|

| The White Bug (Page 32/46) |

|

pmbrunelle

|

MAR 20, 07:43 PM

|

|

| quote | Originally posted by fieroguru:

You really don't want to drill and slot the rotors yourself. They are cast parts with thicker and thinner spots. When you drill the holes, you are not removing the exact same material from every hole, which will lead to the need to have them rebalanced. When you buy drilled/slotted rotors, they have already been balanced post drilling.

|

|

Now I have my first taste of experience with this!

So first I checked a Centric/Stoptech pre-slotted rotor.

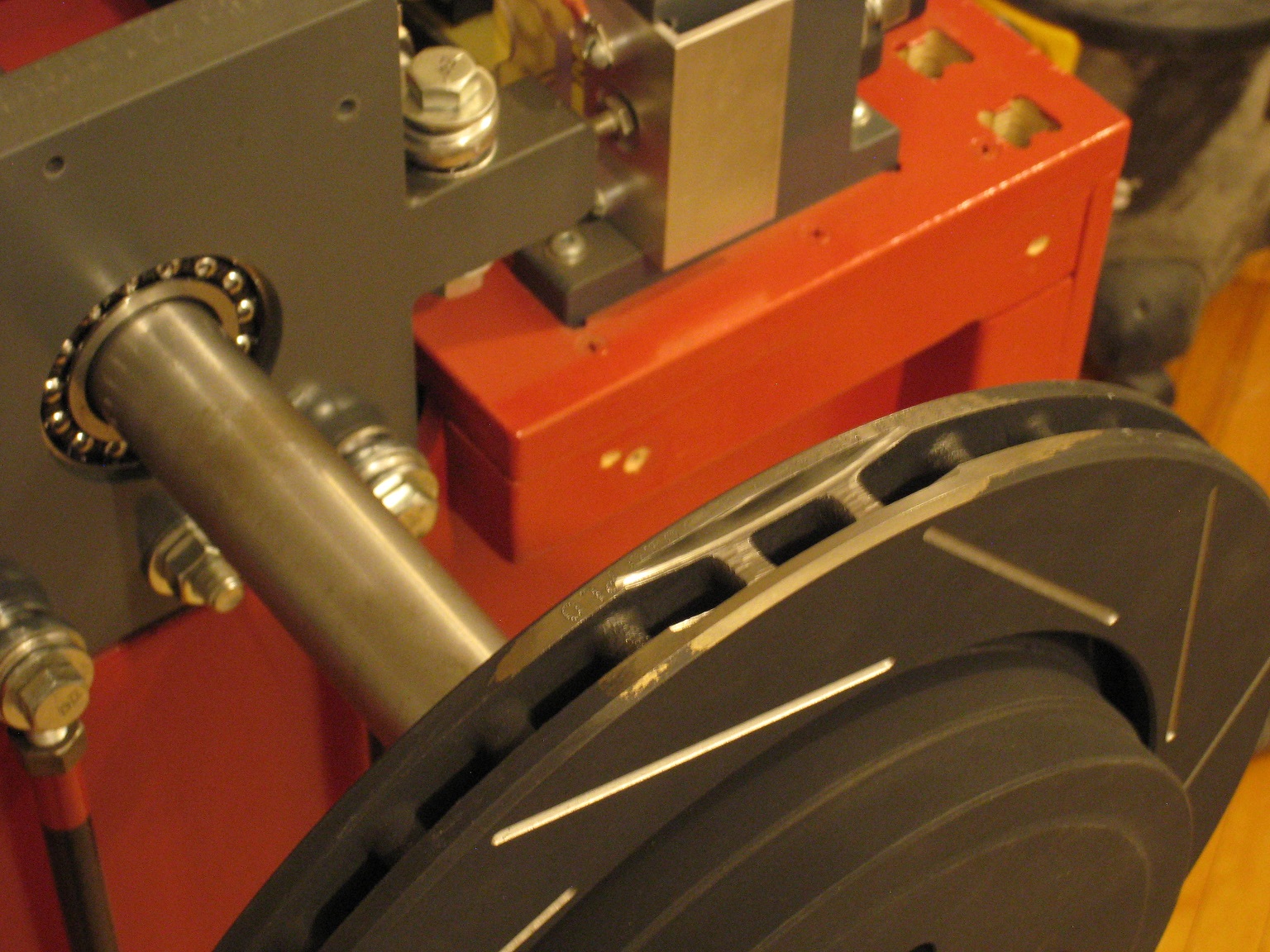

The Centric/Stoptech pre-slotted rotor had 0.34 oz of imbalance (at the rotor edge). Not so great:

It showed no signs (material removal by machining) of having been balanced. Maybe other fancier brands such as Brembo/Wilwood are better.

********************************************************************************

The DIY rotors were Raybestos 7993R that I slotted.

