|

| Project 3400 Roller Cam Block (Page 36/82) |

|

La fiera

|

APR 26, 02:42 PM

|

|

|

. [This message has been edited by La fiera (edited 04-29-2013).]

|

|

|

lou_dias

|

APR 26, 03:01 PM

|

|

You didn't give much detail. Is your material cast iron or aluminum? For what application (GEN1, GEN2-4)?

In other words, did your re-create the iron head form-factor in a different material but with higher flow in mind?

|

|

|

La fiera

|

APR 26, 05:40 PM

|

|

|

. [This message has been edited by La fiera (edited 04-29-2013).]

|

|

|

sleevePAPA

|

APR 26, 06:24 PM

|

|

| quote | Originally posted by La fiera:

Same iron heads but more flow. The first set we did with the stock valves out flowed of the Falconer heads. I have those in my Fiero now. |

|

and whats the cost of these CNC irons?

|

|

|

lou_dias

|

APR 27, 01:43 AM

|

|

| quote | Originally posted by La fiera:

Same iron heads but more flow. The first set we did with the stock valves out flowed of the Falconer heads. I have those in my Fiero now. |

|

It's not hard to outflow Falconer. They removed the intake vane that split the air around the valve stem, a big no-no. If you look at the opposite wall of the vane, there is a crevice to compensate for that vane that helps direct the air back down towards the combustion chamber.[This message has been edited by lou_dias (edited 04-27-2013).]

|

|

|

Blacktree

|

APR 27, 09:33 AM

|

|

|

|

La fiera

|

APR 27, 04:12 PM

|

|

|

. [This message has been edited by La fiera (edited 04-29-2013).]

|

|

|

lou_dias

|

APR 27, 06:59 PM

|

|

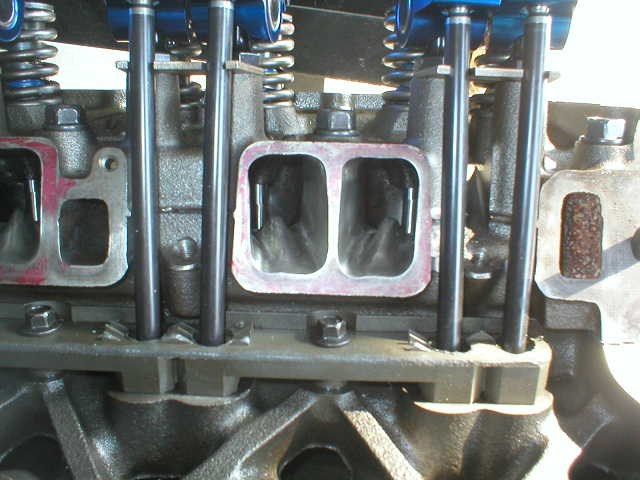

Nice that you got good results. I believe I'm using the same throttle body on my Trueleo intake now but even with the stock bored throttle body on a Mustang dyno I did 187/249. However you are enjoying the power past 4500 RPM that I couldn't reach due to the intake neck.  ...a problem I have since rectified. I believe I spent $1450 on my heads and well worth every penny. It seems you went close to the extreme as my machinist but he did leave the vane. ...a problem I have since rectified. I believe I spent $1450 on my heads and well worth every penny. It seems you went close to the extreme as my machinist but he did leave the vane.

Here's yours:

Here's mine:

Yet another example of iron heads putting down 240+ lbs*ft ... who would have thunk it?

|

|

|

La fiera

|

APR 28, 11:59 AM

|

|

|

. [This message has been edited by La fiera (edited 04-29-2013).]

|

|

|

sleevePAPA

|

APR 28, 12:42 PM

|

|

|

you only picked up ~30 CFM on the intake with CNC porting? after bowl work and minor port work, my irons flowed what yours do, with little variation between ports.

|

|

|