|

| The White Bug (Page 37/46) |

|

pmbrunelle

|

SEP 30, 06:27 PM

|

|

| quote | Originally posted by ericjon262:

I've been looking at getting a 12" and 24" dial caliper. I've recently fallen in love with dial calipers compared to digital, something about being able to watch the needle move as I move the caliper is very satisfying,

|

|

My dad's goto caliper that he keeps at his desk is a 6" dial Mitutoyo. In my first summer job, I always went to my dad's desk to borrow his dial caliper whenever I wanted to measure something. So I got the taste for dial calipers as a teenager. When I finished school, I got a 150 mm dial Mitutoyo (copycat) for work. I got mine in metric because the automotive world is mostly metric.

With a dial, you can more easily see the needle deflect depending on how you squeeze the part than with digital. You can interpolate between the graduations. Dial has the advantage of not running out of battery and starting to blink; it's always ready to go. In a workplace with many people, the dial caliper never goes missing; nobody else wants to borrow it.

I would say that unit conversion is inconvenient; if I was going to work with mixed inch/mm units, then the digital caliper makes more sense as you can switch it over by pressing a button.

At home I have a cheap digital caliper, and I'm having to change the battery every few months. Probably a name-brand such as Mitutoyo or Starrett is better with regards to battery life. At home I'm always switching back and forth between inch and mm units depending on what I'm doing.[This message has been edited by pmbrunelle (edited 09-30-2022).]

|

|

|

ericjon262

|

OCT 02, 03:31 AM

|

|

| quote | Originally posted by pmbrunelle:

My dad's goto caliper that he keeps at his desk is a 6" dial Mitutoyo. In my first summer job, I always went to my dad's desk to borrow his dial caliper whenever I wanted to measure something. So I got the taste for dial calipers as a teenager. When I finished school, I got a 150 mm dial Mitutoyo (copycat) for work. I got mine in metric because the automotive world is mostly metric.

With a dial, you can more easily see the needle deflect depending on how you squeeze the part than with digital. You can interpolate between the graduations. Dial has the advantage of not running out of battery and starting to blink; it's always ready to go. In a workplace with many people, the dial caliper never goes missing; nobody else wants to borrow it.

I would say that unit conversion is inconvenient; if I was going to work with mixed inch/mm units, then the digital caliper makes more sense as you can switch it over by pressing a button.

At home I have a cheap digital caliper, and I'm having to change the battery every few months. Probably a name-brand such as Mitutoyo or Starrett is better with regards to battery life. At home I'm always switching back and forth between inch and mm units depending on what I'm doing.

|

|

I plan on getting a few dial calipers in both inch and metric, ideally a 6", 12", 150mm and 300mm. I try to avoid calculating conversions because stacked tolerances can lead to problems. The needle deflection is key, you can't split hairs with digital. one day I'll have a handful of them!

|

|

|

pmbrunelle

|

OCT 27, 08:39 PM

|

|

| quote | Originally posted by pmbrunelle:

Now, I need to rack up some city mileage on the car; I need to break-in the clutch.

The clutch chatters a bit; while I could live with it how it is, I'd prefer if the chatter went away. |

|

In the past month, I've driven the car about 2300 km with the Scorpion rockers and new Spec 3+ clutch. About 1200 km of that was pure highway.

The Scorpion rocker arms have been quiet.

The chatter is mild, but it's still there when I drive the car. Leaving from a stop, if I raise the engine revs up to 1200 RPM (hot idle is 900 RPM), and then I quickly release the clutch just before the clutch disk catches up with flywheel RPM, then I avoid the chatter. If I keep engine speed at 900 RPM, and keep the clutch at the friction point until the clutch disk matches flywheel RPM, then I get chatter when the RPM difference is low. I used to drive that way with the RAM HD clutch.

I guess some people just naturally have the right technique. My dad tried the car last weekend, and the clutch didn't chatter on him. My dad didn't make any particular effort to drive a certain way.

I've been running the car at 180 kPa MAP, and the clutch doesn't slip. That's the most important part.

********************************************************************************

At the higher MAP level allowed by the new clutch, the VR crank sensor analog-to-digital Maxim MAX9924 interface has been malfunctioning and causing the ECU to lose synchronization with the crankshaft.

I did a quick-and-dirty test with a 4-pin HEI module acting as the crank sensor interface; it worked well. Over this winter I'll figure how to install the HEI module cleanly.

********************************************************************************

The aluminium spacer plates haven't been leaking oil. When the engine is cold, I run my fingers along the perimeter of the spacers; my fingers remain dry.

I was concerned that with the differing thermal expansion coefficients, that the aluminium plate sitting on the iron head would grow more and shear the RTV between the parts.

I did use Permatex Optimum Black 59823 RTV, which is advertised as having high flexibility and suitable for joints between dissimilar metals.

********************************************************************************

Hot AFR and hot fuel trim (EGO correction in MegaSquirt language) with the Scorpion rocker arms is as it used to be with stamped rocker arms. Therefore, I thought that I should leave the tune alone...

