|

| The White Bug (Page 30/46) |

|

pmbrunelle

|

AUG 08, 07:01 PM

|

|

I test-fitted the new Enkei PF05 wheels for the first time today. So far, I have no noticed any major issues:

The Fiero has been on the backburner since I moved in May; I've been more occupied with house-related repairs.

The center caps don't fit on the front or rear:

How does Enkei not know how much clearance is needed for the center caps? This happened on Eric's Enkei wheels, my dad's Saturn's Enkei wheels...

Anyway, I'll probably be doing a set of 3D-printed center caps, probably with Pontiac arrowheads or something.

|

|

|

ericjon262

|

AUG 13, 10:19 PM

|

|

the wheels look great! FWIW, I was able to 3d print cap extenders. I printed them in PLA, the entire time I was in WA, they were fine, but when I moved back down south, the passenger side warped can fell off. I haven't had time to find a proper solution yet, but eventually I'll either print them in ABS and try again, or try some kind of exotic filament.

The file I made is available for download here if you need/want it:

https://www.thingiverse.com/thing:4772551------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

pmbrunelle

|

AUG 15, 10:51 PM

|

|

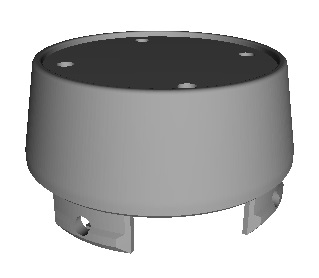

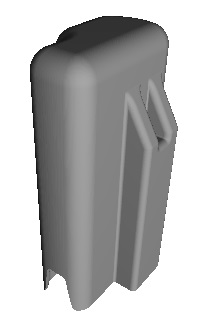

I just ordered some center caps from www.hubs.com

They have a recess so a sticker can be applied, and four holes so I can push out the sticker from behind, in case I want to change the look.

Stickers (I purchased some a few years back, and I decided to buy from the same place again):

https://3dcarstickers.com/p...goblack-background-/

I recently ordered (for work) 3D-printed parts made on a Multijet Fusion (black PA 12 material), and I liked the results. I liked the look of the plastic, and I thought that it had the right balance of stiffness/flexibility for use with springy tabs in plastic. From that experience, I decided to try the same thing for my Fiero parts. The Multijet Fusion won't delaminate between layers since it is not filament-based. I do not own my own 3D printer.

The price was not too bad, but there was a $90 minimum order, so I also ordered a cap (and a spare) to protect my oil pressure sender from rain.

It slides over the oil pressure sender to keep rainwater out of its connector.

|

|

|

pmbrunelle

|

SEP 03, 12:28 PM

|

|

So here we see the applicability of a racecar turbo support solution on a street car:

Over the last year of summer driving, nothing got frozen, though the upper ball near the turbo is a bit stiff. In general, the upper rod end fared worse, I suppose with the heat burning off the zinc plating from the carbon steel rod end.

I'll probably look for some stainless steel replacements. The jam nuts (400-series stainless IIRC) with surface rust don't bother me too much; they'll just get Scotchbrited and oiled.

For the threaded hex piece, which was cold-blued and oiled, I'll most likely be getting that Cerakoted, along with a bunch of other heat shields. I will be meeting a local Cerakote shop next week.

My sandblast + VHT header paint job didn't hold up on many of the heat shields.

The heat shields closest to the hottest parts of the exhaust are the ones that rusted the most, presumably with the paint being burned off, and ambient temperature accelerating the oxidation of the metal.

With the stock 2.8, VHT paint did OK on the heat shields. With the present setup, it is not rare to see some parts of the exhaust glowing a dark cherry red (visible at night).

|

|

|

Will

|

SEP 03, 12:31 PM

|

|

|

What size are the rod ends on your turbo support? You can probably find a stainless adjuster for it.

|

|

|

pmbrunelle

|

SEP 03, 12:34 PM

|

|

|

They are 7/16-20. One end is LH, the other is RH.

|

|

|

pmbrunelle

|

NOV 11, 07:05 PM

|

|

So the car has been out of service since late August.

