|

| The White Bug (Page 34/46) |

|

Will

|

MAY 13, 08:04 PM

|

|

| quote | Originally posted by pmbrunelle:

*****Camshaft*****

Crower F18059 hydraulic flat tappet

Duration @ .050" Lift: Intake / Exhaust 212° / 218°

Lobe Lift: Intake / Exhaust 0.290" / 0.299"

*****Springs*****

Crower 68301X1-12

Seat: 1.700" @ 101 lbs

Nose: 1.200" @ 297 lbs

Coil bind: 1.130"

I'm not sure what the actual spring heights are on the base circle or nose of the lobe on my installation, but these catalog numbers give a rough idea.

Coil bind would increase the rocker arm pivot force dramatically, and while I do vaguely remember checking for that, I don't have any written record of having done so. So the possibility of coil bind might be worth investigating. |

|

Higher lift than stock, I assume? Higher spring loads as well?

|

|

|

La fiera

|

MAY 13, 11:43 PM

|

|

| quote | Originally posted by pmbrunelle:

*****Camshaft*****

Crower F18059 hydraulic flat tappet

Duration @ .050" Lift: Intake / Exhaust 212° / 218°

Lobe Lift: Intake / Exhaust 0.290" / 0.299"

*****Springs*****

Crower 68301X1-12

Seat: 1.700" @ 101 lbs

Nose: 1.200" @ 297 lbs

Coil bind: 1.130"

|

|

What's the advertise duration and LSA of the cam Patrick?

|

|

|

pmbrunelle

|

MAY 14, 01:02 AM

|

|

ARP 100-7201 is the 3/8-24 conversion stud kit.

https://arp-bolts.com/kits/...tail.php?RecordID=35

I like ARP, so I'll probably get those ones.

| quote | Originally posted by La fiera:

As far as the raising of the valve cover, I have a neighbor with a CNC plasma cutter that can make the spacers. If you can't get them done let me know and I'll make a batch to get what you need and sell the rest on ebay.

|

|

Thanks for the offer!

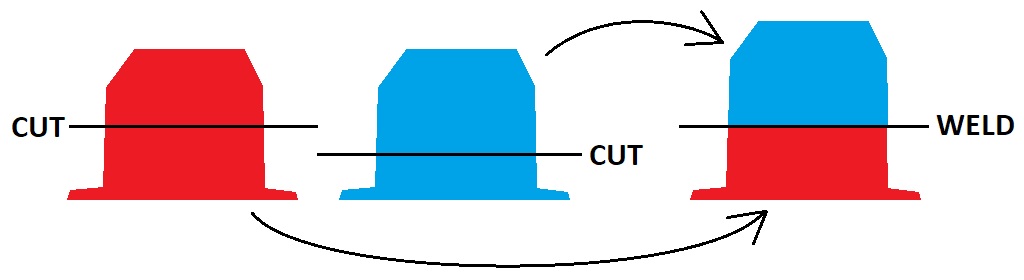

For now my plan is to make taller valve covers like this:

First, I'll discuss with SDP Autosport to see if this plan is good; they're my goto automotive tuning shop. They do aluminium welding.

Then, I would have to get a slitting saw for the milling machine to make the cuts, which I would do myself.

| quote | Originally posted by Will:

Higher lift than stock, I assume? Higher spring loads as well? |

|

About 10% more lift than stock 2.8 Fiero.

A crapload more spring force than for 3400 LA1, based on this information (I didn't find information about stock 2.8 valve springs):

https://www.fiero.nl/forum/...041015-2-051117.html

It is possible that my Fiero falls outside the application area of a ball-and-socket rocker arm pivot... so perhaps the issue is that I made a mistake in rocker arm selection for my project.

| quote | Originally posted by La fiera:

What's the advertise duration and LSA of the cam Patrick?

|

|

Oops, I mixed up the intake and exhaust numbers in my previous post. Now this information is good:

*****Camshaft*****

Crower F18059 hydraulic flat tappet

Duration @ .050" Lift: Intake / Exhaust 218° / 212°

Lobe Lift: Intake / Exhaust 0.299" / 0.290"

Advertised duration: Intake / Exhaust 284° / 278°

LSA: 114°

|

|

|

Will

|

MAY 16, 10:16 AM

|

|

| quote | Originally posted by pmbrunelle:

About 10% more lift than stock 2.8 Fiero.

