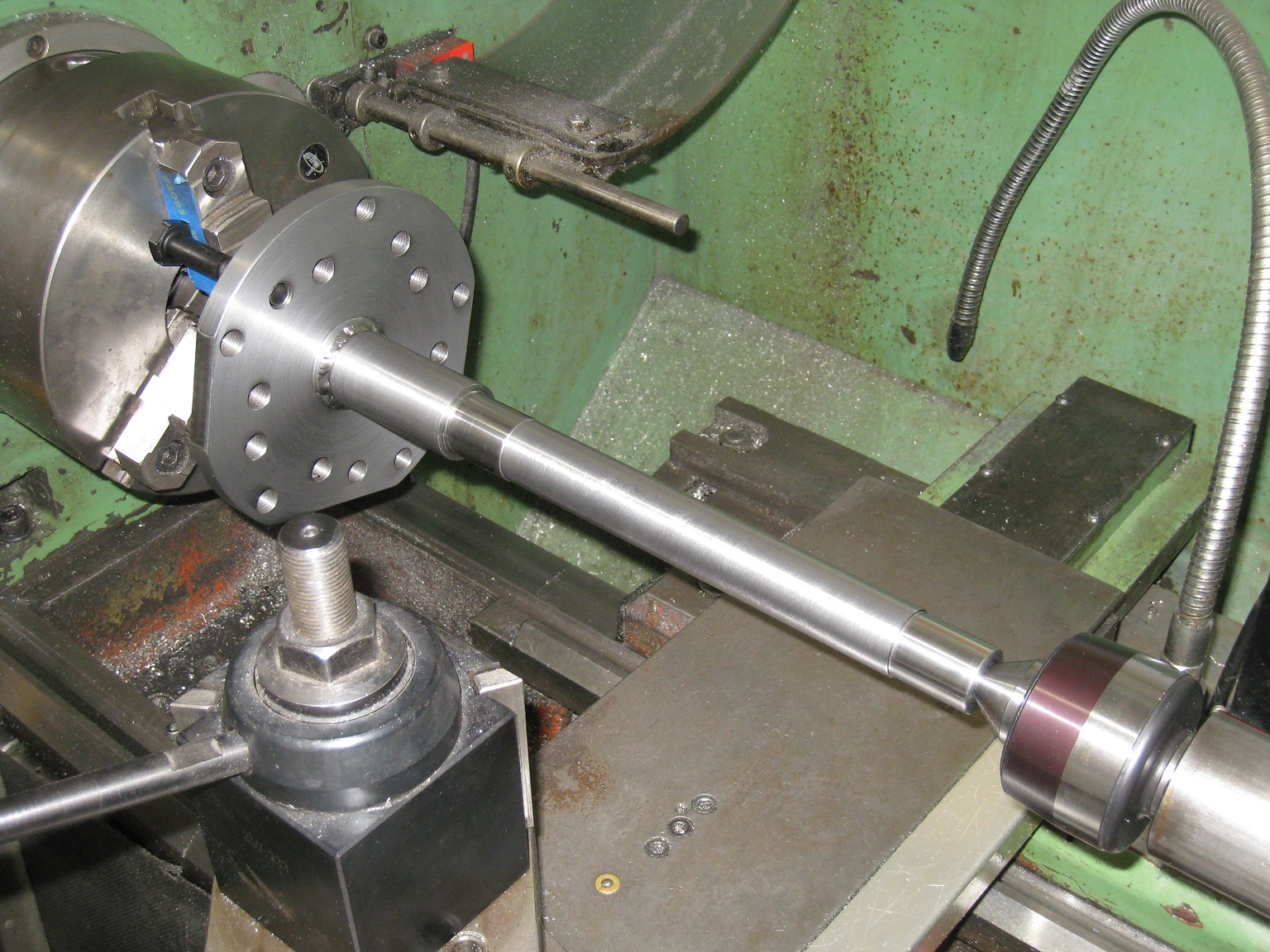

I would suggest the same sort of setup like I did for my tire mounting tool:

When I want to turn between centres, in most cases, I chuck a piece of mild steel rod with a 60° cone (generally reusing the same one) and use that as the centre in the headstock end. Before use, I take a skim cut with the compound slide to make the 60° cone concentric with the headstock rotation.

