|

| The White Bug (Page 36/46) |

|

La fiera

|

JUN 18, 10:19 PM

|

|

|

Patrick make sure you do a good degreasing job on those valve covers before welding. My fabricator had a hard time welding them and I attribute that to the poor degreasing job I did on them before welding. With all the years of oil impregnation I can see the difficulty on welding.

|

|

|

Will

|

JUN 18, 10:52 PM

|

|

Yeah, cast aluminum is porous enough that the surface soaks up oil and junk over years and can make used components difficult to weld.

|

|

|

OldsFiero

|

JUN 20, 07:13 AM

|

|

Running them through my transmission washer (160 degrees) for 20 minutes works well. Maybe you could ask a local trans shop if they would throw them in when they are washing a batch of parts.

Marc

|

|

|

pmbrunelle

|

JUN 26, 04:55 PM

|

|

| quote | Originally posted by pmbrunelle:

With the stock rocker arm, there is enough remaining travel to avoid coil bind. Not a lot, but at the low end of what is considered acceptable. 0.060" clearance is a common guideline. I may have had coil bind issues with the Magnum rockers.

|

|

| quote | Originally posted by La fiera:

|

|

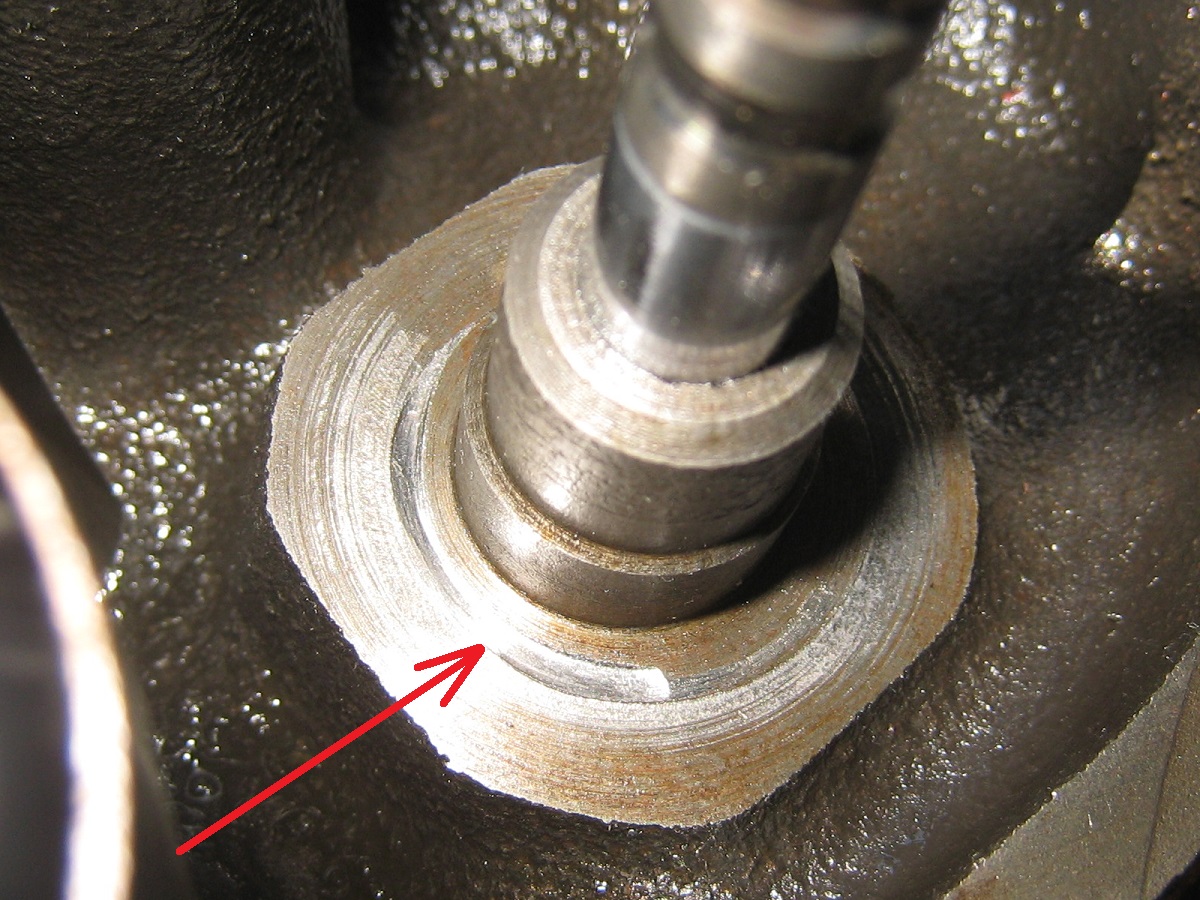

Looks like the valve springs were being pushed hard into the head (probable coil bind) with the 1.52 ratio Magnum rockers.

Notice the imprint of the spring on the head:

Oops!

The +0.050" offset valve keepers are now installed on the engine.