A crapload more spring force than for 3400 LA1, based on this information (I didn't find information about stock 2.8 valve springs):

https://www.fiero.nl/forum/...041015-2-051117.html

It is possible that my Fiero falls outside the application area of a ball-and-socket rocker arm pivot... so perhaps the issue is that I made a mistake in rocker arm selection for my project. |

|

I don't think it's outside the performance envelope of a ball and socket rocker pivot, but it looks like it's outside the load limits of THOSE rocker arms. Are those stock replacement rockers? With a higher lift, higher acceleration cam and stiffer springs, you're running well in excess of the OE load case.

Remember that in your earlier attempts, your load case wasn't too much for the pivot... the aftermarket rockers had design flaws related to lubrication.[This message has been edited by Will (edited 05-16-2022).]

|

|

|

pmbrunelle

|

MAY 16, 08:05 PM

|

|

Right... I was conflating the performance envelope of the pivot with the performance envelope of the rocker arm structure. Good thing Will is there to point out errors in logic and steer us on the correct path!

So from what I saw, there are basically two families of ball-and-socket rocker arms that can easily be installed on the Fiero V6:

Cast steel rockers with roller tip. The ones that aren't Comp Cams are copycat designs, including the wrong oil hole orientation.

-Comp Cams Magnum (failed twice on me with burned up pivots, oil hole is pointing the wrong way)

-Speedmaster Procomp Electronics

-PRW Sportsman

Stamped steel rockers. Some have shoe tips, some have roller tips (I don't really care about this feature). All of the stamped rockers have the oil hole pointing towards the stud. They all have the same basic shape, so any increase in fatigue strength would have to come from better materials/treatments and care in reducing stress concentrations.

-Melling MRK-407 (the stamped steel stock replacements I most recently used that failed)

-Comp Cams High Energy (looks stock-ish, no evidence to suggest it would be superior)

-Manley 43140 (looks stock-ish)

-Summit Racing brand (looks stock-ish)

-Proform Stamped Roller Tip (looks stock-ish)

-Howards Cams Track Smart Nitro-Carbided (maybe this magic treatment might do something)

I decided to order a set of Scorpion SCP1037 rocker arms as recommended by Rei.

I am still curious about the wear resistance of the ball-and-socket on a stock-style rocker. Prior to installation, I measured the mass of every ball and rocker. When I remove the old rocker parts, I'll re-measure them and see if any mass was lost.

|

|

|

La fiera

|

MAY 16, 10:43 PM

|

|

|

I cut my valve covers like your drawing and added 1 inch of space for the 1.7 full roller rockers

|

|

|

zkhennings

|

MAY 17, 03:46 PM

|

|

|

Glad the bottom end is ok, and I think it is wise to move away from the ball pivots with the additional RPMs and load from the cam/springs, especially when GM has moved to needle bearings. Interested to see if the pivots have lost some mass over time.

|

|

|

Will

|

MAY 18, 08:51 AM

|

|

GM used ball pivot rockers on the Camaro RS/SS 302 and other high winding/big valve/stiff spring combos over the years.

Do Small Block Chevy rockers not fit?

|

|

|

La fiera

|

MAY 19, 10:36 PM

|

|

Just make sure you clean the valve covers very good. My fabricator had a hard time welding it because he said it was like pot aluminum.

My theory is that the valve covers have been impregnated with oil due to their age.

Dip them in acid or something!

|

|

|

pmbrunelle

|

MAY 20, 01:29 AM

|

|

| quote | Originally posted by zkhennings:

Glad the bottom end is ok, and I think it is wise to move away from the ball pivots with the additional RPMs and load from the cam/springs, especially when GM has moved to needle bearings. Interested to see if the pivots have lost some mass over time. |

|

Oops, I only measured the parts from the 2nd set of rocker hardware.

| quote | Originally posted by Will:

GM used ball pivot rockers on the Camaro RS/SS 302 and other high winding/big valve/stiff spring combos over the years.