The Raybestos rotor was also imbalanced, but I think that the main cause of imbalance was a poor centering of the casting when it was machined at Raybestos. A visible runout in the 0.050" to 0.100" range was visible between the as-cast surfaces (the vanes) and the machined surfaces.

My slots were cut pretty evenly, so I don't think they are much of a factor.

This is the material I removed with an angle grinder:

The material I removed was pretty much 180° away from the low runout spot of the casting, which supports the poor machining setup (at Raybestos) hypothesis for the main cause of rotor imbalance.

|

|

|

ericjon262

|

MAR 26, 08:37 PM

|

|

|

wheel balancer in the middle of a dining room. you truly are my kind of people. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

Skybax

|

MAR 27, 01:00 PM

|

|

|

This is a great build thread, keep up the good work.

|

|

|

Will

|

MAR 29, 11:28 AM

|

|

| quote | Originally posted by ericjon262:

wheel balancer in the middle of a dining room. you truly are my kind of people.

|

|

The dining room is in the background... that's clearly the toy room.

|

|

|

ericjon262

|

MAR 31, 07:22 PM

|

|

| quote | Originally posted by Will:

The dining room is in the background... that's clearly the toy room.  |

|

oh, please excuse my egregious mistake... LOL!

PMBrunelle, Where are you picking up the oil feed for your turbo? what size line are you running for the feed/Are you running any kind of restrictor?

| quote | Originally posted by pmbrunelle:

So here we see the applicability of a racecar turbo support solution on a street car:

Over the last year of summer driving, nothing got frozen, though the upper ball near the turbo is a bit stiff. In general, the upper rod end fared worse, I suppose with the heat burning off the zinc plating from the carbon steel rod end.

I'll probably look for some stainless steel replacements. The jam nuts (400-series stainless IIRC) with surface rust don't bother me too much; they'll just get Scotchbrited and oiled.

For the threaded hex piece, which was cold-blued and oiled, I'll most likely be getting that Cerakoted, along with a bunch of other heat shields. I will be meeting a local Cerakote shop next week.

My sandblast + VHT header paint job didn't hold up on many of the heat shields.

The heat shields closest to the hottest parts of the exhaust are the ones that rusted the most, presumably with the paint being burned off, and ambient temperature accelerating the oxidation of the metal.

With the stock 2.8, VHT paint did OK on the heat shields. With the present setup, it is not rare to see some parts of the exhaust glowing a dark cherry red (visible at night). |

|

This guy zinc plated parts for his turbo Sonoma, turned out pretty good, I wonder how that would hold up for you heat sheilds?

https://www.youtube.com/wat...&ab_channel=turbo_v6

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper[This message has been edited by ericjon262 (edited 03-31-2022).]

|

|

|

pmbrunelle

|

MAR 31, 10:30 PM

|

|

| quote | Originally posted by Will:

The dining room is in the background... that's clearly the toy room.  |

|

Well it used to be my living room, now it's sort of the wheel balancer / tool storage room, as well as being a construction site

Technically, I have a TV in there.

| quote | Originally posted by ericjon262:

PMBrunelle, Where are you picking up the oil feed for your turbo? what size line are you running for the feed/Are you running any kind of restrictor?

|

|

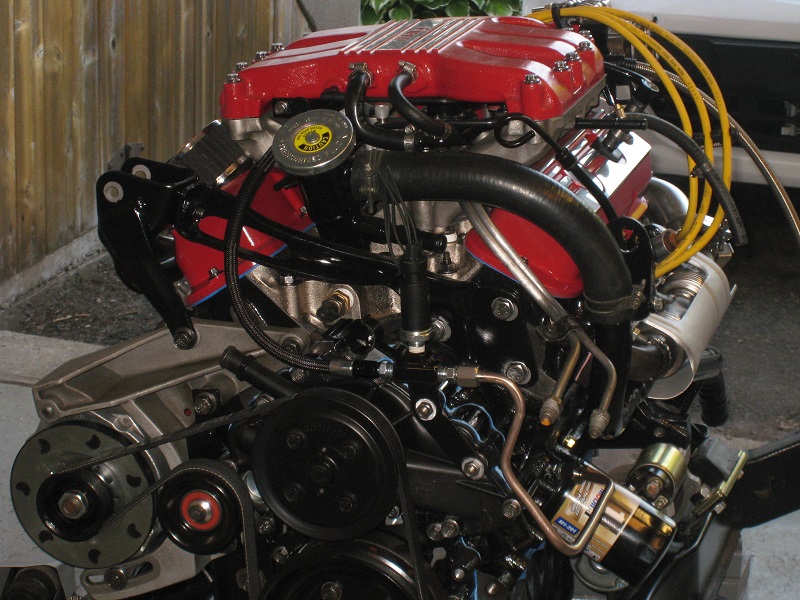

I'm grabbing a 1/8" NPT port on the engine block next to the oil filter:

From there, I have a -6AN cupro-nickel hard line to a T-block, where the oil pressure sender is connected. Then, there is an Aeroquip -4AN PTFE-lined braided hose going into the turbo. My dad convinced me that I shouldn't mess with rubber hoses for handling hot pressurized oil, especially when failure could result in a spray of oil over a red-hot turbo...