I've noticed that following cold starts (5°C coolant temperature typical), I'm seeing very a rich AFR indicated on the wideband gauge. It is showing about 10.5 AFR, whereas it used to run around 12.5 indicated AFR. From the driver's perspective, the car (when cold) feels sluggish and overfuelled.

I am hesitant to simply reduce the warmup enrichment in the tune without really understanding what happened, though that's probably what will happen (next year, as Fiero season for me is ending)...

I do have a hypothesis... the way I installed the Scorpion rockers, the ratio appears to increase with valve lift. So, for low lobe lift, the valve might be opening less than expected.

With a smaller gap between the seat and valve, perhaps liquid fuel in the port is sheared more and is better mixed with the air. With a better mixing, the AFR indicated on the wideband is lower, which corresponds with the sluggish feeling.

Perhaps before with the stamped rockers the true AFR was the same, but the excess fuel remained inert and simply passed through and out the tailpipe.

********************************************************************************

I don't have a garage, so tomorrow I drive the Fiero to spend the winter in my parents' garage. Thanks parents!

When I go there to visit, I'll be able to get some work done such as the HEI module mentioned above, and I want to work on the front suspension (including, but not limited to Will's spherical bearings).

I haven't posted a picture of the car itself in a while, so here we go (three weeks ago when I washed it):

|

|

|

La fiera

|

OCT 29, 08:29 PM

|

|

Car looks very nice Patrick! I've always wanted a white Fiero because for me that's the perfect color for any car.

But regarding the AFR difference between the stamped vs Scorpion aluminum rockers could be related to the difference in metal expansion rate.

Even with my muffler-less engine I can hear the rockers rattle louder when the engine is running right after cold start up until about 160F of water temp.

After that I still hear it because unlike yours, my lifters are solid so they always make noise but the difference in the frequency of the rattle is clearly different after it warms up.

I attribute the difference of rocker noise to a change of clearance between the valve tips and the rockers. So, in my case the valve lifts less due to the larger clearance when cold.

I add .002 of clearance when cold to the recommended valve lash since I changed to the aluminum rockers because If I didn't once the engine was warmed it was hard to start.

After doing compression test in all the cylinders while hot compression was down substantially because the valves were held open when hot, just enough to bleed compression through the valves.

Since you have lifters that can make up the clearance hydraulically, the only remaining cause for the difference in EGO vs the steel rockers is the expansion rate of the metals. Aluminum shrinks more than steel when cold and expands more than steel at the same hotter temperatures. And since we are talking about thousands of an inch the hypothesis seems to make sense to me. That's my 2 chillings to contribute.

What do you think?

Will, can you chime in??

PS. Keep up the good work!

|

|

|

pmbrunelle

|

OCT 31, 08:45 PM

|

|

Yes, I agree that having the aluminium rocker arm could change the amount of lash hot/cold with solid lifters.

I am running hydraulic lifters though, so any small changes will be compensated by the lifters. I recently changed to 0W-40 synthetic oil (with ZDDP additive extra), partly because I want to fill the lifters with with oil quickly following a cold start. The other reason for the synthetic oil is to keep it from coking too much inside the turbo when I shut down the engine.

So the ratio of a rocker arm depends on the distance from pivot to pushrod, and the distance from pivot to the roller wheel on the valve. I do not think the ratio of the rocker arm changes with temperature, because both distances change in proportion with each other. Since the rocker arm is aluminium, and aluminium is a highly conductive material, I assume that the rocker arm has the same temperature everywhere.

I reduced the amount of warmup enrichment, and the car is running better like that, but further tweaking will be needed. Getting the car to drive correctly immediately after turning the key is a quite time-consuming part of the tune!

|

|

|

pmbrunelle

|

NOV 08, 11:26 PM

|

|

I decided to do some benchracing! Horsepower estimation by studying a datalog recorded on 9 October 2022. A clear day with 16°C ambient temperature.

Engine configuration: 180 kPa MAP with Scorpion rocker arms

The approach is to estimate horsepower by studying the 2nd gear acceleration from the datalog.

1st gear: can't hook, no traction

2nd gear: just right

3rd gear: aerodynamic drag starts to become significant

Main assumptions:

Total weight: 2735 lbs (measured on truck scale)

Vehicle speed sensor: calibrated with a GPS

In the 5000 to 6000 RPM range, injector duty cycle is approximately constant. So I assume that this is the power peak (well, plateau) of the engine. Therefore, I calculate power over this range.

Starting speed: 40.3 mph

Ending speed: 51.1 mph

Elapsed time: 0.799 seconds

Using a simple E = 1/2 mv2 model, the change in kinetic energy is: 90061 ft*lb

Energy of rotating front wheels and brakes is neglected.

Net power: 204.9 hp

Wheel power is greater than net power, because of drag.