Do Small Block Chevy rockers not fit?

|

|

The rocker arm alternatives I've identified above are mostly SBC rockers.

Actually, the Scorpion ones I bought are SBC rockers too. I have a set of 16.

| quote | Originally posted by La fiera:

Just make sure you clean the valve covers very good. My fabricator had a hard time welding it because he said it was like pot aluminum.

My theory is that the valve covers have been impregnated with oil due to their age.

Dip them in acid or something! |

|

Yeah, SDP Autosport said it was tricky to weld my transmission case when the mount area cracked, so I'm aware of that issue.

Since these valve covers have no plastic parts, I'll be able to bake them at a high temperature for a long time to boil off the junk.

********************************************************************************

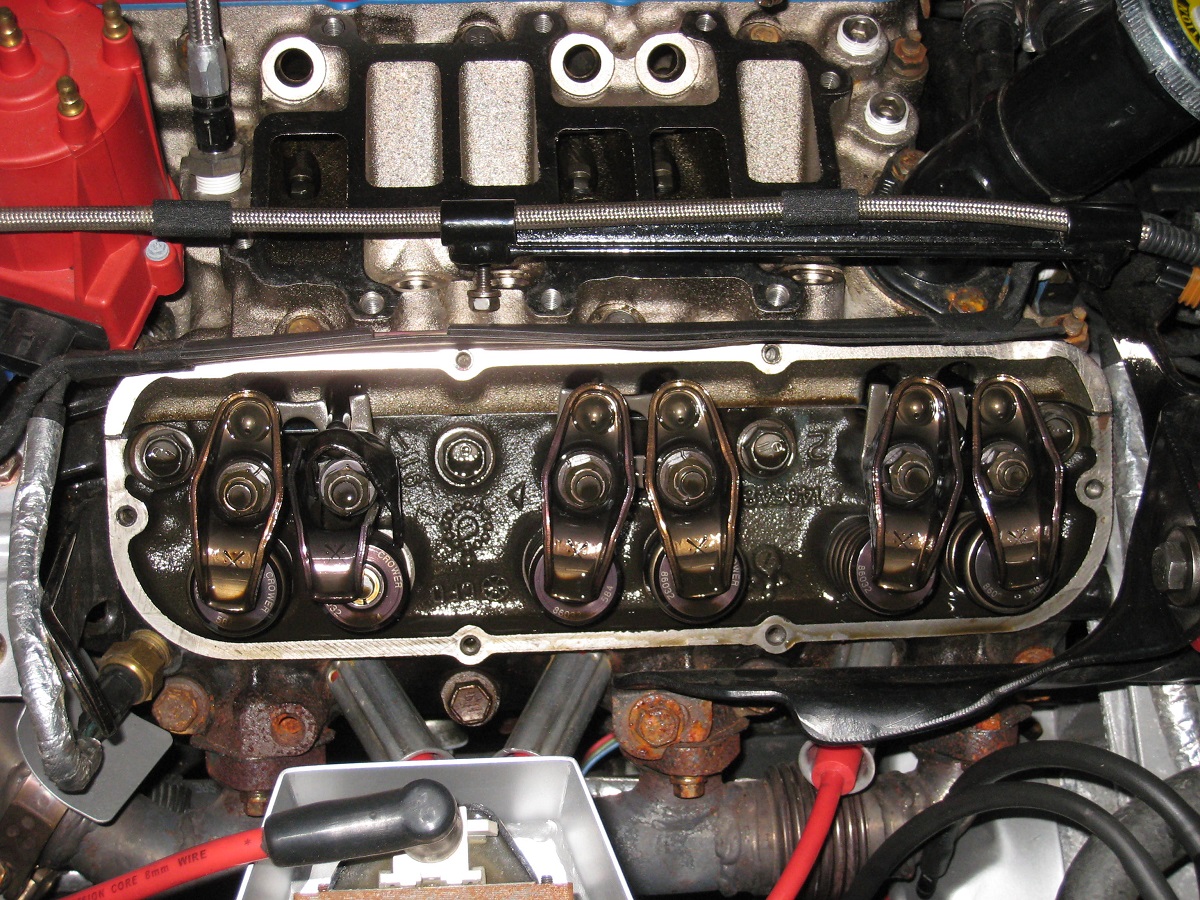

And now, the investigation! I had a peek in the valve cover last night. Not much collateral damage. The valve cover and spring retainer got cosmetic dings. The tip of the valve stem had a slight burr; I filed that away. The spring wasn't scratched.

All rockers, including the broken one, had about the same amount of oil pooled in the cup above the valve. Furthermore, the pushrod serving the broken rocker had a clear hole. Not much coked oil (suggesting enough cooling) around the pivot area as with the Magnums. From these observations, oil starvation is discarded as a possible cause of the failure.