My turbo has journal bearings. Journal bearing turbos are often run with an unrestricted oil supply, so I did the initial setup that way. After a few thousand kilometres, I noticed a thin oil film inside the charge pipe. Presumably, the oil came from the turbocompressor. Engine oil pressure seemed high in general. At cold start, I was seeing 60+ psi. From these factors, I decided to run a 0.0625" restrictor (typical size for journal bearing turbos).

Some people use a smaller -3AN line to supply a turbo with some restriction, but the restriction it provides is less "well-defined" than the restriction created by an orifice. I have some unsupported lengths of hose, so I also thought that -4AN would support itself better than -3AN, while having more mechanical robustness at the fittings. -3AN may be better if you want to flex the hose with tighter-radius bends.

Ball bearing turbos need a less oil than journal bearing. A 0.035" to 0.040" orifice seems typical.

Since you have a "dummy distributor" rather than a real distributor, you might be able to modify the dummy distributor to get oil from it. The dummy distributor does intersect an oil gallery on the LX9, right? The dummy distributor is also close to your turbo.

I had the heat shields done with Cerakote. We shall see how the Cerakote holds up compared to VHT header paint that was on there before.

I had zinc-plated bolts fixing the turbo heat shield to the turbine housing. The heat burned the zinc off the bolts, so I'd say that zinc is a no-go around the turbine/CHRA area. I have replaced the zinc-plated bolts with black oxide bolts. We shall see how the black oxide finish holds up.

Homebrew zinc plating still could be useful for many other parts, such as the trigger disc in the video, or other random bracketry.

Due to the risk of hydrogen embrittlement, I would avoid homebrew zinc plating parts made of high strength steel that are under constant stress, such as bolts.

I think the wide and flat strip of zinc is key to the guy's success. Electrolysis works better when the electrodes have large surface areas, so the current density is not too high.

|

|

|

ericjon262

|

MAR 31, 11:12 PM

|

|

after posting that, I saw the hardware and thought about how it faired, either way the plating process was interesting enough for me to share it.

Thanks for the description for your turbo oil setup, I'm running a similar setup to oil my turbo. the biggest curiosity was the restrictor. I'm not currently running one, but planning on putting one in.

as far as using the dummy distributor as an oil source, that's not something I had considered, it's an interesting idea, but I would want to map the oil galleries and ensure it was filtered source before dedicating it to my turbo. I'm also not sure the design for the dummy distributor would permit an oil passage to be installed in it. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

ericjon262

|

APR 02, 12:16 AM

|

|

| quote | Originally posted by pmbrunelle:

Since you have a "dummy distributor" rather than a real distributor, you might be able to modify the dummy distributor to get oil from it. The dummy distributor does intersect an oil gallery on the LX9, right? The dummy distributor is also close to your turbo.

|

|

I took apart a spare dummy distributor, I don't think that would be a good way to get an oil supply for a turbo.

here are all the parts laid out, left to right, we have the drive shaft, the main body, a wear plate, a thrust washer, and finally, the gear. not pictures is the roll pin that holds the gear, and the plug that seals the top of the unit.

the body is not quite as simple as just being a big hunk of aluminum, there's a support bushing inside to maintain alignment, which is supported by 5 radial supports, there's not really a way to make a passage for oil to flow up to the top where a fitting could be attached.

additionally, the oil gallery is only sealed on one side, I assume this is to provide oiling for the drive gear. this is the main reason why I don't want to use it for an oil feed, I would prefer to provide a more positive source of oil to the turbo.

there may be a way to build something to work better, but I think running a line from the oil filter is the safer/easier way. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

pmbrunelle

|

MAY 09, 08:19 PM

|

|

So at the end of last year, the engine puked a bunch of coolant (not sure if any damage occurred then); I then parked the car for the winter and left it alone. Last weekend, I tightened a loose coolant hose clamp, and drove the car for a bit.

Today, my car started to make a knocking sound (after running for a few seconds at WOT). More of a bottom end knock than a valvetrain tick. I'm not really sure what happened.

No apparent disaster that I can see on the spark plugs.

This year, I did observe some knock retard. I had never seen knock retard in 2020 or 2021. The ECU has an SD card datalogging every drive I take. I retrieved the datalog of the last drive when the knocking began.

For 2022, I slightly advanced the ignition timing by 1.6°.[This message has been edited by pmbrunelle (edited 05-10-2022).]

|

|

|

pmbrunelle

|

MAY 10, 08:03 PM

|

|

Broken rocker arm on cylinder #5!

|

|

|

|