Since then, I have done/prepared:

General degreasing/washing

New oil-pressure sender (was water-damaged) with 3D-printed protective cap

Replaced alternator (bad bearing)

Replacement of various rusty bolts/nuts

Spec Stage 3+ clutch (RAM HD was slipping at 175 kPa)

Retorqued the not-so-tight harmonic balancer bolt, then painted with reference marks.

Cerakote (subcontracted) C-7700 coating on heat shields and some small hardware items.

Stainless steel rod ends for turbo support, PTFE-lined

Sandblasted + recleared (with better quality spray can clear) some aluminium brackets (alternator, shift linkage, clutch slave)

New coolant hoses, T-bolt clamps

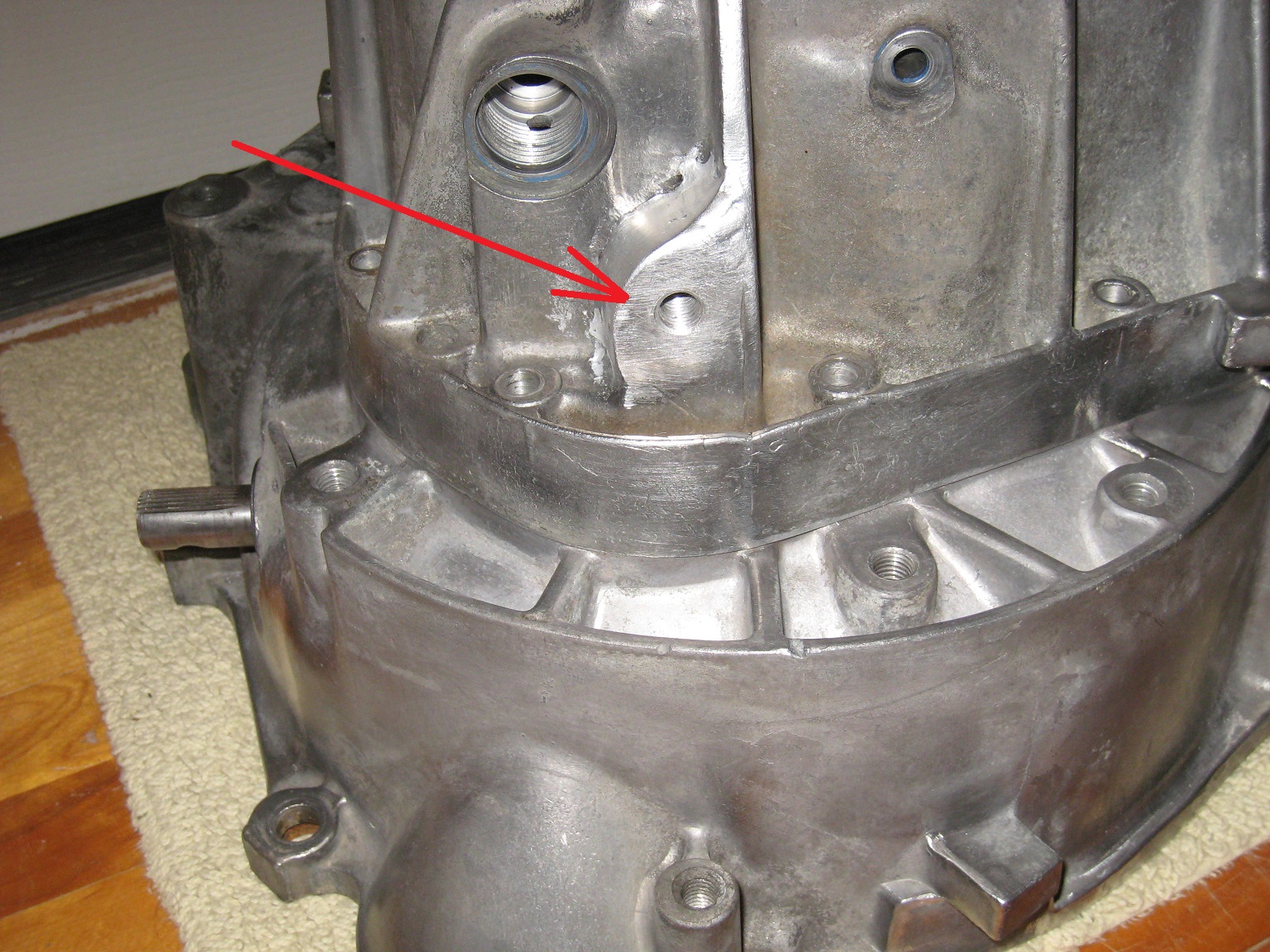

Ground away and rewelded (subcontracted) broken transmission mount boss on transmission case. Drilled and tapped for mount.

Ground away the sharp edges / parting lines from the transmission case.

Resprayed some steel parts black

Scavenged some tripod cups, polished the seal journals, and assembled onto my axles (hope to fix the transmission oil leak). New transmission seals as well.

Repaired broken transmission mounts (overtightened on attempted installation, damaged fasteners)

I'm getting very close to being able to button up everything together.

********************************************************************************

I have always done automotive work either outdoors in the summer, or indoors in a heated garage.

Now, my car is outside, and the daytime high temperature reaches around 5 °C. The low is around 0 °C.

Are they any gotchas I need to know about working on a car in the cold?

Do steel bolts become brittle?

Is the transmission seal rubber still soft enough to allow for insertion of the axles without tearing the rubber?

I have no Loctite, silicones, paints, or anything that requires curing.[This message has been edited by pmbrunelle (edited 11-11-2021).]

|

|

|

87_special

|

NOV 12, 03:37 AM

|

|

|

At 0* C I doubt steel embrittlement is an issue. For the rubber seals just use a heat gun or blow dryer to warm them before axle entry. Cool build.

|

|

|

longjonsilver

|

NOV 12, 07:16 AM