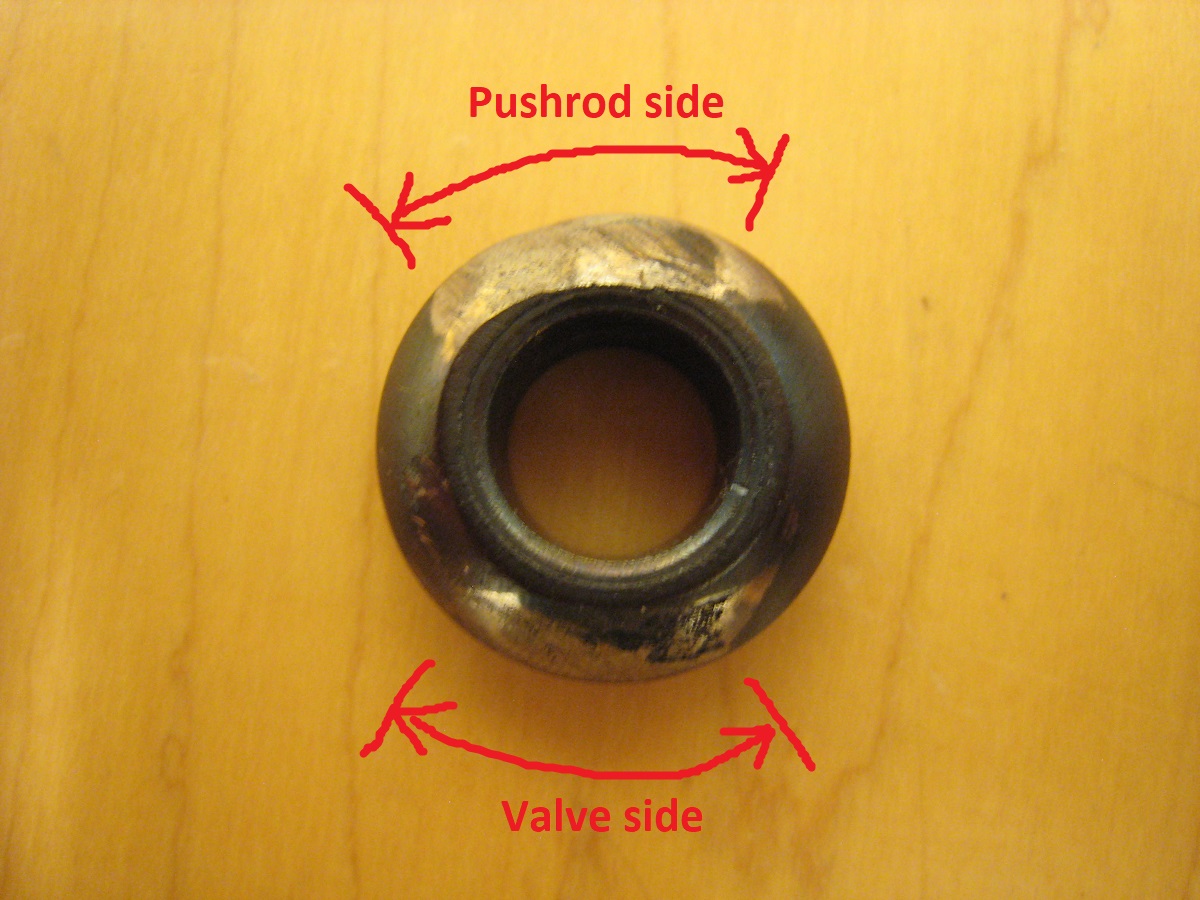

The rocker ball was heavily worn (about 1 mm of material gone) on the pushrod side, while things were OK on the valve side.

Ideally, the rocker ball is polished everywhere. In this case, it looks like the curvature of the rocker arm was wrong, so it was only touching the ball in two spots rather than all around.

With the load concentrated in those two spots, I think that created a high-stress area (and high-heat too) where the crack started (marked by the "X" on the photo). The crack then slowly zipped upwards over time. This crack took a while to develop; its face is stained with oil.

As the crack on the left side grew, more bending moment had to be handled by the right side, which is what started the right side crack. The right side crack began at the rocker slot, and then grew upwards. The right side crack wasn't stained with oil. Maybe the right side crack was only initiated during the last drive.

There wasn't much plastic deformation. The broken pieces almost fit together like a broken ceramic tile. Not quite, but close.

So, I'd say that the primary cause of the rocker failure was that the socket shape wasn't close enough to an ideal sphere.

Now, onto a contributing factor!

| quote | Originally posted by pmbrunelle:

Coil bind would increase the rocker arm pivot force dramatically, and while I do vaguely remember checking for that, I don't have any written record of having done so. So the possibility of coil bind might be worth investigating. |

|

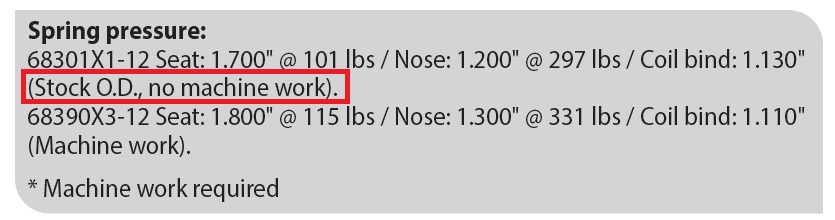

Here I checked the installed height of the spring of the failed rocker.

1.609" installed height. Coil bind height is 1.130".