Drag estimation using this website:

http://www.apexgarage.com/t...orsepower_calc.shtml

Drag Coefficient (Cd): 0.377 (bumperpad Fiero, found online)

Frontal area (sq. ft.): 19 (found online)

Weight (lbs): 2735

Speed (mph): 45.7 (average of starting and ending speeds)

Drag power: 7.9 hp (this is small enough, so even if this is inaccurate, there will not be too much error propagated to the final result)

Wheel power: 204.9 hp + 7.9 hp ≈ 213 whp

|

|

|

La fiera

|

NOV 09, 08:09 PM

|

|

|

|

pmbrunelle

|

MAR 10, 05:27 PM

|

|

As I work on cleaning up the front suspension, I'm working out the details of how I want to modifiy it to remove the pro-dive.

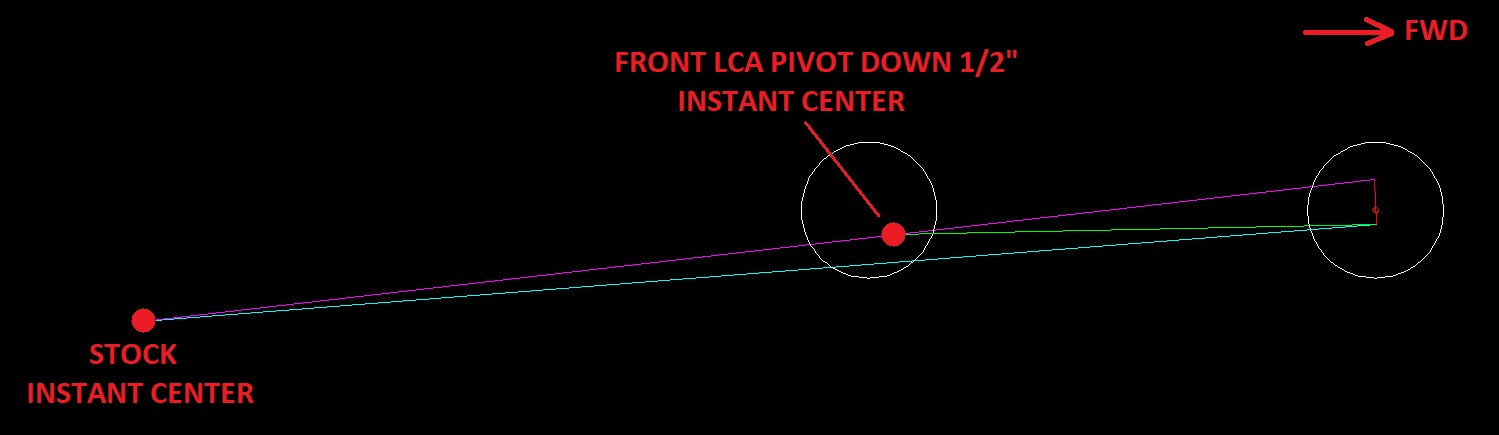

I think I will lower the front LCA pivot by about 1/2":

Stock, the side-view instant center was behind the car, some distance below the road surface. With the modification, the side-view instant center will be above the road surface, by about the same distance as the stock IC was below the road surface. As the instant center is closer to the knuckle, there will be more caster change than stock.

From the following thread, forum member mender seems satisfied with this type of modification:

https://www.fiero.nl/forum/Forum2/HTML/000118.html

I probably want to increase the amount of static caster, so the caster change has less of an effect, relatively speaking. Most likely I will cut caster shim washers to shift the UCA rearwards. Maybe when I tack-weld Will's bushing shells in place, I will shift the LCAs slightly forwards.

I bought some M12x1.75x90 ARP bolts for the LCA pivots. These have a smaller hex size than typical bolts, so they require a smaller socket. Therefore, the bolt can move down, closer towards the bent lip of the crossmember, without interfering with the socket.

Factors that limit the amount I lower the front LCA pivot:

1. I don't want too much caster change.

2. There's a limit to how low I can move the steering rack to keep it in-plane with the LCA.

3. The socket for the pivot bolt will interfere with the crossmember's bent lip.

4. In the front view, the front suspension roll center moves down. It might be OK, but I don't want to make overly drastic changes.

I'm not planning on moving the rear LCA pivot up. Reasons:

1. There's not much room to move the LCA up without hitting the body.

2. Welding the holes shut and then redrilling while I'm underneath the car would be tricky...

3. This way, I'm keeping the spaceframe stock. So, if I don't like my modification, I can get another crossmember and roll back to stock.

********************************************************************************

Here, with the stock suspension, I used a floor jack to bottom out the LCA:

The KYB front shock still has extra travel available, so there is room to modify things without bottoming out the shock.

|

|

|

pmbrunelle

|

MAR 13, 07:45 AM

|

|

I cut the outside face of the brake caliper bracket mounting ears this weekend.

In a stock Fiero, these surfaces are as-cast.

Initially, I trying to figure out how to set up the knuckle on a milling machine, while referencing the existing machined pads for the stock caliper brackets. I was imagining this to be rather tricky...

Then, once I cleaned the knuckles, I noticed the centre drill hole that was hidden beneath the dirt!

I put the knuckles between centres on a lathe, and presto.

|

|

|

fieroguru

|

MAR 13, 02:17 PM

|

|

|

Glad to see someone machine that surface before attaching a caliper bracket to it.

|

|

|

|