|

|

i used the Spec stage 3+ clutch in my 3800SC application into my MY8 4 speed and i still have some chattering going on in first and reverse. i am on my third full tank of gas - odometer doesn't work - so i don't know the mileage, but hope that this annoying chattering stops.

jon

PS i didnt build a frankentranny with a M17 and an MY8 cuz it would have slowed down my build and i figured that it might never get done that way. However i am picking up some parts for an M17 today just in case, for the future

|

|

|

pmbrunelle

|

NOV 12, 08:05 PM

|

|

| quote | Originally posted by 87_special:

At 0* C I doubt steel embrittlement is an issue. For the rubber seals just use a heat gun or blow dryer to warm them before axle entry. Cool build. |

|

Good tip on the heat gun. I dropped into my parents place to borrow my dad's heat gun.

| quote | Originally posted by longjonsilver:

i used the Spec stage 3+ clutch in my 3800SC application into my MY8 4 speed and i still have some chattering going on in first and reverse. i am on my third full tank of gas - odometer doesn't work - so i don't know the mileage, but hope that this annoying chattering stops.

jon

PS i didnt build a frankentranny with a M17 and an MY8 cuz it would have slowed down my build and i figured that it might never get done that way. However i am picking up some parts for an M17 today just in case, for the future |

|

Do you have rubber or polyurethane engine/trans mounts? If you have rubber, that may aggravate the chatter.

If I wrap up things quickly, I'll find out soon enough for myself how the chatter is like.

I know what you mean about leaving out things to finish the build quicker. For instance, I ran the axles I had, knowing that their seal journals weren't smooth, and likely to leak oil. That's what happened, and that's what I ended up fixing a year after the big rebuild project.

What transmission do you have now? The benefit of driving with something else is that it gives you a baseline; from there you can ask yourself what you like changed in the transmission to suit your tastes better. Or maybe you like it how it is now?

|

|

|

|