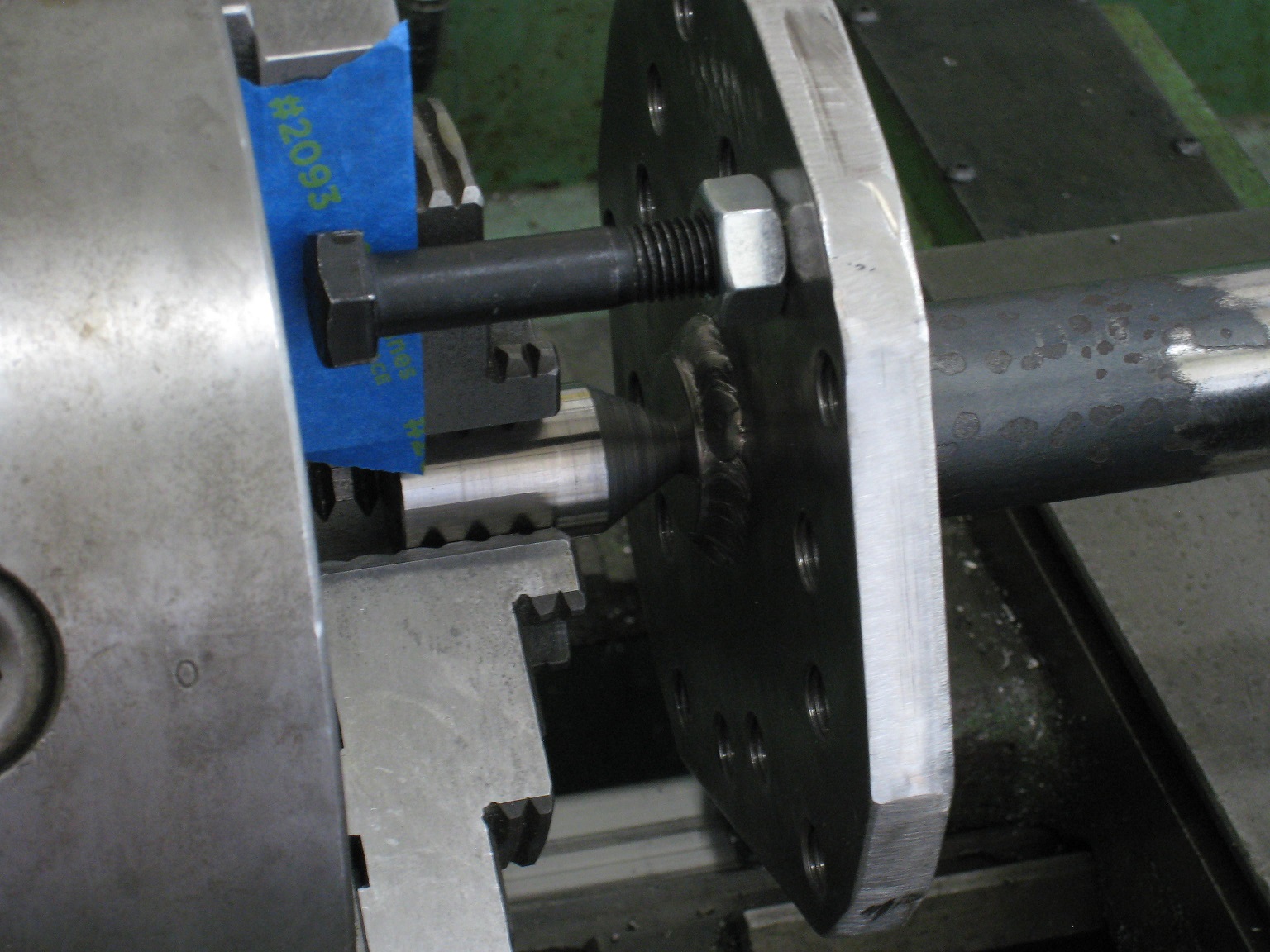

A bolt+jam nut is a convenient way to drive the part, if your part happens to have a threaded flange:

On the Fiero knuckle, a simiar bolt+jam nut could be used in the caliper mounting bracket hole. In the general case, use a lathe dog.

********************************************************************************

That green lathe at work was pretty nice, but I don't have access to it anymore. That lathe was included as part of a recent divestiture...

I instead used my dad's light-duty 9x20 lathe.

The 9x20 doesn't have the swing clearance to spin the knuckle all the way around. However, since I only needed to cut material from a ~100° arc, that worked out with me manually pushing the knuckle back and forth. Between each stroke, I turned the handwheels to set the cutting depth.

I don't have a good photo showing the overall setup, but I snapped this one:

********************************************************************************

262, I don't know if your concern is about about insufficient thread engagement in your knuckles, but if that's the case, you could drill out the threaded holes and use nuts on the other side in the interim.

|

|

|

zkhennings

|

MAR 14, 04:31 PM

|

|

I have done a decent amount with a manual mill, and a fair amount with a cnc mill and cnc lathe, but only a handful of jobs with a manual lathe without a blast door, and they were all round aluminum stock kinda jobs. So imagining the spindle on there right near your face is scary. I have to start messing with my lathe, first I need to get a set of tools and quick change doodads.