********************************************************************************

After cutting the valve covers, I used paint stripper to remove the paint and remaining oil sludge.

Then, the valve covers went into the dishwasher.

Now, the valve covers are baking at 400 °F to bake out oily contamination in the cast aluminium.

This week I should be able to bring the valve covers to my aluminium welding guy.

|

|

|

pmbrunelle

|

SEP 16, 10:12 PM

|

|

| quote | Originally posted by pmbrunelle:

This week I should be able to bring the valve covers to my aluminium welding guy. |

|

My usual aluminium welding guy was too busy, so I tried another shop... bad idea...

The other shop stopped answering my phone calls and disappeared with my parts! A few weeks wasted this summer

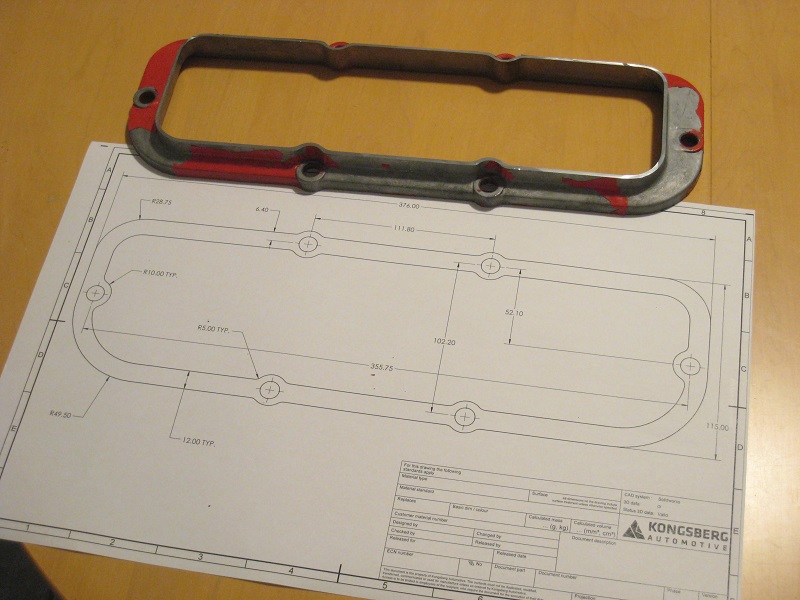

Last Thursday I decided to work on the contingency plan; the spacer idea.

The spacers are 3/8" thick laser-cut aluminium.

I don't expect everything to bolt back on; I may have to adjust some items such as the PCV vacuum line.

|

|

|

La fiera

|

SEP 16, 10:59 PM

|

|

|

That looks awesome Patrick!

|

|

|

pmbrunelle

|

SEP 25, 08:52 PM

|

|

I got my Fiero running with the Scorpion rockers!

The VE table I had with the stamped rockers seems to work well with the Scorpion rockers.

Here is a WOT pull from 1500 RPM to 6000 RPM:

The measured AFR tracks the target AFR as it did with the stamped rockers.

If there was no improvement in breathing, probably the stamped rockers did deliver on their advertised 1.50 ratio, just like the Scorpion rockers.

The main objective of this rocker arm change was to improve reliability, and not so much to improve breathing.

********************************************************************************

Now, I need to rack up some city mileage on the car; I need to break-in the clutch.

The clutch chatters a bit; while I could live with it how it is, I'd prefer if the chatter went away.

|

|

|

ericjon262

|

SEP 27, 07:20 AM

|

|

looks like it's running nice! did you draw the valve cover spacers? the looks like they turned out to be a very good fit!

FYI, you don't have to take screenshots of MLV, under "file" there's an option to "save graph as PNG or JPEG"

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.[This message has been edited by ericjon262 (edited 09-27-2022).]

|

|

|

pmbrunelle

|

SEP 28, 08:20 AM

|

|

Yeah, I drew the spacer shape myself.

We have a 24" slide caliper at work which helped with taking measurements; it was rather useful compared to just the usual 6" slide caliper.

I also printed the drawing 1:1 on an 11x17 sheet of paper, so I could place the valve cover on top of the printed drawing, and then make adjustments as necessary where things looked off.

[This message has been edited by pmbrunelle (edited 09-28-2022).]

|

|

|

ericjon262

|

SEP 30, 09:50 AM

|

|

| quote | Originally posted by pmbrunelle:

Yeah, I drew the spacer shape myself.

We have a 24" slide caliper at work which helped with taking measurements; it was rather useful compared to just the usual 6" slide caliper.

I also printed the drawing 1:1 on an 11x17 sheet of paper, so I could place the valve cover on top of the printed drawing, and then make adjustments as necessary where things looked off.

|

|

you did a great job of it, although based on some of our other conversations, I think it's fair to assume you have a bit of practice.

I've been looking at getting a 12" and 24" dial caliper. I've recently fallen in love with dial calipers compared to digital, something about being able to watch the needle move as I move the caliper is very satisfying, ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

|