Here is the remaining travel before coil bind for different rocker ratios:

Stock "1.5" ratio, estimated 1.45 ratio (because stamped rockers often don't deliver on their specified ratio). 0.434" valve lift. 0.045" remaining.

Scorpion 1.5 ratio. 0.448" valve lift. 0.031" remaining.

Comp Magnum 1.52 ratio. 0.454" valve lift. 0.025" remaining.

With the stock rocker arm, there is enough remaining travel to avoid coil bind. Not a lot, but at the low end of what is considered acceptable. 0.060" clearance is a common guideline. I may have had coil bind issues with the Magnum rockers.

Even though I don't believe I ran into coil bind with the failed rocker, I still consider the short installed height to be a contributing factor. When the spring is working closer to the coil bind region, the spring force is greater than it would be with a taller installed height.

And now, the human factor behind this contributing factor...

There was no record of checking for coil bind, because I didn't.

Now I remember what happened. I saw this in the Crower catalog:

And then I thought, oh cool, the springs are supposed to work as-is, I don't have to check the springs.

Lesson: In engine assembly, check everything.

Today, I ordered a set of +0.050" offset valve keepers that will raise the spring retainers. I'll have a more comfortable margin with respect to coil bind, especially with the Scorpion rockers. I also ordered a stud-mounted valve spring compressor (works with 7/16-20 or 3/8-24 rocker arm studs). With the spring compressor, I should be able to swap valve keepers without removing the engine from the car.[This message has been edited by pmbrunelle (edited 05-20-2022).]

|

|

|

|