But I was re-reading through your thread and I have a couple comments.

Regular old split lock washers have always worked great for me on joints that loosen up due to thermal expansion and cooling, I put them on everything subjected to thermal cycling or vibration.

I had recommended POR-15 high temp exhaust coating for turbo headers to you in a PM once. I take it back, it was much better than VHT, but it did not hold up for more than 6 months in a turbo application. Would probably be great for heatshields and brackets. How has your cerakote held up?[This message has been edited by zkhennings (edited 03-14-2023).]

|

|

|

pmbrunelle

|

MAR 15, 06:15 PM

|

|

I don't see much use in split lock washers.

If you tighten your bolt a minimum amount, the split lock washer flattens and becomes a solid spacer. At that point, the only added value it has are the sharp edges which can bite into the surface and bolt head, preventing unscrewing.

At that point, you might as well use something more designed to prevent unscrewing, such as a serrated head, a star washer with multiple teeth, or the Nord-lock style of washer.

With regards to temperature variations, I think you should just arrange so that your bolts remain sufficiently stretched throughout the temperature range of the assembly.

I haven't had any problems with exhaust manifold to head gaskets since I replaced the gaskets with Fel-Pro and I used the wedge-lock bolts. I think the main issue was the previous cheap exhaust gaskets burning out, causing a total loss of bolt load. The wedge-lock bolts were a bonus on top, but not the main fix. I retained the stock 2.8 stud-bolts in three positions, in order to mount the stock 2.8 exhaust manifold shield.

********************************************************************************

The Cerakote has been generally OK on most heat shields, but not a slam dunk.

Some signs of rust showed up on the hottest heat shield (with exposure to rain); the shield covering the turbine housing. I rubbed away the rust with Scotchbrite, and then resprayed over the Cerakote with VHT in the same colour.

I think that some sort of plating process might work better...[This message has been edited by pmbrunelle (edited 03-15-2023).]

|

|

|

zkhennings

|

MAR 15, 08:47 PM

|

|

The purpose of the split washer is to put tension on the bolt, they make wave style washers that do the same job as well, split washers is just the cheapest way to manufacture them. It is essentially a single coil spring that helps prevent loosening when there are slight changes in clamping force from vibration or temperature change. I generally use a high grade split washer (8/10.9 or higher) as they take a lot more force to flatten, and generally hold their shape even when compressed for a long time.

I agree your exhaust issues were from the gaskets, but just as a general suggestion they do work very well in my experience. I use them a lot with exhaust flanges of all kinds.

Also try out the Eastman brand paints, you can get the 2K high temp paint in spray cans where you break an internal activator compartment and have limited time to use it. I thnink it would work great for heat shields.[This message has been edited by zkhennings (edited 03-15-2023).]

|

|

|

pmbrunelle

|

MAR 16, 09:24 PM

|

|

How much force does it take to flatten an M8 split washer? I'm guessing on the order of 250 lbs?

If you have a class 10.9 M8 bolt at 75% proof load, you have 5123 lbs of clamping load.

If the bolt somehow relaxes to the point that the split washer is now working as a spring (versus solid), then something seriously wrong has already occurred, and the bolted joint has already failed, in my opinion.

|

|

|

fieroguru

|

MAR 16, 09:58 PM

|

|

| quote | Originally posted by zkhennings:

The purpose of the split washer is to put tension on the bolt, they make wave style washers that do the same job as well, split washers is just the cheapest way to manufacture them. It is essentially a single coil spring that helps prevent loosening when there are slight changes in clamping force from vibration or temperature change.

|

|

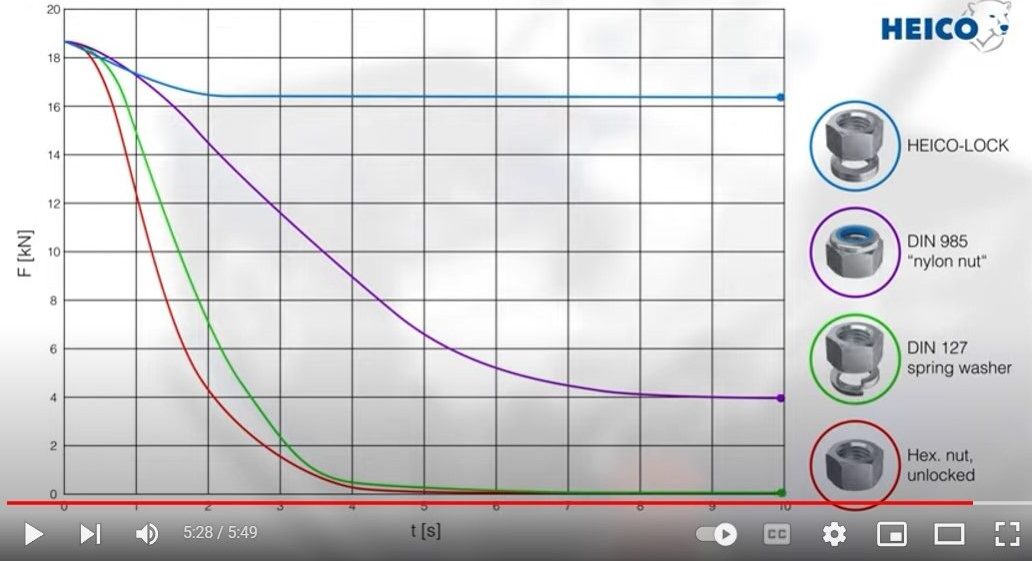

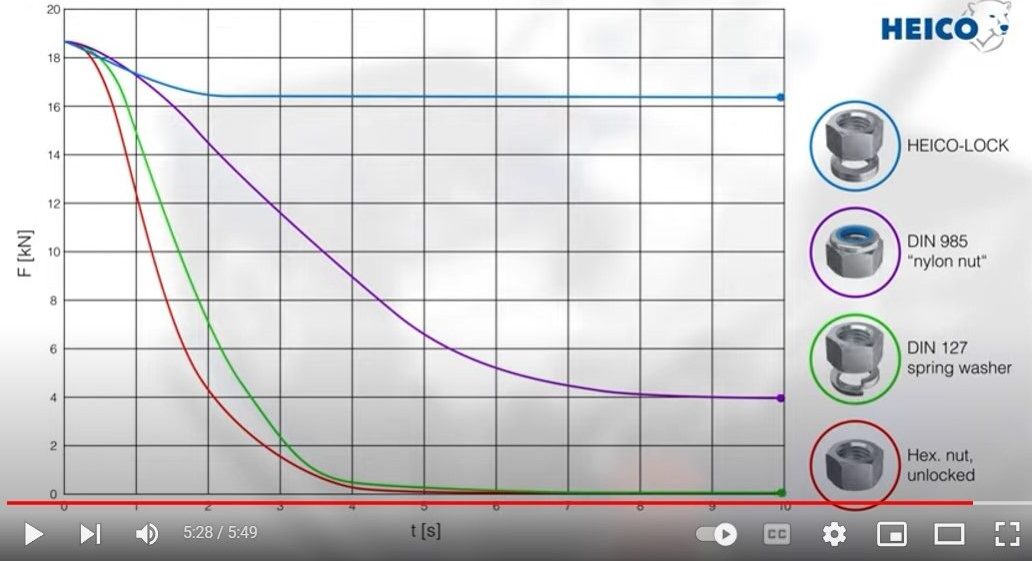

In my reliability training we watched an old video about bolted joints subjected to vibrations via the junker test. What we learned was the normal lock washers performed about the same at resisting loosening from vibration as a bolt w/o lock washer. Loctite was the winner in that video. My reliability instructor's mantra was Loctite on every bolt, every time.

Here is a video of a newer junker test that shows the same result (source for the chart above) with the lock washer and improved holding of their custom washers.

|

|

|

ericjon262

|

MAR 16, 10:59 PM

|

|

| quote | Originally posted by fieroguru:

In my reliability training we watched an old video about bolted joints subjected to vibrations via the junker test. What we learned was the normal lock washers performed about the same at resisting loosening from vibration as a bolt w/o lock washer. Loctite was the winner in that video. My reliability instructor's mantra was Loctite on every bolt, every time.

Here is a video of a newer junker test that shows the same result (source for the chart above) with the lock washer and improved holding of their custom washers.

|

|

This is the kind of content I like to see in a forum, Thanks for posting it!------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

ericjon262

|

MAR 19, 09:38 AM

|

|

| quote | Originally posted by pmbrunelle:

262, I don't know if your concern is about about insufficient thread engagement in your knuckles, but if that's the case, you could drill out the threaded holes and use nuts on the other side in the interim. |

|

thread engagement was a concern one of the concerns, the casting is just very thin at the caliper ears, to an almost uncomfortable degree. the aftermarket part was clearly made to a lower standard than the OEM, which is not entirely surprising, but still disappointing.

machining that surface must have taken a while doing it by hand like that! the outcome however looks great, good job!

|

|

|

|